4

Summary

Warnings............................................................................................................................................................ 3

1. Product ....................................................................................................................................................... 5

1.1. Intended uses .................................................................................................................................... 5

1.2. package ............................................................................................................................................. 6

1.2.1. Package Contents ..................................................................................................................... 6

1.3. Machine description........................................................................................................................... 6

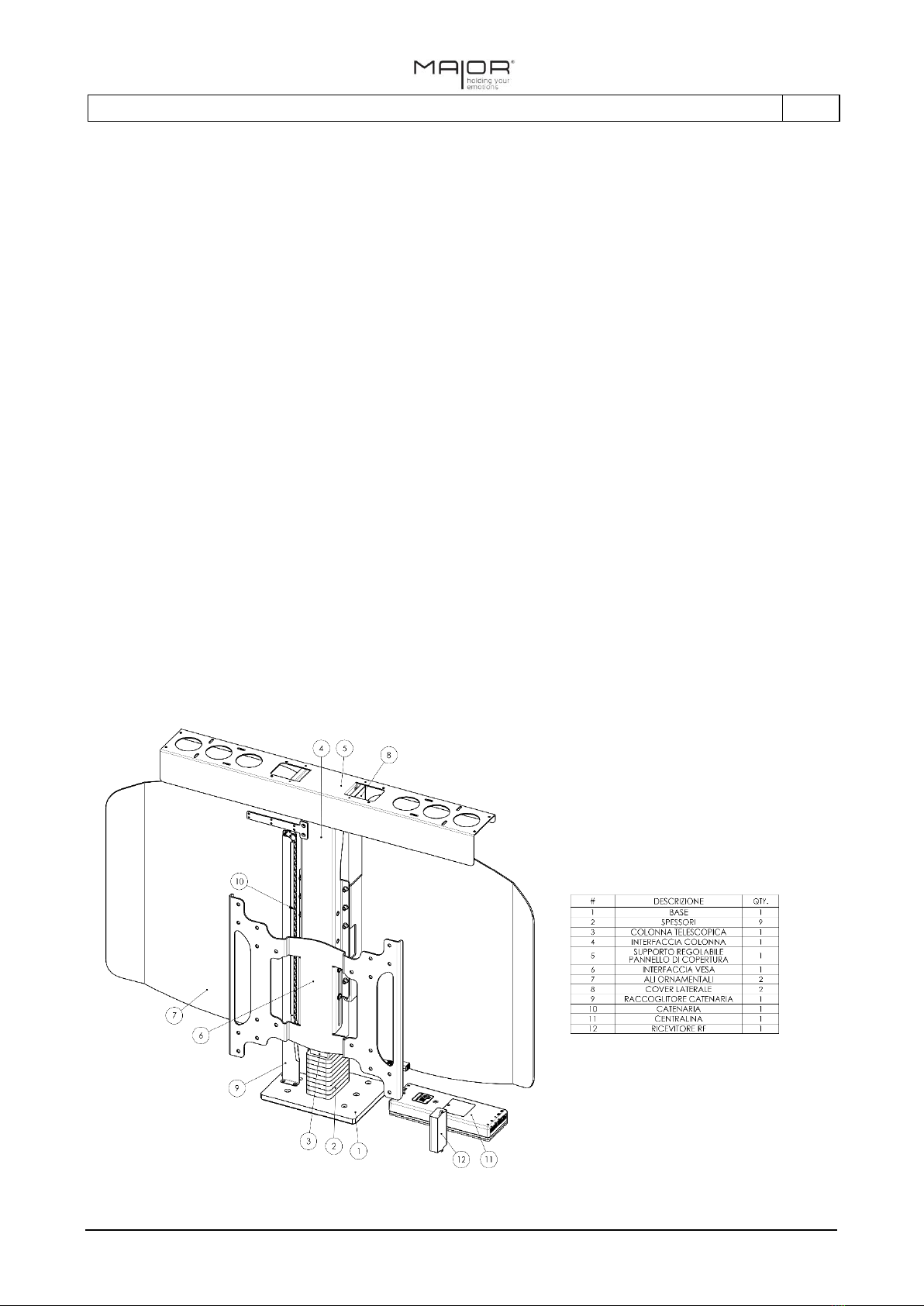

1.3.1. Components and knots.............................................................................................................. 6

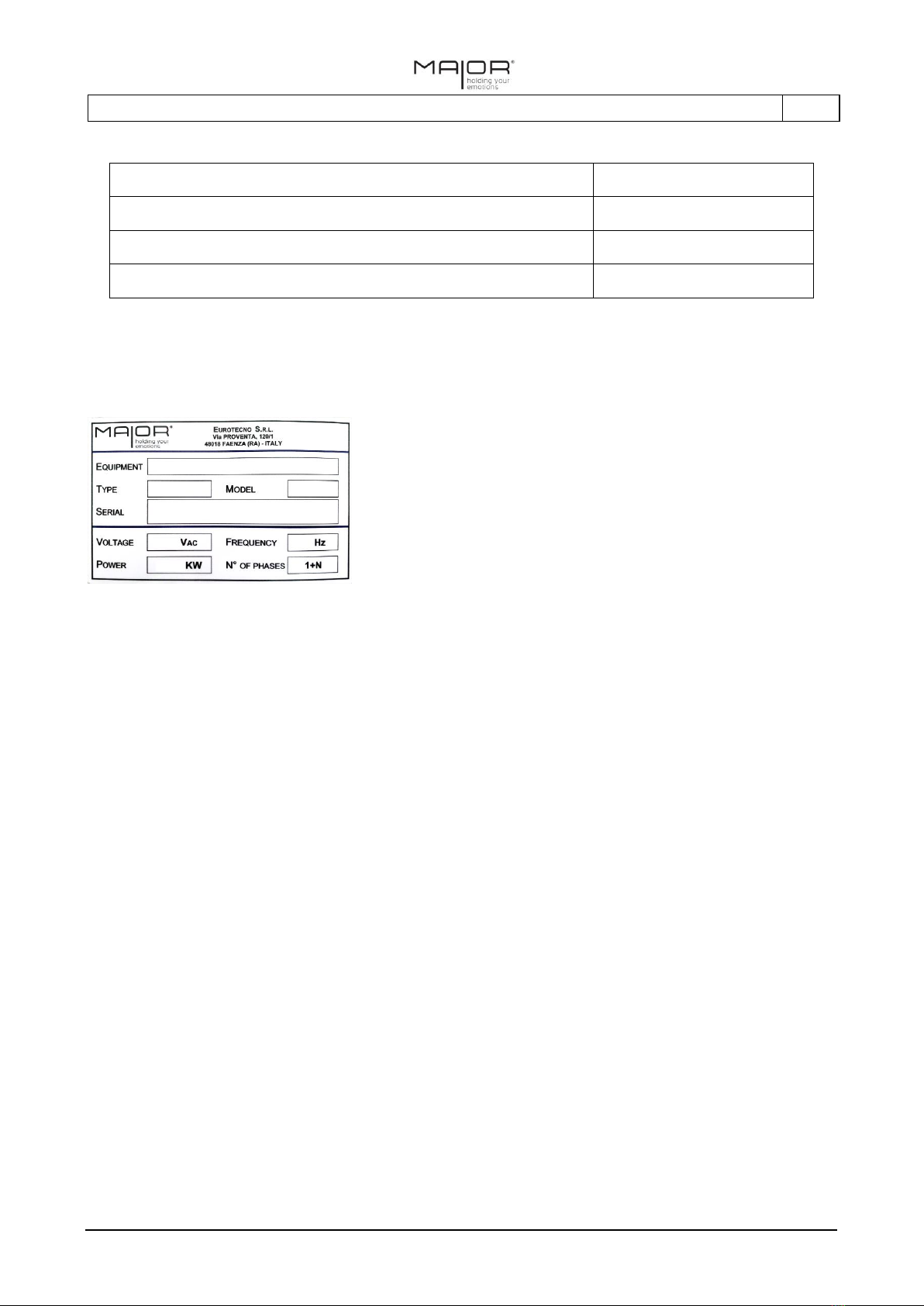

1.3.2. Identification of the machine...................................................................................................... 7

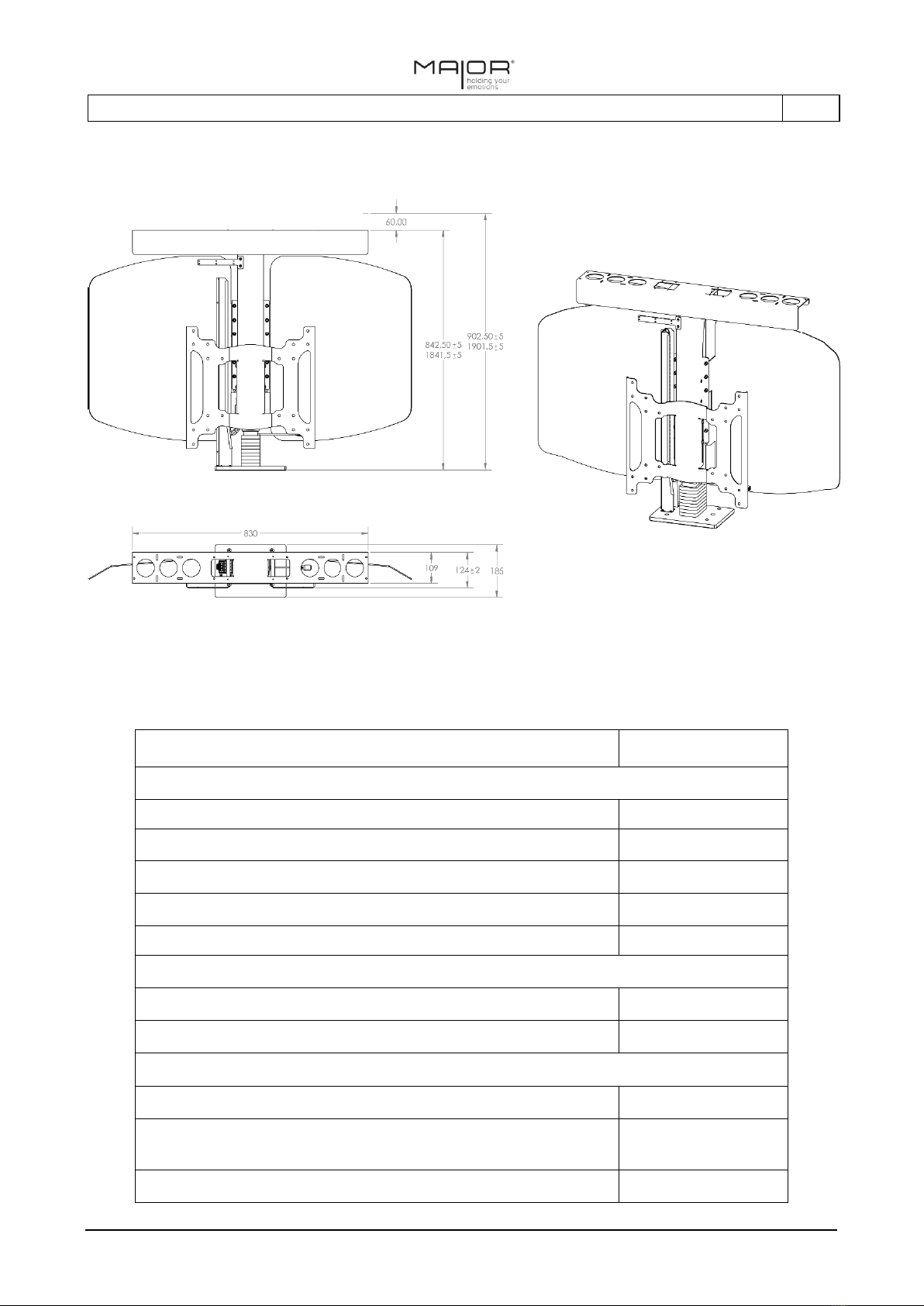

1.3.3. Dimensions and technical data.................................................................................................. 8

1.3.4. Linak Actuator DL12XL.............................................................................................................. 9

1.3.5. motor lead.................................................................................................................................. 9

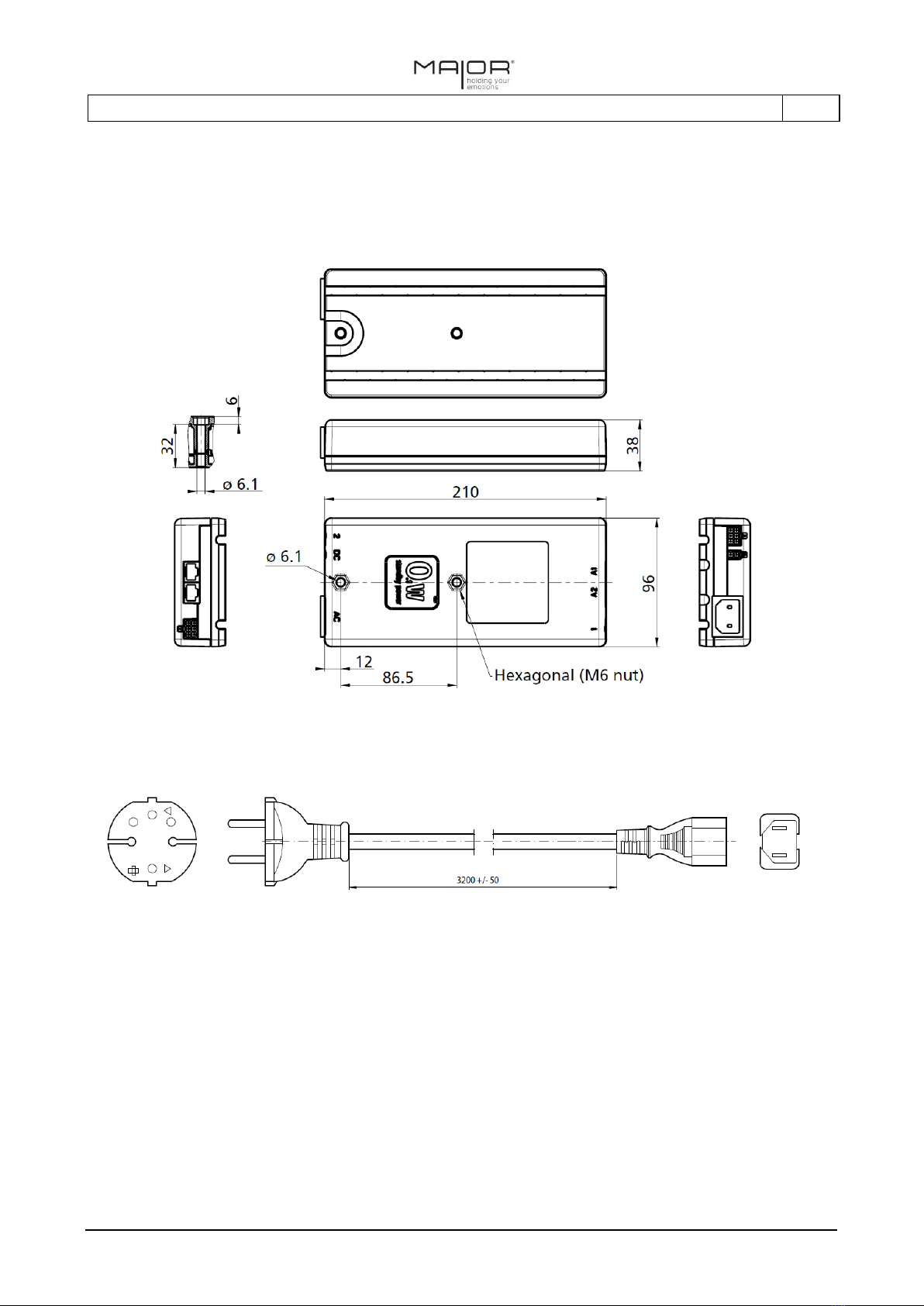

1.3.6. CDB6S unit................................................................................................................................ 9

1.3.7. Power cable compatible (EU version) ..................................................................................... 10

1.3.8. RFRL Receiver ........................................................................................................................ 10

2. Assembly instructions............................................................................................................................... 11

2.1. General safety instructions .............................................................................................................. 11

2.2. Installation........................................................................................................................................ 11

2.2.1. Instructions and tips for creating mobile.................................................................................. 11

2.2.2. installation Steps...................................................................................................................... 12

3. Operation, use, maintenance and disposal.............................................................................................. 15

3.1. Operating instructions...................................................................................................................... 15

3.2. commands ....................................................................................................................................... 15

3.3. Remote control optional................................................................................................................... 16

3.4. Procedure coupling between transmitter and receiver.................................................................... 16

3.5. Malfunction....................................................................................................................................... 17

3.6. Reset Procedure.............................................................................................................................. 17

3.6.1. Precautions.............................................................................................................................. 17

3.6.2. the column reset procedure (DL12XL) .................................................................................... 17

3.7. Maintenance .................................................................................................................................... 18

3.8. Demolition and disposal................................................................................................................... 18

4. Attached documentation........................................................................................................................... 19

4.1. EC Declaration of Conformity.......................................................................................................... 19