1INDEX

1INDEX.......................................................................................................................................................................................... 2

2CAUTION .................................................................................................................................................................................... 3

3NECESSARY REPAIRING TOOLS ........................................................................................................................................... 3

4LUBRICANT AND ADHESIVE APPLICATION ...................................................................................................................... 4

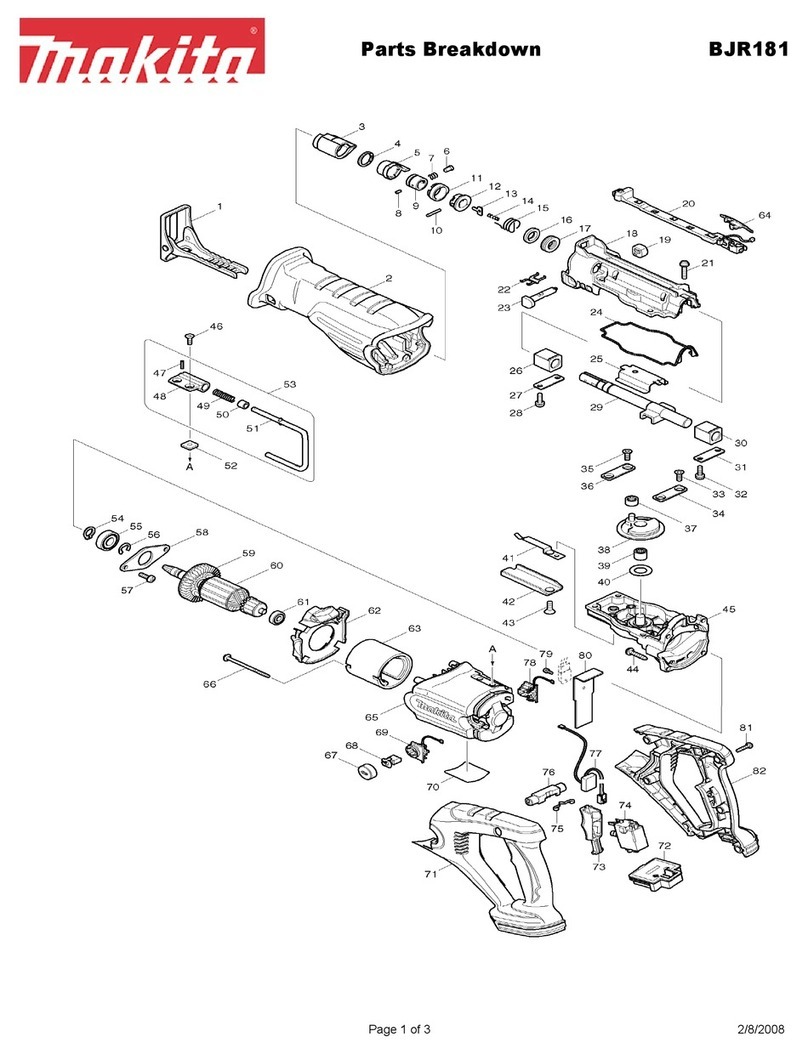

5REPAIR ........................................................................................................................................................................................ 6

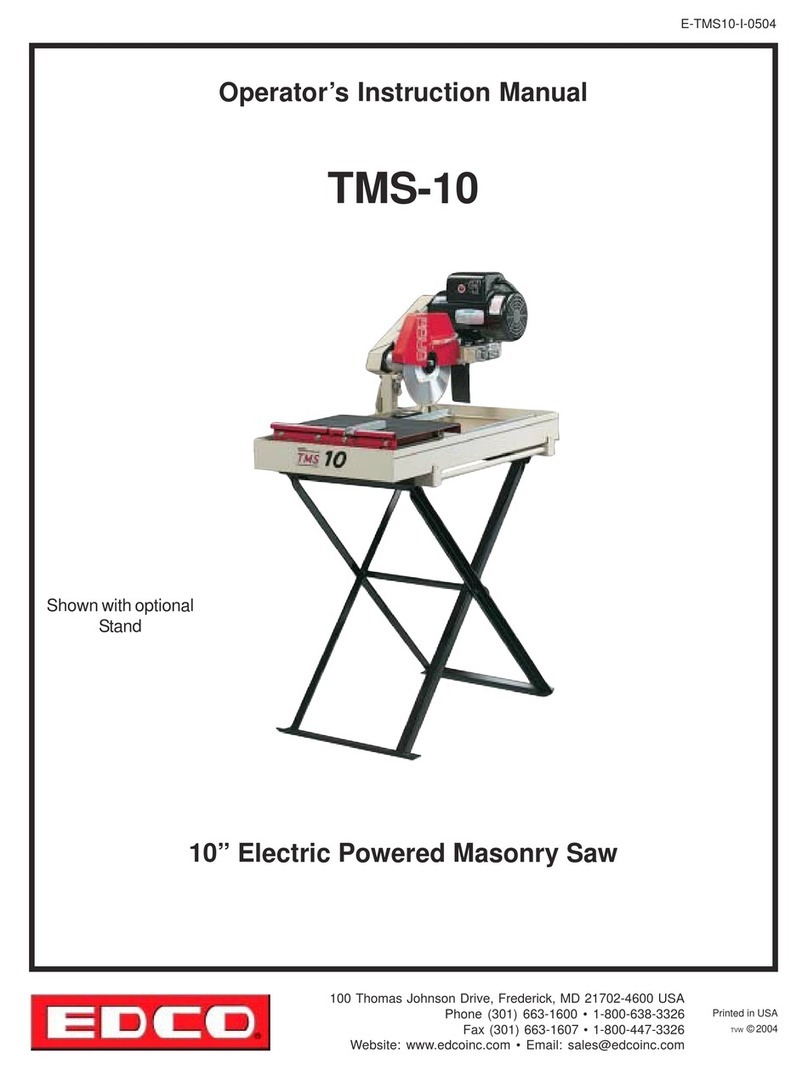

5-1 Insulation cover.................................................................................................................................................................... 6

5-1-1 Disassembling ............................................................................................................................................................. 6

5-1-1-1 For DJR187, DJR360.............................................................................................................................................. 6

5-1-1-2 For DJR186............................................................................................................................................................. 6

5-1-2 Assembling.................................................................................................................................................................. 7

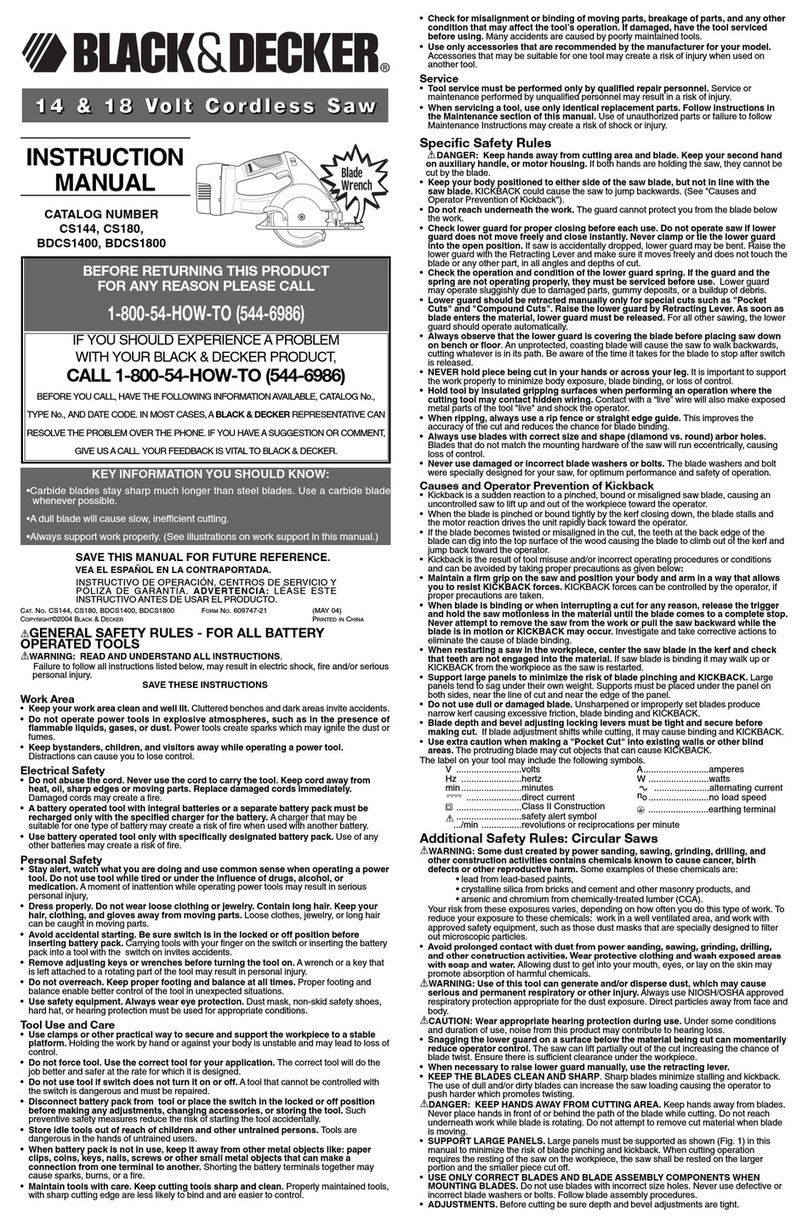

5-2 Slider assembly .................................................................................................................................................................... 7

5-2-1 Disassembling ............................................................................................................................................................. 7

5-2-2 Assembling.................................................................................................................................................................. 9

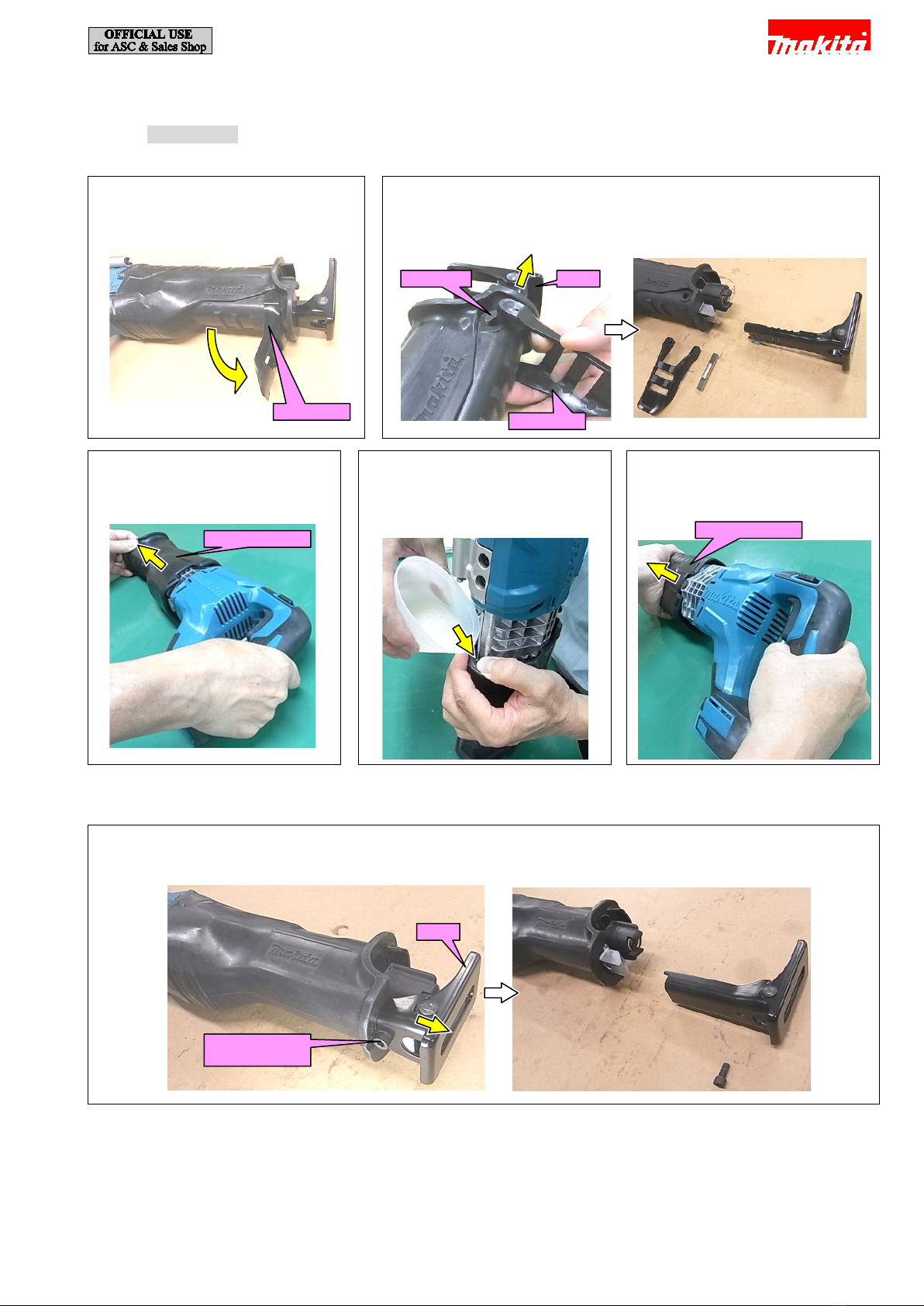

5-3 Rotor ass'y (Armature ass'y)............................................................................................................................................... 12

5-3-1 Disassembling ........................................................................................................................................................... 12

5-3-1-1 For DJR187, DJR360............................................................................................................................................ 12

5-3-1-2 For DJR186........................................................................................................................................................... 14

5-3-2 Assembling................................................................................................................................................................ 15

5-3-2-1 For DJR187, DJR360............................................................................................................................................ 15

5-3-2-2 For DJR186........................................................................................................................................................... 16

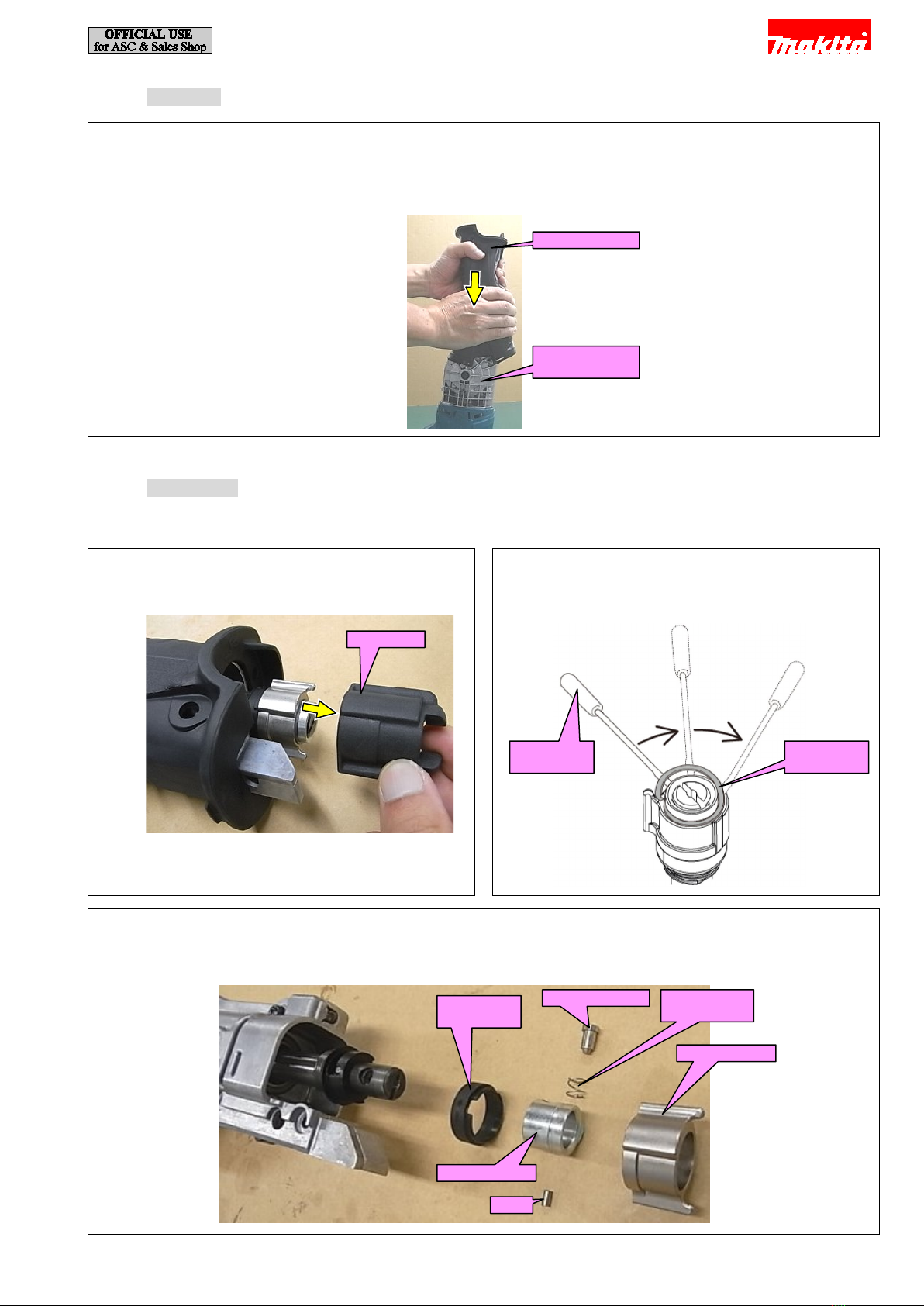

5-4 Gear complete .................................................................................................................................................................... 17

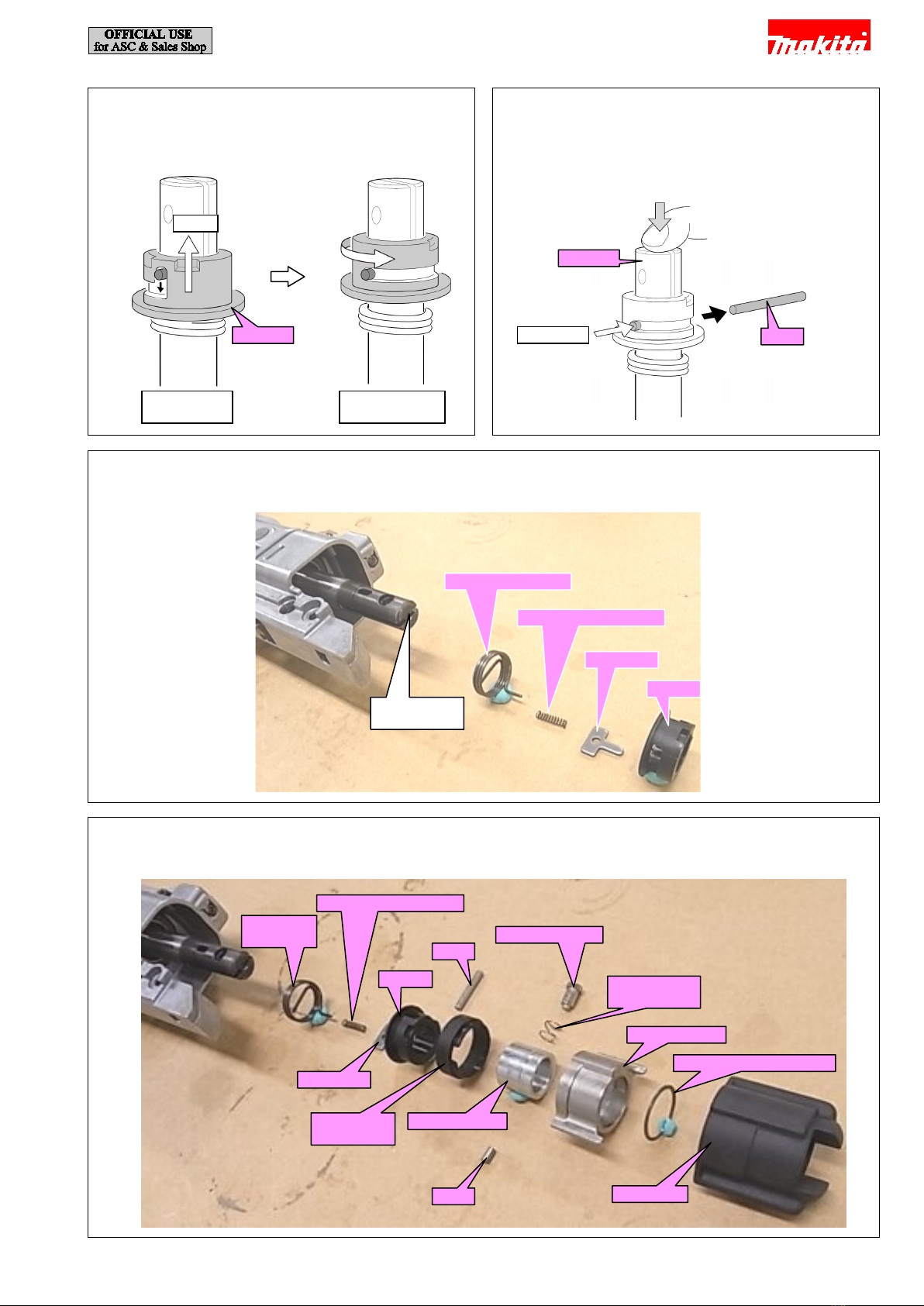

5-4-1 Disassembling ........................................................................................................................................................... 17

5-4-1-1 For DJR187, DJR360............................................................................................................................................ 17

5-4-1-2 For DJR186........................................................................................................................................................... 18

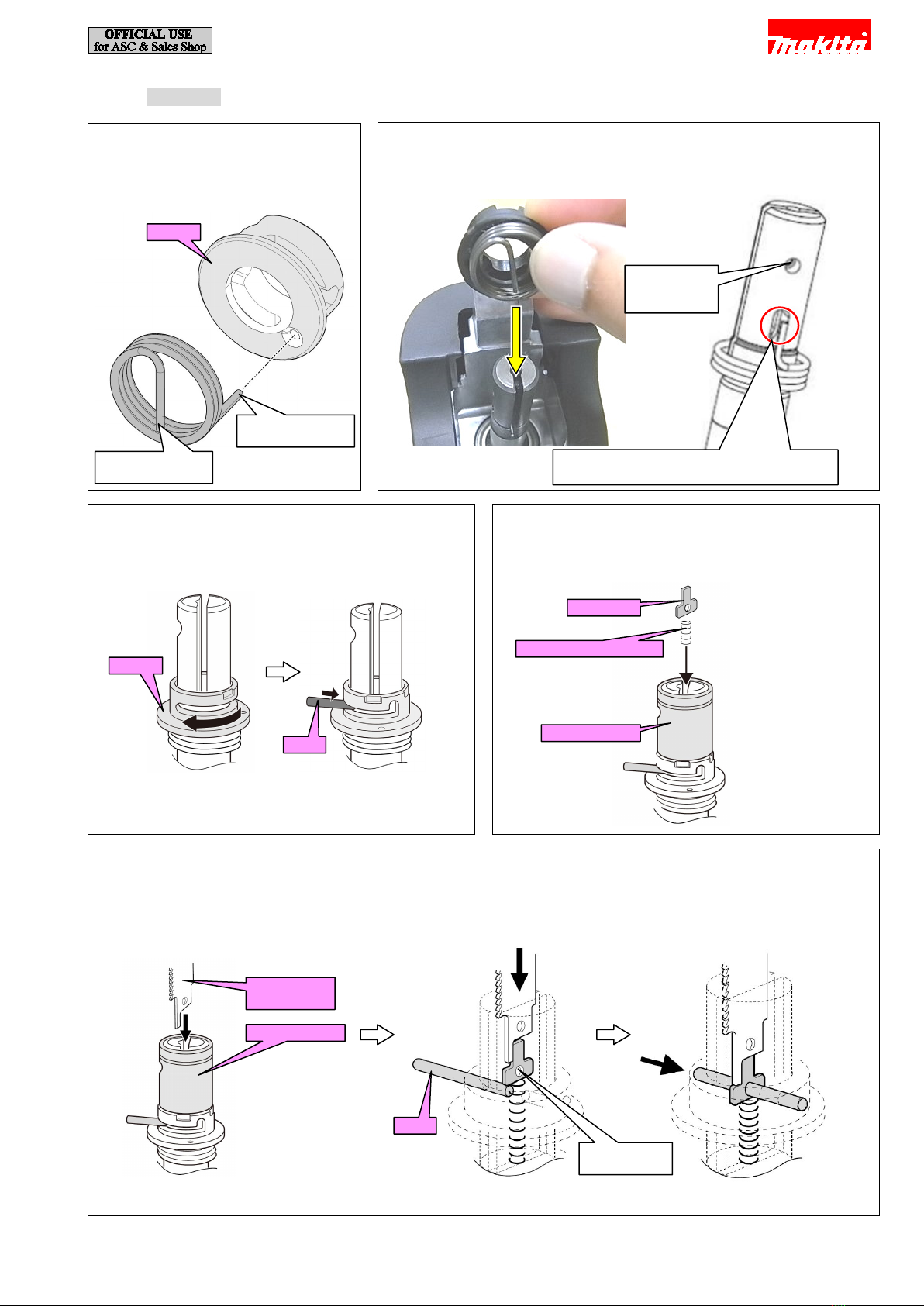

5-4-2 Assembling................................................................................................................................................................ 19

5-5 Slider section...................................................................................................................................................................... 19

5-5-1 Disassembling ........................................................................................................................................................... 19

5-5-2 Assembling................................................................................................................................................................ 19

6Circuit diagram ........................................................................................................................................................................... 20

7Wiring diagram ........................................................................................................................................................................... 21

2 / 22