MAKSIWA MK.300.I User manual

1

MK.300.I

___________________________________________________________________

INSTRUCTION MANUAL

___________________________________________________________________

_

ATTENTION: READ THIS MANUAL BEFORE USING THE PRODUCT.

MITER SAW 10″ WITH LASER GUIDE AND DUAL SLIDING RAIL

2

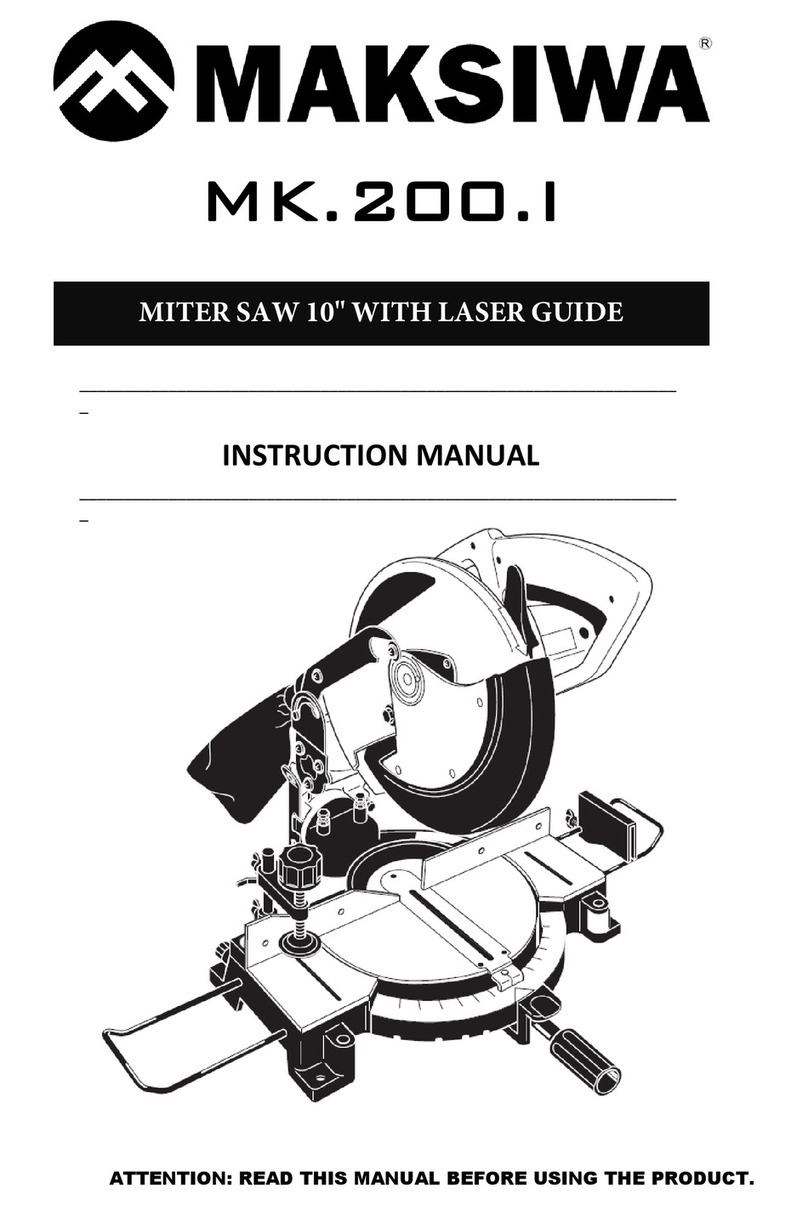

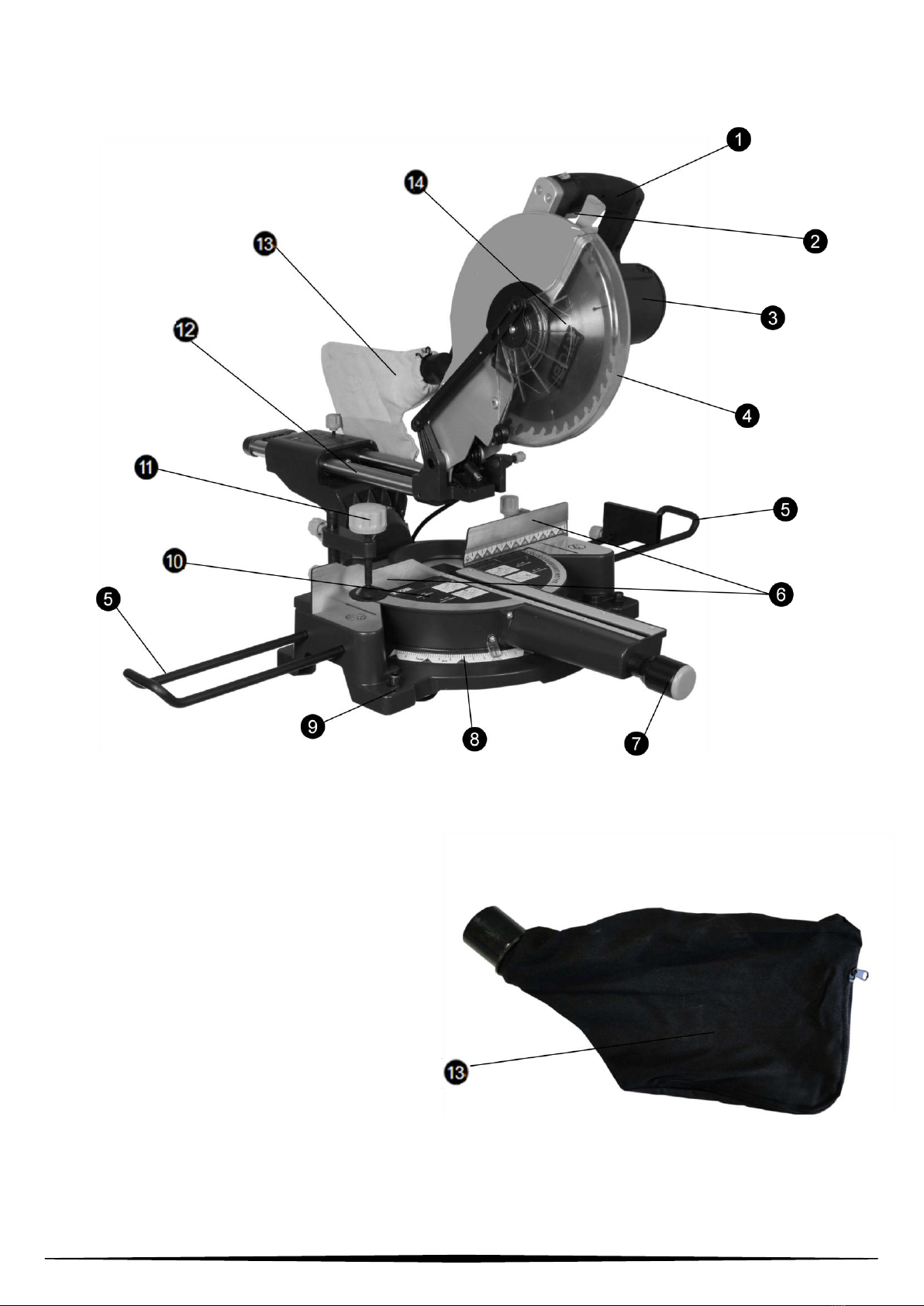

PICTURE 1

(Illustrative Picture)

1. Grip

2. Trigger switch

3. Engine Housing

4. Saw protector

5. Side Extenders

6. Side Guides

7. Square fastener button

8. Square Scale

9. Table Mounting Holes

10. Table

11. Fastener

12. Telescopic Guide

13. Dust Collector Bag

14. Cutting Disc

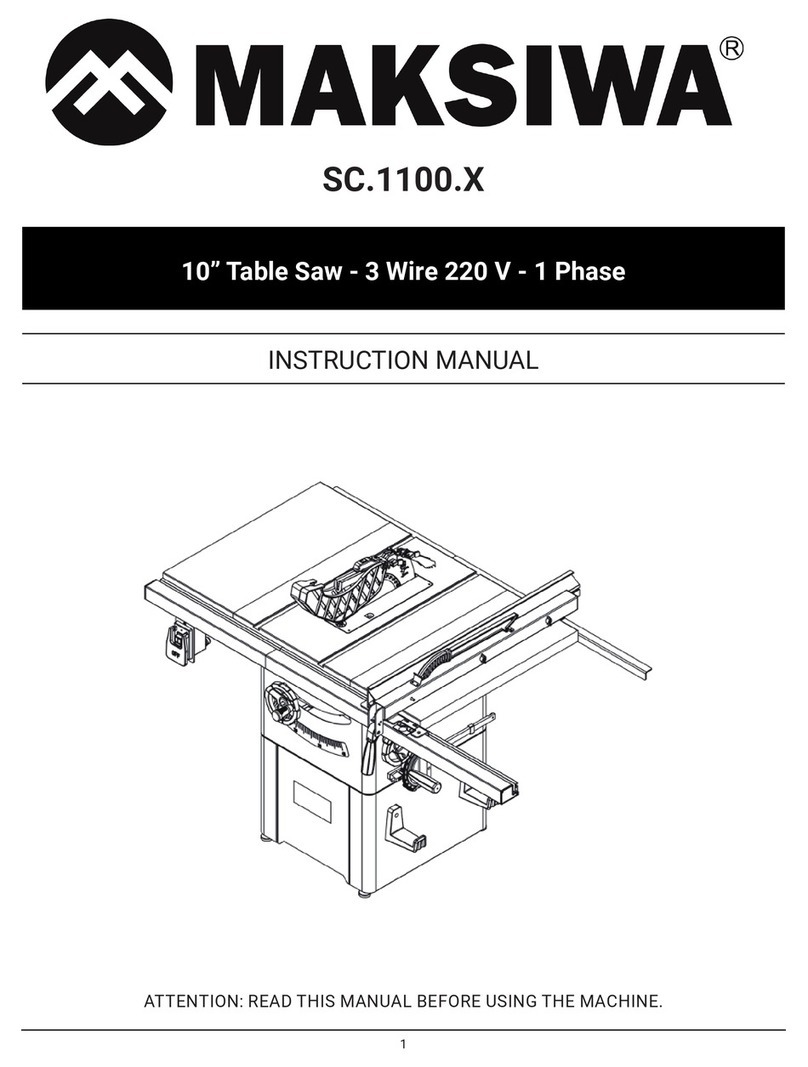

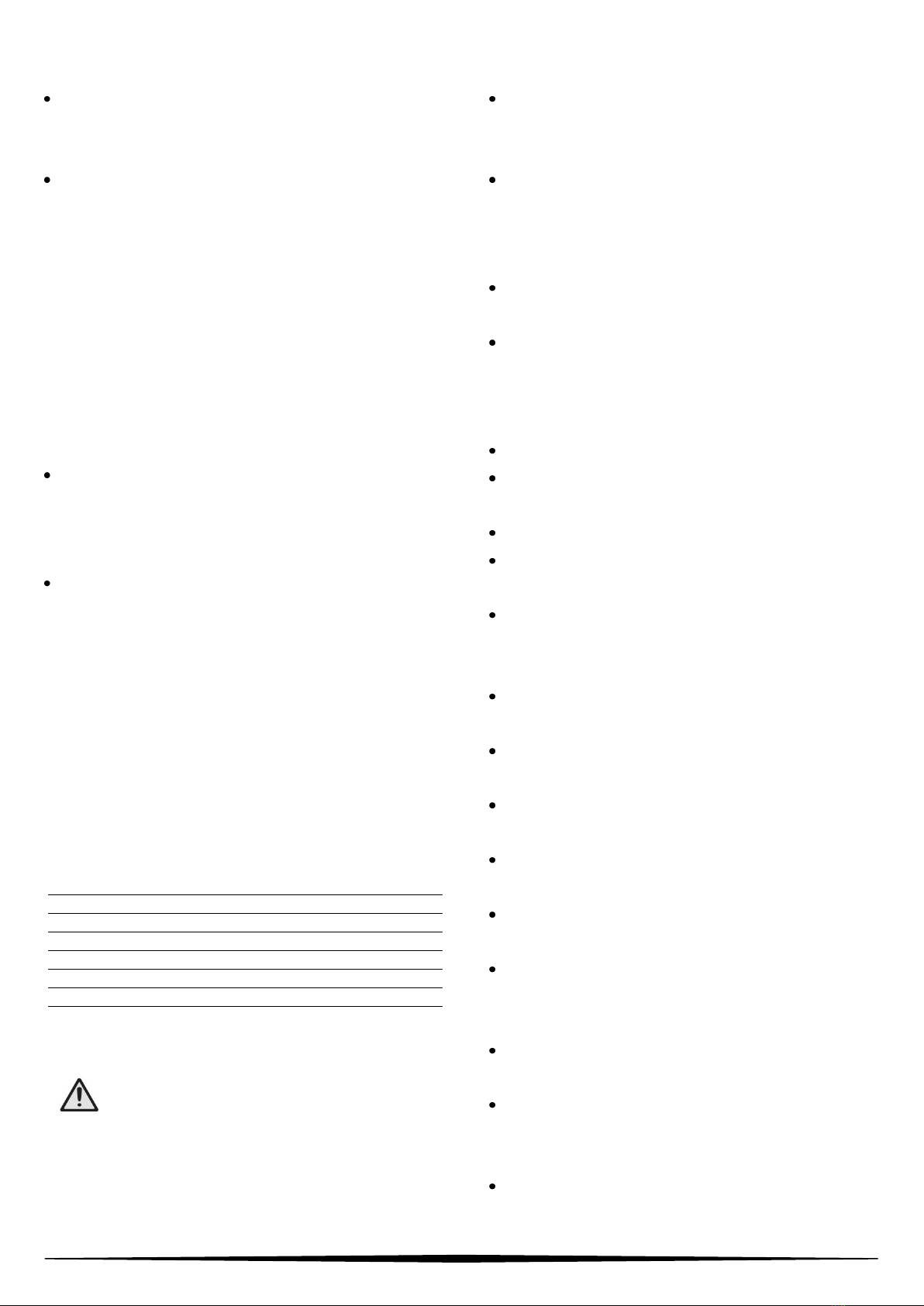

Picture 2

(Illustrative Picture)

3

INSTRUCTION MANUAL

Important information you should know:

Make cuts only with sharp blades. Discs that are not

sharp do not cut properly and overload the engine.

If the saw does not cut accurately, refer to the

PROBLEM DETECTION table in this manual.

ALWAYS USE PROPER PROTECTIVE

EQUIPMENT WHEN OPERATING THIS

EQUIPMENT.

Important Safety Instructions

ATTENTION: When using power tools, always

follow safety precautions to reduce the risk of

fire, electric shock and personal injury, including

the following:

READ ALL INSTRUCTIONS

Double Insulation

Double insulation tools are constructed with two

separate layers of electrical insulation or double

insulation thickness between you and the tool's electrical

system. Tools built with this insulation system should not

be grounded. As a result, your tool is equipped with a

two-pin plug that allows the use of an electrical

extension without the concern of maintaining a

connection to the ground wire.

NOTE: Double insulation does not replace normal safety

precautions when operating this tool. The isolation

system is to add protection against personal accidents

resulting from a possible failure in the electrical

insulation of the tool.

CAUTION: WHEN MAINTAINING, REPLACE

ONLY WITH INDENTICAL PARTS. Repair or

replace damaged wires.

SECURITY INSTRUCTIONS

FOR ALL TOOLS

Remove the adjustment key. Make it a habit to

ensure that the adjustment wrench is removed from

the shaft before starting the tool.

Keep the work surface clean. Disorganized areas

and work surfaces invite accidents.

Do not use the saw in hazardous environments. Do

not use power tools in damp or wet or exposed to rain.

Keep the work area well lit.

Keep children away. All visitors must be kept at a

safe distance from the work area.

Make the workplace childproof by using padlocks,

master keys or by removing the ignition key.

Do not force the tool. It will do the job better and

safer for the intended use. Use the correct tool.

Do not force the tool when doing work for which it

was not designed.

Use suitable equipment. Do not wear loose clothing,

gloves, chains, rings, bracelets or other accessories

that could get caught in moving parts. Shoes with non-

slip soles are recommended. Wear hair protection to

secure it.

Always wear safety glasses. Also wear a face mask.

Secure the part to be worked. Use fasteners or vises

when you are unable to secure the workpiece to the

table and against the guide by hand or when your

hand is dangerously close to the blade.

Do not overreach. Keep your balance and your feet

in a comfortable position at all times.

Keep tools in order. Keep tools sharp and clean for

better and safer performance. Follow instructions on

lubricating and changing accessories.

Disconnect tools before servicing or changing

accessories, such as blades, tips, cutters, etc.

Reduce the risk of unintentional starting. Make sure

the switch is in the “OFF” position before connecting

the wire to the plug,

Use recommended accessories. Refer to the

instruction manual to check the recommended

accessories. Improper use of accessories can cause a

risk of accident for people.

4

Never step on the tool. A serious accident can occur

if the tool is tilted or if the tool is touched accidentally.

Check for damaged parts. Before continuing to use

the tool, a guard or other part that is damaged must be

carefully examined to determine its proper functioning

and perform its function properly. Check the alignment

of moving parts, broken parts, assembly and any other

condition that may affect its operation. A protector or

other part that is damaged must be repaired or

replaced immediately. Do not use the tool if switch

does not turn it on or off.

Never leave a tool running unattended. Turn off the

ignition key. The engines of these tools can emit

sparks and explode flammable gases.

Extension cables. Make sure your extension is in

good condition. When using an extension cord, ensure

that it is capable of transmitting the electrical current

used by your product. An undersized cable will cause

a voltage drop resulting in loss of power and

overheating. The following table shows the correct size

to be used depending on the cable diameter and the

amperage rating. If in doubt, use a cable with higher

voltage capacity. CAUTION: Do not use extension

cords longer than 20 meters.

2-Way Wire 3-Way Wire

Ø (mm2)

Amperage

Ø (mm2)

Amperage

0,5

9

0,5

8

1,0

13

1,0

12

1,5

16,5

1,5

15

2,5

23

2,5

20

Additional Safety Rules for Miter Saw:

CAUTION: FAILURE TO MEET THESE

WARNINGS MAY RESULT IN PERSONAL

ACCIDENT AND SERIOUS DAMAGE TO

THE MACHINE.

Protect the power supply line with at least a 15 amp

fuse or a circuit breaker.

Make sure that the blade is turning in the correct

direction and that the teeth at the bottom of the blade

are pointing towards the rear of the miter saw.

Make sure the fasteners are secure before starting

any operation.

Make sure that all washers on the blade and

fasteners are clean and that the sides preceded by

flanges are against the blade. Tighten the axle screw

securely.

Keep the saw blade sharp.

Keep the engine vents free of chips or dirt.

Always use the blade guard.

Keep your hands out of the way of the saw blade.

Turn off the saw, disconnect the cable from the

power outlet and wait until the blade stops completely

before performing maintenance or adjustments to the

tool. Support long pieces with a wood fixing device.

Do not attempt to operate the saw at a voltage other

than the designated voltage.

Do not operate the saw unless all fasteners are

secure.

Do not use blades larger or smaller than

recommended.

Do not force anything against the fan to hold the

motor shaft.

Do not force the cut. Partial or total forced shutdown

of the engine can cause serious damage. Allow the

engine to reach full speed before starting to cut.

Do not cut ferrous metals or any masonry material.

Do not use abrasive bearings. Excessive heat and

abrasive particles generated by these will damage the

saw.

Do not allow anyone to remain behind the saw.

5

Do not apply lubricant to the blade when in

operation.

Do not put any hand on the blade area when the

saw is connected to the power outlet.

Do not use blades designed for less than 5,500

RPM.

Do not cut small pieces without the aid of fasteners.

Keep your hands away from the blade.

Do not operate the saw without the guides.

Do not perform any hands-free operation.

Do not reach around or behind the blade.

Do not put your hands within 6 inches of the saw

blade.

Do not put your hands under the saw unless it is

disconnected and unplugged. The saw blade is

exposed at the bottom of the saw.

Do not move your hands from the saw or workpiece

or raise your arms until the blade has stopped.

Do not use the saw without the base or when it is

wider than 10mm (3/8 ’’).

Do not use lubricants or cleaning products

(particularly sprays and aerosols) in the vicinity of the

plastic protector. The polycarbonate material used in

the protector is sensitive to certain chemicals.

ATTENTION: Any dust created by

sanding,cutting, grinding, drilling and other construction-

related activities contain chemicals that can cause

cancer, birth defects and other reproductive harm. Some

examples of these products are: lead-based paints; brick

silica crystal, cement and other masonry products; and

arsenic and chromium from chemically treated wood.

CAUTION: Do not connect the unit to an electrical

outlet or power on until all instructions have been

read and understood.

Always tighten the adjustment clips before

using the saw. Keep hands at 15 cm

away from the saw blade. Never perform hands-free

operations. Never cross your arms in front of the saw

blade. Think, how can I avoid accidents!

Do not operate the saw unless the guards are in

place. Never place your hands on the saw blade.

Always wear safety glasses. Turn the tool off and wait

for the disc to stop before restarting service, making

adjustments or moving your hands.

Electrical Connection

Make sure your power supply matches the designation

on the plate. A 10% decrease in voltage or more will

cause loss of power and overheating. All MAKSIWA

equipment is tested at the factory. If this tool does not

work, check the power supply.

Familiarize yourself with the machine

Place the tool on a smooth, flat surface, such as a

workbench or a strong, flat table. Check figures 1 and

2, and pay attention to the part descriptions to

familiarize yourself with its different components. The

next section will deal with the necessary adjustments

for the tool to function properly, and will refer to the

end that accompanies the illustrations. To do this, you

must know these parts and you must know where they

are. The name of each component is followed by a

corresponding number in the illustration.

Specifications

Wattage

2000 W

Speed

4500 RPM

Net Weight

19,5 Kg

Saw Dimension

Ø254 x 16 x 2,8mm

Table Tilt

45º esquerda –45º direita

Saw Tilt

0º a 45º

Max Cutting

90º x90º: 90 x 305mm

90º x 45º: 90 x 215mm

45º x 90º: 42 x 305mm

45º x 45º: 42 x 215mm

Transport and Installation

For packaging reasons, the machine is not completely

assembled.

If you notice any damage caused by transportation

while opening the package, notify your supplier

immediately. Do not operate the machine.

6

Dispose the packaging in a sustainable

environmental way.

The miter saw is designed to operate indoors and

must be placed on a firm, stable and level surface, as

explained below:

Mounting on a workbench

The four legs of the saw have holes, as shown in

figure 1, to facilitate the assembly of the table. Always

assemble your saw by securing it firmly to prevent it

from moving. To improve the transport of your tool,

you can mount it on a piece of wood 13mm (1/2 ’’) or

thicker, which can be fixed on the raised support to

other work places.

NOTE: If you are going to fix your saw on a wooden

plate, make sure that the screws will not go through

the thickness of the wood. The wood must be parallel

to the work table. When attaching the saw to any work

surface, use vise or sergeants and fix it only by the

feet where the screw holes are located. Attachment to

any other part of the saw may interfere with the proper

functioning of the equipment.

CAUTION: To prevent the saw from becoming

move and cause lack of precision, make sure that the

table where the saw is supported is not uneven. If the

saw moves over the surface, place a support under the

base until the saw settles firmly on the surface.

Installing a New Blade on the Equipment

IMPORTANT: Remove the miter saw from the

socket.

Do not cut ferrous materials or masonry materials with

this miter saw.

With the saw arm in the raised position, raise the blade

guard as far as possible. Loosen (but do not remove)

the guard console screw, until the guard console can

be raised high enough to allow access to the blade

screw. The blade guard will be held in the raised

position by the console guard screw. Push the button

lock the shaft with one hand and use the blade wrench

with the other to loosen (clockwise) the screw in the

slot on the left side of the blade.

NEVER TIGHTEN THE AXLE LOCK PIN WHILE THE

BLADE IS SPINNING. Be sure to hold the guard

console down and securely secure the guard console

screw when you finish installing the saw blade. Failure

to do so will cause serious damage to the saw and

possible personal injury.

NOTE: There are two different cut diameters on the

inner plate, which have marked 25.4mm and 16mm.

When installed, the outer diameter of the inner plate

must correspond with the diameter of the saw blade.

To install, place the blade and screw. Press and hold

the shaft and tighten the screw in the opposite

direction of the cranks with the key, then tighten again

in the direction of the cranks (clockwise) with the metal

guard screw.

NOTE: Only use the key that comes with the saw to

install and remove the saw blade.

Saw assembly and adjustment: Switch off the saw

before adjusting it.

Installing the square fastener button: Remove plastic

bag square fastener button

Carefully screw on the arm located at the front of the

saw.

Dust Bag Installation

Your saw comes with a dust bag. To install the bag,

place the plastic opening in the dust extraction socket

of the tool.

The saw can be used with a suction hose fitted to the

machine's dust extraction support, or without any

device.

MAKE THE ADJUSTMENTS HAVING THE SQUARE

SAW DISCONNECTED FROM THE OUTLET.

NOTE: Your miter saw was precisely adjusted at the

factory during manufacture. If it is necessary to

readjust according to the transport and

7

handling or any other reason, follow the steps below

to adjust your saw. Once these adjustments are

made, they will remain accurate. Follow these

instructions carefully to maintain the accuracy your

saw is capable of.

Adjusting the Miter Scale

Place a square against the saw blade and guide (do

not touch the tips of the blade teeth with the square.

This will cause the fine adjustment to fail). Loosen the

square fastener button and rotate the square arm until

the square edge locks in the 0º position. Do not press

the fastener button. If the saw blade is not exactly

perpendicular to the guide, loosen the two screws that

hold the square scale to the base and move the scale /

square arm assembly to the right or left until the blade

is perpendicular to the guide, as measured with

square.Retighten the two screws. Do not pay attention

to reading the square pointer at this point.

Protector Activation and Visibility

The saw blade guard is designed to lift automatically

when the arm bends down and covers the disc when

the arm rises.

The guard can be lifted manually when installing and

removing the cutting disc or when necessary

inspection of the saw.

NEVER LIFT THE CUTTING DISK PROTECTOR

WHEN THE SAW IS IN OPERATION.

NOTE: Certain special cuts require you to lift the

guard manually. To do this, simply place your right

thumb on the top of the protector and slide it upwards

to generate enough space for the piece to pass. Never

remove the protector or prevent normal operation.

Connect the saw to any electrical outlet. Refer to the

rating plate on your tool for the proper voltage. Make

sure that cable is not on your way.

Switch:

Turn on the saw, press the trigger switch. To turn the

tool off, release the switch. There is no mechanism to

lock the switch in the on position.

Hand and Body Positioning

The proper positioning of the body and hands during

the operation of the miter saw will make cutting easier,

more accurate and safer. Never place your hands near

the cutting area. Place your hands no closer than 15

cm from the blade. Hold the piece firmly against the

table and the guide while cutting.

Keep your hands in position until the trigger has been

released and the blade has come to a complete stop.

ALWAYS DO A TRIAL TEST (DISCONNECTED

FROM THE POWER) BEFORE MAKING FINNISHING

CUTS SO YOU CAN CHECK THE BLADE PATH.

Cutting with your saw

NOTE: Although your saw cuts wood and many other

non-ferrous materials, we will limit ourselves to

discussing only wood cutting. The same guidelines

apply to other materials. DO NOT CUT FERROUS

MATERIALS (containing iron and steel) OR

MASONRY MATERIALS WITH THIS SAW.

DO NOT USE ABRASIVE BLADES.

Cross sections

Cutting multiple pieces is not recommended, but can

be done safely by ensuring that each piece is securely

fastened against the table or the guide.

Cross-cutting is done by cutting the wood in the

opposite direction to the fibers at any angle. A straight

cross section is made with the miter arm in the 0º

position. Set the square to zero, hold the wood firmly

on the table against the guide. Turn the saw on by

pulling the trigger. When the saw starts to pick up

speed (after approximately 1 second), gently lower

your arm to perform the

OPERATION

8

cut in the wood. Allow the blade to come to a complete

stop before lifting the arm.

Transverse cuts are made with the square arm at any

angle other than 0º. This angle is often 45º for making

corners, but can be adjusted from 0º to 45º to the right

or left. After selecting the desired angle, be sure to

press the square fastener button. Make the cut as

described above. Beveled Cuts

A bevel cut is a cross-section made with the saw blade

not perpendicular to the wood. To adjust the chamfer,

loosen the chamfer holder button and move the saw to

the left as desired (it is not necessary to move the left

side of the guide to allow opening). Once the chamfer

is at the desired angle, press the fastener button firmly.

The chamfer angles can be adjusted up to 45º to the

left and the cut can be made with the square arm

positioned between 0º and 45º to the right or left.

Cut Quality

The smoothness of any cut depends on a number of

variables. Factors such as the type of material being

cut, type of blade, blade sharpening and rate of cut

contribute to the quality of the cut.

When smoother cuts are required for frames or other

precision work, a sharp blade (60 - 80 carbon teeth)

and a slower and more uniform rate of cut will produce

desired results. Make sure that the material does not

vibrate when cutting. Hold it firmly in place. Always

wait for the blade to stop completely before raising

your arm.

If small wood fibers continue to splash on the back of

the piece, place a piece of masking tape on the wood

where the cut will be made. Saw through the tape and

carefully remove it when the cut is finished.

Setting the Workpiece

Unplug and unplug the saw.

If you are unable to secure the workpiece on the table

and against the guide by hand (irregular shapes, etc.)

or if your hand is less than 15 cm from the blade, a

fastener or other fixation method should be used.

Other accessories such as spring clips, bar or “C”

press may be suitable for certain sizes and shapes of

material. Be careful in the selection and placement of

these fasteners. Make sure to test with the tool off

before making the cut.

Support for Long Pieces

Unplug and unplug the saw.

ALWAYS SUPPORT LONG PARTS.

Support long pieces using any convenient shape such

as easels or similar structures to prevent the ends from

falling.

CHECK THE MAKSIWA CATALOG AND FIND

PRODUCTS FOR THIS FUNCTION. Cutting Frames,

Boxes and Other Parts with Four Sides

To better understand how to make the items listed

above, we suggest that you do some simple projects

using wood scraps until you develop a certain skill with

your saw.

Your saw is the perfect tool for cutting corners in

frames. The adjustment of the square to chamfer the

ends of two boards at an angle of 45º each produces

a corner of 90º. For this joint, the square arm must be

locked at 45º. The wood must be positioned with the

wide, flat side against the table and the thin portion

against the guide. The cut can also be done by cutting

to the right and left with the wide surface against the

guide.

The following table provides the appropriate angles for

a number of shapes. The table assumes that all sides

are the same length. For a format that is not shown in

the table, use the following formula: 180º divided by

the number of sides is equal to the angle of the

chamfer or the square.

9

Examples

Number of sides Chamfer or Square angle

4

45º

5

36º

6

30º

7

25,7º

8

22,5º

9

20º

10

18º

Cutting Compound Frames

A composite frame is a cut made using a square angle

and a chamfer angle at the same time. This type of cut

used to make frames or boxes with slanted sides.

NOTE: if the cutting angle varies from cut to cut, check

that the chamfer firing button and the square lock

button are securely tightened. These buttons must be

pressed after any changes to the chamfer or square

have been made. The table shown will help to select

the appropriate settings for chamfer and square for

cutting common frame compounds.

Cutting of frames

In order to make a proper adjustment, the frames must

be cut very precisely. The two flat surfaces of a frame

have angles that, when joined, add exactly 90º. Most

frames have an upper back angle (the side that goes

against the flat part) of 52º and a lower back angle

(the side that goes against the wall) of 38º.

In this case, doing preliminary tests with patchwork of

frames is very important! Place the lower part (which

goes against the wall) against the guide of the miter

saw. Place the upper part (the one that goes against

the flat part) against the saw table and the frame

guide.

Instructions for cutting angular frames between

the guide and the saw table, for all types of cuts:

1. Place the frame so that the bottom

of this (the one that goes against the wall when

affixed) is against the guide and the upper part of

the frame against the saw table.

2. 2. The miter plans at the rear of the frame must fit

directly on the guide and the saw table.

3. 3. Check the cuts so that they are flat, thus

avoiding free spaces for their accuracy.

INTERNAL CORNER:

Left side

1. 45º left cut

2. Keep the left side of the cut

Right Side

1. 45º Right cut

2. Keep the right side of the cut

EXTERNAL CORNER:

Left side

3. 45º left cut

4. Save the left side of the cut

Right side

3. 45º straight cut

4. Keep the right side of the cut

SPECIAL CUTS

NEVER MAKE A CUT IF THE MATERIAL IS NOT

SECURE ON THE TABLE AND GUIDE.

Aluminum Cutting

Use only specific discs for this cut. The instructions for

aluminum, such as those used to make frames, rails

etc., can be easily executed with the saw, using a disc

for cutting non-ferrous metals. Place the material so

that the thinnest part is exposed to the cut. When

cutting aluminum, use wax lubricant. Apply the wax

directly to the disc before cutting. Never apply wax

when the disc is in motion. The wax available in most

tool stores or in deposits of industrial suppliers offers

adequate lubrication and prevents the frames from

damaging the cutting disc. Make sure you have

properly fixed the part. Due to their size, shape and

surface finish, some parts may require

10

press, a mold or any other element to prevent

movement during cutting.

Arched Material

When cutting a material that is arched, position it with

the hollow facing the front of the equipment, and never

facing the side guides. The incorrect position of the

material may cause it to tighten the disc before

finalizing the cut.

Cutting of Plastic Tubing and Other Circular

Cross-Cutting Materials

The plastic tubing can be easily cut with your saw, just

like cutting wood. For this, the material must fit firmly

against the guide in order to prevent its movement,

particularly when making angular cuts.

1. All fixed parts of the saw are sealed. They are

permanently lubricated and require no

maintenance.

2. Clean and remove all dust and wood chips from the

surroundings and under the base and rotary table

periodically. Even if there are consoles to allow that

waste to drain, there will be

3. the accumulation of dust.

4. The bushings are designed to provide several years

of use.

Important: To maintain security and reliability

of the product, repairs, maintenance and adjustments

should only be carried out by authorized technical

assistance that will use identical parts for replacement.

Frequent Troubleshooting Guide Be sure to follow the

safety rules and instructions according to the table

below.

CAUTION: The use of any accessory not

recommended as a set for cutting channels, cutting

frames or discs abrasives, can be dangerous.

TECHNICAL ASSISTANCE

For your greater safety, entrust repairs, maintenance

and adjustments (including inspection and

replacement) to the technical assistance

recommended by MAKSIWA, which will always use

genuine spare parts and accessories, reassembling

your saw in the same way as the original.

The use of this tool for professional or industrial

purposes is not recommended by MAKSIWA. Before

using an extension cord, check for loose or exposed

wires, damaged insulation and defective fittings.

Repair or replace the extension if necessary.

Imported by Maksiwa USA Inc.

4100 N Powerline Rd, Suite D3 Pompano Beach, FL 33073

www.maksiwa.com

754-205-6717

MAINTENANCE

ISSUE CAUSE HOW TO FIX IT

Saw doesn't turn on

The saw is not connected to power Connect the saw

There is a burned fuse Exchange the fuse

The switch is open. Close the switch

The wire is damadged Exchange the wire at a authorized workshop

The coals have worn out. Replace the coals at an authorized workshop.

Saw doesn't make

satisfactory cuts

The disc is not sharp. Exchange the disc

The disc is mounted upside down. Switch the position of the disc

The disc is dirty. Take off the disc and clean it

Wrong disk for the job type. Exchange the disc

Part is poorly fixed. Fix the part properly to your saw.

The angle scale is not adjusted. Check and adjust the scale.

The disc is not aligned with the guide. Check and adjust.

The disc is not perpendicular to the table. Check and adjust according to the instructions.

The moving work table. Fit the workpiece to the guide.

The disc does not

reach working speed.

Extension cable too thin or too wide. Replace with a suitable extension.

Dirt preventing movement of the disc. Remove the disc and clean it.

The electric current is too low (oscillating). Contact your power supplier

The machine vibrates

excessively.

Saw incorrectly attached to the table. Check the assembly instructions.

Table or bench with uneven surface r. Place the saw on a suitable surface.

The saw blade is damaged. Replace the disc.

The material

damages the disc.

It is cutting arched material. Place the part according to the instructions.

Material in disagreement with the instructed. See instructions for materials.

Table of contents

Other MAKSIWA Saw manuals

Popular Saw manuals by other brands

Black & Decker

Black & Decker BDCCS20 instruction manual

Gude

Gude GWS 600 EC 230 Volt Translation of the original instructions

Scheppach

Scheppach Deco-flex instruction manual

Holzmann

Holzmann DKS 21PRO user manual

DeWalt

DeWalt DE3000 instruction manual

Powermatic

Powermatic 64B Operating instructions and parts manual