MakerPi K5 Plus User manual

1

2

Content

Chapter 1 Learn about your 3D printer..................................................................... 3

1.1 3D printer introduction...................................................................................4

1.2 Cautions..........................................................................................................5

Chapter 2 Preparation before printing...................................................................... 6

Chapter 3 Adjustments to the printing platform....................................................... 9

3.1 Coarse tuning................................................................................................. 9

3.2 Fine tuning....................................................................................................11

Chapter 4 Printer functions..................................................................................... 13

4.1 Preparation......................................................................................................14

4.1.1 Return to zero........................................................................................ 14

4.1.2 Unlock stepper motor............................................................................14

4.1.3 Load filament......................................................................................... 15

4.1.4 Unload filament..................................................................................... 15

4.1.5 XYZ move axis.........................................................................................16

4.1.6 Preheat.................................................................................................. 16

4.1.7 Cool........................................................................................................17

4.2 Print................................................................................................................. 17

4.3 Machine setting............................................................................................... 18

4.3.1 Key sound...............................................................................................18

4.2.2 Alarm sound...........................................................................................18

4.3.3 Touch calibration....................................................................................19

4.3.4 Z distance measurement....................................................................... 19

4.4 Machine status query...................................................................................... 19

4.5 Other functions................................................................................................20

4.5.1 Basic functions.......................................................................................20

4.5.2 Midway refueling................................................................................... 20

4.5.3 Temperature, printing speed and nozzle fan adjustment...................... 21

4.5.4 WiFi connection and video monitoring..................................................21

3

Chapter 5 Software usage introduction...................................................................23

5.1 Slicing software installation.......................................................................... 23

5.2 Introduction to the application of slicing software.......................................26

5.2.1 Fast print(Not recommended for use).......................................... 26

5.2.2 Full mode printing...............................................................................26

5.2.3 Basic setup..........................................................................................26

5.2.4 Advanced setup.................................................................................. 28

5.2.5 CURA print interface........................................................................... 29

5.3 View the model.............................................................................................30

Chapter 6 Printing exercises...................................................................................... 32

Chapter 7 Printing skills............................................................................................. 35

7.1 Flat bottom................................................................................................... 36

7.2 Avoid overhang.............................................................................................36

7.3 Assemble matching graphic tolerances........................................................ 38

7.4 Big size model print...................................................................................... 38

Chapter 8 Printing picture relief................................................................................ 38

Chapter 9 Exports STL format files.............................................................................40

9.1 Pro/E exports STL files.................................................................................. 41

9.2 UG export STL file......................................................................................... 42

9.3 Solidworks export STL files............................................................................44

Chapter 10 Analysis of common problems................................................................45

4

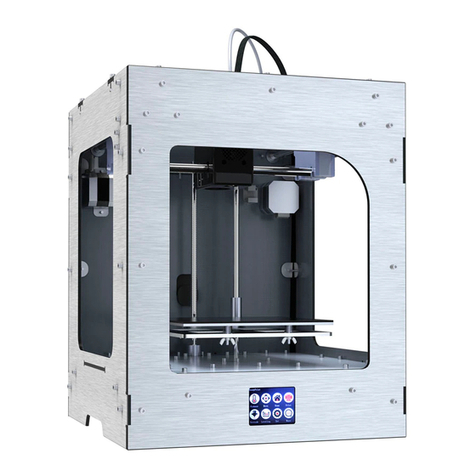

Chapter 1 Learn about your 3D printer

1.1 3D printer introduction

5

6

1.2 Cautions

1. The nozzle temperature is up to 200℃during the working period of the 3D printer

and after printing. So do not touch the nozzle with your hand;

2. Please follow the instructions in the guide to operate and use the machine. If you

have any questions, you can contact the after-sales department;

3. If the printed model needs to be disassembled for support, please wear gloves so as

not to be scratched by tools or supporting materials during the disassembled process;

4. In daily use,it is necessary to regularly clean and lubricate the optical axis of the cross

slide table of the 3D printer, and be careful not to drip onto the casing or belt when

adding lubricating oil.

5. Reading "User guide", at the same time with the actual operation of the machine will

be more conducive to your operation.

6. In the printing process encountered a problem with the machine print, you can first

take a photo to reflect the problem more intuitively, at the same time provide the

machine number of photos (the label at the bottom of the back of the machine), and

then contact after-sales.

7

Chapter 2 Preparation before printing

Take out the machine and use it for

packing, remove the tape, open the

front door, and remove the foam.

Take out the accessory box, etc.

Take out the power cord from the

accessory box, connect the power

cord.

"-" is power on, "O" is power off.

Install filament racks on the back of

the machine with an open end stuck

in the hole.

8

Install WIFI antenna on the side

of the machine, Rotate clockwise

to fix the antenna.

Install white feeding pipe,

separate the two ends insert into

hole.

9

Chapter 3 Adjustments to the printing platform

3.1 Coarse tuning

Platform leveling, filament must be unloaded.

When the platform is down, confirm that there is no debris inside

the machine.

Remove the swift-change nozzle, replace the leveling module.

1. 2.

10

3. 4.

Tighten the four nuts counterclockwise.

Twist the nut according to screen indicated

11

Turn off the power

Replace the swift-change nozzle

1. 2.

3.

12

3.2 Fine tuning

Select a model and wait for the printer to start printing, look at the print platform,

again to see the distance between the nozzle and the platform is probably a piece of

paper, and then start to print the debugging file, adjust.gcode, by looking at the the effect

of the first layer to fine-tune platform, print out the first layer can stop printing, fine-tune

and adjustment of the next print.

If the filament spilled out is serrated, the

distance between the platform and the

nozzle is too large, and the filament is

thrown down from the nozzle instead of

sticking tightly.

Turn the nut a little clockwise to make the

platform go up until the phenomenon disappears

and a tight line appears.

If the filament is found to be too thin or

incoherent, it means that the distance

between the nozzle and the platform is too

small, resulting in too small amount of the

nozzle.

Turn the nut slightly counterclockwise to

lower the platform until the wire output is full and

smooth.

Adjust well the effect of platform printing

should be full out of the filament and the line

pressure is flat on the platform.

13

If the distance between the nozzle and the platform is too large or too small, please

stop printing and adjust the platform until the distance is appropriate. In most cases, the

printing failure is caused by the platform not being adjusted properly. Therefore, please

debug repeatedly as required to ensure that the platform height has been adjusted to a

better level.

And when printing the first layer, it's best to watch the machine print and make sure

the machine prints properly before leaving.

14

Chapter 4 Printer functions

4.1 Preparation

Each function in the "Prepare" option

on the main interface is the preparatory

work before we print the model. Click the

corresponding option to operate. We will

describe them in detail below.

4.1.1 Return to zero

The machine moves to zero automatically,

and the XYZ coordinate is 0.

Click "Prepare" to enter the preparatory

operation interface, select "Return to

zero", and wait for the machine to return

to zero automatically.

4.1.2 Unlock stepper motor

Remove the self-locking state of the

stepper motor. Only after unlocking the

stepper motor can the cross slide be

moved manually.

Click"Prepare"to enter the

preparatory operation interface, and

select "Unlock stepper motor".

15

4.1.3 Load filament

When loading, we confirm again

whether the filament is stuck to the

transmission gear of the filament

feeder. After confirming it, select

"Prepare" and click " Load filament".

The machine will be zeroed and then

lowered for a short distance. At the

same time, the nozzle will be heated,

when the nozzle is heated to 230°C,

the filament feeder will evenly and

smoothly squeeze the filament out of

the nozzle. (loading filament

automatically finish, click exit it will

stop).

4.1.4 Unload filament

Unload filament is an operation often

used in the process. Select

“Prepare” and click "Unload

filament" nozzle heating, when

replacing filaments, we usually

choose to unload the filament first.

Nozzle is heated to 230°C, the feed

motor quickly pulls the filament out

of the nozzle. (unloading filament

automatically finish, click exit it will

pause).

16

4.1.5 XYZ move axis

In use, we often need to manually

move the axis.

Select "XYZ move axis".

Then it will enter the coordinate

movement interface of XYZ. Every

touch of "+" and "-" will change the

coordinate to 1, and the long press

will change the coordinate to 10.

4.1.6 Preheat

Before preparing to print, the

nozzle and the hotbed can be

heated together by selecting

preheating to reach the selected

temperature, which can reduce the

preparation time of temperature

rise before printing.

There are two forms of

preheating, preheating PLA and

preheating ABS.

Selecting preheat PLA, it can

be found that the screen goes

back to the main interface, the

temperature setting value

becomes 180, the hot bed setting

value becomes 70, and both the

nozzle and the hotbed are heated

at the same time.

17

4.1.7 Cool

When you choose not to print after you

select preheating, you can choose to cool

down the nozzle and hotbed temperature,

and the machine will cool down

automatically after printing.Select “Cool”.

You can see that the interface is

back to the main interface, and that the

temperature of the nozzle and the hot

bed is set to zero.

4.2 Print

Before printing, the preparatory work

that needs to be done well is to adjust

the platform. For specific methods, refer

to chapter 2. After confirming that the

platform is set up, select “Print”.

Then select the Gcode file you want to

print.

18

Determine the printed Gcode file again, and

then wait for the machine to warm up and

print automatically.

4.3 Machine setting

In the machine settings, you can calibrate

the machine key sound settings and alarm

sound settings, as well as the Z distance

measurement.(This function is required if

there is a power failure.)

4.3.1 Key sound

Click "Key sound" to cancel the key sound

and click again to resume.

4.3.2 Alarm sound

Click "Alarm sound" to cancel the alarm

sound and click again to restore (it is not

recommended to cancel it).

19

4.3.3 Touch calibration

When the touch screen keys are

inaccurate, you can recalibrate the

touch screen and click "Touch

calibration".

After the calibration starts, click the

red point center until the calibration is

completed. The screen will indicate

whether the calibration succeeded or

failed. If it fails, it will need to be

recalibrated once again.

4.3.4 Z distance measurement

During use, the maximum distance of

Z may change slightly. Select "Z

distance measurement" to

re-measure the distance of Z.

4.4 Machine status query

Click "Status" on the main interface

to view the version information of the

machine. When there is a problem in

the use of the machine, after-sales

will often need to view this

information.

20

You can see the machine information

and the firmware version of the

machine and the running time.

4.5 Other functions

4.5.1 Basic functions

Pause printing:

Click "Pause printing" and the machine

will pause, the interface will change to

"Continue printing". Click "Continue

printing", and the machine will print

according to the original process.

Stop printing:

If you find that the printing failed or for

some other reasons, the model is no

longer printed, you can click "Stop

printing". After the printing is stopped, the

printing is over and cannot be resumed.

4.5.2 Midway refueling

When the machine is printing a large

model, it often encounters that the

filament are not enough to complete the

printing, so this function can be used to

replace the filament

Table of contents

Other MakerPi 3D Printer manuals