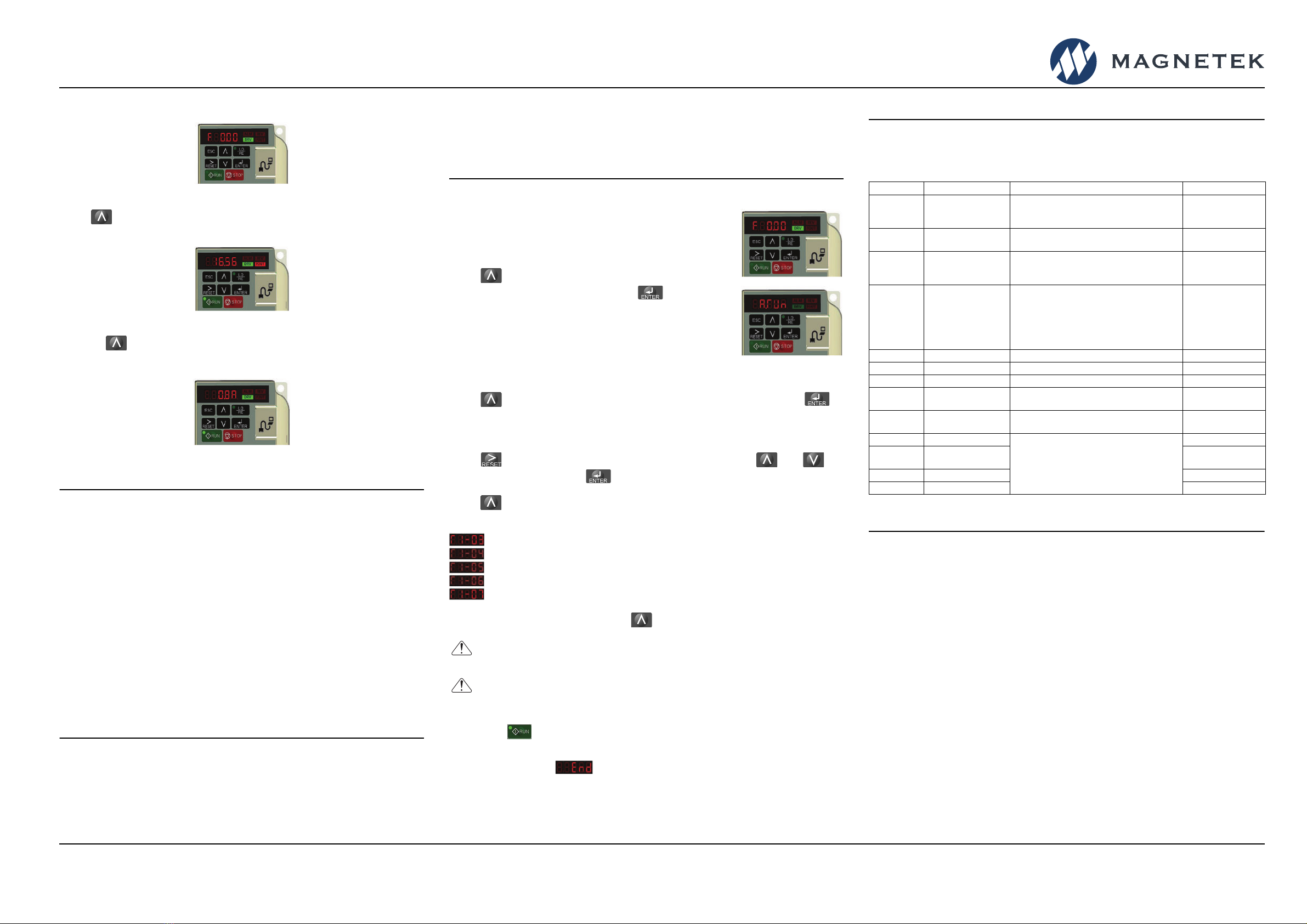

Monitor Motor Frequency and Motor Current

Figure 7: Digital Operator Main Display

Press until the FOUT LED turns on. The display now shows the actual

output frequency in Hz.

Figure 8: Output Frequency

Pressing again will show the motor output current in Amps.

NOTE: Refer to the technical manual on how to access other drive monitors.

Figure 9: Motor Current

Step 4

Select a Control Method and Motion

This step explains how to configure the VFD for a Hoist or Traverse

application. For hoisting applications, the IMPULSE•G+ Mini should only be

used to control a hoist with a mechanical load brake.

Traverse:

Set parameter A01.03 = 0 (Traverse).

It is recommended that the Control Method is set to V/f (A01.02 = 0).

If Open Loop Vector is desired, set A01.02 = 2.

Hoist (with Mechanical Load Brake):

Set parameter A01.03 = 1 (Hoist).

It is recommended that the Control Method is set to V/f (A01.02 = 0).

If Open Loop Vector is desired, set A01.02 = 2.

NOTE: An Auto-tune is recommended when using the Open Loop Vector

control method or Hoist motion.

Step 5

Select a Speed Reference

This step lists the speed reference settings that are selected with parameter

A01.04.

NOTE: Default speed settings will be automatically applied via X-Press

Programming™. Reference the technical manual for more details and wiring

instructions.

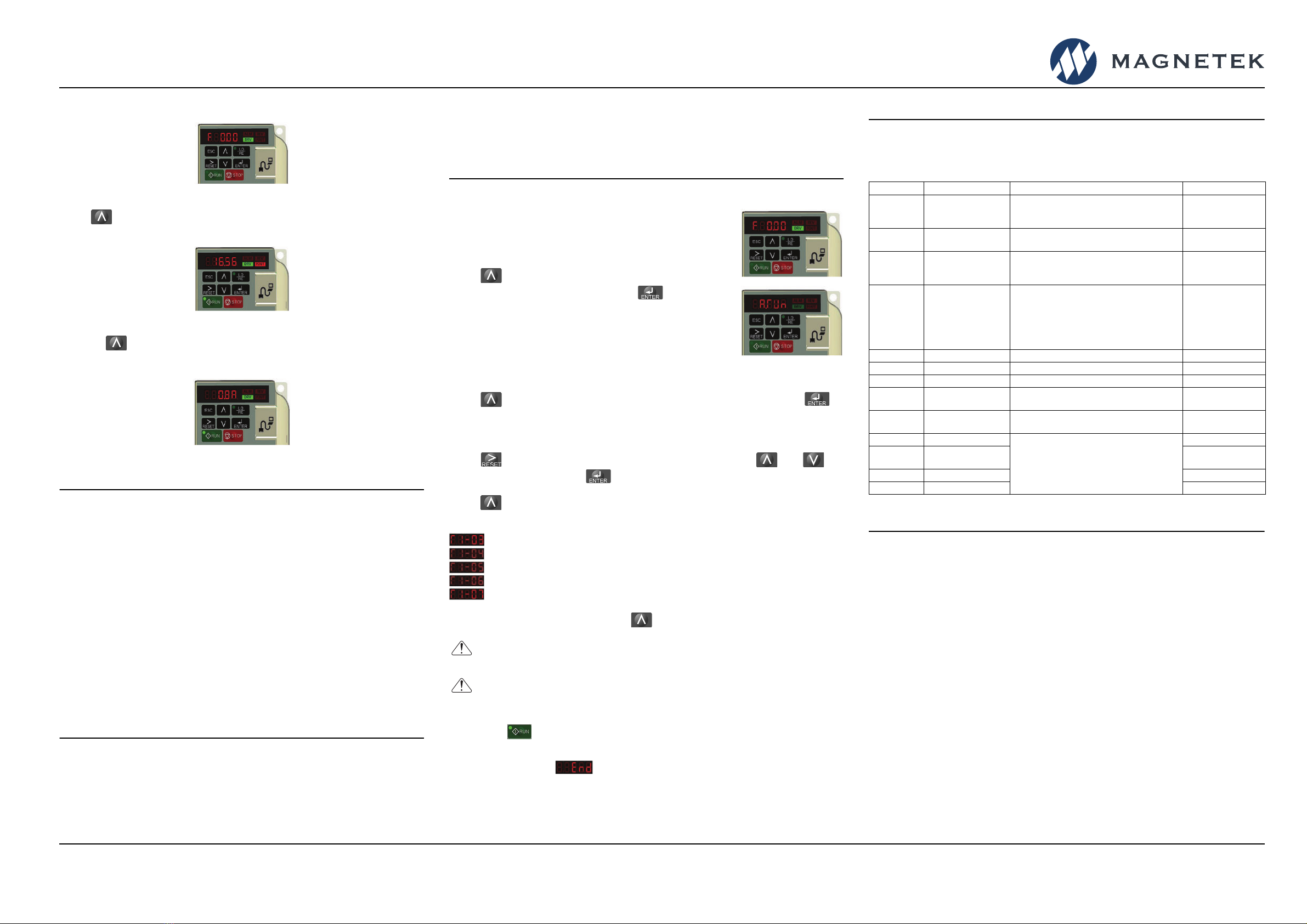

Step 6

Auto-Tuning with Motor

In this step the IMPULSE•G+ Mini is set up for use with the

motor. Make sure all protective covers have been re-

attached and then apply power to the IMPULSE•G+ Mini.

DO NOT RUN THE MOTOR.

Press until the Digital Operator shows the

Auto-Tuning menu (A. Tun) then press .

V/f:

Set T01.01 = 2 (Term Resistance)

Open Loop Vector:

Decouple motor from load and disengage brake.

Set T01.01 = 0 (Standard Tuning)

Press until the Digital Operator shows parameter T01.02 then press .

For Europe: Enter Motor Power in kW

For USA: Enter Motor Power in HP

Press to select the digit you would like to change and use and to

adjust the value, then press to save the value.

Press to select the next parameter and follow the same procedure described

above to adjust its value.

After setting parameter T01.07 press to select the Auto-Tuning command.

Next, press on the Digital Operator. The IMPULSE•G+ Mini will now start the

Auto-Tuning procedure.

The display will show when the Auto-Tuning procedure has successfully

completed. Please reference the IMPULSE•G+ Mini technical manual or repeat

Auto-Tuning procedure if the display shows an error message.

2-Speed Multi-Step: A01.04 = 0 2-Step Infinitely Variable: A01.04 = 3

3-Speed Multi-Step: A01.04 = 1 3-Step Infinitely Variable: A01.04 = 4

5-Speed Multi-Step: A01.04 = 2 Uni-Polar Analog: A01.04 = 5

Motor Rated Voltage (e.g. 230 V, 460 V)

Motor Rated Current (e.g. 22.0 A)

Motor Rated Frequency (e.g. 60.0 Hz)

Motor Poles (e.g. 4 Poles)

Motor Rated Speed (e.g. 1750 rpm)

WARNING! SUDDEN MOVEMENT HAZARD. The IMPULSE•G+

Mini and motor may start unexpectedly during Auto-Tuning.

WARNING! ELECTRIC SHOCK HAZARD. High voltage will be

supplied to the motor when Auto-Tuning is performed. Do not

touch the motor.

Step 7

Quick Start Parameters

The following table lists the commonly used parameters as well as frequently

asked questions.

Frequently Asked Questions

Question: How do I reset the drive back to factory default settings?

Answer: Go to parameter A01.05 and enter 1110.

Question: How do I adjust the time it takes the motion to speed up or slow down?

Answer: Adjust the acceleration time parameter B05.01 and deceleration time

parameter B05.02.

Question: How do I prevent my drive from tripping on an OV fault (overvoltage)

while my motor is ramping down?

Answer:

Increase deceleration time parameter B05.02 and check braking resistor.

Question: How do I prevent my drive from tripping on an OL1 fault (overload)

while my motor is ramping down?

Answer: Verify motor rated current parameter E02.01 and motor overload

protection time parameter L01.02.

Question: How can I run my motor above the nominal motor speed?

Answer: Increase the value of parameter E01.04 Maximum Frequency.

Verify that the motor and system allow for this.

Question: How can I change motor direction without changing the motor leads?

Answer: Set parameter B03.04 to 1 (exchange phases).

Question: Where can I find troubleshooting information regarding faults and

alarms?

Answer: Reference the technical manual.

Parameter Description Settings Comments

A01.01 Access Level

0 = User

1 = Basic

2 = Advanced

A01.02 Control Method 0 = V/f

2 = Open Loop Vector*

* Auto-Tune

recommended

A01.03 Motion

0 = Traverse

1 = Hoist

4 = Braketronic

A01.04 Speed Reference

0 = Two-Speed Multi-Step

1 = Three-Speed Multi-Step

2 = Five-Speed Multi-Step

3 = Two-Step Infinitely Variable

4 = Three-Step Infinitely Variable

5 = Uni-Polar Analog (0-10VDC, 4-20mA)

B01.01 - 16 Speed References 0.00 - 150.00 Hz Limited by E01.04

B05.01 Acceleration Time 0.0 - 25.5 Seconds

B05.02 Deceleration Time 0.0 - 25.5 Seconds

E01.01 Input Voltage 155 - 255 VAC (200 VAC Models)

310 - 510 VAC (400 VAC Models) Line Voltage

E02.01 Motor Rated FLA 0.01 - 70.0 Amps See Motor

Nameplate

H01.xx Digital Inputs

See Technical Manual for Options

Terminals S1 - S7

H02.xx Digital Outputs Terminals MA/MB,

P1, P2

H03.xx Analog Inputs Terminals A1, A2

H04.xx Analog Output Terminal AM

N49 W13650 Campbell Drive

Menomonee Falls, WI 53051

Phone: 262.783.3500

Fax: 262.783.3510

Toll-Free Phone: 800.288.8178

Toll-Free Fax: 800.298.3503

For questions regarding service or technical information contact:

1.833.SVC.CMCO (1.833.782.2626)

International Service

Outside the U.S. & Canada call 1.262.783.3500, press 3

www.columbusmckinnon.com/magnetek

IMPULSE•G+ Mini Quick Start Guide

144-25543 R1

August 2020 © Copyright 2020 Magnetek

IMPULSE®•G+ Mini Variable Frequency Drive

Quick Start Guide