MakerPi P2 User manual

Catalogue

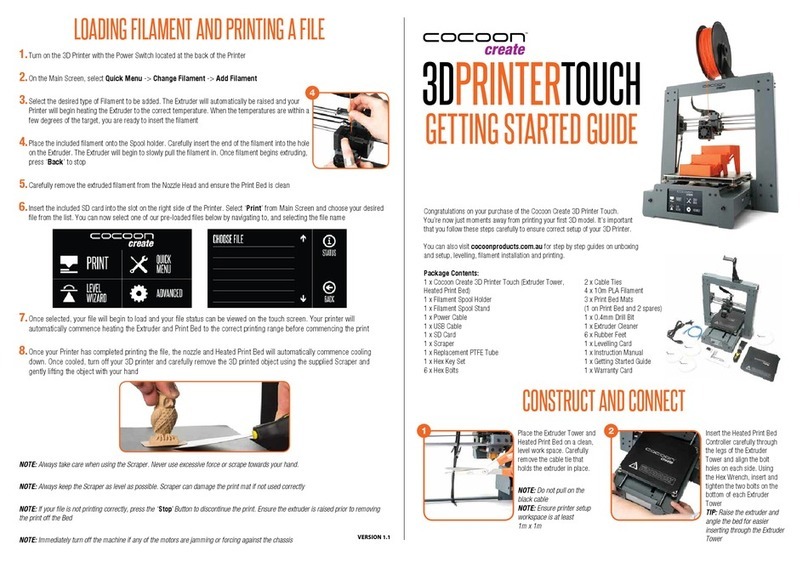

Chapter 1 Learn about your 3D printer.......................................................... 1

1.1 3D printer introduction.....................................................................1

Chapter 2 Preparation before printing............................................................ 3

2.1 Install the gantry frame .................................................................. 3

Chapter 3 Adjustment to the printing platform..............................................5

3.1 Coarse tuning.....................................................................................5

3.2 Fine tuning ....................................................................................... 7

Chapter 4 Load, unload and change filament.................................................9

Chapter 5 Choose the model to print............................................................ 11

Chapter 6 Motherboard wiring diagram.......................................................12

Chapter 7 Analysis of common problems.................................................... 13

Attachment:................................................................................................. 16

1

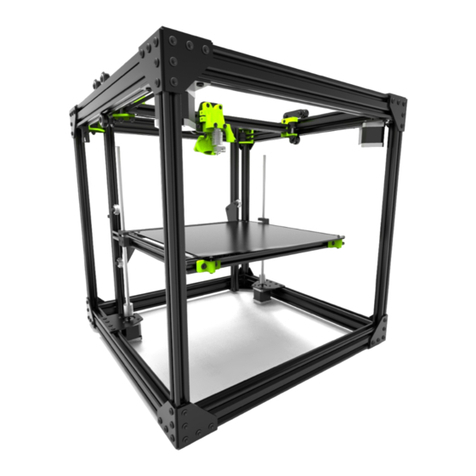

Chapter 1 Learn about your 3D printer

1.1 3D printer introduction

1、X-axis limit switch

7、Leveling nut

13、Z-axis limit switch

2、Extrusion head kit

8、TF card slot

14、X-axis motor

3、Magnetic printing

platform

9、USB port

15、Z-axis motor

4、LCD screen

10、Micro-USB port

16、Y-axis motor

5、Knob

11、Feeder

17、Power switch

6、Y-axis limit switch

12、Extrusion (E) motor

2

1.2 Cautions

1.The nozzle temperature can reach temperatures greater than

200℃while printing and remains hot for a period of time during

cool down after the completion of a print. Take caution while

removing your printed model - do not touch the nozzle with your

hand;

2.Please follow the instructions in the guide while operating this

machine. If you have any questions contact your reseller or the

MakerPi after-sales department;

3.If support material needs to be removed from the printed

model, please wear gloves so as not to be hurt by tools or the

support material during the clean-up process;

4.Reading the "User guide", while actually operating the

machine will be more conducive to your operation as you

become familiar with the printer;

5.If you encountered a problem with a print or a machine part,

please take a photo that represents the problem and another

with the machine identification number (the label at the bottom

back of the machine), and then contact our after-sales support

or your reseller;

6.The use of original factory filament is recommended;

7.If your machine does not power on check the power supply

under the machine and select the appropriate voltage for your

region.

3

Chapter 2 Preparation before printing

2.1 Install the gantry frame

①base frameX1

②gantry frame X1

4

④

①

②

④

③

③

Insert the gantry frame into the corresponding hole of the base

frame, then fix the two M5*8 screws at the bottom first, and finally

tighten the four M5*25 screws on both sides of the machine. It may be

easier if you temporarily remove the magnetic bed.

5

Chapter 3 Adjustment to the printing platform

3.1 Coarse tuning

LCD screen select Motion → Auto Home

When the machine returns to zero, the motor will be

automatically locked. You need to select Motion →Disable

Steppers to unlock the motors

Move the nozzles from corner to corner around the glass

plate. Turn the knobs to adjust the distance between the nozzle and

the glass plate.Rotate the platform leveling knob clockwise to

raise platform

6

Rotate the platform leveling knob counterclockwise to

lower the platform

In coarse tuning, the approximate distance between the

nozzle and the glass plate is the thickness of a piece of paper.

If the distance is too great, the platform leveling knob should

be rotated clockwise to move the platform upward. If the

distance is too little and the nozzle is too close to the platform,

turn the leveling knob counterclockwise to move the platform

down.

7

3.2 Fine tuning

Select a model to print. By looking at the result of the first

layer you can determine if fine-tuning of the platform is required. If

you do not have a good first layer with proper flow of material you

can stop printing, fine-tune and adjustment for the next print. Or you

can continue fine tuning the level as the machine prints, live leveling.

If the filament extruded does not

adhere to the bed then the distance

between the platform and the nozzle is

too great. The filament is thrown

down from the nozzle instead of

sticking tightly.

Turn the leveling knob a little clockwise

to make the platform go up. Continue

this until the excessive gap disappears

and a tight line appears.

If the filament is found to be too thin or

not coherent, it suggests that the

distance between the nozzle and the

platform is too small, resulting in too

small amount of material flow, possibly

leading to clogs.

Turn the leveling knob slightly

counterclockwise to lower the platform

until the filament output is full and

smooth.

Adjust well the effect of platform

printing should be full out of the

filament and the line pressure is flat on

the platform.

8

If the distance between the nozzle and the platform is too large

or too small, please stop printing and adjust the platform until the

distance between the platform and the nozzle is appropriate. In

most cases, the printing failure is caused by the platform not

being adjusted properly. Therefore, please debug repeatedly as

required to ensure that the platform height has been adjusted to a

better level. And when printing the first layer, it's best to watch the

machine print and make sure the machine prints properly before

leaving.

9

Chapter 4 Load, unload and change filament

Select Change Filament in the main interface of the menu. There

are three options, they are Change Filament ,Load Filament and

unload Filament.

Pass the filament

through the hole of

the feeder

10

Change Filament: Preheat PLA –Preheats the hotend to a

temperature suitable for PLA material changes ;Preheat ABS

–Preheats the hotend to a temperature suitable for ABS material

changes;Preheat Custom –Preheats to a custom temperature to

change (Choosing these three options will unload filament and

re-start to load filament)

Load Filament :Preheat PLA –Preheats the hotend to a

temperature suitable for PLA to load;Preheat ABS –Preheats the

hotend to a temperature suitable for ABS to load;Preheat Custom

based on custom temperature to load.

Unload Filament:Preheat PLA based on PLA suitable temperature

to unload ;Preheat ABS based on ABS suitable temperature to

unload;Preheat Custom based on custom suitable temperature to

unload.

11

After the load filament is completed the interface will display;

Purge more; will continue to extrude more; Continue; allows you

to proceed. The final step, after selection, will return you to the

main interface.

Chapter 5 Choose the model to print

Press the knob to enter the menu, select "Print from Media", and

press the knob to confirm the selection.

Choose the test files or a file that you have compiled in the slicer

software as .gcode, wait for the machine to prepare temperatures

and start printing.

12

Chapter 6 Motherboard wiring diagram

13

Chapter 7 Analysis of common problems

1. Shocked by the machine when using it

The metal-clad machine itself is electrostatically charged, which does not

harm the human body. The reason for static electricity is that there is no

ground wire at home. The solution to this problem is:

(1) Connect the ground when laying wires at home;

(2) Attach a wire to the metal-clad machine (which can be connected to

the bottom of the axis of the Z-axis platform). Guide the other end to

large metal objects in the room. Or ground the printer to the ground

screw of your electrical socket;

2. The print is not adhering to the print platform

(1) The distance between the printing platform and the nozzle is too large

(bed leveling). You can adjust the four horizontal adjustment nuts under

the platform to ensure that the distance is appropriate. The approximate

distance can be the same as the thickness of a business card;

(2) The printing platform temperature is not high enough, Generally, the

temperature of the printing platform using PLA is set at about 60℃, and

the ABS is set at about 100℃;

(3) The printing platform does not use high-temperature adhesive tape,

you can improve the viscosity by affixing high-temperature adhesive tape.

(4) The platform cooling fan is turned on too early, you can set this in your

slicer software;

14

3.Filament will not load normally due to the extruder gear being stuck

(1) The temperature has not reached the best melting point of filaments.

The temperature can be adjusted properly on the LCD. Generally, the

temperature is not high enough.

(2) The feeding reel is knotted and the filament is not available. After

cutting off the filament, adjusting the filament and printing again.

(3) The distance between the print platform and the nozzle is too small,

plugging the nozzle Re-level the bed.

(4) The diameter of filaments is too large, replace with the correct

filament (1.75mm).

(5) Nozzle has been plugged or damaged, for many reasons, contact the

after-sale service or your local reseller.

4.The printing process has shifted

(1) Look to see if there is any foreign material interfering with the the

works of the undercarriage.

(2) Friction increases as dust builds up on the axes, use a paper towel or

lint free cloth with alcohol to wipe and remove any dirt sticking to the oil.

(3) Check all the synchronous wheels on the X and Y axes and motor to

see if anything is anything is loose. Check to make sure that belts are not

loose, if so please tighten them.

15

5.The nozzle temperature does not rise, triggering an alarm

(1) Check whether the heating cartridge and the thermistor wire are

inserted properly, and that there is no breakage or damage;

(2) The line terminal is in poor contact, shut down and re-plug the plug-in

terminal and the rehearsal line, and restart the machine;

(3) There are too many filament on the heat block near the nozzle, which

may cause the thermistor to not measure temperature properly, remove

the residue or replace the thermistor;

6.The machine suddenly stops printing during printing

(1) Check if the power supply is normally energized, the display is wrong,

take photos as much as possible, and contact the technician;

(2) Multiple printing stops at the same height, the data was not fully

exported when the file was sliced or you have a corrupt SD card. Slice the

file again;

(3) After the heating is completed and the print starting but the machine

doesn’t print after returning to the home position. When the software is

sliced, the correct model was not selected. Re-sliced the model.

16

Attachment:It is recommended to use the original slicing software.

If the machine is damaged by using any other software, the consequences

will be borne by you. If you use other people's software, please refer to

the following to change the parameters and commands.

Add the machine

17

Configuration parameter

Table of contents

Other MakerPi 3D Printer manuals