MakerPi M1 User manual

Quick Start Guide

- 1 -

Contents

Chapter 1 Getting to know your MakerPi M1................................................................2

1.1 Introduction of M1.......................................................................................................2

1.2 Notices.............................................................................................................................. 3

Chapter 2 preparation before printing.............................................................................4

Chapter 3 Load & Unload .................................................................................................... 6

3.1 Load....................................................................................................................................6

3.2 Unload...............................................................................................................................8

Chapter 4 Printing.....................................................................................................................9

Chapter 5 Analysis of Common Problems.................................................................... 11

- 2 -

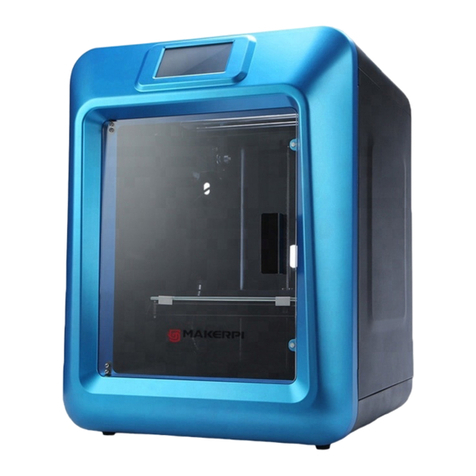

Chapter 1 Getting to know your MakerPi M1

1.1 Introduction of MakerPi M1

Power input

Start Button

Platform

Extruder

PTFE Tube

Extruder

TF card slot

DIP Switch

USB interface

micro-USB interface

- 3 -

1.2 Notices

1, During the period of operation of the 3D printer and for a period of time after the end of

printing, the temperature of the nozzle is as high as 200 ° C or more. So do not touch the nozzle

with your hand.

2, Please follow the instructions in the guide to operate the machine. If you have any questions,

please contact the after-sales service;

3, If the printed model needs to be disassembled for support, please wear gloves to avoid being

scratched by tools or supporting materials during disassembly.

4,During daily use, it is necessary to regularly clean and lubricate the cross slide optical axis of the

3D printer. Be careful not to drip onto the casing and belt when adding lubricant.

5,While reading this “ User Guide”, Please combine with the actual operation of the 3d printer,

it will be more conducive to your familiarity with the use of the machine.

6, Please take pictures or videos to reflect the problem more intuitively in the process of printing.

And provide a photo of the machine number (label on the bottom of the back of the machine),

then contact the after-sales.

7, Suggest to use the original filament.

- 4 -

Chapter 2 Preparation before Printing

Connect TPFE Tube to extruder and filament intake

- 5 -

Hang the filament at the side of the 3d printer.

Connect power supply to 3d printer

Rack Mounting hole

- 6 -

Chapter 3 Load & Unload

3.1 Load

Passing the filament trough extruder

Toggle the switch to the left as the load (to the left is the load, the right is the

unload, the middle is the stop).

Passing the filament trough extruder

- 7 -

When the red light flickers, the printer nozzle begins to heat, the green light is always on, the

printer nozzle is heated, and the printer begins to load。

- 8 -

3.2 Unload

Toggle the switch to the right as the unload (to the left is the load, the right is the unload, the

middle is the stop).

When the red light flickers, the printer nozzle begins to heat, the green light is always on, the

printer nozzle is heated, and the printer begins to unload.

- 9 -

Chapter 4 Printing

Please named your printing file as 0.gcode, download on the TF Card.

Then insert the TF Card(please power off before insert the TF Card).

- 10 -

Please turn the DIP Switch on the middle.

Click the front print button to automatically recognize the print file and start

printing (wait for the nozzle to heat up and the M1 starts printing)

- 11 -

Chapter 5 Analysis of Common Problems

1. When using the machine, the metal shell on the surface of the machine may be

electrostatically charged and will not cause any impact on the human body. The solution can be

done by grounding the metal of the machine housing.

2. During the printing process, the printing platform is scraped somewhere, please make sure

there is no foreign matter under the PVC magnetic sticker.

3. If the filament can not come out normal as following reasons:

3.1 Temperature does not reach the optimum melting point of filament. Temperature can be

adjusted appropriately.

3.2 Filaments can't be supplied. After cutting out the filaments, readjust the filaments and

reprint them.

3.3 The filaments purchased are too large, to change a better filament as 1.75mm

3.4 The nozzle might be damaged due to various reasons, please contact customer service.

4. shifted.

4.1 Light shaft dust is too much friction, you can use paper towels or cloth plus alcohol

Wipe to remove dust from the oil.

4.2 Check all the synchronous wheels on the optical axis and the motor to see if there is

looseness and tighten loosely.

4.3 Some customers' original pictures are scanned, and the scanned parts have not been well

processed, resulting in cura generating Gcode not printing properly. So the scanned parts must

be processed well.

4.4 The nozzle is forcibly blocked in the middle of printing. The first moving nozzle cannot be

touched by hand during printing. Secondly, if the model map prints the uppermost layer with the

negative distortion, the next time the printing will repeat the increase of the engraving, a certain

degree of hardening of the anomaly will prevent the nozzle from moving normally, causing the

motor to lose position and cause misalignment.

4.5 The voltage is unstable. When printing misalignment, observe whether it is a high-power

electric appliance such as an air conditioner. When some of the electric appliances are turned off,

the printing is misplaced. If there is, the printing power supply plus the voltage stabilizing device.

4.6 If all of the above are normal, you can slow down the printing speed and try again.

4.7 Manually move the XY axis to check the XY axis operation

4.8 Problem of motherboard. The above problems can not solve the misplacement, and the

most common is to print any model with the same height misalignment, considering the

motherboard problem

5. The nozzle does not come out, it is not necessarily the problem of nozzle clogging. If the

maintenance is done in a normal position, the consumables used are relatively stable, and the

plug is usually rarely blocked. It is very likely that some of the following factors may cause the

wire to be fed normally. So users can try the following:

- 12 -

5.1 Loading the extrusion gear card, the load is not smooth

5.2 Whether the loading is normal (eg: the tray is stuck)

5.3 Disassemble the extrusion gear, clean the gear, and check the degree of gear wear.

5.4 The PLA print nozzle temperature is 190-220, and the ABS print nozzle temperature is

210-230. The printing temperature required for the consumables fluctuates. If the wire is not

smooth, you can try to increase the printing temperature (such as 200 to 205 or 210 printing) and

try to increase the temperature by 5-10 degrees.

6. What parts of the 3D printer should be routinely maintained?

First, before starting the 3D printer printing every day, you should carefully check whether

the nozzle is blocked or damaged, whether the connection lines of each part are normal, whether

the motor bearings and guide rails are short of oil, and whether the platform is calibrated. If there

is any retentate in the nozzle, it should be cleaned up immediately. If the part is damaged or aged,

it should be replaced in time. Regularly add lubricating oil to the moving parts, and the nut

should be tightened if it is loose.

Secondly, during the printing process of the 3D printer, the parameter settings should not

exceed the limit of the device. Otherwise, the qualified product cannot be printed. If the

temperature is too high or the load is too large, the device may be damaged. There is also a place

where something is wrong during the printing process. If necessary, stop the machine. Do not let

the device continue to work if you want to reprint because of the downtime.

Finally, clean the work after printing is complete. The dirt on the nozzles, platforms, guide

rails, motors, fans, etc. of the 3D printer should be cleaned up. Do not accumulate for a long time

and cause the last bad cleaning.

Table of contents

Other MakerPi 3D Printer manuals

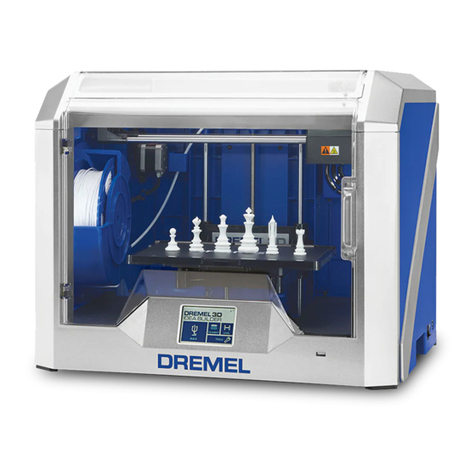

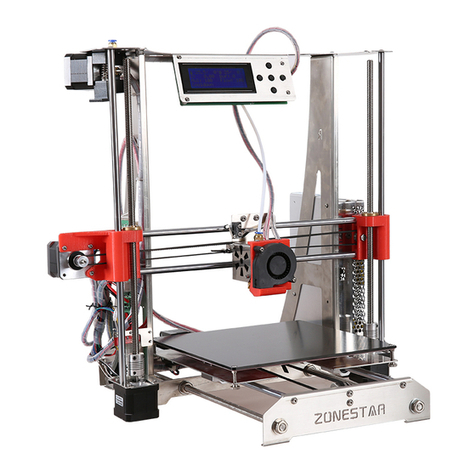

Popular 3D Printer manuals by other brands

Geeetech

Geeetech Delta Rostock mini G2 Building instructions

Polar Electro

Polar Electro Polar3D Guide

3D Prototyping

3D Prototyping X1 user manual

SprintRay

SprintRay MoonRay quick start guide

SUBLIMATION

SUBLIMATION Vacuum Heat Press Machine instruction manual

Prusa

Prusa Original Prusa i3 MK2.5 user manual