7ENGLISH

Holdthetoolrmlyandplacethepointofthedriverbit

inthescrewhead.Applyforwardpressuretothetoolto

the extent that the bit will not slip off the screw and turn

the tool on to start operation.

NOTE:

• Usetheproperbitfortheheadofthescrew/bolt

that you wish to use.

• WhenfasteningscrewM8orsmaller,carefully

adjustpressureontheswitchtriggersothatthe

screw is not damaged.

• Holdthetoolpointedstraightatthescrew.

•

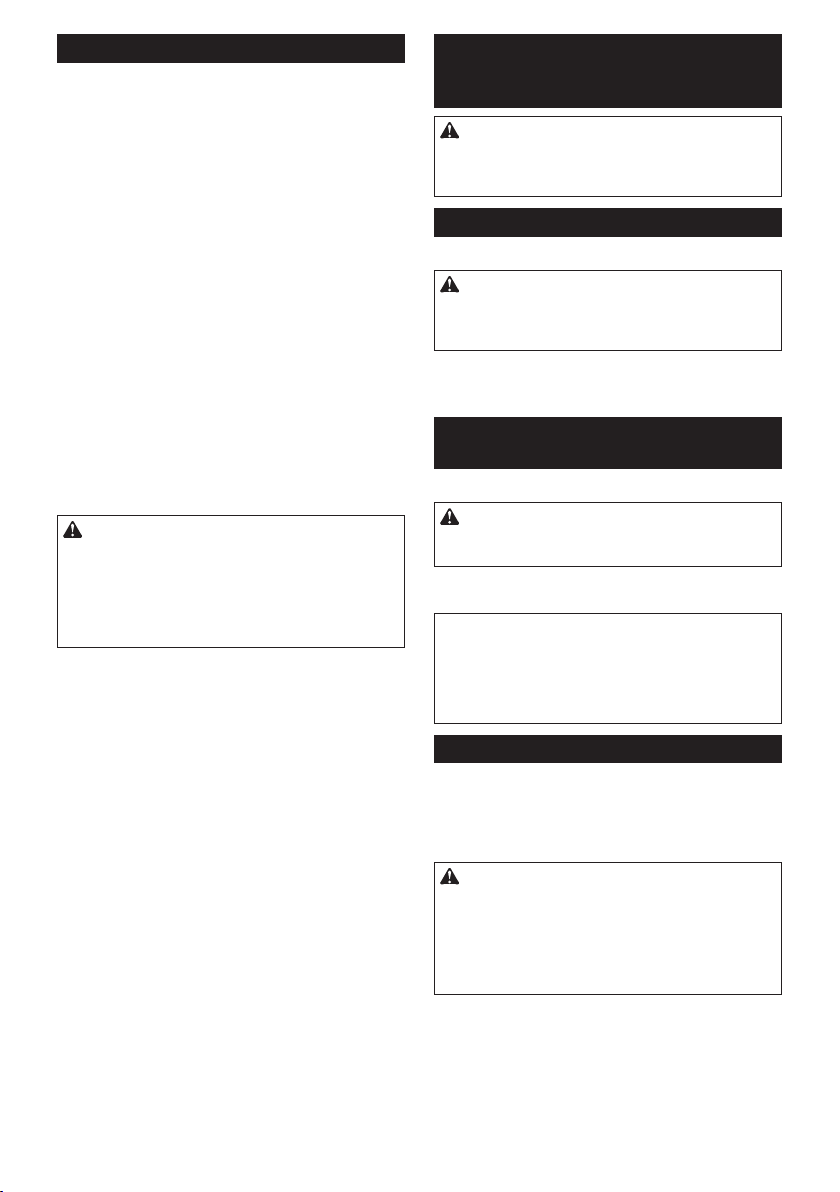

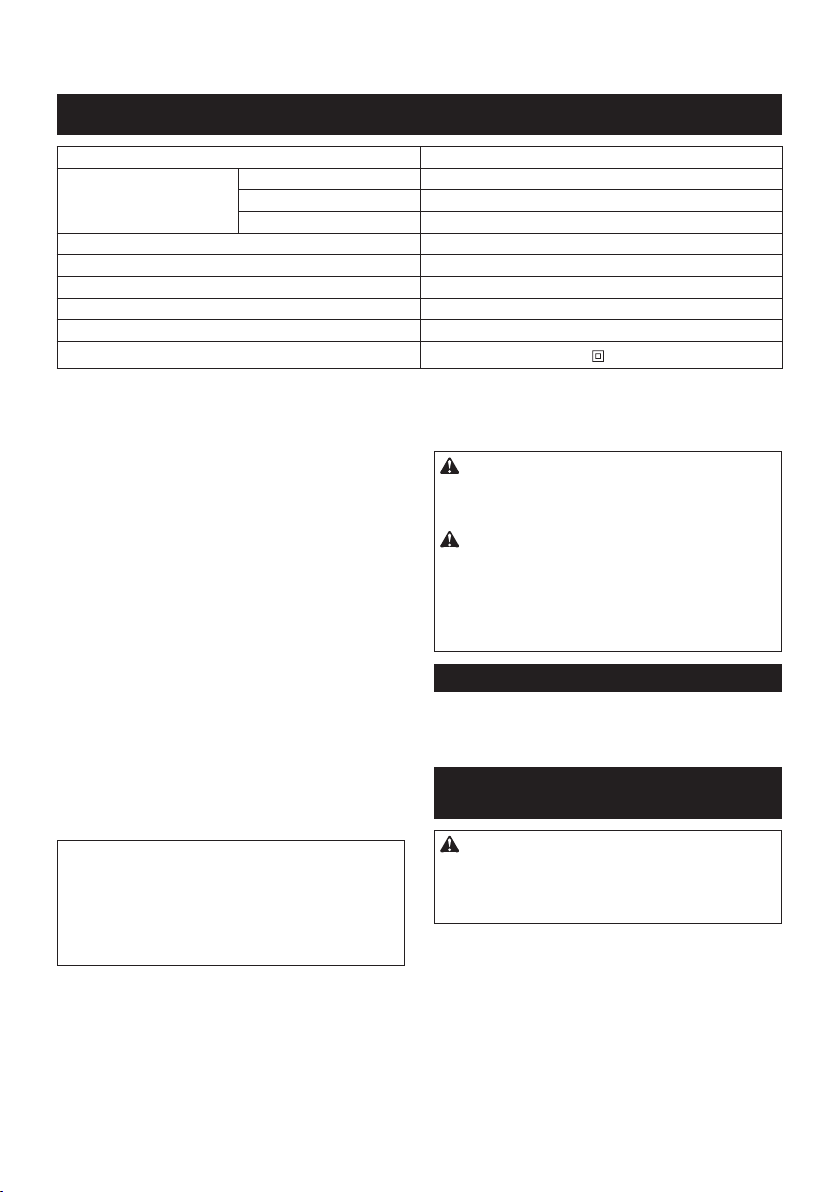

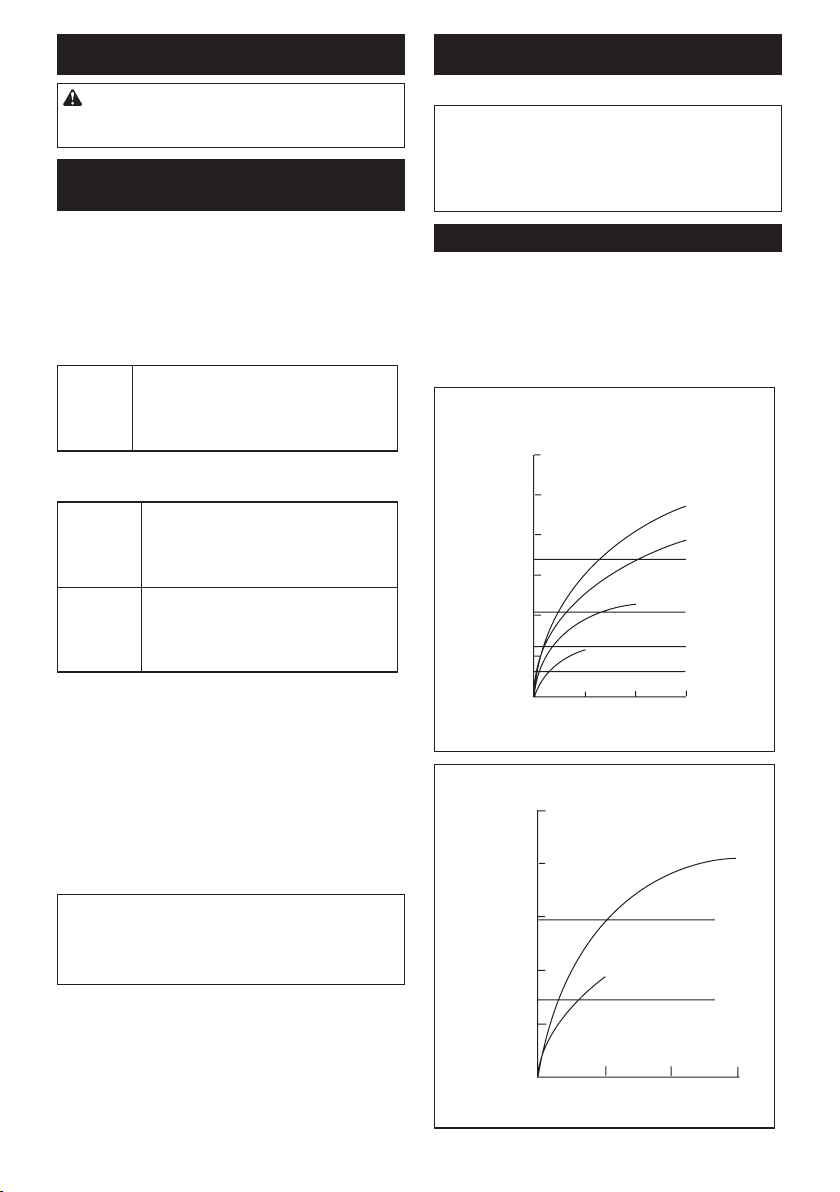

If you tighten the screw for a time longer than shown

inthegures,thescreworthepointofthedriverbit

maybeoverstressed,stripped,damaged,etc.Before

startingyourjob,alwaysperformatestoperationto

determine the proper fastening time for your screw.

Thefasteningtorqueisaffectedbyawidevarietyof

factorsincludingthefollowing.Afterfastening,always

check the torque with a torque wrench.

1. Driverbitorsocketbit

Failuretousethecorrectsizedriverbitorsocket

bit will cause a reduction in the fastening torque.

2. Bolt

•

Eventhoughthetorquecoefcientandtheclass

of bolt are the same, the proper fastening torque

will differ according to the diameter of bolt.

• Eventhoughthediametersofboltsarethe

same, the proper fastening torque will differ

accordingtothetorquecoefcient,theclass

of bolt and the bolt length.

3.

The manner of holding the tool or the material of

drivingpositiontobefastenedwillaffectthetorque.

4. Operating the tool at low speed will cause a reduc-

tion in the fastening torque.

MAINTENANCE

CAUTION:

• Alwaysbesurethatthetoolisswitchedoffand

unplugged before attempting to perform inspec-

tion or maintenance.

•

Neverusegasoline,benzine,thinner,alcoholorthe

like. Discoloration, deformation or cracks may result.

Replacing carbon brushes

►Fig.8: 1. Limit mark

Removeandcheckthecarbonbrushesregularly.

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

Bothcarbonbrushesshouldbereplacedatthesame

time. Use only identical carbon brushes.

Useascrewdrivertoremovethebrushholdercaps.

Take out the worn carbon brushes, insert the new ones

and secure the brush holder caps.

►Fig.9: 1.Screwdriver2.Brushholdercap

TomaintainproductSAFETYandRELIABILITY,repairs,car-

bon brush inspection and replacement, any other maintenance

oradjustmentshouldbeperformedbyMakitaAuthorized

ServiceCenters,alwaysusingMakitareplacementparts.

OPTIONAL

ACCESSORIES

CAUTION:

• Theseaccessoriesorattachmentsarerecom-

mendedforusewithyourMakitatoolspecied

in this manual. The use of any other accessories

orattachmentsmightpresentariskofinjuryto

persons. Only use accessory or attachment for

its stated purpose.

If you need any assistance for more details regard-

ingtheseaccessories,askyourlocalMakitaService

Center.

• Screwbits

• Socketbits

• Bitpiece

• Adjustablelocatorwithbit

• Hook

NOTE:

• Someitemsinthelistmaybeincludedinthe

tool package as standard accessories. They

may differ from country to country.

Hook

►Fig.10: 1. Screw 2. Hook 3.Groove

Thehookisconvenientfortemporarilyhangingthetool.

This can be installed on either side of the tool.

Toinstallthehook,insertitintoagrooveinthetool

housing on either side and then secure it with a screw.

Toremove,loosenthescrewandthentakeitout.

Adjustable locator with bit

►Fig.11: 1.Bumper2.Hammercasecover

Tousetheadjustablelocatorwithbit,removethe

bumperandtheninstallit.Thebumpercanberemoved

by pulling forward.