Read this Manual Befo e Installing

This manual provid s information on th Solit l®

Vibrating Rod L v l Switch. It is important that all

instructions ar r ad car fully and follow d in s qu nc .

D tail d instructions ar includ d in th Complete

Installation s ction of this manual.

Conventions Used in this Manual

C rtain conv ntions ar us d in this manual to conv y

sp cific typ s of information. G n ral t chnical mat rial,

support data, and saf ty information ar pr s nt d in

narrativ form. Th following styl s ar us d for not s,

cautions, and warnings.

Notes

Not s contain information that augm nts or clarifi s

an op rating st p. Not s do not normally contain

actions. Th y follow th proc dural st ps to which

th y r f r.

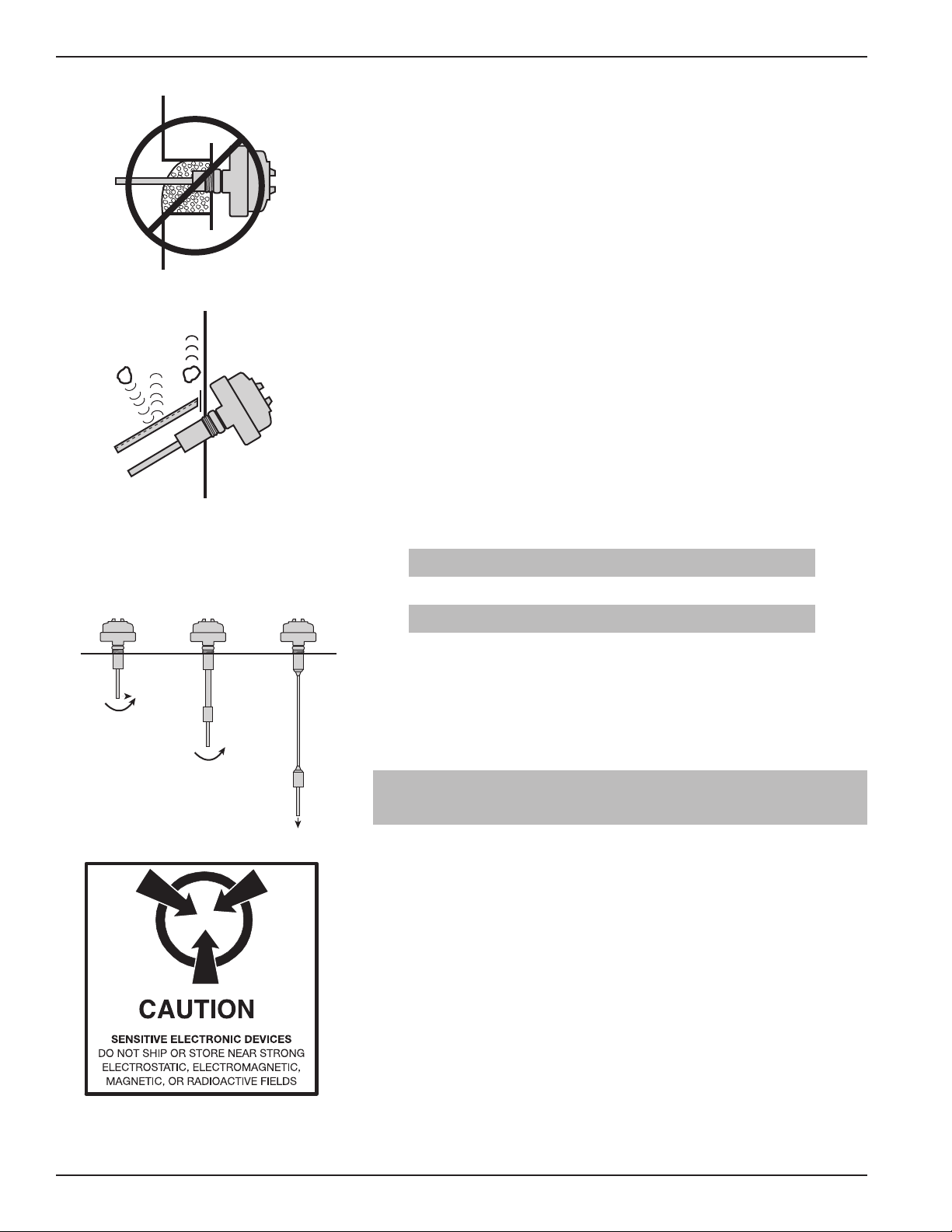

Cautions

Cautions al rt th t chnician to sp cial conditions that

could injur p rsonn l, damag quipm nt, or r duc

a compon nt’s m chanical int grity. Cautions ar also

us d to al rt th t chnician to unsaf practic s or th

n d for sp cial prot ctiv quipm nt or sp cific

mat rials. In this manual, a caution box indicat s a

pot ntially hazardous situation which, if not avoid d,

may r sult in minor or mod rat injury.

Wa nings

Warnings id ntify pot ntially dang rous situations or

s rious hazards. In this manual, a warning indicat s an

immin ntly hazardous situation which, if not avoid d,

could r sult in s rious injury or d ath.

Safety Messages

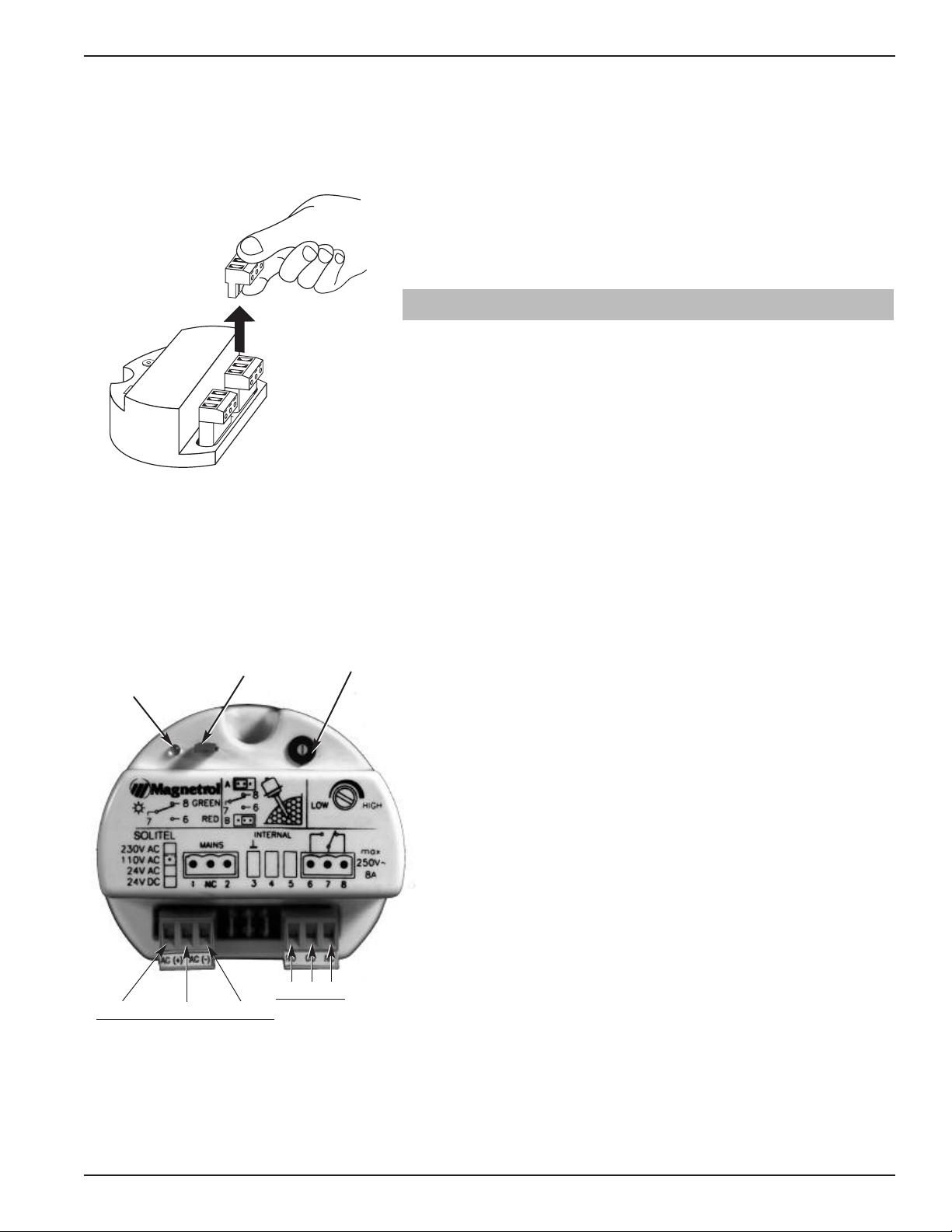

Th Solit l syst m is rat d by th IEC for us in Cat gory

II, Pollution D gr 2 installations. Follow all standard

industry proc dur s for s rvicing l ctrical and comput r

quipm nt wh n working with or around high voltag .

Always shut off th pow r supply b for touching any

compon nts. Although high voltag is not pr s nt in this

syst m, it may b pr s nt in oth r syst ms.

El ctrical compon nts ar s nsitiv to l ctrostatic

discharg . To pr v nt quipm nt damag , obs rv saf ty

proc dur s wh n working with l ctrostatic s nsitiv

compon nts.

This d vic compli s with Part 15 of th FCC rul s.

Op ration is subj ct to th following two conditions: (1)

This d vic may not caus harmful int rf r nc , and (2)

This d vic must acc pt any int rf r nc r c iv d, includ-

ing int rf r nc that may caus und sirabl op ration.

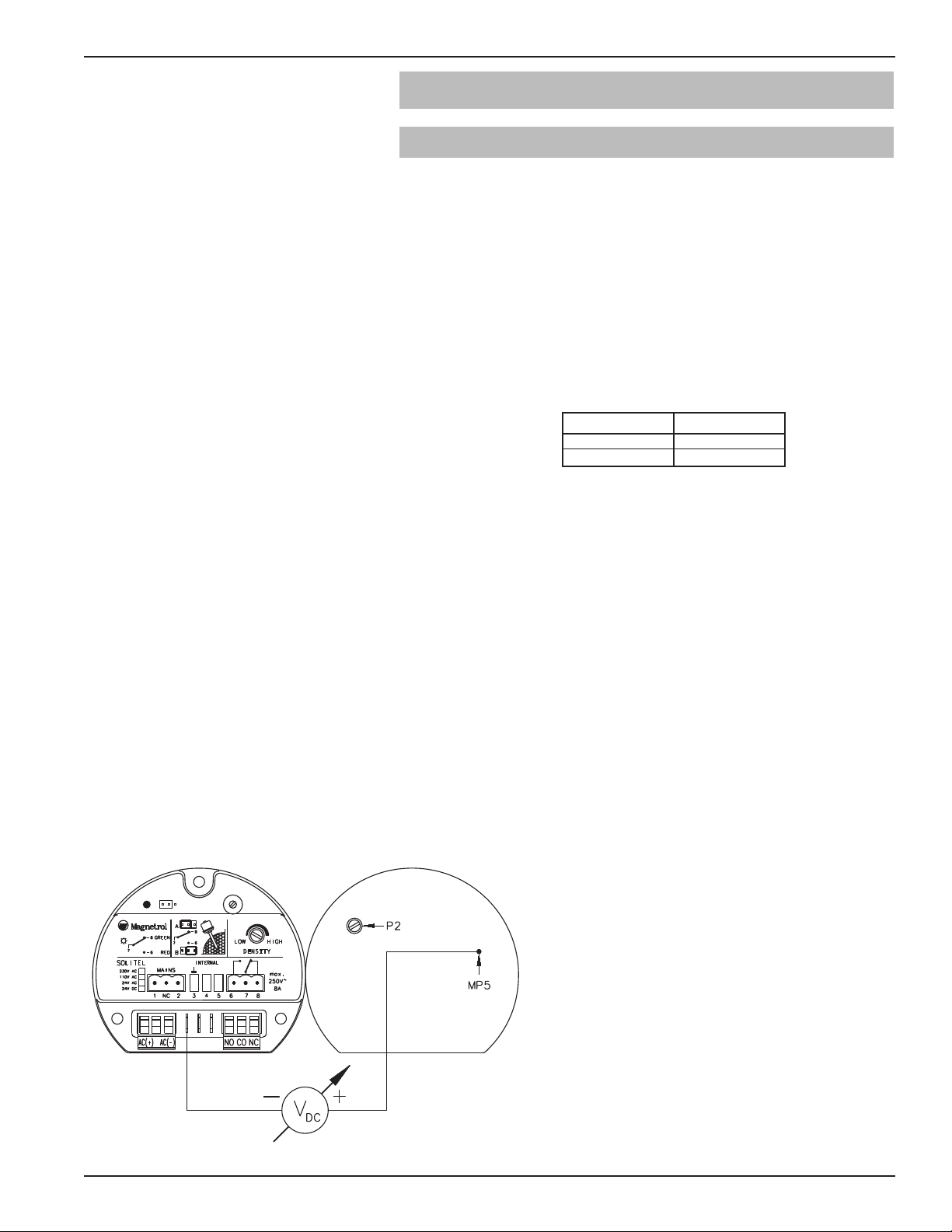

Low Voltage Di ective

For us in Cat gory II installations. If quipm nt is us d

in a mann r not sp cifi d by manufactur r, prot ction

provid d by quipm nt may b impair d.

WARNING! Explosion hazard. Do not conn ct or

disconn ct quipm nt unl ss pow r has b n switch d off

or th ar a is known to b non-hazardous.

Notice of Copy ight and Limitations

Copyright © 2019 Magn trol Int rnational

MAGNETROL r s rv s th right to mak chang s to th

product d scrib d in this manual at any tim without

notic . MAGNETROL mak s no warranty with r sp ct

to th accuracy of th information in this manual.

Wa anty

All MAGNETROL l ctronic l v l and flow controls ar

warrant d fr of d f cts in mat rials or workmanship

for ight n months from th dat of original factory

shipm nt.

If r turn d within th warranty p riod; and, upon

factory insp ction of th control, th caus of th

claim is d t rmin d to b cov r d und r th warranty;

th n, MAGNETROL will r pair or r plac th control at

no cost to th purchas r (or own r) oth r than

transportation.

MAGNETROL shall not b liabl for misapplication,

labor claims, dir ct or cons qu ntial damag or xp ns

arising from th installation or us of quipm nt. Th r

ar no oth r warranti s xpr ss d or impli d, xc pt

sp cial writt n warranti s cov ring som MAGNETROL

products.

Quality Assu ance

Th quality assuranc syst m in plac at MAGNETROL

guarant s th high st l v l of quality throughout th

company. MAGNETROL is committ d to providing

full custom r satisfaction both in quality products and

quality s rvic .

Th MAGNETROL quality assuranc syst m is

r gist r d to ISO 9001 affirming its commitm nt to

known int rnational quality standards providing th

strong st assuranc of product/s rvic quality availabl .