PRODUCT

CONCEPT AND MAIN APPLICATIONS

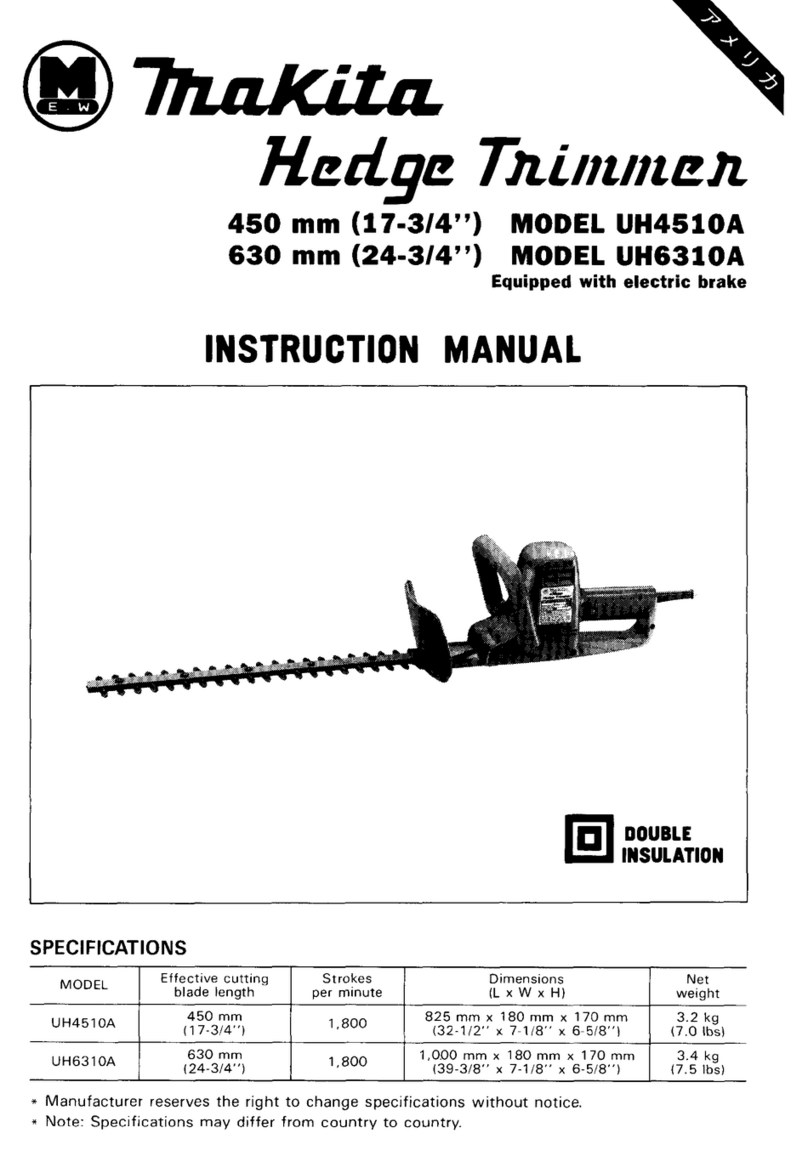

Specification

Standard equipment

Optional accessories

P 1/ 13

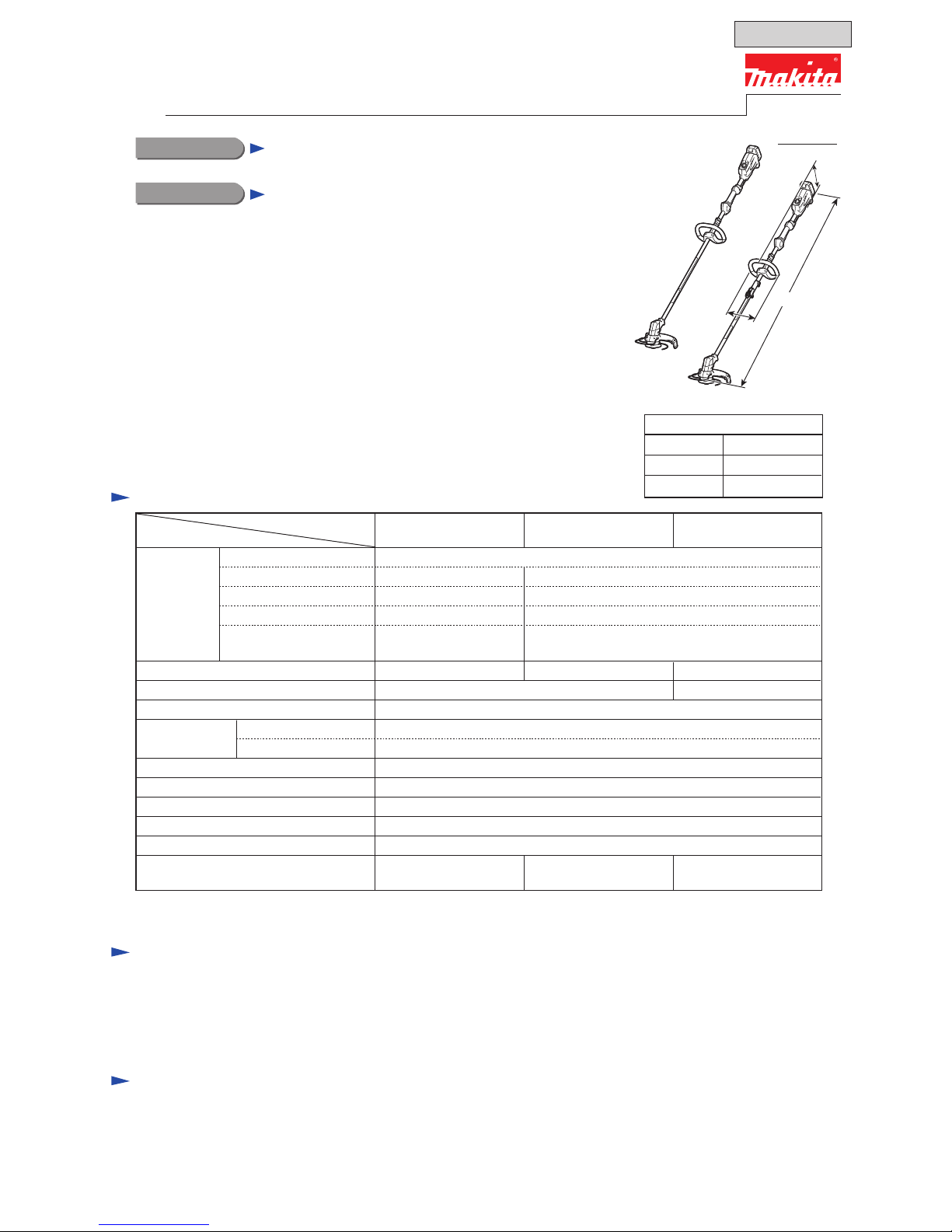

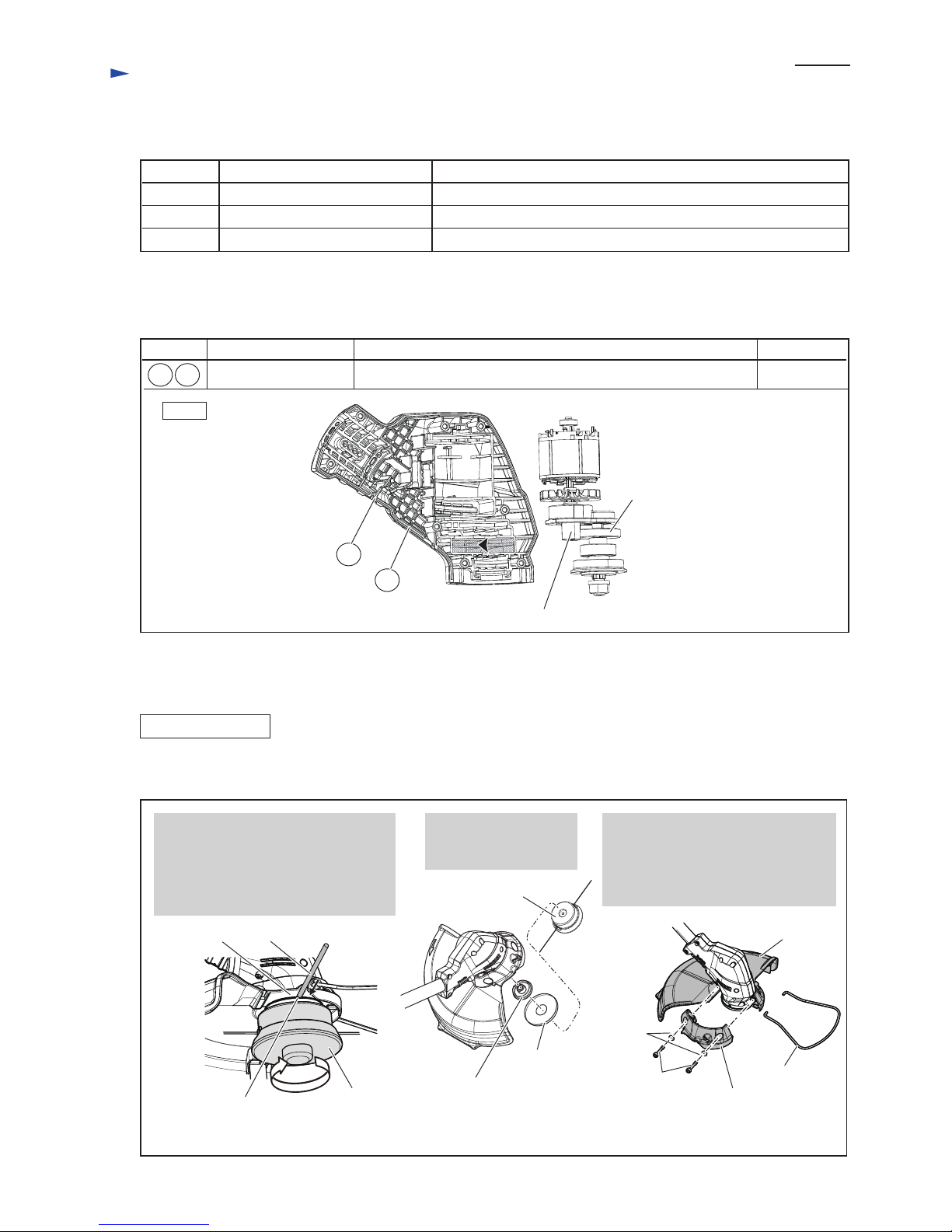

Models DUR142L/DUR182L and DUR183L are lightweight yet powerful

cordless grass trimmers, powered by 14.4/18V Li-ion batteries.

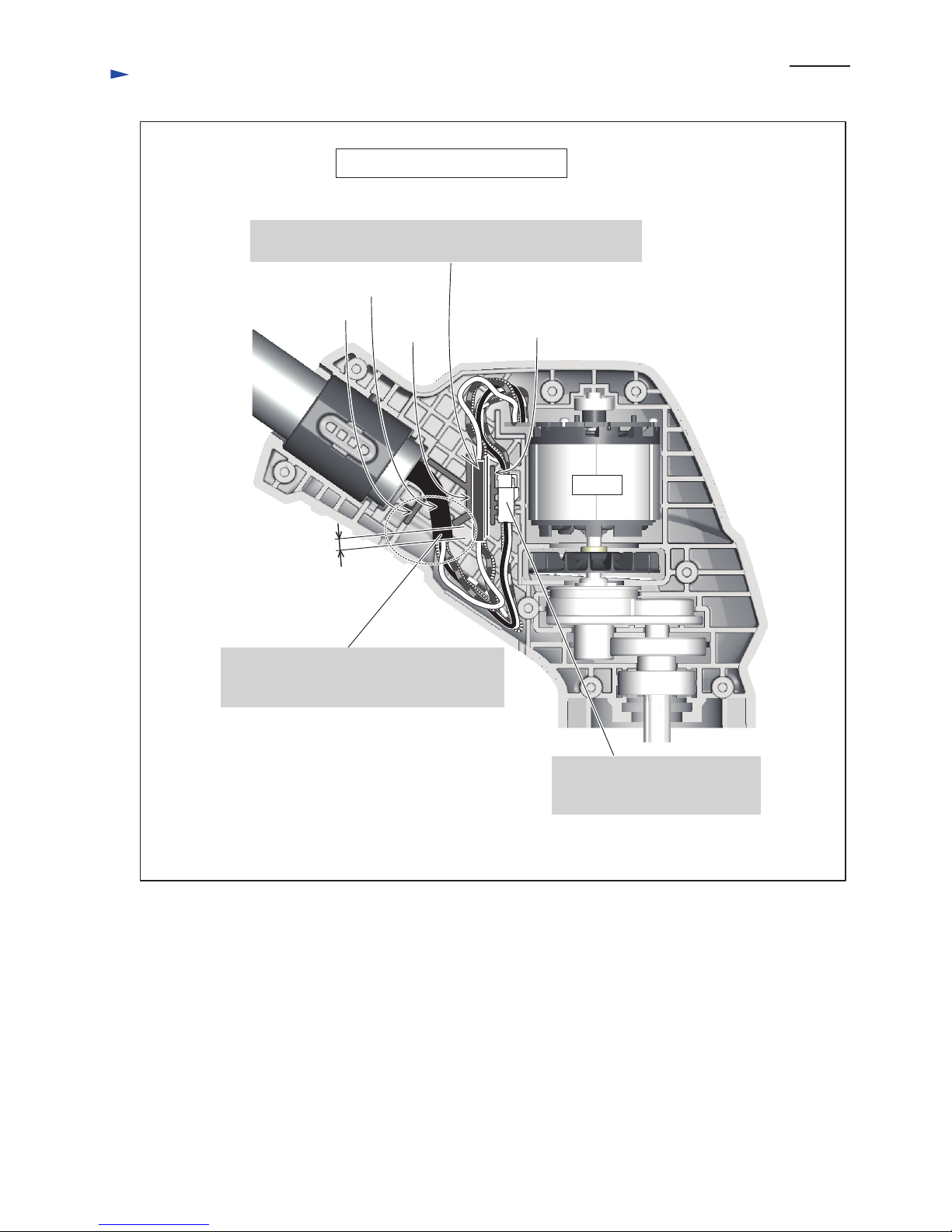

High power yet lightweight Brushless DC motor placed on the bottom side

of the shaft will provide easy handling and high trimming performance.

DUR142L and DUR182L are one-piece shaft models while DUR183L is

a split shaft model.

Their other main features are:

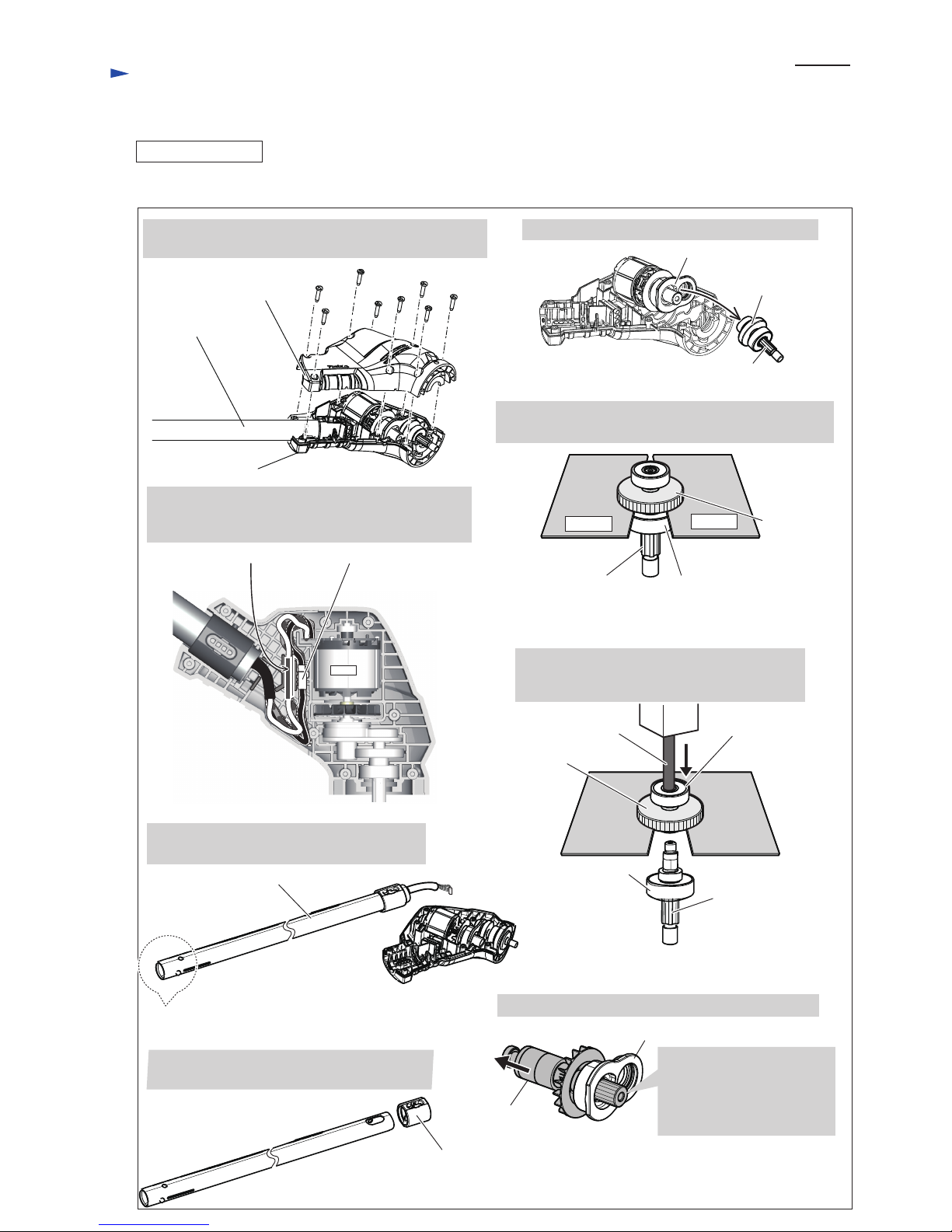

• Enhanced dust and drip-proof performance for use in bad weather

• Compatible with Metal blades, Nylon cutting heads and Plastic blade

• Reverse switch for removing grass clippings from the cutting tool

Dimensions: mm (")

Height (H)

Width (W)

1,843 (72-1/2)Length (L)

253 (10)

287 (11-1/4)

Single harness

Nylon cutting head

Hex wrench 4

Hex wrench 5

Safety goggles

Accessory bag

Cap 24 (for BUR183L only)

Note: The standard equipment may vary by country or model variation.

DUR142L/DUR182L

DUR183L

Cordless Grass Trimmer

Model No.

Description

Fast charger DC18RC

Charger DC18SD

Charger DC24SC

Four port multi charger DC18SF

Automotive charger DC18SE

Universal guard

Nylon cord ø2mm -15m

Metal blades*

(Triple blade, Star blade, Eddy blade)

Plastic blade (cutting width: 260mm)

For DUR142L

Battery BL1415N

Battery BL1415NA

Battery BL1430

Battery BL1430A

Battery BL1440

Battery BL1450

For DUR142L

Battery BL1815N

Battery BL1820

Battery BL1830

Battery BL1840

Battery BL1850

*1With Battery, Nylon cutting head, Harness, Protector, Handle

*2With BL1430, BL1440 or BL1450 *3With BL1830, BL1840 or BL1850

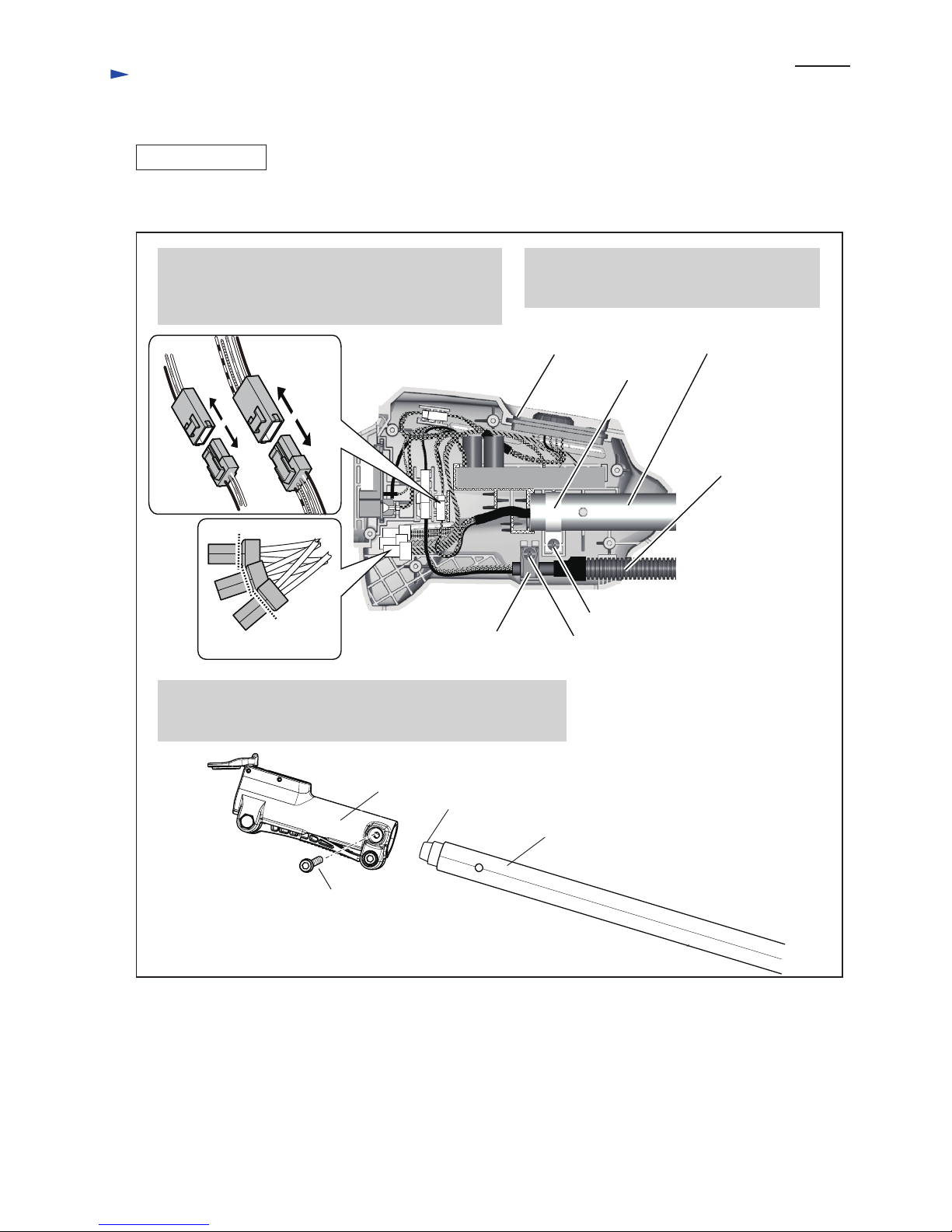

Cutting width:

mm (")

Nylon cutting head

Shaft type

Weight according to

EPTA-Procedure01/2003*1: kg (lbs)

No load speed: minˉ¹=rpm

300 (11-3/4)

Metal blade 230 (9)

200 250

Split shaftOne-piece shaft

Reverse switch Yes

Variable speed control Yes

Electric brake Yes

Spindle thread size M8x1.25, Left-handed

Over load protection Yes

250

3,500 - 6,000

4.1 (9.1)*3

3.9 (8.6)*33.8 (8.3)*2

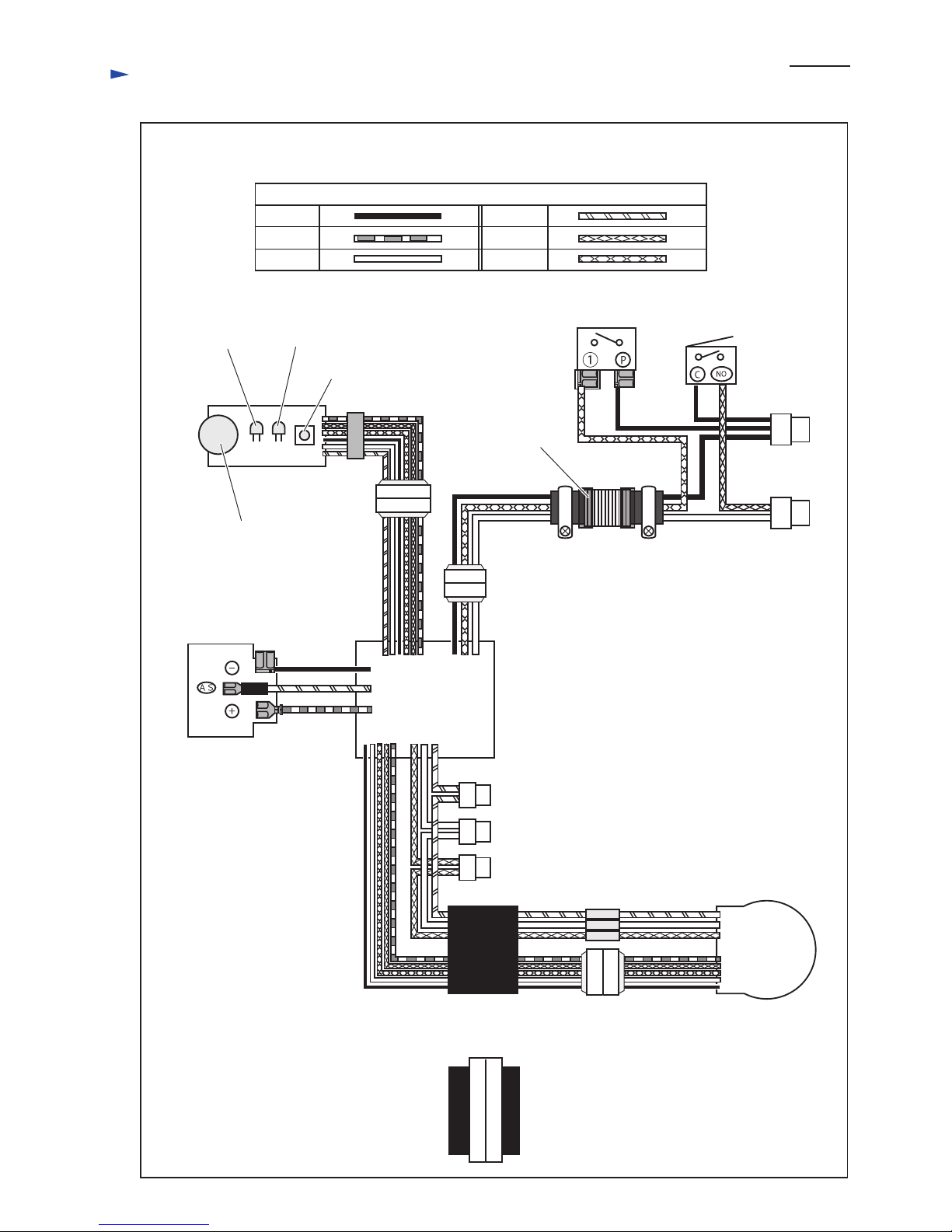

Battery

Max. output: W

Charging time: min.

Capacity: Ah

Cell

Voltage: V 14.4 18

DUR183LDUR142L DUR182L

1.5, 2.0, 3.0, 4.0, 5.01.5, 3.0, 4.0, 5.0

Energy capacity: Wh 22, 44, 58, 72 27, 36, 54, 72, 90

Li-ion

15, 22, 36, 45

with DC18RC

15, 24, 22, 36, 45

with DC18RC

Model

Specification

Note: • These products are not compatible with BL1415/ BL1815.

• Use of metal blades in some countries is prohibited due to

their safety regulations.

DUR183L

DUR182L

L

W

H

*Only for countries without regulations

TECHNICAL INFORMATION

OFFICIAL USE

for ASC & Sales Shop