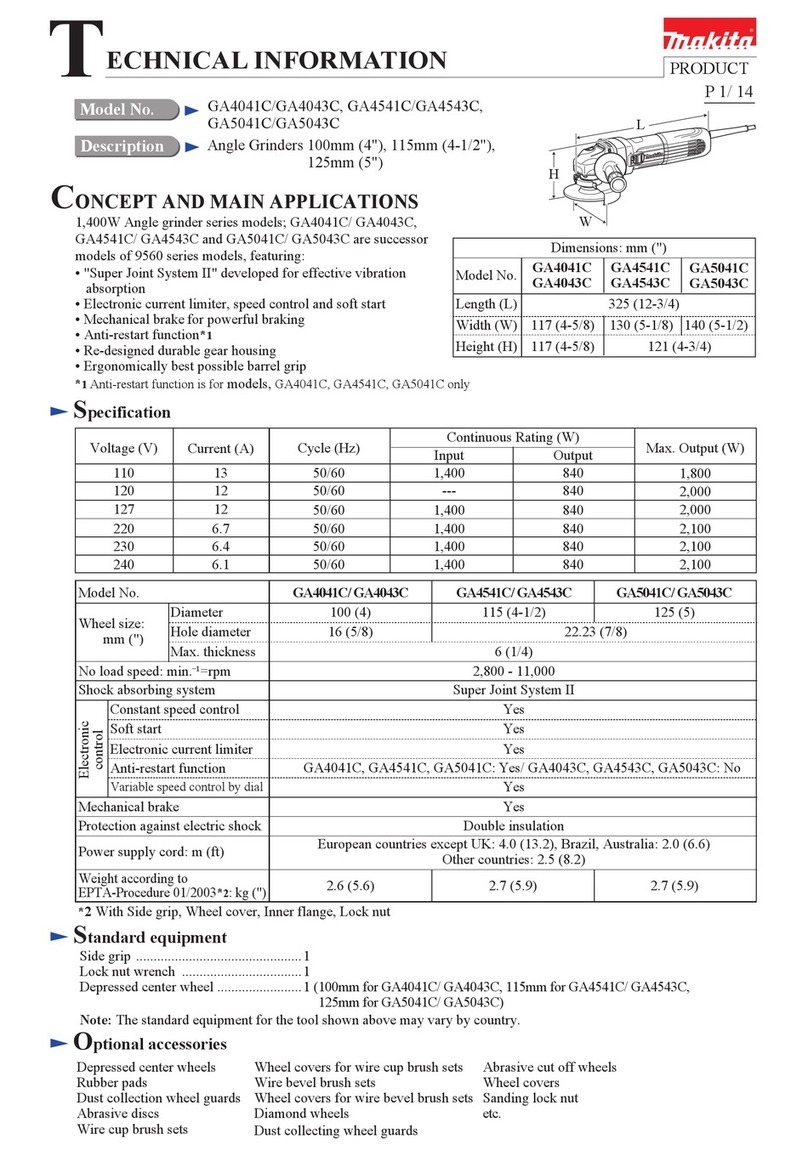

L

H

W

PRODUCT

P 1/ 11

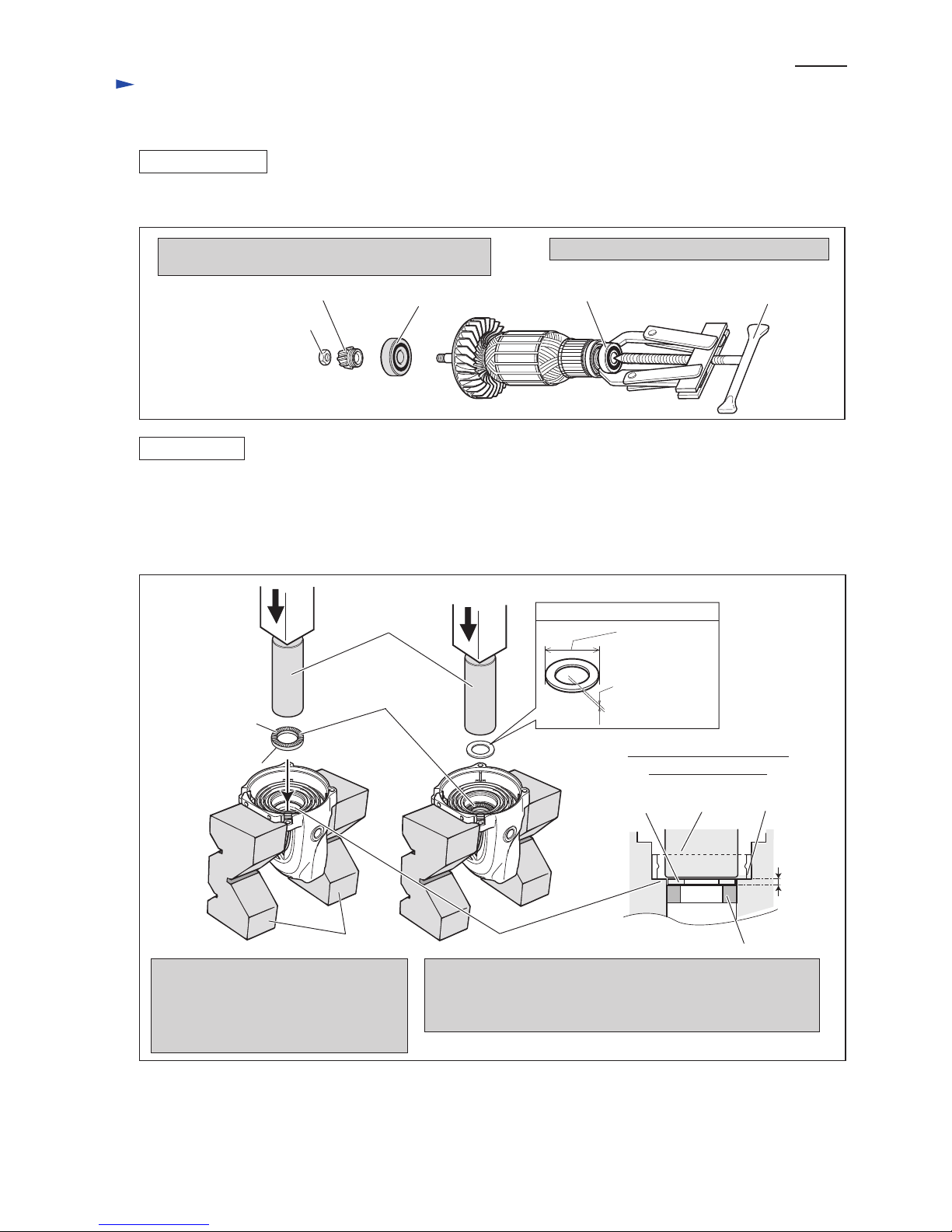

Standard equipment

Optional accessories

Note: The standard equipment for the tool shown above may vary by country.

Output

Lock nut wrench 35 .................... 1 pc

Vibration absorbing side grip ..... 1 pc

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

Model No. GA7030R

GA7040R

GA9030R

GA9040R

503 (19-4/5)

200 (7-7/8) 250 (9-7/8)

140 (5-1/2)

Toolless quick adjustable wheel cover, Toolless lock nut, Dust cover attachment, Plastic carrying case

GA7030R/ GA7040R: Accessories for 180mm angle grinder

GA9030R/ GA9040R: Accessories for 230mm angle grinder

Model No.

Description

CONCEPT AND MAIN APPLICATIONS

Specification

GA7030R, GA7040R/ GA9030R, GA9040R

Continuous Rating (W)

Voltage (V) Cycle (Hz) Input Max. Output (W)

110

120

220

230

240

15

15

11.5

11.0

10.5

50/ 60

50/ 60

50/ 60

50/ 60

50/ 60

1,650

---

2,400

2,400

2,400

850

900

1,700

1,700

1,700

2,900

2,900

4,500

4,500

4,500

Current (A)

Continuous Rating (W)

Voltage (V) Cycle (Hz) Input Output Max. Output (W)

110

120

220

230

240

23

15

12.5

12

11.5

50/ 60

50/ 60

50/ 60

50/ 60

50/ 60

2,400

---

2,600

2,600

2,600

1,500

1,000

1,800

1,800

1,800

3,700

3,700

4,900

4,900

4,900

Current (A)

GA7030R/ GA9030R

GA7040R/ GA9040R

Angle Grinders 180mm (7'')/ 230mm (9'')

Soft start feature

Anti-restart function

Double insulation

Net weight*3: kg (lbs)

Power supply cord: m (ft)

No load speed: min-1= rpm.

Wheel size: mm (") Diameter

Specification Model No. GA7030R/ GA7040R GA9030R/ GA9040R

Hole diameter

6,6008,500

Yes

Yes

Yes

180 (7)

22.23 (7/8)

230 (9)

2.0 (6.6)*1/ 2.5 (8.2)*2

6.3 (13.8)/ 6.6 (14.6) 6.5 (14.4)/ 6.9 (15.2)

Models GA7030R/ GA7040R/ GA9030R/ GA9040R are developed

as sister tools of GA7030S/ GA7040S/ GA9030S/ GA9040S.

Additionally to the benefits of GA7030S series models,

Models GA7030R/ GA7040R/ GA9030R/ GA9040R feature:

Anti-restart function

Large trigger switch with a lock lever having two different

actions for releasing the switch from Lock-off position and

locking the switch on in order to comply with the requirement

of the new IEC Regulations

Wheel size is:

180mm (7'') for Models GA7030R/ GA7040R

230mm (9'') for Models GA9030R/ GA9040R

TECHNICAL INFORMATION

*1 for Brazil, Australia

*2 for all countries except the two listed above

*3 Weight according to EPTA-Procedure 01/2003, with Side grip, Wheel cover, Inner flange, Lock nut