6

Safetyprecautionsforchainsawoperators

While operating the chain saw please observe the

following rules:

a) Contactoftheguidebarnosewithanyobject

shouldbeavoided.

b) Tipcontactmaycausetheguidebartomove

suddenlyupwardandbackward,whichmaycause

seriousorfatalinjury.

c)Alwaysoperatethechainsawwithbothhands.

WARNING!

Readandfollowall safety precautionsinthe owner’s

manual. Failure to follow instructions could result in

seriousinjury.Itisrecommendedtolendthechain

saw only to people who are experienced in working

withchainsaws.AlwayshandovertheOwner’sand

Safety Manual.

WARNING!

This chain saw is capable of severe kickback

thatcouldresultinseriousinjurytotheoperator.

Do not operate this chain saw unless you have

extraordinary cutting needs and experience in and

special training for dealing with kickback. Chain

sawswithsignificantlyreducedkickbackpotential

areavailable.

WARNING!

Kickbackmayoccurwhenthenoseortipoftheguide

bartouchesanobject,orwhenthewoodclosesin

and pinches the saw chain in the cut. This contact

mayabruptlystopthesawchainand in some cases

may cause a lightning fast reverse reaction,kicking

theguidebarupandbacktowardstheuser,orpush

theguidebarbacktowardstheoperator.Kickback

may cause you to lose control of the saw.

As a chain saw user, you can take several steps to

reducetheriskofakickbackandpotentialinjury.

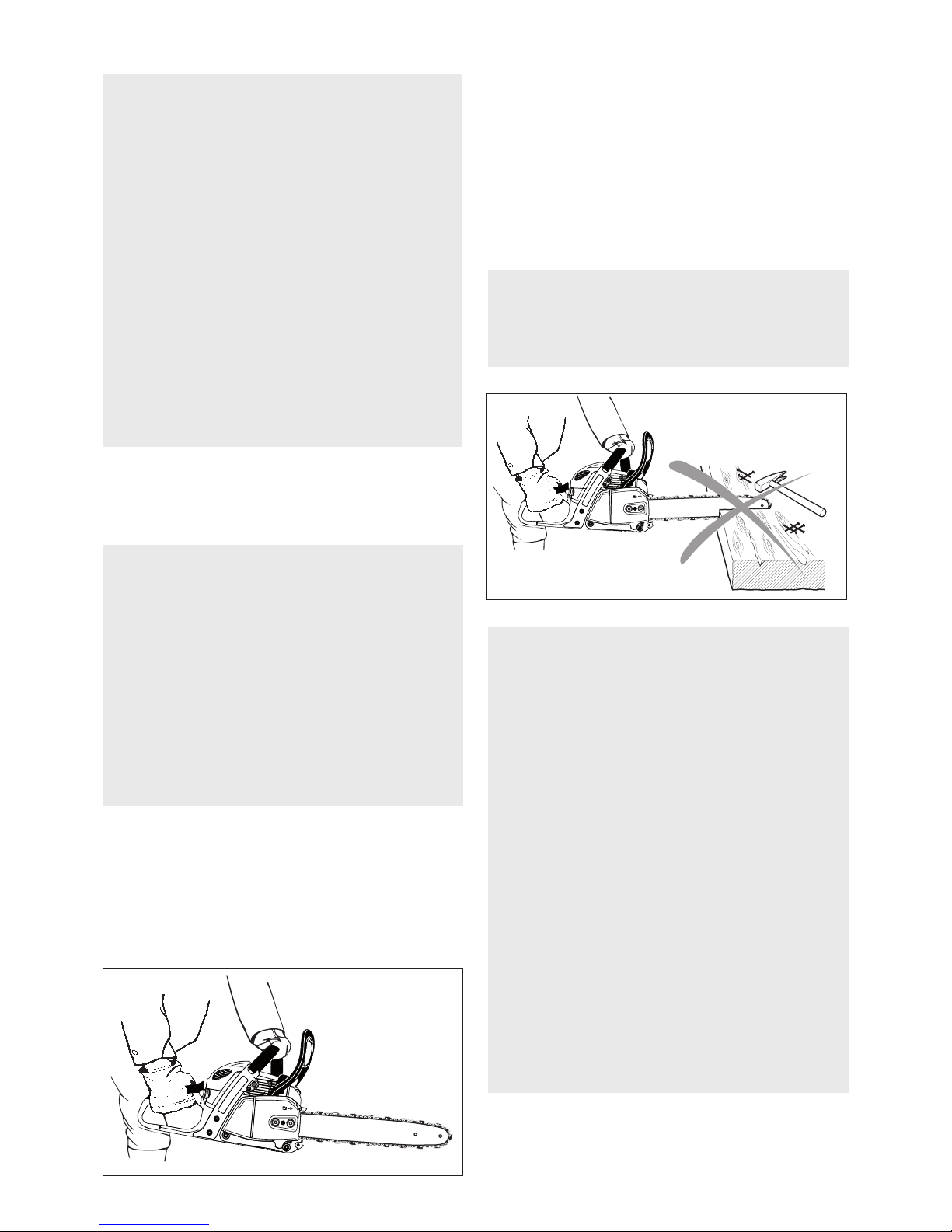

A. Withabasicunderstandingofkickback,youcan

reduceoreliminatetheelementof surprise. Itisa

suddensurprisethatcontributestoaccidents.

B. Keep a good firm grip on the saw with both

hands, your right hand on the rear grip and

yourlefthandonthetubularhandle,whenthe

engineisrunning.Useafirmgripwiththumbs

andfingersencirclingthechainsawhandles.A

firmgripcanneutralizekickbackandhelpyou

maintain control of the saw. Don’t let go!

C. Make sure that the area in which you are cutting

isfreefromobstructions.Donotletthenoseof

theguidebarcontactthelog,branch,orany

otherobstructionswhichcouldbehitwhileyou

are operating the saw.

D. Do not overreach or cut above shoulder

height.

E. Followmanufacturer’ssharpeningand main

tenance instructions for the saw chain.

F. Onlyusereplacementbarsandchainsspecified

bythemanufacturerortheequivalent.

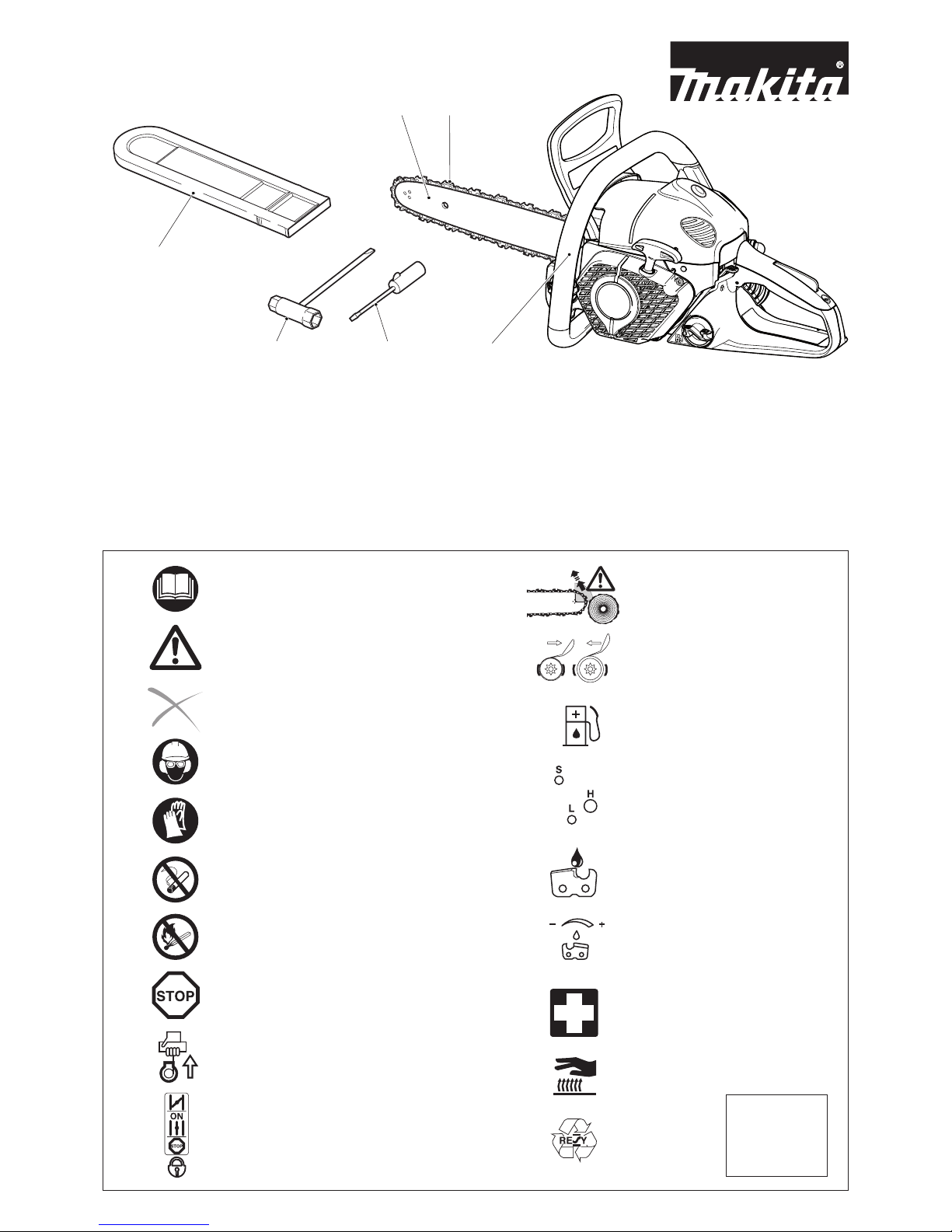

Additionalsafetyprecautions

Thefollowingadditionalsafetyprecautionsmustbe

observedbyallusersofchainsaws:

1. Do not operate a chain saw when you are fatigued.

2. Usesafetyfootwear;snugfittingclothing;

protective gloves; and eye, hearing, and head

protection devices.

3. Use caution when handling fuel. Move the chain

saw at least 10 feet (3 m) from the fueling point

beforestartingtheengine.

4. Donotallowotherpersonstobenearthechain

saw when starting or cutting with the chain saw.

Keepbystandersandanimalsoutofthework

area.

5. Do not start cutting until you have a clear work

area, secure footing, and a planned retreat path

from the falling tree.

6. Keepallpartsofyourbodyawayfromthesaw

chain when the engine is running.

7. Before you start the engine, make sure that the

saw chain is not contacting anything.

8. Carry the chain saw with the engine stopped,

theguidebarandsawchaintotherear,andthe

mufflerawayfromyourbody.

9. Do not operate a chain saw that is damaged, is

improperlyadjusted,orisnotcompletelyand

securelyassembled.Besurethatthesawchain

stops moving when the throttle control trigger is

released.

10. Shutofftheenginebeforesettingitdown.

11. Useextremecautionwhencuttingsmallsize

brushandsaplingsbecauseslendermaterial

maycatchthesawchainandbewhippedtoward

youorpullyouoffbalance.

12.Whencuttingalimbthatisundertensionbealert

forspringbacksothatyouwillnotbestruckwhen

thetensiononthewoodfibersisreleased.

13. Keep the handles dry, clean, and free of oil or fuel

mixture.

14.Operatethechainsawonlyinwellventilated

areas.

15. Do not operate a chain saw in a tree unless you

havebeenspecificallytrainedtodoso.

16.Allchainsawservice,otherthantheitemslisted

in the owner’s manual maintenance instructions,

shouldbeperformedbyMAKITA.(Forexample,if

impropertoolsareusedtoremovetheflywheelor

ifanimpropertoolisusedtoholdtheflywheelin

order to remove the clutch structural damage to

theflywheelcouldoccurandcouldsubsequently

causetheflywheeltoburst.)

17. When transporting your chain saw, use the chain

protection cover.

18. Lowkickbackbarsandlowkickbackchainsare

designedtoreducetheriskofkickbackinjury.

AskyourMAKITAdealeraboutthesedevices.