P 2 / 17

Repair

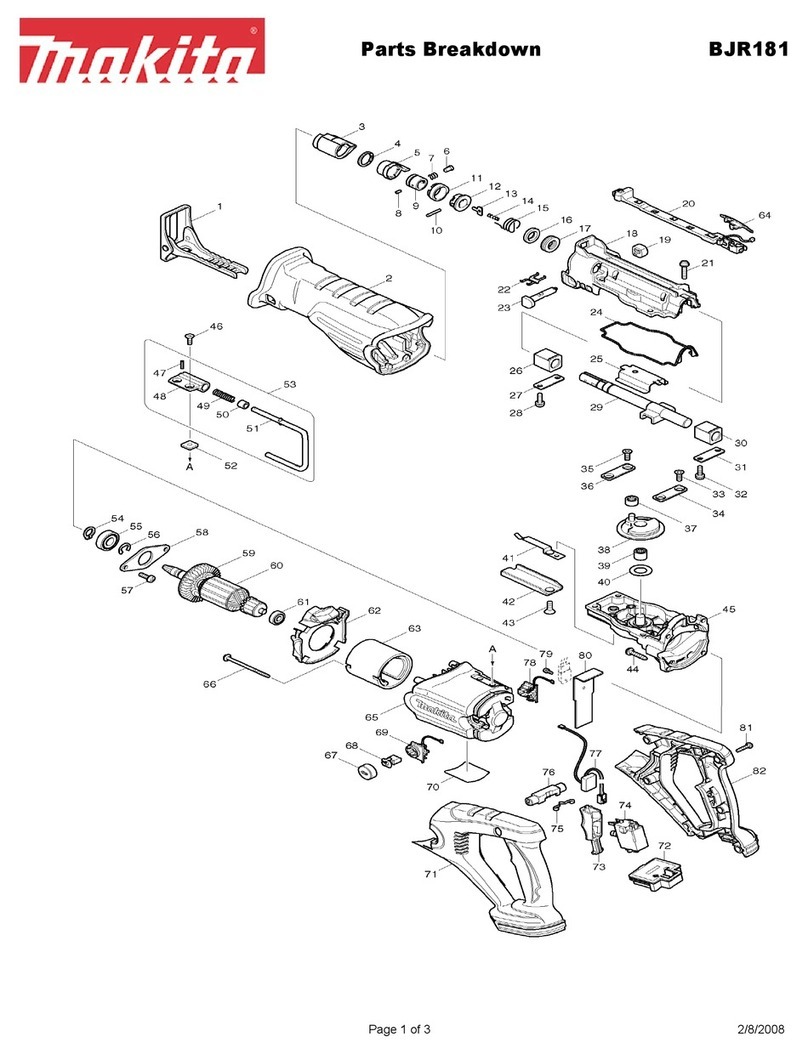

[1] NECESSARY REPAIRING TOOLS

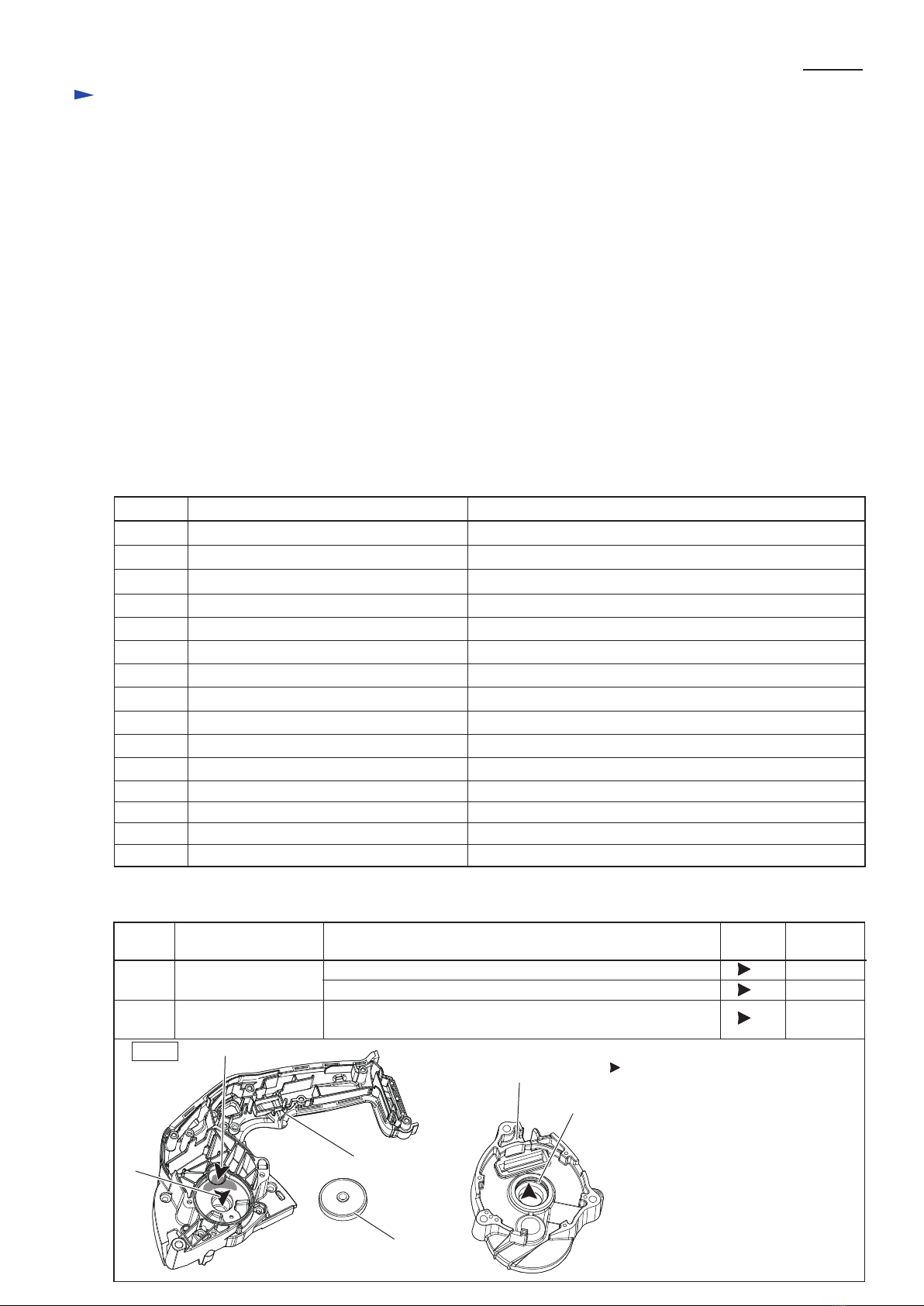

Code No. Description Use for

1R003 removing Retaining ring WR-26

1R027 press fitting Ball bearing 606ZZ

1R028

1R033

1R035

1R037

1R041

1R164

1R212

1R269

1R278

1R282

1R283

RETAINING RING PLIERS ST-2N

BEARING SETTING PIPE 18-10.2

BEARING SETTING PIPE 20-12.2

BEARING SETTING PLATE 10.2

BEARING SETTING PLATE 15.2

BEARING SETTING PLATE 20.2

VISE PLATE

RING SPRING SETTING TOOL A

TIP FOR RETAINING RING PLIERS

BEARING EXTRACTOR

ROUND BAR FOR ARBOR 4-50

ROUND BAR FOR ARBOR 8-50

ROUND BAR FOR ARBOR 9-50

1R356 BEARING PLATE 10MM

1R361 BEARING RETAINER TIGHTEN' TOOL

press fitting Helical gear 28

removing Helical gear 28

removing Helical gear 47

protecting Bearing box from crack

removing Spindle, Helical gear 28

together with 1R003

removing Ball bearing 606ZZ

removing Helical gear 47, Ball bearing 606ZZ

removing Helical gear 28

removing Spindle, Helical gear 28

removing Ball bearing 604ZZ

disassembling / assembling Bearing retainer 14-23

press fitting Helical gear 47 and Helical gear 28

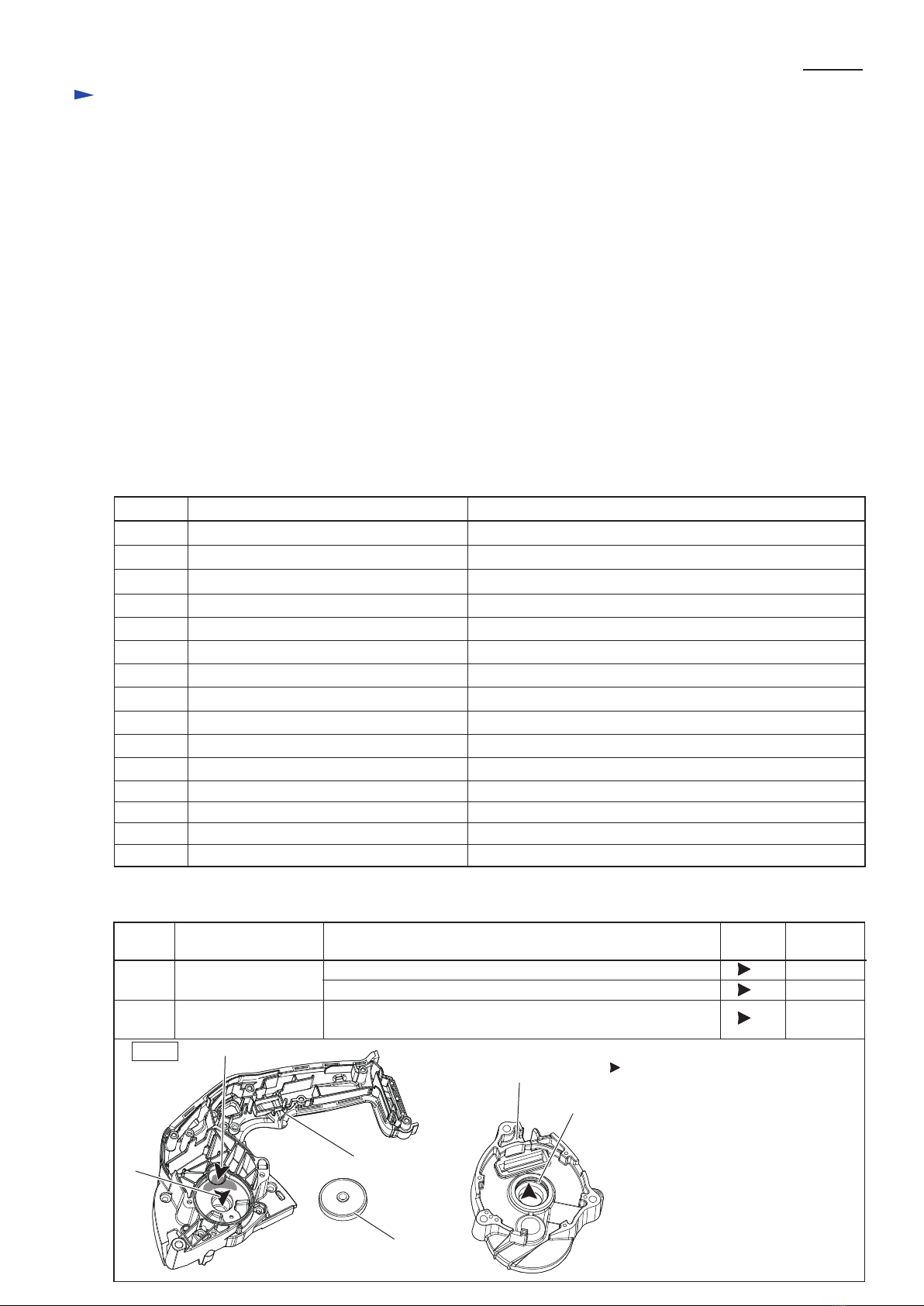

[2] LUBRICATION

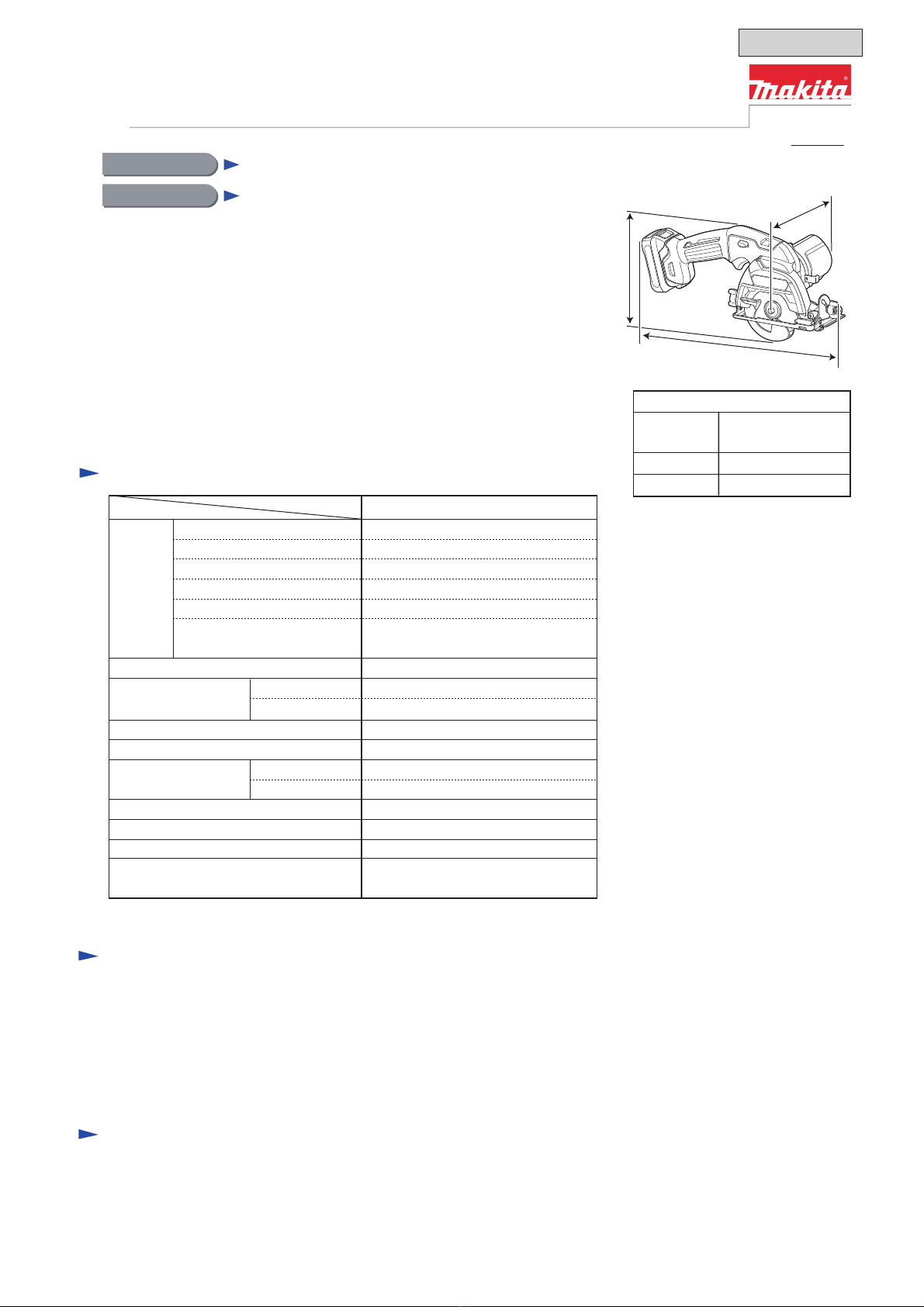

Fig. 1

Item No. Description

Handle set R A: Portion in Gear room where Helical gear 47 (26) rotates

B: Hole for Spindle in Gear room

a little

3 g

1 g

(23c) O ring 19 which is a component parts

of Gear housing (23)

Gear housing

Amount

Symbol of

lubricant

Portion to lubricate

Apply Makita grease FA. No.2 to the parts designated with black triangle.

(17)

(17)

(23)

(23)

(26)

(23c)

Makita grease FA. No.2

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

Index

A

B

[1] NECESSARY REPAIRING TOOLS

[2] LUBRICATION

[3]-1 Tightening torque for Screws

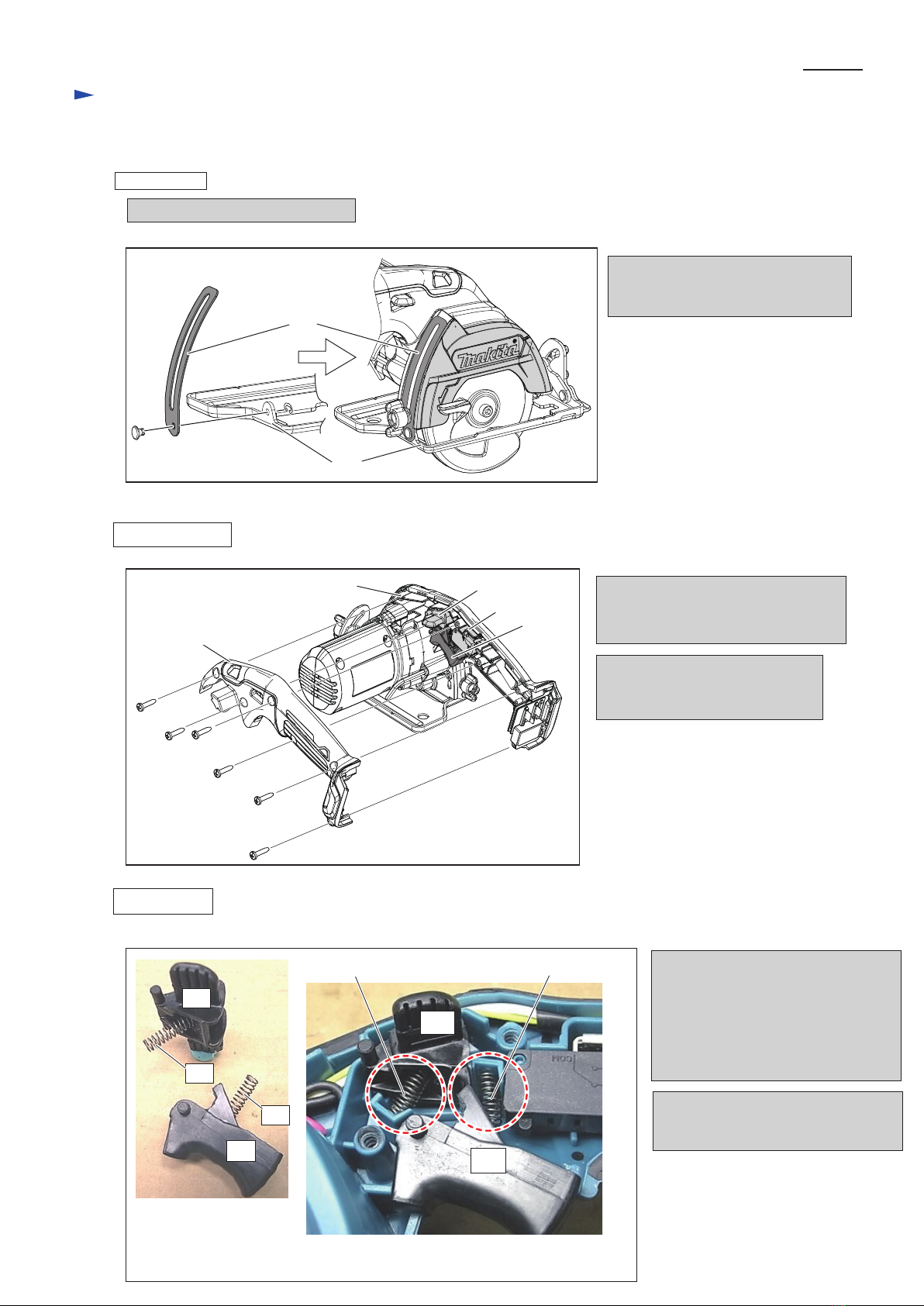

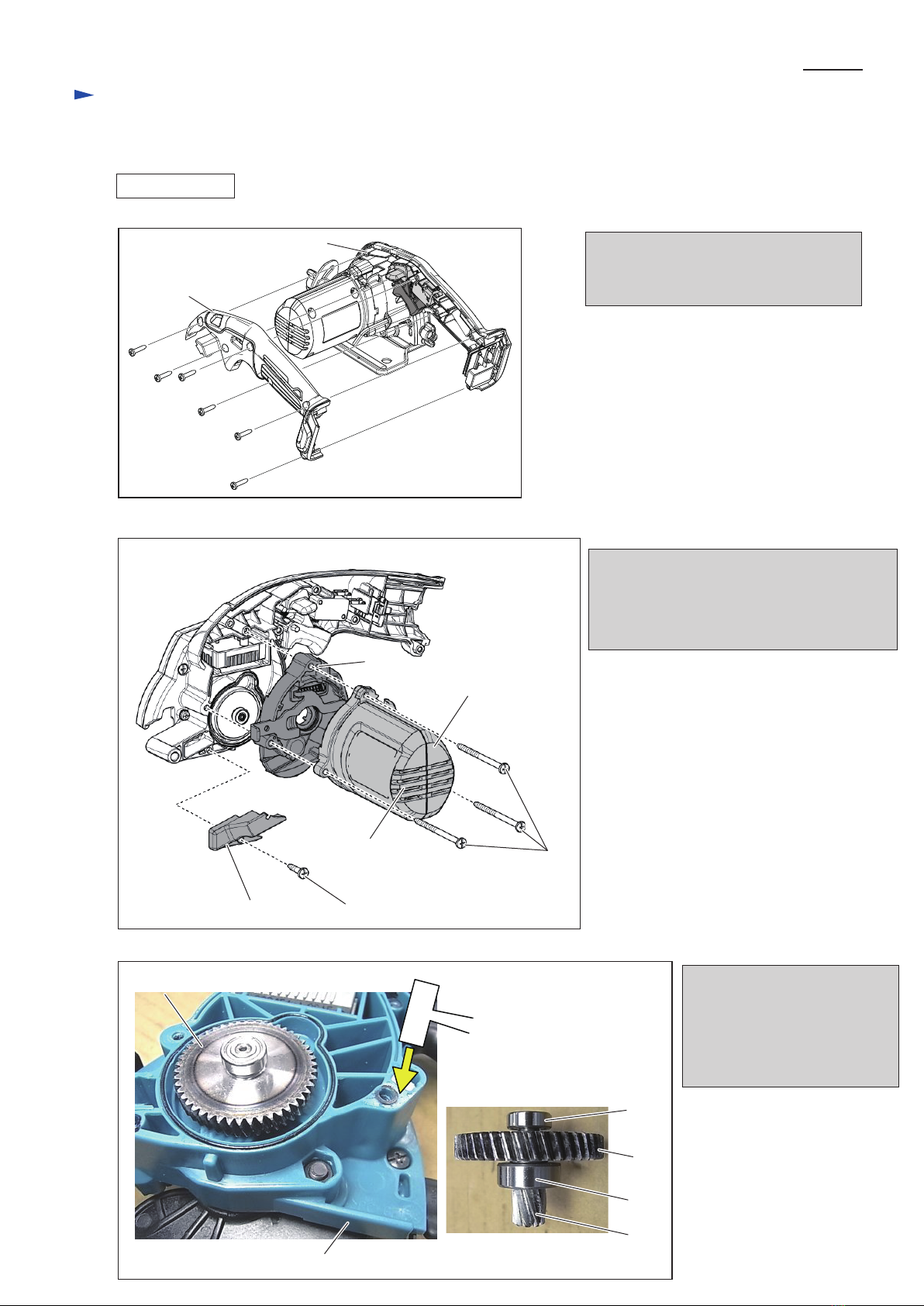

[3]-2. Base

[3]-3. Lock off lever, Switch lever

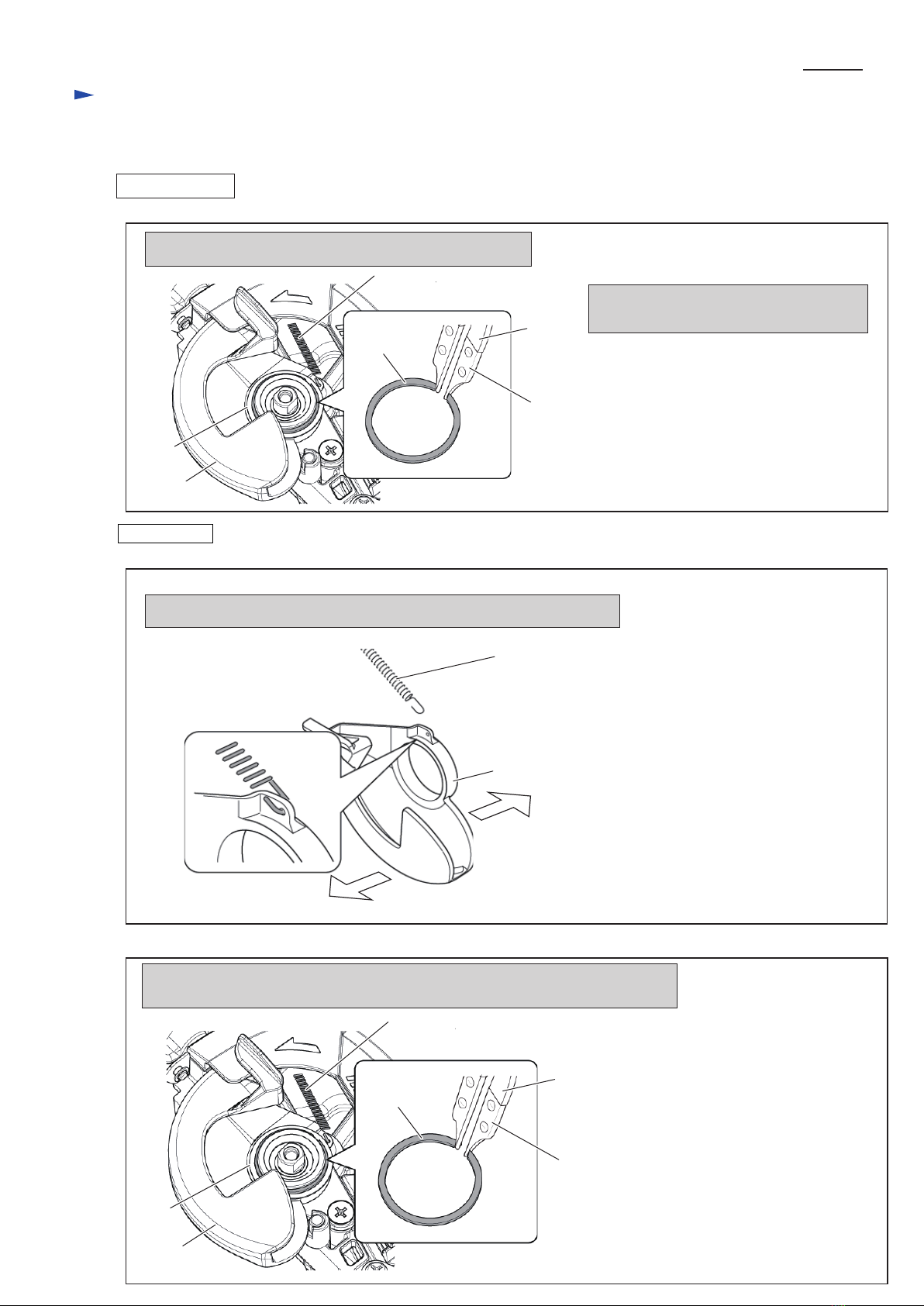

[3]-4. Safety cover

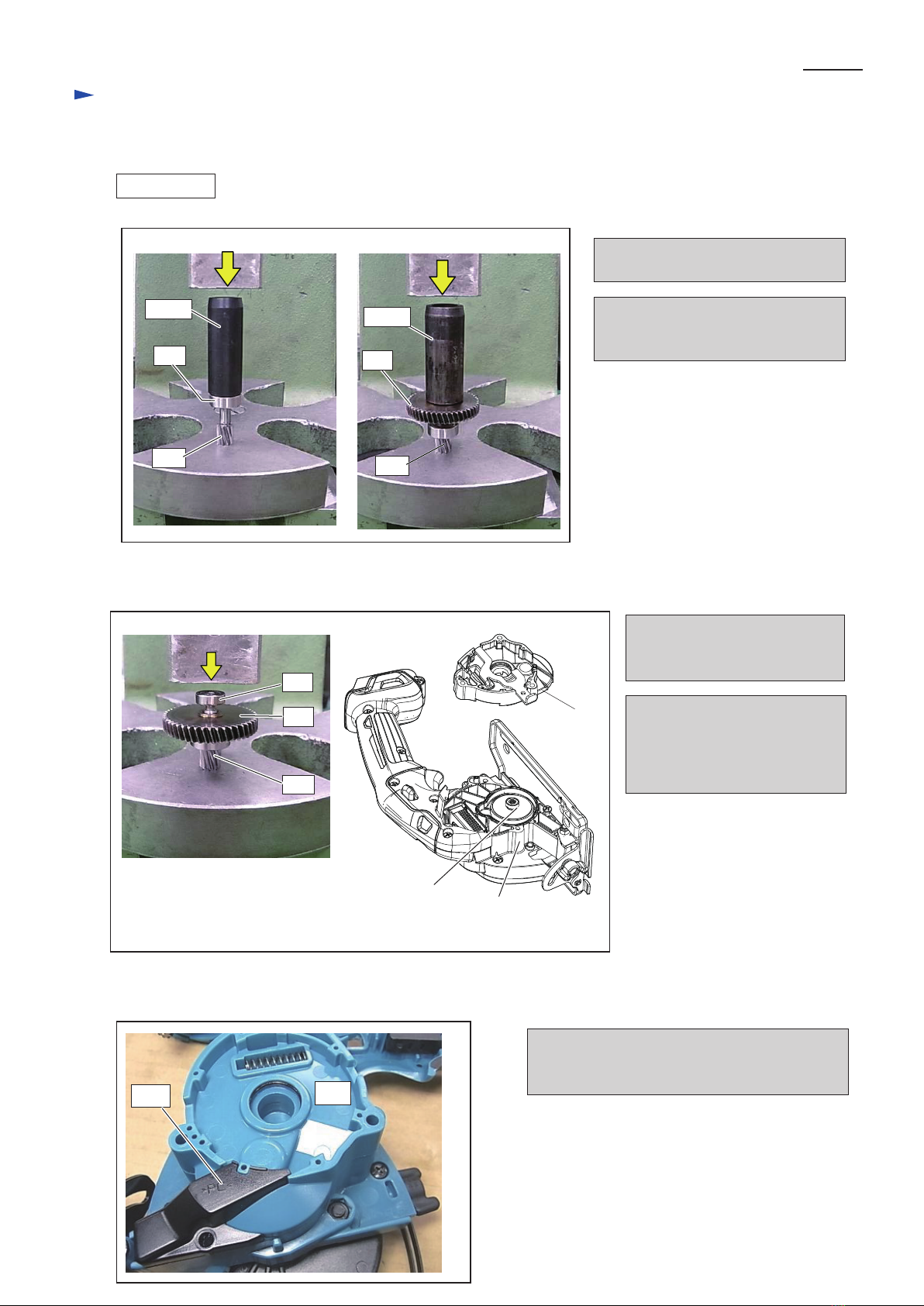

[3]-5. Helical gear 47, Helical gear 9B,

Ball bearing 606ZZ, Ball bearing 604ZZ

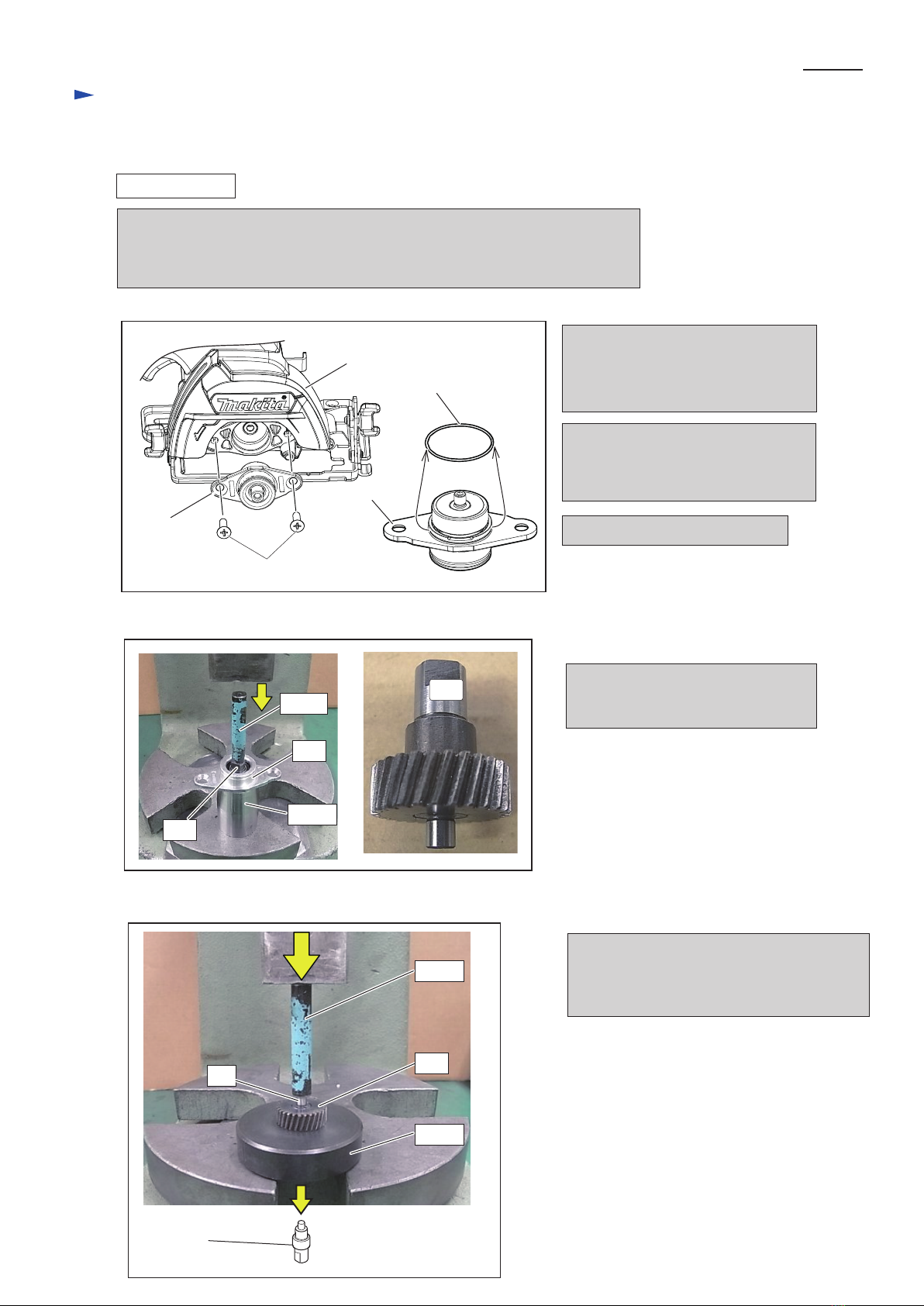

[3]-6. Helical gear 28, Ball bearing 6900DDW

[3]-7. DC Motor

* Circuit diagram

* Wiring diagram

Wiring to DC Motor, Wiring in Motor housing

* Wiring of Controller unit

* Wiring in Handle set R

P 2

P 3

P 3-4

P 5

P 6-8

P 9-13

P 13

P 14

P 15

P 16

P 17