Contents

Contents ................................................................................................................................... 1

Revision history....................................................................................................................... 3

1. Overview ............................................................................................................................ 4

2. Basic information ............................................................................................................ 5

2.1. System configuration.................................................................................................. 5

3. Setting ................................................................................................................................ 6

3.1. Download setting application and EDS file ............................................................. 6

3.2. About IO data .............................................................................................................. 6

3.3. Setting various parameters ....................................................................................... 6

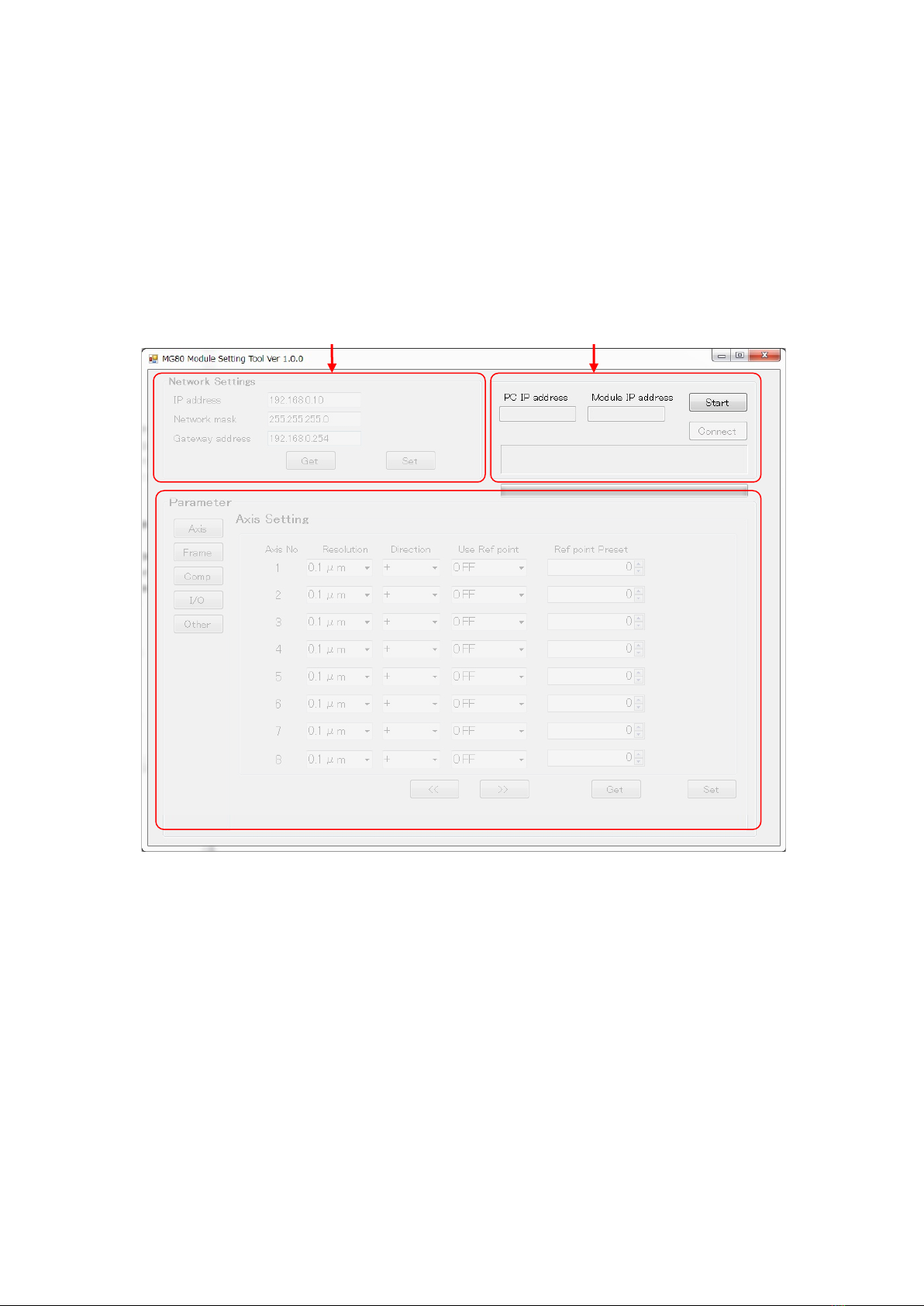

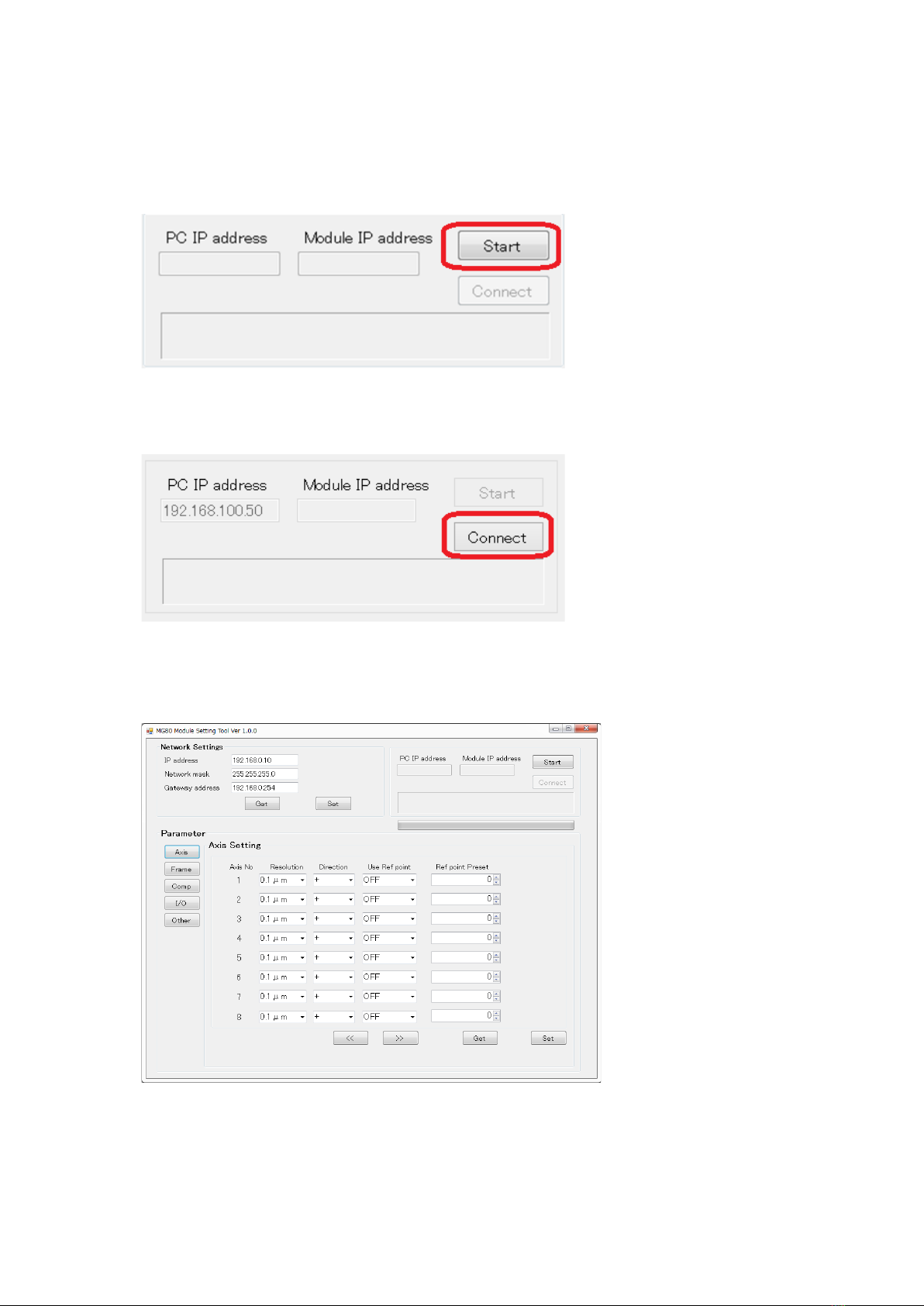

3.3.1. Connecting MG80-EI with PC ............................................................................. 7

3.3.2. Parameter Setting ................................................................................................... 8

3.3.3. Restart MG80-EI ................................................................................................... 15

4. Specifications.................................................................................................................. 16

4.1. Interface specifications ............................................................................................ 16

4.2. LED indicator.............................................................................................................. 17

5. Function ........................................................................................................................... 19

5.1. Function list................................................................................................................ 19

5.2. Frame definition ........................................................................................................ 20

5.3. Detail of function....................................................................................................... 21

5.3.1. Peak hold............................................................................................................. 21

5.3.2. Pause.................................................................................................................... 22

5.3.3. Start ..................................................................................................................... 22

5.3.4. Reset .................................................................................................................... 22

5.3.5. Preset................................................................................................................... 22

5.3.6. Master preset...................................................................................................... 22

5.3.7. Comparator......................................................................................................... 23

5.3.8. Addition/Subtraction ......................................................................................... 23

5.3.9. I/O module control ............................................................................................ 24

6. Communication.............................................................................................................. 25

6.1. Communication with EtherNet/IP device (Scanner) ........................................... 25

6.1.1. Tag data link(Implicit message) .................................................................. 25

6.1.2. CIP communication (Explicit message) .......................................................... 35

6.1.3. CIP communication command list................................................................... 37

6.2. CIP object................................................................................................................... 58

6.2.1. Supported CIP object ........................................................................................ 58