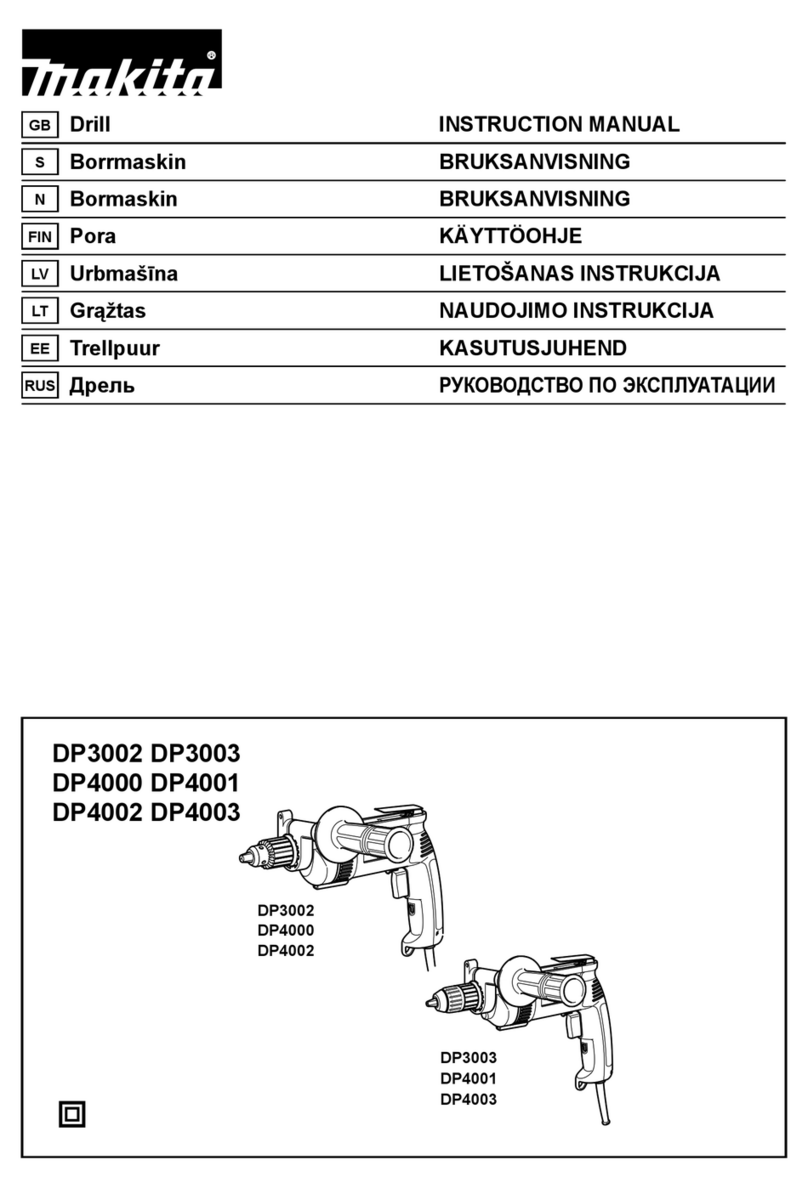

Models No.

Description

PRODUCT

TECHNICAL INFORMATION

CONCEPT AND MAIN APPLICATIONS

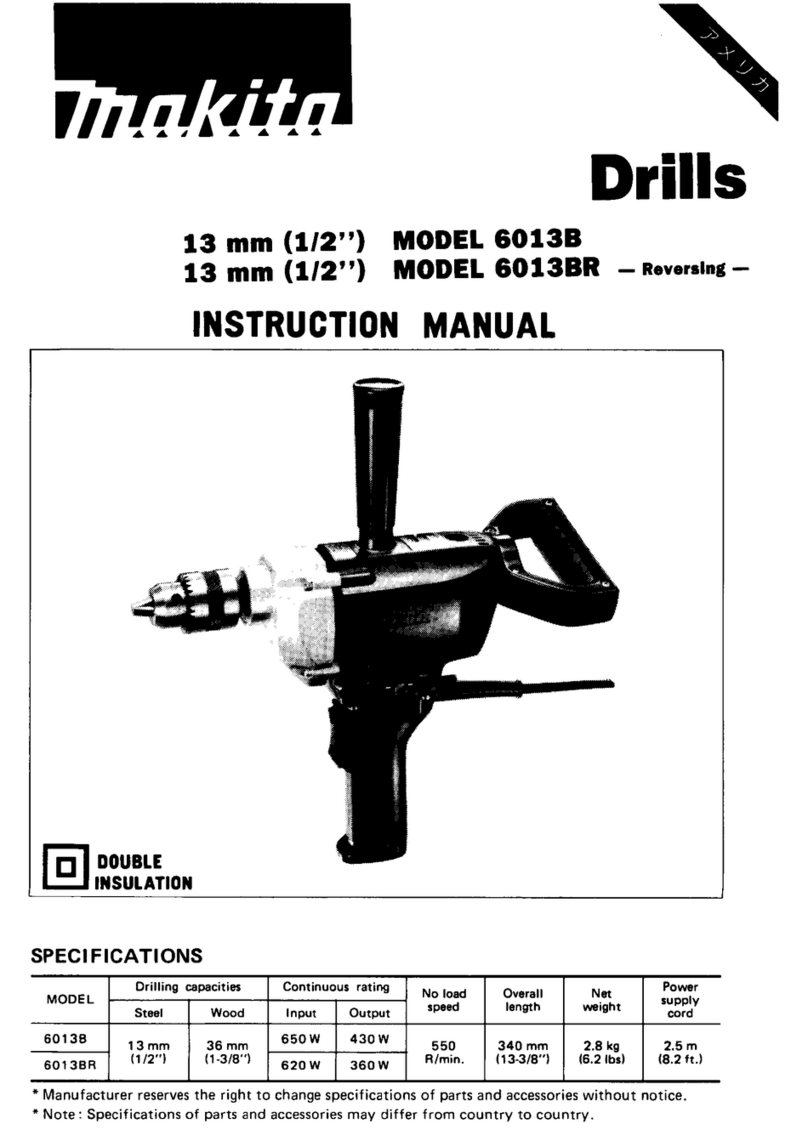

Specification

Standard equipment

Optional accessories

P 1/ 25

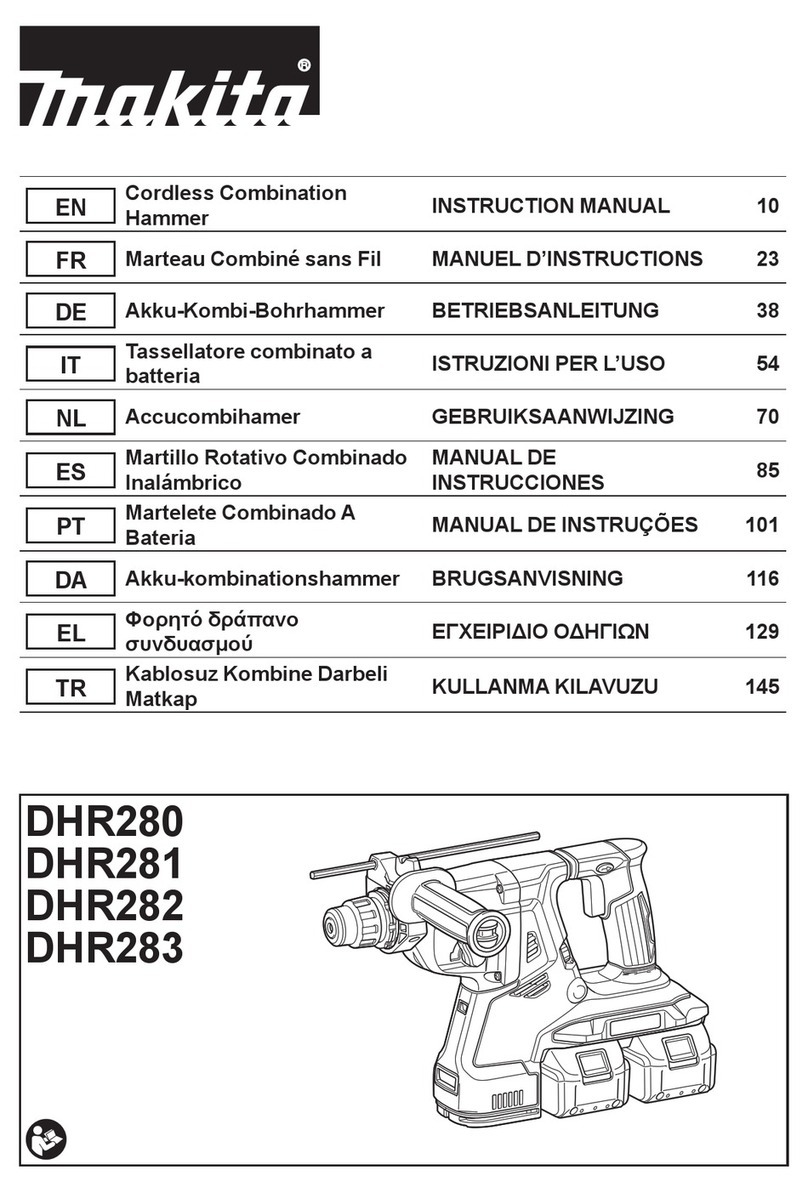

BHR242 (LXRH01*1), BHR243 (LXRH02*1)

Cordless Combination Hammer 24mm (15/16")

Dimensions: mm (")

Width (W)

Height (H)

Length (L) 328(12-7/8)

353(13-7/8)

85 (3-3/8)

213 (8-3/8)

The subject models are 24mm (15/16") Cordless Combination Hammers

powered by 18V Li-ion Battery, featuring:

• Efficient Brushless DC motor provides higher productivity than that of

18V Cordless Combination Hammer model BHR202.

• Able to drill in concrete as fast or faster than 24V Cordless Combination

Hammer model BHR200.

•3 operation modes (rotation only/ rotation with hammering/ hammering only)

• Quick change drill chuck for models BHR243 (LXRH02*1) only

• Makita’s first Cordless Combination Hammers with Dust extraction system.

Note: • These products are not compatible with 1.3Ah battery BL1815.

BHR242 (LXRH01*1)

BHR243 (LXRH02*1)

Normal chuck

For Model and its Chuck systemDust extraction system

DX01

Quick change chuckDX02

Battery

Voltage: V

Cell

Capacity: mm (")

Charging time: min.

18

3.0

Yes

Yes

10 (3/8)

13 (1/2)

27 (1-1/16)

24 (15/16)

3.4 (7.6)3.3 (7.2)

1.3 (3.0) for DX01,

1.4 (3.0) for DX02

22 with DC18RC (DC18RA*2)

Note: The standard equipment for the tool

shown above may vary by country.

Bit shank

Chuck capacity: mm (")

Adapted for SDS-PLUS

Steel

Wood

Concrete

Reverse switch

Yes

Variable speed control

by switch trigger

YesConstant speed control

Clutch (Torque limiter)

Weight of Dust

extracting system: kg (lbs)

Weight according to EPTA-

Procedure 01/2003: kg (lbs)

*2: for North and Central American countries only

Side grip assembly ............................ 1

Depth gauge (Stopper pole) .............. 1

Plastic carrying case ......................... 1

Quick change drill chuck set

for BHR243 (LXRH02*1) only ....... 1

0 - 950

0 - 4,700Blows per min.: (bpm=min-1)

No load speed: (min-1= rpm)

Quick change drill chuck No Yes

Operation mode

3 modes

(Rotation only/ Rotation with Hammering/

Hammering only)

*1 Model number for North and Central American countries.

H

L

W

BHR242

BHR243

Dimensions: mm (")

Height (H)

Length (L) 372(14-5/8)

397(15-5/8)

287 (11-1/4)

Width (W) 88 (3-1/2)

DX01

DX02

DX01, DX02

These are the accessories as Makita’s first Dust extracting system exclusively

for model BHR242 (LXRH01*1), BHR243 (LXRH02*1).

This system is designed to collect dust effectively with on-off operation

of the tool’s on-off trigger switch interlocked with this system.

Note: • This system can be applied for concrete drilling only and comes with

Dust case, Filter and 5 pcs. of extra Sealing caps.

• The following parts are available optionally:

Dust case set, Filter set, Plastic carrying case (can be stored with BHR242

or BHR243)

Model BHR242

(LXRH01*1)

BHR243

(LXRH02*1)

Capacity: Ah

54

Energy capacity: W

Li-ion

SDS-PLUS bits, Taper shank T.C.T bits,

Taper shank adapter, Cotter, Center bit,

Core bit adapter, Drill chuck assembly,

Chuck adapter, Drill chuck S13,

Chuck key S13, Keyless drill chuck,

Tool holder set, Dust cup 5 & 9,

Dust cup set, Bull point, Cold chisel,

Grooving chisel, Scaling chisel,

Scraper assembly, Grease vessel 30g,

Blow out bulb, Safety goggles,

Bit grease, Plastic carrying case,

Battery BL1830,

Fast charger; DC18RA*2, DC18RC,

Charger; DC18SC, DC24SC,

Automotive charger DC18SE,

Dust extraction system (DX01, DX02)

L

H

W