MAKSIWA BMS.3200.IR User manual

1

BMS.3200.IR

INSTRUCTIONS MANUAL

S. C. Sliding Panel Saw 3200 mm

Attention: Read this manual before using the machine.

2

INSTRUCTIONS MANUAL

Important information you need to know:

Read all of these instructions. Failure to follow all of

these instructions listed below may result in personal

injuries and damage to the equipment.

SAVE THIS MANUAL

ATTENTION: When you use electrical equipment,

always follow the safety measures to reduce re

hazard,electrical shock and personal injuries, including

but not limited to:

1. WORK AREA:

• Maintain a clean work area. Messy work spaces are a

huge cause of work related accidents.

• Do not use saws in dangerous areas. Do not use

electronic tools in humid areas, wet areas, exposed to

rain, in the presence of liquids or ammable gasses.

Maintain your work area well illuminated.

• Maintain kids away from the machine. All visitors

should maintain a safe distance to avoid injuries.

• Maintain kids away from the machine. Utilize locks

to lock the machine’s main power switch, activate

the emergency buttons and un-plug the machine to

prevent it from being turned on.

2. ELECTRONIC SAFTY

Make sure that your outlet is in accordance with the

machine. An increase or decrease of 10% in the voltage

may cause the machine to malfunction or even get

damaged. All of MAKSIWA’s tools are tested in our

factories. In case this machine does not work, check

your power supply.

CAUTION: WHEN DOING MANTNENCE ONLY SWAP

PARTS FOR IDENTICAL PARTS

• Fix or change damaged wires.

• The plug of the equipment needs to be compatible

with the outlet. Never modify the plug. Do not use

a plug adapter with this equipment. By note using

adapters and using only compatible sockets you

reduce the risk of electric based injuries.

• Avoid physical contact with any component

connected to your ground wires. There is an increase

in getting electrocuted if you are in direct contact

GENERAL SAFTY GUIDELINES

with such components.

3. PERSONAL SAFETY

• Be alert, look at what you are doing and use common

sense when using this tool. Do not use this tool if you

are tired, under the inuence of any drug, alcohol or

medicine. A moment of distraction when operating

this machine could cause severe injury.

• Always use safety glasses, mask agents the dust,

shoes that do not slip, gloves, and ear plugs to reduce

any risk.

• Use adequate equipment. Do not use large clothes,

gloves, chains, rings, bracelets or other accessories

that may get snagged on the moving parts. It is

recommended that you use shoes that do not slip.

Use hair protection so it can’t get snagged on the

equipment.

• Do not stretch yourself out to reach something.

Always maintain your balance to avoid falling on the

sawblade.

• Unplug the machine before doing any maintenance

on it including, but not limited to, removing the saw

blade.

•Reduce the risk of unintentionally turning the

machine on by always checking it the main power

switch is o before plugging the machine in.

• Use only recommended accessories. Consult the

instructions manual to validate it the accessories is

recommended. Use of inappropriate accessories may

increase the risk of accidents.

• Never step on the machine nor clime on top of

it. Sirius accidents may occur to either you or the

machine if you do.

4. HOW TO USE AND MAINTAIN THE EQUIPMENT

• Only make cuts with sharp blades. Dull blades do

not cut well and put too much strain on the motor.

• Do not force the equipment. If you are feeling a

resistance, remove your panel and look around to nd

the issue. Forcing your equipment will only increase

risk of injury and/or damaging the equipment.

• Use the appropriate equipment. Do not force the

machine to cut something it was not meant to.

ALWAYS USE THE APROPRIET SAFTY

EQUIPMENT WHEN OPERATEING THIS

EQUIPMENT.

3

• Fixate the panel that will be worked on. Use clamps

to hold down panels and press it against the guide.

Be attentive when holding the panel to not cut your

hand.

• Maintain the equipment sharp and clean for a much

easier and safer work environment and production.

Follow the cleaning, accessories change and

lubrication instruction.

• Check any damaged component before continuing

to use the equipment. Any damaged component must

be examined in detail to determine if the damage

hinders its performance. Verify the alignment of any

moving part that is damaged before use. Any safety

equipment that is broken and no longer serves its

function adequately needs to be xed or changed

immediately. Do not use the equipment in case the

circuit breaker does not turn on or o.

• Never leave a machine working alone, always have

someone supervising it. Turn of the main power

switch. Motors may emit a small electrical discharge

and ignite ammable gasses.

WARNING: FAILURE TO FOLLOW THESE WARNINGS

MAY RESAULT IN ACIDENTS TO YOU OR THE

MACHINE.

• DO NOT operate this machine until it is assembled in

accordance with the instructions.

• PROTECT the power supply cable with a minimum

of a 30 amps fuse or a circuit breaker.

• CONFIRM that the blades are spinning in the

correct direction. The main blade’s top teeth should

be pointing and spinning towards the front of the

machine (where the buttons are) while the scoring

blade should be pointing and spinning towards the

back of the machine (away from the buttons).

• CHECK the washers and nuts of the blades to see

if they are clean and tighten. The washers and nuts

need to be pressing the blade together with no lth in

between to avoid accidents.

• MAINTAIN a sharp blade.

• MAINTAIN the tubes for the motor free of any pieces

of wood and lth.

• ALWAYS use a guard protected for the blade.

• ALWAYS maintain your hands away from the path

of the blades.

• TURN OFF the machine, disconnect the power

cable and wait till the blade stops spinning before

attempting to do any maintenance.

• ALWAYS support long panels with clamps or other

similar devices.

• DO NOT attempt to use the machine in a voltage

that it was not designed to handle.

• DO NOT use blades bigger nor smaller than the

recommended.

• DO NOT put anything inside of the motors.

• DO NOT force the machine to cut if it is giving

resistance. A partial or full stop of the motor caused

by forcing a cut may result in damages to the motor.

Wait until the motor is running at full speed before

continuing.

• DO NOT attempt to cut metals, concrete nor cement.

• DO NOT use sanders nor sand paper on the machine.

The heat generated and the particles emitted may

damage the machine.

• DO NOT allow anyone behind the machine.

• DO NOT apply any type of grease nor lubrication

on the blade if it is in motion.

• DO NOT put any of your hands near the blades when

the machine is receiving power.

• DO NOT use blades designed for less than 5,500

RPM

• DO NOT cut small pieces with ought clamps. Maintain

your hands away from the blades.

• DO NOT operate the machine with ought any guides.

• DO NOT cut anything with ought holding it.

• DO NOT grab anything in front of or behind the

blades with your bare hands.

• DO NOT put your hands less than 5 inches away

from the blades.

• DO NOT put your hands below the machine unless

the machine is o and un-plugged.

• DO NOT remove your hands from the panel until it

has been completely removed from the blades.

ADITIONAL SAFTEY RULES FOR

CIRCULER SAWS

4

The BMS.3200.IR is a sliding panel saw tailor made

to provide high quality precise cuts in diverse angles

with a max cut depth of 4 inches (100 mm) at 90º.

It includes a 5 CV motor, cutting guides, miter guide,

blade guard. The noise level of this equipment is 76.5

dB (the machine turned on only) up to 110 dB (with

the machine on and the exhaust system on. The noise

will vary in accordance with the location the machine

is in and the materials used).

Specications

• General:

- Weight: 1,470 LBS

- Machine dimensions (closed): 130” X 126” X 48’’

- Machine dimensions (max): 180” X 262” X 48’’

- Mobile table dimension: 14 11/64” X 125 63/64”

- Mobile table max travel length: 262”

- Fixed table max width: 49 7/32”

- Guide size (closed): 67”

- Guide size (max): 120’’

• Electric - Main motor:

- 3 Phases

- 220V

- 5 HP

- 10 Amps

- Non-loaded blade speed: 4,000 RPM

• Electric - Scoring motor:

- 3 Phases

- 220V

- 3/4 HP

- 1.5 Amps

- Non-loaded blade speed: 4000 RPM

- Non-loaded scoring blade speed: 8000 RPM

- Does not come with an outlet wire

• Blade:

- Main blade diameter: 13 25/32”

- Main blade arbor size: 1 3/16”

- Scoring blade diameter: 4 ¾’’

- Scoring blade arbor size: 25/32”

- Max tilt: 45°

- Max depth cut: 3 15/16”

- Max cutting length: 125 63/64”

• Dust collection:

- Port 1 diameter: 4’’

- Port 2 diameter: 4’’

- Minimum CFM needed: 600 CFM

NOTE: Pictures and illustrations contained in this

manual are only ILLUSTRATIONS and may not reect

the color, tags or accessories and is present to only

demonstrate the technique.

• DO NOT use the machine if it is not xated properly.

• DO NOT grease nor lubricants nor any cleaning

product (sprays in particular) around plastic guards.

The materials used to make them are highly sensitive

to chemicals and may cause damage.

• AVOID KICKBACKS (when the panel moves back

unintentionally) by maintaining the blades sharp,

clean, maintaining the guide on the mobile table in a

right-angle position relevant to the blades,maintaining

the guide from the immobile table in parallel to the

blades, and utilize all the safety equipment from the

machine.

• DO NOT make longitudinal cuts on a piece that is

twisted, deformed or does not had a at side to use

as a guide.

• ALWAYS use a Push Stick to push loose pieces,

never use your hands and you risk injuring yourself.

• NEVER cut a big piece that cannot be clamped

down on the machine.

• NEVER orientate yourself based on the cutting

guide when making a transverse cut.

• NEVER cut wood knots nor other deformities on the

wood.

ATENTION: Some dust caused by the act of sanding,

cutting, molding, drilling, and other activities related

to construction contain chemicals that may cause

cancer, birth defects, and other raspatory problems.

Some examples of this products are: lead based paint;

crystal of silica bricks, cement and other masonry

products; and arsenic and chromium from chemically

treated woods.

CAUTION: Do not connect the equipment to an outlet

before reading and understanding all the instructions.

Always tighten the adjustable tabs before utilizing the

equipment. Maintain your hands at least 6 inches (15

cm) from the blade. Never utilize the machine with

free hands. Never cross your arms on the equipment.

Always think “What can I do to prevent accidents?”

Do not operate the equipment with ought taking the

necessary safety measures. Never put your hands

on the saw blade. Always utilize protection goggles.

Always turn o the machine and wait for the blade

to stop spinning completely before preforming any

adjustment, cleaning and reassuming your task.

FUNCTIONAL DISCRIPTION

5

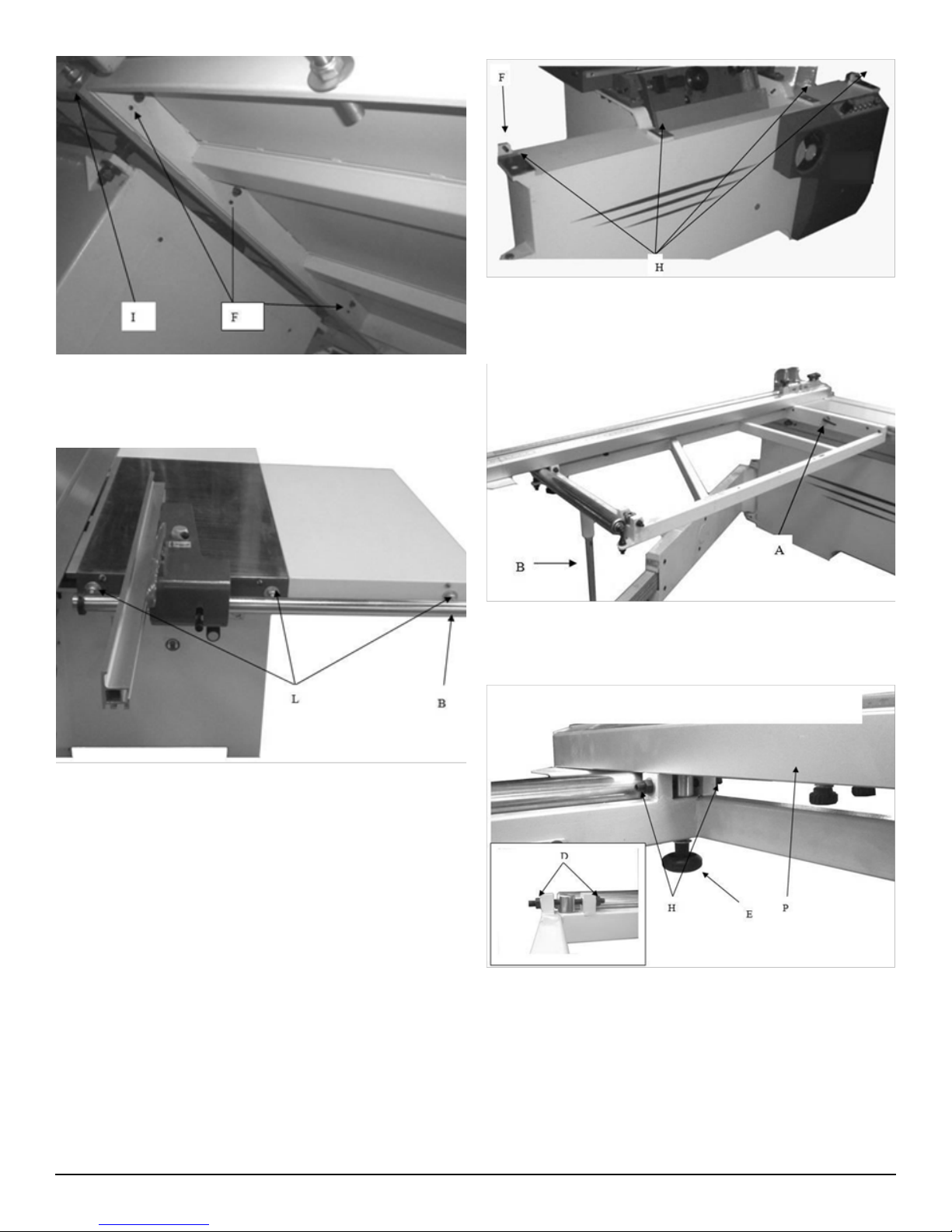

Install the equipment on top of a at surface. The next

section will talk about the necessary adjustments

needed to maintain your equipment running at its

best and the illustrations will refer to these steps.

For this you need to know the parts and know where

they are located. The name of each component will

be accompanied by a number and/or letter for its

respective part on the illustrations.

Transportation and Installation

For packaging reasons, the equipment is not fully

assembled. If you notice any damage that occurred

when transporting the equipment or while you are

opening the equipment, notify the store where you

bought it from immediately. Do not turn on the

machine. Remove the equipment from the crate with

cation. A lot of the parts are loose on either the top,

side or inside the equipment. Remove all the stretch

wrap from all the parts. You can clean the non-painted

areas of the equipment with a piece of cloth and some

solvent (be cautious as some solvents may damage

the paint). After cleaning the non-painted areas, you

can pass some wax on it.

REMEMBER TO DISCARD THE TRASH IN

ITS APPROPRIATE RECYCLING BIN.

TRANSPORTATION:

To move the equipment with a crane or a pallet jack/

fork lift follow the positioning indicated in the following

pictures avoiding contact with the nonstructural parts

(the thin metal sheets) of the equipment. Do not use

any equipment to lift this equipment if it can’t support

up to 2,200 LBS (1 metric ton).

Position the machine in accordance with your space,

remember to leave space for the sliding table along

with the necessary space for your panels. For greater

stability bolt the machine to the oor:

GET TO KNOW YOUR SLIDING PANEL

SAW

ASSEMBLY Assemble the remaining components which includes:

the mobile table, mobile table guide (3200mm), side

and back stationary tables, stationary table guide,

miter guide, stopper, blade guard, among others.

Since the equipment was already assembled in our

factory, you will not have any issues to assemble your

BMS.3200.IR.

CAUTION: Never remove the blade guard. It should

always be in the correct position at all times to avoid

any possible accidents.

STATIONARY TABLE:

Install the tables that extend the work top area for

the stationary table as it is depicted on the next

illustration.

6

Fixate the rail of the guide in the front of the stationary

table keeping in mind that the three parts need to be

parallel to each other:

Install the second part of the table and adjust the

Hight to suit your needs and install the guide on top

of the table:

In case you need to straighten out the guide you can

by adjusting the nuts and allen screw. The left most

nuts need to be tight at all times. If the guide is too

low or too high, adjust the allen screw underneath the

middle nut to move it up or down. Keep the middle

nut loose for now. To adjust the front tip of the guide

(the closest edge to the blade) to the left (towards

the blade) you will tighten the right nuts, to move it

to the right (way from the blade) you will loosen the

right nuts. After installing and adjusting it, cut some

boards to test it. In case you need to, you can always

re-adjust it.

SLIDING TABLE:

With the help of another person, install the sliding

table (3200mm) on the base of the equipment. Screw

it in place to hold rmly as seen in the illustration next

to:

To properly adjust the guide, and to straighten you

cuts, you will rst grab a panel and cut all four sides

by rotating the panel counter clock-wise. After you

did the fourth cut, you will place that side agents the

guide. Now you will cut once more then ip your panel

over so the side that you just cut is now on the opposite

side and the side that was touching the guide is still

touching the guide. Cut once more. Measure the side

that is touching the guide and the opposite side.

Fixate the guide Pon top of the sliding table and

adjust the screws underneath it to manipulate the

guide and to straighten out your cuts:

7

If the opposite side is larger then the side touching

the guide, you will loosen the left allen screw Hthen

tighten the right allen screw Hon the illustration above.

If the opposite side is smaller than the side touching

the guide, you will loosen the right allen screw Hthen

tighten the left allen screw H on the illustration above.

Repeat this until both sides are of equal sizes, cut all

four sides again and measure all four sizes to see if it

all matches. If it does not match, repeat these steps

until it matches.

SAW BLADE PROTECTION:

All of the safety systems need to be installed and

used at all times. Install the splitter (riving knife) with

a maximum distance of 8mm.

ENERGY:

With the machine still not plugged in, connect the

cable’s wires to the equipment.

Familiarize yourself with the front panel of your

equipment:

Spin the left knob to move the scoring blade up and

down while spinning the right knob will move the

scoring blade left and right. The scoring blade needs

to align with the main blade. To test if it is you will

grab a panel and pass it through the scoring blade

and only a little bit on the main blade. Then go back

and remove the piece. You will see both the Scoring

blade and the main blade cuts on the panel and can

make the adjustments as needed.

SAW BLADE INSTALLATION:

To install the main blade, you will use the provided

allen wrench and wrench. To remove the main blade,

hold the nut with the provided wrench and the allen

wrench in the middle and spin the wrench clock wise.

Allow only trained professionals to work on the

electrical wires of this equipment to avoid damages

and injuries.

CAUTION: Do not connect this equipment to an

outlet before reading and understanding all of the

instructions. This equipment can be connected to

a 220V 3 phase or 380V 3 phase outlet. Verify with

your electricity company what you have and then

verify both the motors and the transformer of the

equipment. Utilize a cable that is at least 2,5mm².

DUST COLLECTOR PORT:

An adequate dust collection system needs to be

connected to both exhaustion ports (one on top of the

blade guard and one on the side of the equipment)

for a cleaner and safer work area. Consult Maksiwa’s

catalog for several dust collection options.

FRONT PANEL:

A – Blade angle adjustment weal

B – Blade angle indicator

C – LED power indicator

D – Main saw blade on button

E – Scoring blade on button

F – O button

G – Emergency o button

SCORING BLADE:

The scoring blade can be adjusted in accordance with

the pictures below.

8

The blade will always spin clock wise so when putting

your blade conrm that the teeth are pointing clock

wise. For the scoring blade it is the same but mirrored.

Spin the nut counter clock wise to loosen and the

teeth must face counter clock wise when putting the

blade.

Always check to see if the blade is fastened properly

before turning on the machine. Test the blades if

needed.

MOTOR BELT:

Adjust the tensioner Aindicated to adjust the tension

in accordance with your necessities.

Always check the tension of the belt every 500

hours of use. Always preform this with the machine

unplugged.

STATIONARY TABLE GUIDE:

To adjust the only the guide for the stationary table,

release leaver Aand move the guide forward and

back. To move the entire part, release Bto move it.

PUSH STICK:

The push stick needs to be used to maintain your hand

at least 150mm (5’’) from the blade to avoid injuries.

It is a safety precaution to reduce the risk of cutting a

nger o with a cut on the tip to help push the panel

safely.

You can use the provided push stick or make your

own. The push stick needs to be thinner then the

panel that it will be pushing. See the diagram below

for an example (illustration C).

9

NOTE: Your BMS.3200.IR was adjusted in the factory

during its fabrication. In case it needs to be re-adjusted

because of the transportation or any other reason,

follow the following steps. Once these adjustments

are done they will stay correct. Follow these steps

carefully to maintain your equipment’s precision.

Connect the equipment in an outlet that matches

your equipment’s voltage and phase. Certify that the

wire is not in your way to avoid possible accidents.

HAND AND BODY POSITIONING

The correct hand and body position during the use of

this equipment will make the cut easier, precise and

safer. Never put your hand close to the blade. DO not

put your hand any closer than 15 cm (6”) of the blade.

Hold the piece rmly agents the guide during the cut.

ALWAYS RUN A TEST (WITHOUGHT TURNING THE

MACHINE ON) BEFORE YOU DO ANY CUTS TO

VERIFY THE BLADE’S PATH. DO NOT CROSS YOUR

HANDS IN FRONT OF THE EQUIPMENT.

CUTTING WITH YOUR BMS.3200.IR

NOTE: Although your equipment can cut wood and

other materials non-metal based, we will only be

discussing cuts with wood. The same parameters will

apply to any material though. DO NOT USE SAND

DISC BLADES.

TRANSVERSAL CUTS

It is not recommended to cut multiple panels together

but it is possible if the panels are safely and rmly

held down on the table and against the guide. A

transversal cut is made when you cut a panel in the

opposite orientation to the bers of the wood in any

angle. A straight transversal cut is done with the blade

at 0º. Put the miter gauge at 0º, hold the wood rmly

agents both the guide and the miter gauge. Turn

the equipment on. When it is at max speed (about

1 second) move the panel smoothly forward to cut

the wood. Transversal cuts are usually made with the

miter gauge at an angle greater than 0º. This angle is

usually 45º to make corners but can be adjusted from

0º to 45º. After selecting your angle, tighten the knob

on your miter gauge and make the cut as described

above.

BEVEL CUTS

A bevel cut is a cut made with the blade at an angle.

To adjust the blade, you need to spin the Blade angle

adjustment weal and the height of the blade. After

you have the desired angle, put your miter gauge at

FUNCTIONALITY 0º against the panel and tighten it. The blade can tilt

up to 45º.

QUALITY CUT

The quality of the cut depends on several factors such

as the type of material being cut, the type/quality of

the blade being used, how sharp the blade is, etc…

When you want smoother cuts for precision cuts, a

sharp blade with 80 or more teeth is recommended

along with moving the sliding table slowly. Certify that

the panel being cut is held down rmly by locking it

down. In case small bers start to splinter out of your

panel when you cut you can put a piece of tape along

where you will cut, cut as normal along the tape then

peel o the tape slowly.

FIXATING THE PANEL

To xate the panel, use the provided miter gauge and

clamp to hold it down. If you decide to use a dierent

tool, turn your equipment o rst and test it with the

machine o. Remember to keep your hands at least 15

cm (6”) away from the blade. Be cautious and mindful

of your safety when selecting a new clamp or tool.

Thoroughly test it before using it.

SUPPORT FOR LONG PANELS

Turn o the equipment rst and foremost. ALWAYS

SUPPORT LONG PANELS. Support long panels using

any available support to avoid the panel from falling.

Consult Maksiwa’s catalog for several roller stand

options.

CUTTING 4 SIDED PANELS

To better understand the above-mentioned cuts, we

recommend you start with small and simple projects

to get use to your new equipment. The beveled cut

of 45º onto two panels will make a 90º corner. The

following table will show you what angle you need to

set the equipment to in order to make a perfect shape:

Number of sides Angel of the blade

4 45º

5 36º

6 30º

7 25.7º

8 22.5º

9 20º

10 18º

10

MAINTENANCE

1. All of the locked and soldered components do not

need maintenance.

2. Apply the correct oil on the parts that move only

when the equipment is completely clean.

3. Clean and remove all the saw dust and pieces of

wood periodically. Even if you use dust collectors

there may still be pieces that remain as they are not

perfect.

4. The parts were projected to las for several years of

use and should not break easily.

For your own safety always check the repairs and

adjustments made before using your equipment.

Always contact Maksiwa to get recommended

technicians and appropriate parts that will work on

the equipment and maintain its quality. Before using

any extension cords verify if it has any lose or exposed

wires. Swap the extension cord if necessary.

Imported by:

Maksiwa International Inc.

2707 NW 19th St

Pompano Beach, FL, 33069

Oce: (754) 205-6717

Toll free: (844) 319-6594

e-mail: customer.service@maksiwa.com

www.maksiwa.com

TECHNICAL ASSISTENCE

Other manuals for BMS.3200.IR

2

Table of contents

Other MAKSIWA Saw manuals