ACCEPTANCE OF THE DEVICE

At the time of delivery it is essential to check at once and

make sure you have received all the material indicated in

the shipping documents, and that the device has not

undergone damage during shipment. In this case, show the

damage to the forwarder and inform our customer service

department. Only if you proceed promptly in this way will it

be possible to obtain any missing material and

reimbursement of thedamage.

FOREWORD

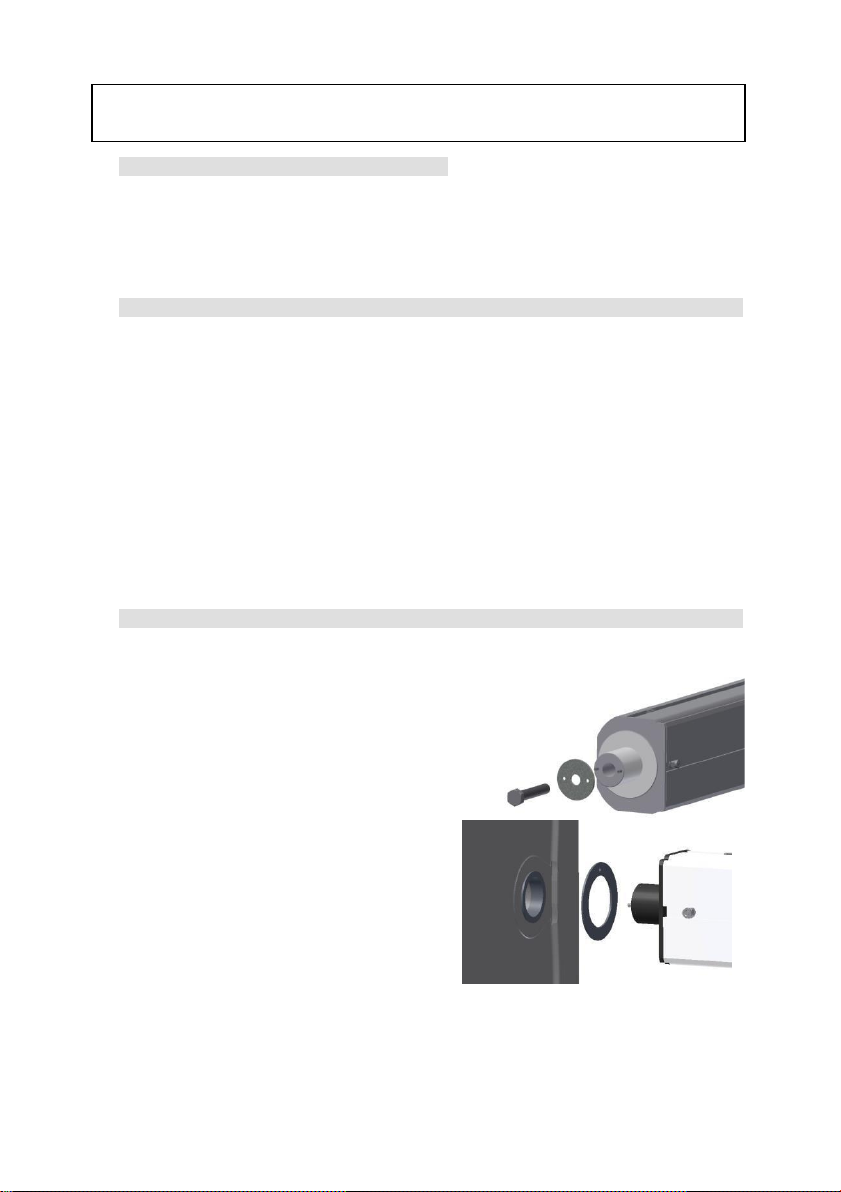

This is a device designed for correct beam alignment of any

type of automobile or motor vehicle headlight.

The device must be used for this purpose only. Even the

finest of devices can function properly and ensure profitable

service only if it is used correctly and kept in the best

possible condition. For this reason, we ask you to read this

manual with care and to reread it whenever difficulties

should arise in using the device. In case of need, we

remind you that our service centers, organized in

cooperation with our retailers, are always at your disposal

for any advice you mayneed.

NOTE: the manufacturer may decide to make changes in

the device without notice, in order to adapt it to

technological advances and specific production or

installation needs. Therefore, even if the illustrationsshown

in the manual differ slightly from the device in your

possession, the safety and instructions about it are

guaranteed.

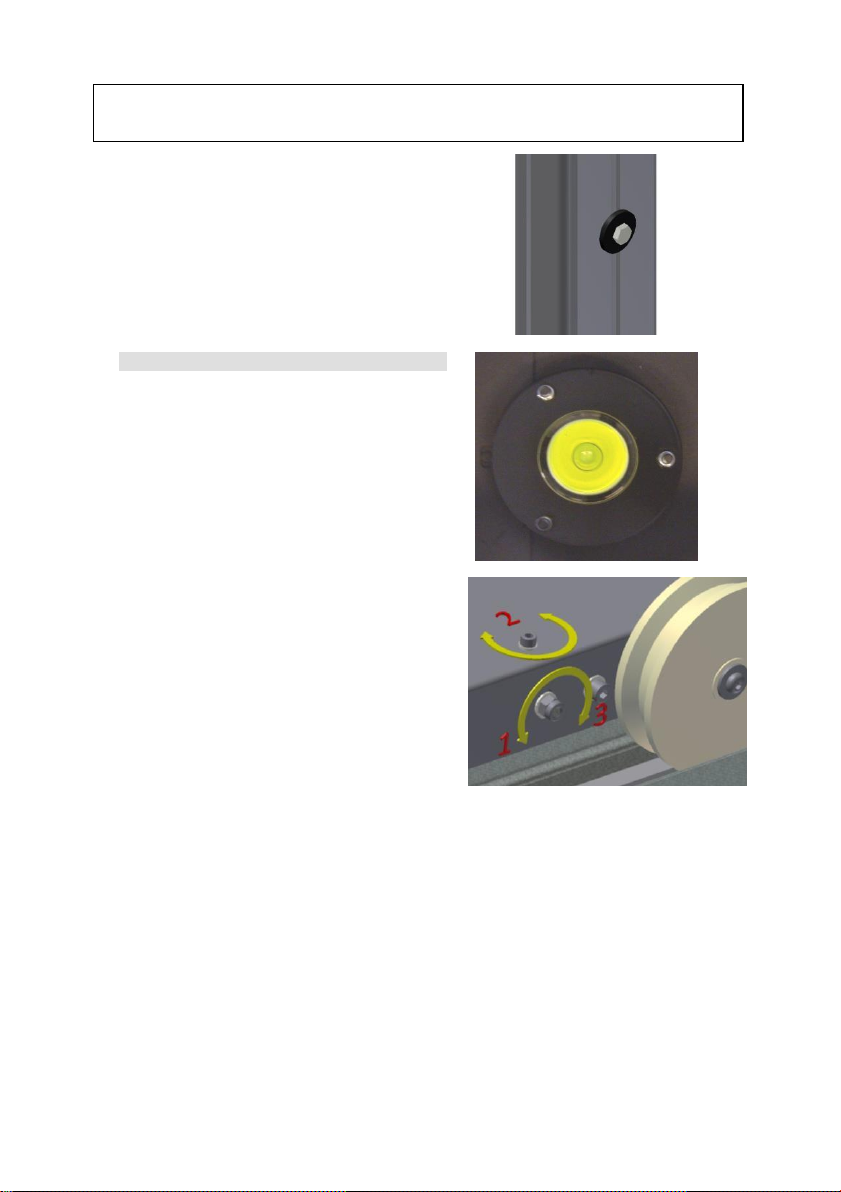

orientation: above and below

right and left

0 –600 mm / 10 mt (0 - 6 %)

0 –1000 mm / 10 mt (0 - 10 %)

0 - 240 lx (Lux/25mt)

0 - 150.000 cd (Candle)

0 –150.000 lx (Lux/1mt)

Unit of intensity measurement

Lux (a 25mt) –Kcand –Klux (a 1 mt)

Unit of orientation measurement

Height from ground of optical center

Supply voltage with internal battery

Input voltage of battery charge

100 –240 V / 50 mt (0 - 60 Hz)

Laser product classification

2 Laser modules in the optical box

class 3R

wave length is 635 nm

power is 5 mW

fan angle 90°

class 3R

wave length is 635 nm

power is 5 mW

fan angle 130°

LASER RADIATION

AVOID DIRECT EYE EXPOSURE

CLASS 3R LASER PRODUCT