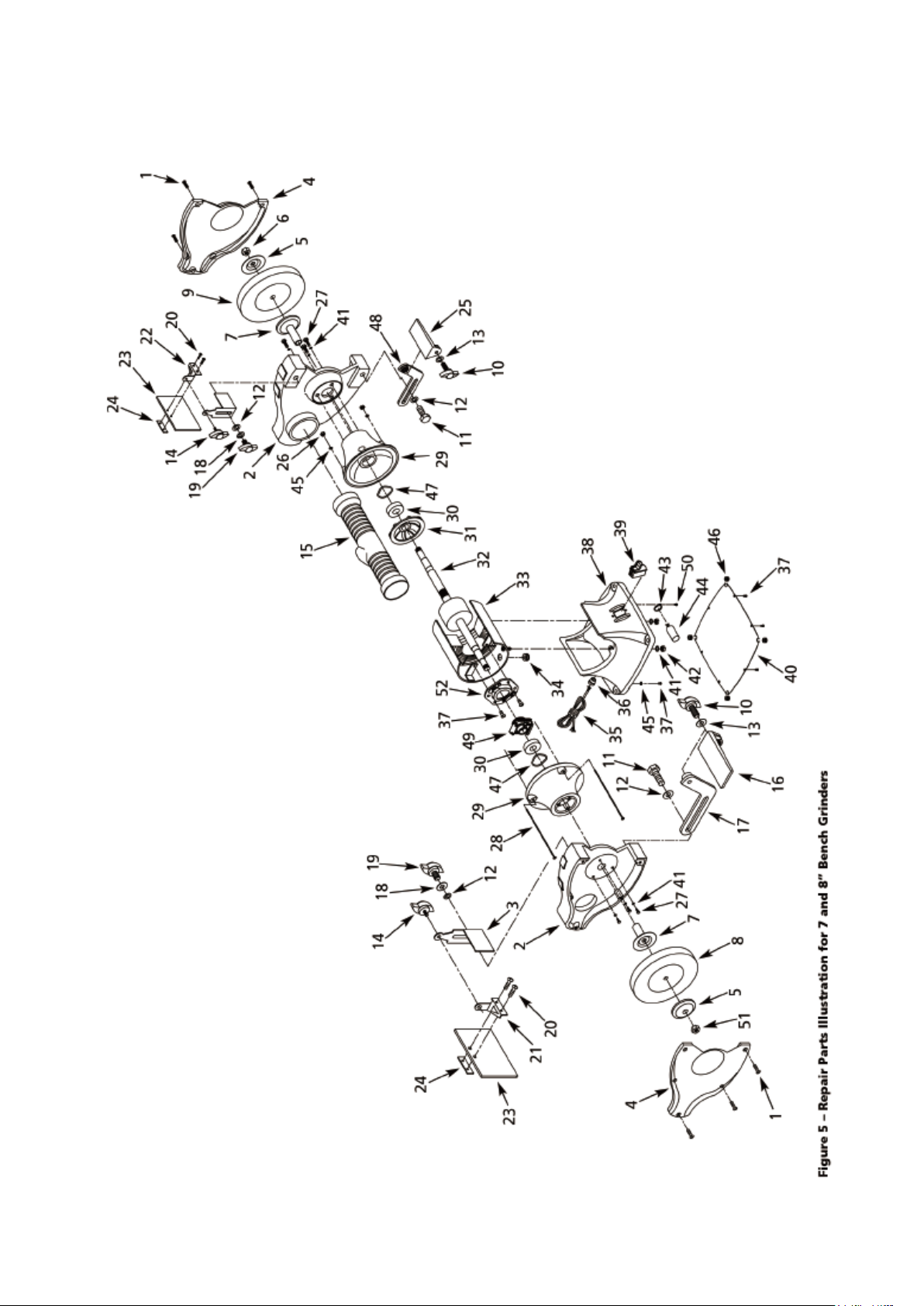

A3/8-16 x 3/4" Hex bolt, 2 each

B3/8" Flat washer, 4 each

CTool rest bracket (left & right), 2 each

D Tool rest (left & right), 2 each

E 5/16" Flat washer, 2 each

F 5/16-18 x 1" Knob, 2 each

G#10-24 x 1/2" Pan head screw, 4 each

HUpper eyeshield bracket, 2 each (left and right)

IEyeshield, 2 each

J Lower eyeshield bracket, 2 each

K3/8" Lock washer, 2 each

L1/4-20 x 3/8" Knob, 2 each

MSpark guard (left and right), 2 each

N3/8-16 x 1/2" Knob, 2 each

Dust collector hose not shown.

TOOL REST ASSEMBLY

1. Place tool rest (D) over tool rest bracket and secure

in position with 5/16" at washer (E) and 5/16-18 x 1"

knob (F).

2. Attach tool rest bracket to the bot- tom of the left

wheel guard using one 3/8-16 x 3/4" hex head bolt (A)

and one 3/8" at washer (B). Make sure that the slot

of the bracket is located over the raised boss on the

guard. Tighten bolts nger tight.

3. Position tool rest so that distance between tool

rest and grinding wheel is less than 1/16".

Reposition angle of tool rest if necessary. Secure all

knobs and bolts.

4. Mount right tool rest in a similar manner.

EYESHIELD ASSEMBLY

1. Attach spark guard (M) to left wheel guard using 3/8-16 x 1/2" knob (N). 3/8" at washer (B) and

3/8" lock washer (K).

2. Mount left upper eyeshield bracket (H) to eyeshield (I) using two #10-24 x 1/2" pan head screws (G)

and lower eyeshield bracket (J).

NOTE: Left upper eyeshield bracket is stamped "L" for identication.

3. Slide 1/4-20 x 3/8" knob (L) through hole at top of left spark guard (M) Into upper eyeshield bracket

(H) and secure in position.

Assembly (Continued)

4. Locate eyeshield In desired position for protecting operator and secure all knobs and bolts.

5. Mount right eyeshleld assembly in a similar manner.

DUST COLLECTOR HOSE

A dust collector hose has been provided with grinder. Slide hoses onto sides of T-connector and

anges. Mount the hose by sliding the anges at each end over the exhaust ports on the left and right

wheel guards. Attach 2-1/2" shop vacuum hose to collector hose. Be sure hose is mounted securely.

DANGER Be sure to empty shop vacuum of all flammable material (flammable liquids

and vapors, paper, wood, plastic, etc.) before connecting vacuum to grinder. Hot sparks

from grinder may ignite flammable materials in shop vacuum. OPTIONAL LIGHTED

EYESHIELD

Position eyeshield bracket assembly over bosses provided on wheel guard. Bosses are tapped to

Figure 1- Left Tool Rest and Eyeshield

Assembly