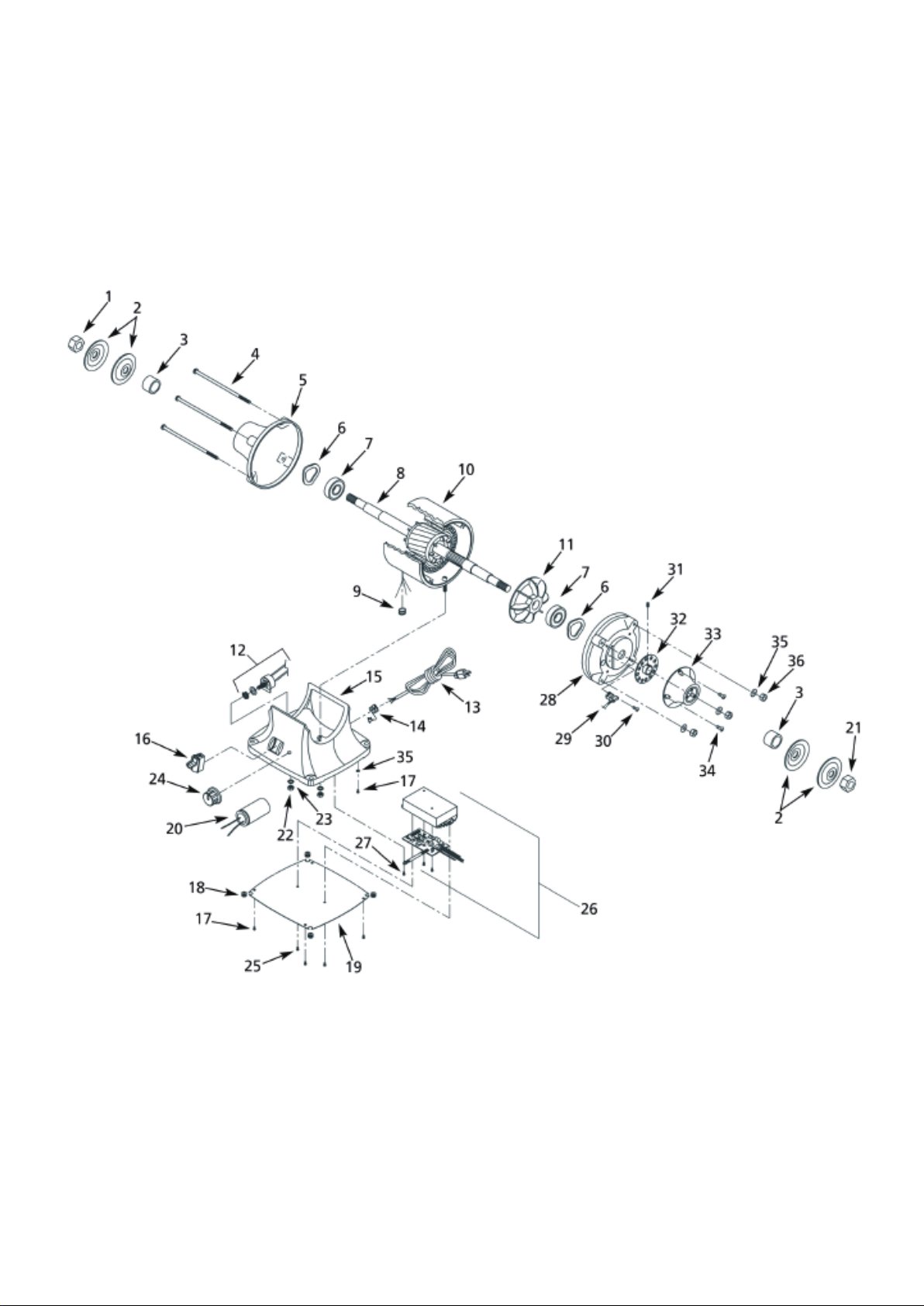

Description

Buffers are equipped with a totally enclosed ball bearing motor.Armature assembly is dynamically balanced for smooth op-

eration. Motor housing is compact so long pieces of work can press against both buffing wheels without touching the motor

frame. Buffing wheels are included

The 6” Buffer, MI-14150, operates at a single speed of 3600 rpm. The 8” Buffer, MI-14350, operates at 3600 rpm and also

can be operated at any speed from 2000 to 3300 rpm.

Unpacking

Check for shipping damage. If damage has occurred, a claim must be filed with the carrier immediately. Check for com-

pleteness. Immediately report missing parts to dealer.

Specifi cations

Model HP RPM AMPS Volts Hz

MI-14150 1/2 3600 5.0 115 60

MI-14350 3/4 3600 7.0 115 60

MI-14350 Variable

speed range ....2000-3300; 3600 RPM

SIZES

MI-14150: 6” Dia., 1/2” Bore

MI-14350: 8” Dia., 5/8” Bore

General Safety Information

WARNING For your own safety, read operating instructions manual before operating tool.

BE PREPARED FOR JOB

1. Wear proper apparel. Do not wear loose clothing, gloves, neckties, rings, bracelets or other jewelry which may get caught

in moving parts of machine.

2. Wear protective hair covering to contain long hair.

3. Wear safety shoes with non-slip soles.

4. Wear safety glasses complying with United StatesANSI Z87.1. Everyday glasses have only impact resistant lenses. They

are NOT safety glasses.

5. Wear face mask or dust mask if operation is dusty.

6. Be alert and think clearly. Never operate power tools when tired, intoxicated or when taking medications that cause

drowsiness.

PREPARE WORK AREA FOR JOB

1. Keep work area clean. Cluttered work areas invite accidents.

2. Do not use power tools in dangerous environments. Do not use power tools in damp or wet locations. Do not expose

power tools to rain.

3. Work area should be properly lighted.

4. Proper electrical plug should be plugged directly into properly grounded, three-prong receptacle.

5. Extension cords should have a grounding prong and the three wires of the extension cord should be of the correct gauge.

6. Keep visitors at a safe distance from work area.

7. Keep children out of the workplace. Make workshop childproof. Use padlocks, master switches or remove switch keys to

prevent any uninten- tional use of power tools.

TOOL SHOULD BE MAINTAINED

1.Always unplug tool prior to inspection.

2. Consult manual for specific maintain- ing and adjusting procedures.

3. Keep tool clean for safest operation.

4. Remove adjusting tools. Form habit of checking to see that adjusting tools are removed before turning machine on.

5. Keep all parts in working order. Check to determine that the guard or other parts will operate properly and per- form their