10

Waste Electric and Electronic Equipment

and its implementation in accordance with

national law, electric equipment that have

reached the end of their life must be

collected separately and returned to an

environmentally compatible recycling facility.

ENE006-1

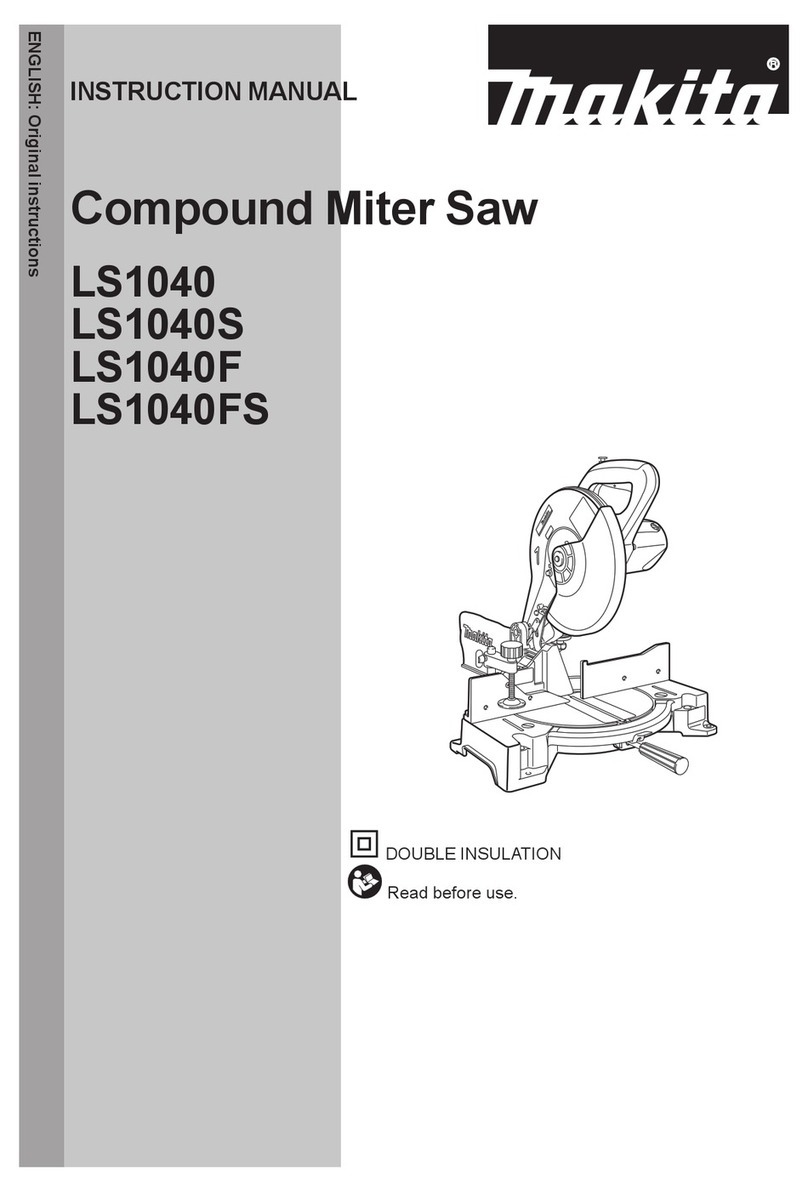

Intended use

The tool is intended for accurate straight and miter

cutting in wood. With appropriate saw blades, aluminum

can also be sawed.

ENF002-2

Power supply

The tool should be connected only to a power supply of the same

voltage as indicated on the nameplate, and can only be operated

on single-phase AC supply. They are double-insulated and can,

therefore, also be used from sockets without earth wire.

ENG905-1

Noise

The typical A-weighted noise level determined according

to EN61029:

Sound pressure level (LpA) : 92 dB (A)

Sound power level (LWA) : 101 dB (A)

Uncertainty (K) : 3 dB (A)

Wear ear protection

ENG900-1

Vibration

The vibration total value (tri-axial vector sum)

determined according to EN61029:

Vibration emission (ah) : 2.5 m/s2or less

Uncertainty (K) : 1.5 m/s2

ENG901-1

•

The declared vibration emission value has been

measured in accordance with the standard test method

and may be used for comparing one tool with another.

• The declared vibration emission value may also be

used in a preliminary assessment of exposure.

WARNING:

•

The vibration emission during actual use of the power

tool can differ from the declared emission value

depending on the ways in which the tool is used.

•

Be sure to identify safety measures to protect the operator

that are based on an estimation of exposure in the actual

conditions of use (taking account of all parts of the

operating cycle such as the times when the tool is switched

off and when it is running idle in addition to the trigger time).

ENH003-15

For European countries only

EC Declaration of Conformity

Makita declares that the following Machine(s):

Designation of Machine:

Slide Compound Miter Saw

Model No./ Type: LS1016, LS1016L, LS1016F,

LS1016FL

Conforms to the following European Directives:

2006/42/EC

They are manufactured in accordance with the following

standard or standardized documents:

EN61029

The technical file in accordance with 2006/42/EC is

available from:

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium

30. 6. 2014

000331

Yasushi Fukaya

Director

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium

GEA010-1

General Power Tool Safety Warnings

WARNING Read all safety warnings and all

instructions.

Failure to follow the warnings and instructions

may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for

future reference.

ENB034-10

MITER SAW SAFETY WARNINGS

1. Keep hands out of path of saw blade. Avoid

contact with any coasting blade. It can still

cause severe injury.

2. Check the saw blade carefully for cracks or

deformation before operation.

Replace damaged blades immediately.

3. Replace the kerf board when worn.

4. Use only saw blades specified by the

manufacturer which conform to EN847-1.

5. Do not use saw blades manufactured from

high speed steel.

6. Wear eye protection.

7. Wear hearing protection to reduce the risk of

hearing loss.

8. Wear gloves for handling saw blade (saw

blades shall be carried in a holder wherever

practicable) and rough material.

9. Connect miter saws to a dust collecting device

when sawing.

10.

Select saw blades in relation to the material to be cut.

11. Do not use the saw to cut other than wood,

aluminum or similar materials.

12.

Always secure all moving portions before

carrying the tool. When lifting or carrying the

tool, do not use the guard as a carrying handle.

13.

Do not operate saw without guards in place.

Check blade guard for proper closing before each

use. Do not operate saw if blade guard does not