Malloca THETA K1520 User manual

1

Please Read The User Manual Carefully!

CHIMNEY HOOD

USER’S MANUAL

INSTRUCTIONS FOR INSTALLATION

AND USE

THETA K1520

2

1. TECHNICAL DRAWING 3

2. WARNING AND SAFETY PRECAUTIONS 4

2.1 Life-Threatening Danger, Poisoning Danger 6

6

2.3 Danger of electric shock! 6

2. 4 Danger of physical injury! 6

2.5 Danger of burn, danger of electric shock! 7

7

3. USAGE WITH AND WITHOUT CARBON FILTER 8

3.1 Replacement of Carbon Filter 9

3.2 Replacement of Carbon Filter 9

3.3 AF 500 Carbon Filter 9

4. CLEANING AND PREVENTIVE MAINTENANCE 10

4.1 Washing in Dishwasher 10

4.2 Hand Wash 10

4.3 Removal/Installation of Aluminium Filter 10

5. INSTALLATION OF APPLIANCE 11

5.1 Installation and Unpacking of the Appliance 11

5.2 Installation and Unpacking of the Appliance 11

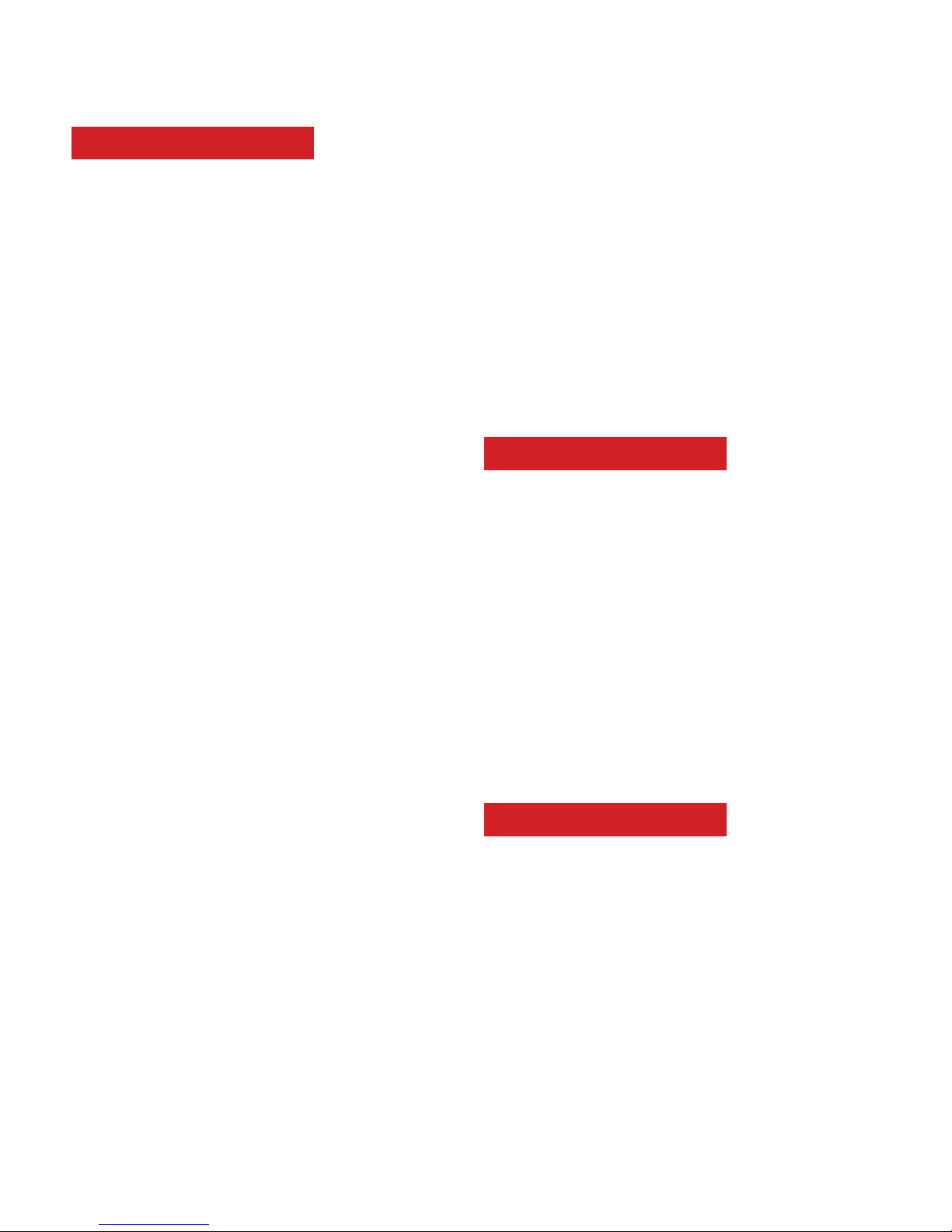

6. CONTENT OF PACKAGE 13

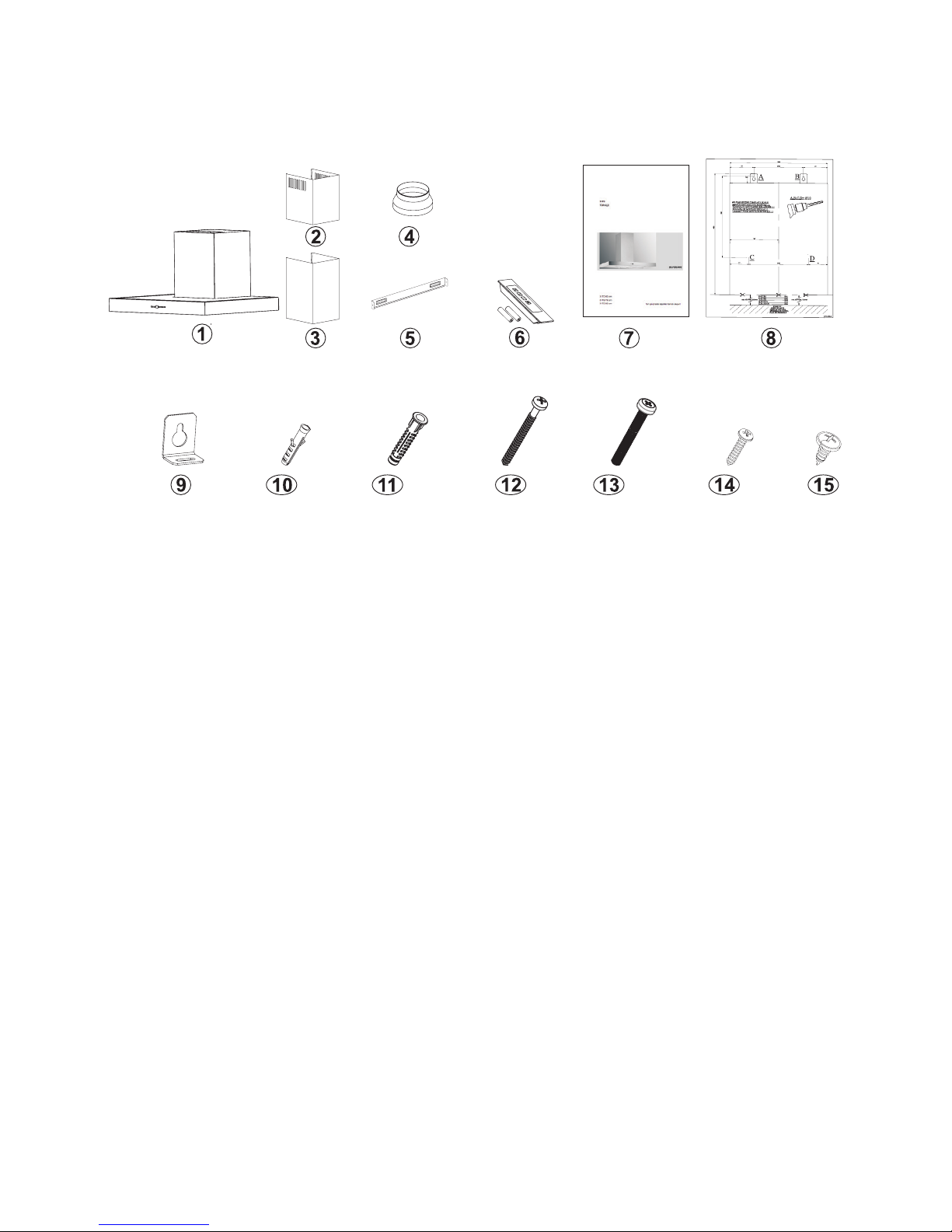

7. OVERVIEW OF COOKER HOOD 14

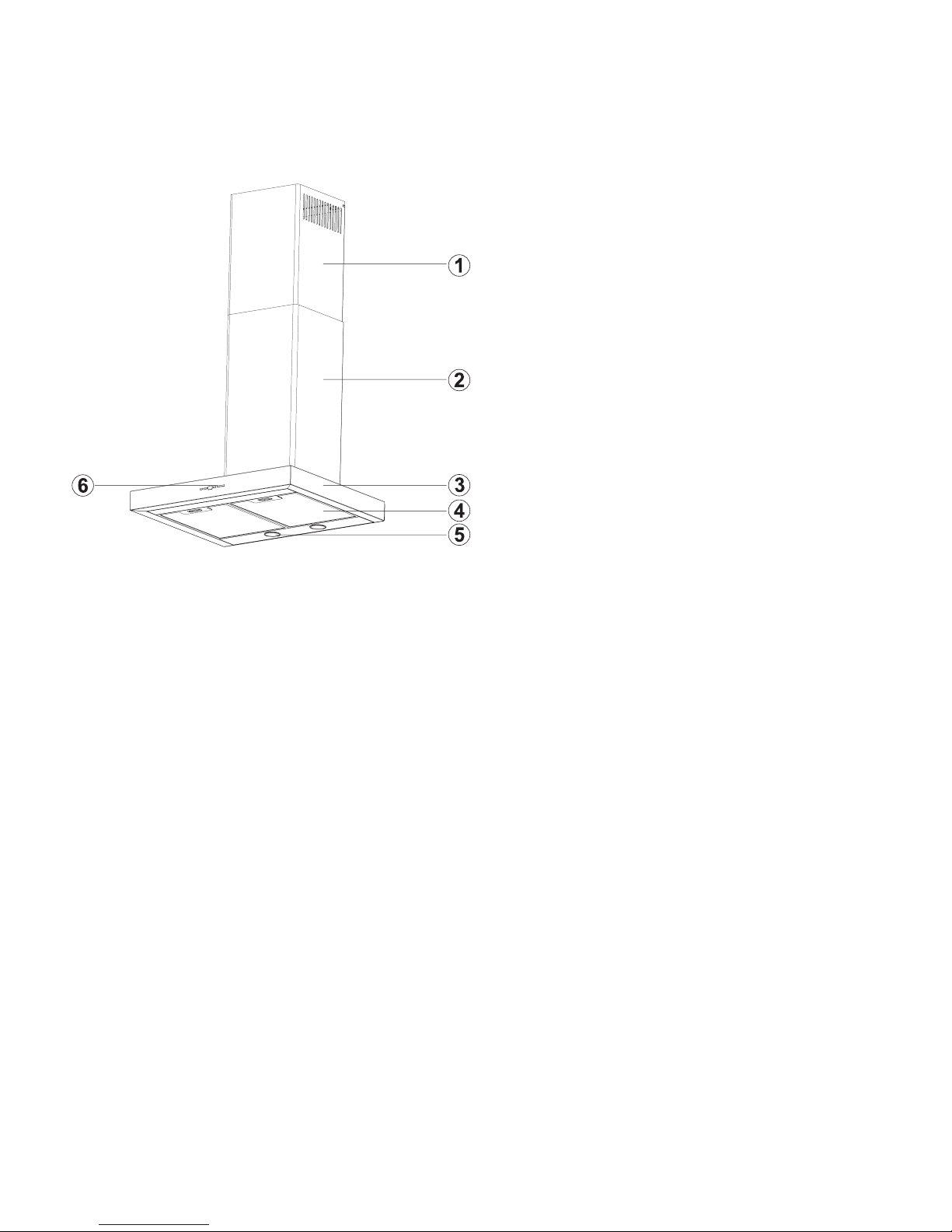

8. ASSEMBLY OF PRODUCT 15

8.1 Installation Template 15

8.2 Installation Diagram and Components 16

9. ASSEMBLY OF SHEET METAL FLUES 17

10 USE OF PRODUCT 18

10.1 3 Spd Touch Button 18

11. REPLACING THE LAMPS 19

11.1 Replacement of Halogen Lamp 19

11.2 Replacement of Spark Plug Lamp 19

12. AUTHORIZED SERVICE 20

12.1 Potential Failures and Solutions 21

12.2 Technical Table 21

3

1. TECHNICAL DRAWING

900

Fig. 1: TECHNICAL DRAWING

4

2. WARNING AND SAFETY PRECAUTIONS

■This appliance can be used by children

aged from 8 years and above and persons with

reduced physical, sensory or mental capabili-

ties or lack of experience and knowledge if they

have been given supervision or instruction con-

cerning use of the appliance in a safe way and

understand the hazards involved.

■This product is designed for home use.

■Usage voltage of your product is 220-240

Volt~50 Hz.

■ Power cord of your product is tted with a

grounded plug. This cord must be plugged into

a grounded outlet.

■The whole electrical wiring must be installed

by a qualied electrician.

■Installation by unauthorized persons could

lead to poor operation performance, damage to

the product, and accidents.

■Feeder cable of the appliance mustn't be ex-

posed to jamming or crashing during assembly.

Feeder cable mustn't be placed near the cook-

er. In such cases, it might melt down and lead

to re.

■Do not plug in the appliance before the in-

stallation.

■Make sure that the installation place allows

the user to easily unplug the power cable in

case of any danger.

■Do not touch your product's lamps when

they work for a long time. Since they would be

hot, they could burn your hand.

■Kitchen cooker hoods are designed for nor-

mal cooking and home use. For uses other than

specied, there is the risk of failure and the ap-

pliance becomes out of warranty.

■Comply with the regulations of the authori-

ties on the discharge of outlet air.

(This warning does not apply to uses without

ue.)

■Flammable foods must not be cooked under

the appliance.

■Turn on the appliance after placing a sauce-

pan, pan, etc. on the cooker. Otherwise, high

temperature might lead to deformation on some

components of your product.

■Turn off the cooker's burner before taking

the saucepan, pan, etc. off the cooker.

■Do not leave hot oil on your cooker. Pots

that contain hot oil might lead to inammation.

■ Since oils could catch re when you cook

fried foods in particular, be careful about your

curtains and tablecloths.

■ Ensure timely replacement of the lters. Fil-

ters not replaced in a timely manner pose risk

of re due to accumulated grease deposits on

them.

■ Do not use non-re-resistant ltering materi-

als instead of the lter.

■ Do not operate your product without lter,

and do not remove the lters when the product

is in use.

■ In case of any deagration, de-energize the

cooker hood and cooking appliances. (Plug off

the appliance or turn off the main switch).

■If your product's periodic cleaning is not

made in a timely manner, it could pose risk of

re.

■De-energize the appliance before any main-

tenance operations. (Plug off the appliance or

turn off the main switch.)

■When electric cooker hood and devices

fed with energies other than electricity operate

simultaneously, the negative pressure in the

room must not exceed 4 Pa ( 4 X 10 bar ).

5

■Gas or fuel oil burning appliances, such as

room heaters, which share the same environ-

ment with your product, must be fully insulated

from the exhaust of this product or they must be

hermetical.

■ When you make a ue connection for your

product, use pipes with a diameter of 150mm

or 120 mm.

■The length of the pipe connection as well as

the number of elbows must be as minimum as

possible.

■Children must not play with the appliance.

■For your safety, use ”MAX 6 A” fuse in the

cooker hood system.

■Since the packing materials could be dan-

gerous, keep them away from children.

■If the feeder cable is damaged, it must be

replaced by its manufacturer or authorized tech-

nical service or any other personnel qualied at

the same level, in order to avoid any dangerous

situation.

■ In case of any deagration, de-energize the

cooker hood and cooking appliances, and cov-

er the ame. Never use water to extinguish the

re.

■When cooking appliances are in operation,

their accessible parts could be hot.

■This appliance is not intended to be used

by people with physical, sensory and mental

disabilities (including children) or those who

have not adequate experience and knowledge

regarding its use, unless they are under the su-

pervision of a person responsible for the safety

of the appliance.

■After the installation of the cooker hood, the

minimum distance must be 65 cm between the

product and any electric cooker; and 75 cm be-

tween it and any gas ranges or cookers burning

other fuels.

■Output of the cooker hood must not be con-

nected to air ducts, where there exist another

smokes.

■You must be careful when using the appli-

ance spontaneously with other appliances (e.g.

gas, diesel fuels, coal or wood burning heaters,

shower heaters, etc.)

■Attention must be paid when using them

simultaneously. Because the cooker hood

could adversely affect the combustion, by

discharging the ambient air.

This warning does not apply to uses without

ue.

■When electric cooker hood is used simulta-

neously with devices that use gas or other fuels,

there must be sufcient ventilation in the room

(might not apply to devices that discharges the

air back into the room).

■Simultaneous operation of more than one

gas cooker leads to generation of high heat. A

ventilation appliance placed on the surface of

cookers might therefore get damaged or burn.

Do not operate two gas cookers in high heat for

more than 15 minutes. One large burner with

more than 5kW (Work) power generates power

equal to that of two gas burners.

6

2.1 Life-Threatening Danger, Poison-

ing Danger

DANGER

There are life-threatening danger and poisoning

danger due to reabsorbed combustion gases.

During the air discharge outlet use, unless suf-

cient air supply is provided, do not use the appli-

ance simultaneously with devices that discharge

toxic gases through ue such as ventilated, gas,

oil, wood or coal burning heaters, shower heat-

ers, water heaters, etc.

Fig. 2: Poisoning Danger

Ventilated devices (e.g. gas, oil, wood or coal

burning heaters, shower heaters, water heat-

ers) take combustion air from the installation

location, and discharge the waste gas through

a waste gas system (e.g. ue). When the cook-

er hood is active, it absorbs air from the kitchen

and neighbouring rooms. If adequate air entry is

not provided

vacuum emerges. In such a case, the toxic gas-

es are absorbed from the ue and waste gas

channel, and are taken into to door again. Fig. 2

Therefore, adequate fresh air ingress must al-

ways be ensured. Fig. 3

Fig. 3

DANGER

2.2 Risk of re!

Due to sparkling. Installation of appliance over

a heating device that is heated by using solid

fuels (for ex. wood or coal) is only allowed if an

non-detachable cover is present. For the instal-

lation process, attention must be paid to current

applicable construction regulations and regula-

tions of local electric and gas companies.

Appliance might lead to re unless it is produced

in accordance with cleaning instructions.

DANGER

2.3 Danger of electric shock!

Do not bend or jam the connection cable during

installation due to danger of damaged connec-

tion cable.

DANGER

2. 4 Danger of physical injury!

■During the installation, there is a danger

of physical injury due to the sharp edges. Use

protective gloves throughout the installation pro-

cess of the appliance.

■Due to risk of dropping the appliance, as-

sembly of all safety bolts and covers must be

performed as specied in the user manual.

7

2.5 Danger of burn, danger of elec-

tric

shock!

DANGER

■Allow the appliance to cool before cleaning or

maintenance process. Switch off the fuse or pull

out the mains plug from the socket.

■There is risk of damage due to ingress of mois-

ture in the electronics. Do not clean the control

components with a wet cloth.

■The surface could be damaged due to a wrong

cleaning process. Clean stainless steel surfac-

es only in their brushing direction. Do not use a

stainless steel cleaner for the control elements.

■The surface could be damaged due to aggres-

sive and abrasive cleaning agents. Never use

aggressive and abrasive cleaning agents.

■ There is risk of damage due to backow of

condensate. Mount the air outlet channel down-

wards from the appliance (slope of 1°).

DANGER

2.6 Dangers of re and physical

injury!

In case of repairing that is not performed accord-

ing to the rules or as required, turn off the fuse

or unplug the feeder cable of your appliance.

Repairing must be performed only by the autho-

rized technical service or authorized experts.

NOTE

If the appliance is faulty or damages, turn off the

fuse or unplug the feeder cable of your appliance

and call the authorized service.

NOTE

If the feeder cable is damaged, it must be

replaced by its manufacturer or its authorized

technical service or any other personnel

qualied at the same level, in order to avoid any

dangerous situation.

NOTE

If the bulbs of your appliance are faulty, turn

off the fuse or unplug the feeder cable of your

appliance. Replace the bulbs immediately to

avoid overload on other bulbs (wait for the bulbs

to cool down rst)

CAUTION

Accessible components might be heated when

used with cooking devices.

DANGER

Air outlet pipe of this appliance mustn't be con-

nected in the ue used to discharge the fume

generated by devices that use gas or other fuels.

8

You can use this appliance in exhaust air mode

and ventilated air mode.

Exhaust air mode

The absorbed air is cleaned by the grease lters,

and is discharged through a piping system. 4

Fig. 4: Air Outlet without Carbon Filter

WARNING

Death Risk!

Exhaust gases that are reabsorbed might lead to

poisoning.Exhaust air must not be transferred to

an active smoke or waste gas ue; or a ue used

for ventilation of the places, where heat sources

are installed.

■If you want to transfer exhaust air to an inac-

tive smoke or waste gas ue, you need to obtain

permission from an authorized chimney sweep.

■If exhaust air is discharged through the exter-

nal wall, a telescopic wall safe must be used.

Ventilated air mode

Absorbed air is cleaned by the grease lters and

an active carbon lter, and then it is transferred

back to the kitchen. 5

Fig. 5: Air Outlet with Carbon Filter

To retain the substances that lead to odour in

ventilated air mode, you must attach an active

carbon lter. Consult your authorized dealer for

various options available to use your appliance

in ventilated air mode. You can purchase the

accessories required for this process for related

sales points, authorized services or online sales

centre

3. USAGE WITH AND WITHOUT CARBON FILTER

9

3.1 Replacement of Carbon Filter

In environments without ue, active carbon lter

must be used for ltering the air and resending

it in. Active carbon lter must be supplied from

service or your dealer. De-energize the appli-

ance before replacing the carbon lter. Since

carbon lter is used in kitchens with no ue

outlet, it must be replaced in every 3-5 months

depending on the use.

Carbon lter must never be washed. Grease l-

ters must be installed in the product, regardless

of whether or not carbon lters are used. Do not

use your product without grease lter.

3.2 Replacement of Carbon Filter

Fig. 6: CARBON FILTER

The appliance you have purchased is

appropriate for use with carbon lters.

1. Place the carbon lter in its housing. Fig. 6

2. Rotating the carbon lter clockwise, ensure

that it is completely t. Fig. 6

3. If carbon lter does not t in completely, it

might drop and damage your product.

DANGER

Do not wash carbon lters. Keep the carbon l-

ters away from children.

3.3 AF 500 Carbon Filter

Fig. 7 AF 500 Carbon Filter

The appliance you have purchased is appropri-

ate for use with AF 500 carbon

lters.

• Place the lower part of the carbon lter to the

motor cabinet (Fig. 1).

• Press on the tab of the carbon lter and push it

forward, and ensure that the tabs of carbon lter

are engaged and locked (Fig. 1).

10

4. CLEANING AND PREVEN-

TIVE MAINTENANCE

CAUTION

■Prior to each maintenance and cleaning,

cooker hood must be unplugged, and appliance

must be dead

■Cleaning and user maintenance of the ap-

pliance shall not be performed by unattended

children.

■The surface could be damaged due to ag-

gressive and abrasive cleaning agents. Never

use aggressive and abrasive cleaning agents.

Supply your cleaning and protective substanc-

es that are appropriate for your appliance from

the authorized technical service. Surface of

appliance and control units are sensitive to

scratching.

■Clean the surfaces with a soft and damp

cloth, dish-washing liquid or mild glass cleaning

agent. Soften the dry, sticky dirt with a damp

cloth. Do not scrape!

■It is not appropriate to use dry cloths, sponges

that may scratch, materials that require rubbing,

and other aggressive cleaning agents contain-

ing sand, soda, acid or chlorine.

■Clean the stainless steel surfaces in their

brushing direction only.

■Do not use stainless steel cleaning agents

and wet clothes for control units. Cleaning of

metal grease lters Used metal grease lters

retain the greasy particles in the moisture and

vapour generated in the kitchen. Clean the met-

al grease lters about every three months, un-

der normal use conditions (1 to 2 hours a day).

■Do not use excessively effective, acidic or al-

kaline cleaning agents.

■ For cleaning the metal grease lters, clean

the holder parts of the metal grease lters in the

appliance, with a damp cloth as well.

■ You can clean the metal grease lters in the

dishwasher or by hand.

4.1 Washing in Dishwasher

■In case of washing in dishwasher, a slight

change might occur in colour. This has no effect

on the function of the metal grease lter.

■Do not wash the excessively dirty metal

grease lters together with dishes.

■ Place the metal grease lters loosely and

freely in the dishwasher. Metal grease lters

must be placed in the dishwasher without jam-

ming.

4.2 Hand Wash

For stubborn dirts, you can use a special

grease solvent. You can buy such an agent

from the authorized sales centre.

■ Soften the metal grease lters in a hot water

with dish-washing liquid.

■Use a brush for cleaning and wait for the liq-

uid in metal grease lters to ow off completely.

■ Rinse the lters thoroughly after cleaning.

CAUTION

Thanks to timely cleaning of metal grease lter,

the re danger caused by excessive heat that is

generated during frying is avoided.

4.3 Removal/Installation of Alumini-

um Filter

Pull the aluminium lter towards you by press-

ing on its tab. Reverse the process to install the

lter.

11

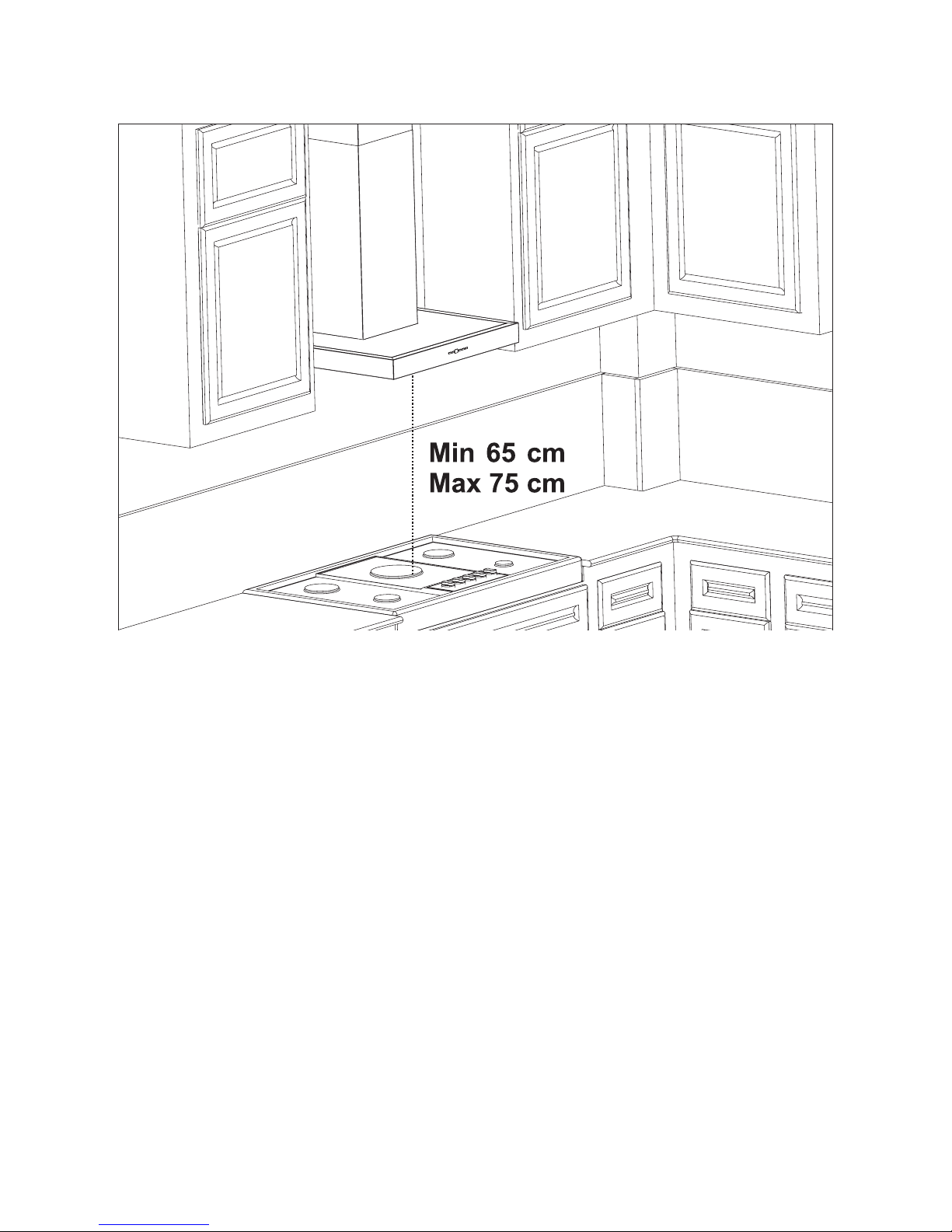

5. INSTALLATION OF APPLIANCE

Fig. 8: INSTALLATION OF APPLIANCE

After completing the installation of cooker hood, the minimum distance must be 650 mm between

the product and any electric cooker; and 750 mm between it and any gas ranges or cookers burning

other fuels. Fig. 8

5.1 Installation and Unpacking of

the Appliance

Check that your appliance is not deformed.

■Report the transport issues immediately to

transport operator.

■Any faults encountered shall be reported to

the dealer, too.

■Do not allow children to play the with packag-

ing materials !!!

5.2 Installation and Unpacking of the

Appliance

■ Replace the carbon lters on a regular basis.

■ Regularly clean your aluminium lters. Since

dirty lters would block the air passage, you

might have to use the appliance at a higher

speed.

■Use your product according to its normal

speeds.

■Use at higher speed would cause an increase

in the energy consumption.

12

5.3 Exhaust Air Mode

WARNING

Death Risk!

Exhaust gases that are reabsorbed might lead to

poisoning. Exhaust air must not be transferred to

an active smoke or waste gas ue; or a ue used

for ventilation of the places, where heat sources

are installed. If you want to transfer exhaust air

to an inactive smoke or waste gas ue, you need

to obtain permission from an authorized chim-

ney sweep.

If exhaust air is discharged over the external

wall,

a telescopic wall case must be used.

5.4 Air Discharge Line

Information: Manufacturer of appliance can-

not be held responsible for defects caused by

laid pipes.

■Appliance shows the highest performance

when a short and at air outlet pipe and a pipe

diameter as large as possible is used.

■Optimum ventilation performance cannot be

reached and noise of fan increases when long

and rough air outlet pipes and multiple pipe el-

bows or pipe diameters smaller than 150mm are

used.

■Pipes or hoses used in laying the air outlet

line must be made of inammable materials.

Circular Pipes

It is recommended that inner diameter should be

150 mm or at least 120 mm.

Flat Channels

Inner Section must be appropriate to the diame-

ter of circular pipes.

Ø150 mm approx. 177 cm²

Ø120 mm approx. 173 cm²

■Flat channels shouldn't have sharp elbows.

Use sealing strips for different pipe diameters.

5.5 Checking the Wall

Wall must be at, straight and have the sufcient

bearing capacity.

Depth of drilling holes must comply with the

length of bolts. Dowels must t in properly.

Bolts and dowels in the enclosure are appro-

priate for use in rigid monolithic walls. Use ap-

propriate fasting materials for different construc-

tions (for ex. plasterboard, aerated concrete,

proton bricks).

Maximum weight of your cooker hood is 40 Kg.

5.6 Electrical Connection

WARNING

Electric Shock Danger!

Components in the appliance might have sharp

edges. Connection cable can be damaged. Do

not bend or jam the connection cable during in-

stallation.

Necessary connection data is provided on the

type label found inside your appliance; metal

grease lters must be removed to see the label.

Length of connection line: approx.

1.3 m

This appliance complies with EU interference

elimination guidelines.

DANGER

5.7 Danger of Electric Shock!

It must always be possible to disconnect the

appliance from the electric network. Appliance

must be plugged in a protected contact outlet

that is mounted in accordance with the rules. If

the plug cannot be reached after installation or

during the required xed connection, there must

be many pole separation assemblies available

with at least 3 mm contact distance to the instal-

lation. Fixed connection must be performed by

an electronics expert only.

13

6. CONTENT OF PACKAGE

Fig. 9: CONTENT OF PACKAGE

1. Product

2. Inner Flue

3. Outer Flue

4. 150/120mm Plastic Flue

5. Flue Connection Plate

6. Remote Control (Optional)

7. User Manual

8. Assembly Pattern

9. Product Hanging Plate

10. Ø6mm Plastic Dowel

11. Ø 10 mm Plastic wall plug

12. 5.5x60 Wall Mount Screw

13. M5x35 Product Mount Screw

14. 3.9x22 Flue Connection Plate Screw

15. 3.5x9.5 Flue Connection Screw

14

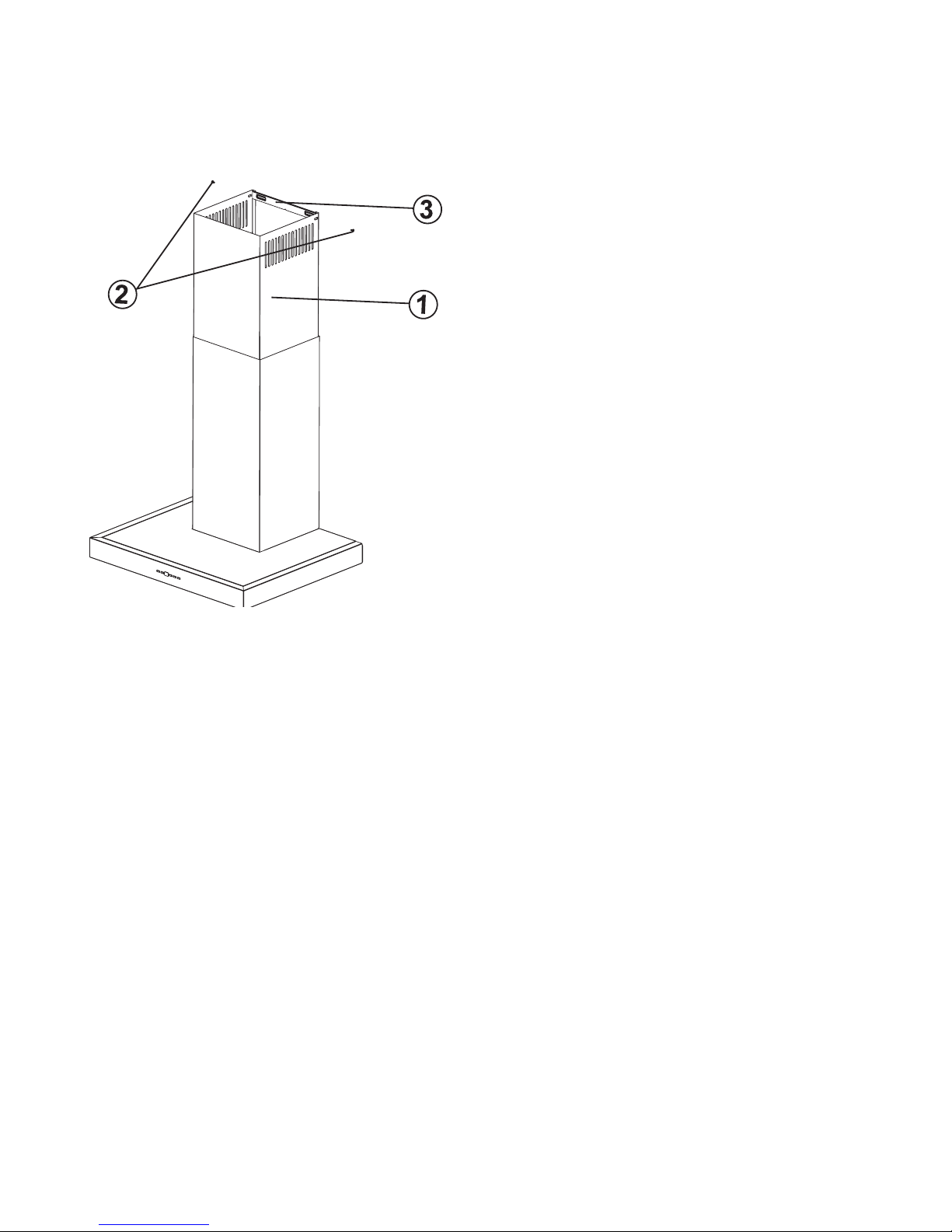

7. OVERVIEW OF COOKER

HOOD

Fig. 10: OVERVIEW OF COOKER HOOD

1. Inner Flue

2. Outer Flue

3. Front Panel

4. Filter

5. Cooker Lighting

6. Control Panel

15

C

B

A

170 mm

A,B,C = Ø8

min.650-max.750mm min.750-max.800mm

OCAK

ELEKTRİK GAZ

307 mm

8. ASSEMBLY OF PRODUCT

8.1 Installation Template

16

8.2 Installation Diagram and Components

1. Inner Flue

2. Outer Flue

3. Product Hanging Plate

4. Product Hanging Plate Fixing Screw

5. Glass

6. 3x 5.5 x 60 Wall Mount Screw

7. 3x Ø 10 mm Plastic wall plug

8. 2x 3.9x22 Screw

9. Flue Connection Plate

10. 2x Ø6mm Plastic Dowel

■Perform the assembly of the cooker hood with

the help of the assembly scheme. (Fig. 8/8).

■ Afx the assembly pattern on the wall at the

specied height (See the minimum and maxi-

mum distances intended for the worktop, in the

assembly pattern) and drill holes A, B and C

with the dimensions specied in the template

(Fig. 11).

■Insert Ø 10 mm

wall plugs into the holes drilled as A, B and C,

and screw down the screws at the points A+B,

in such a way as to ensure a 5mm space be-

tween the screw head and the wall (Fig. 11).

■ Afx the hanging plate of the cooker hood on

the body of the cooker hood with M5x35 screw

(3) (Fig. 11/10).

■Hang the cooker hood from its hanging plates

on the wall at points (A, B). If the cooker hood

is not parallel, position its shape to parallel by

tightening or loosening M5x35 screw (3).

■ Tighten A + B xing screws on the wall, and

completely secure the product at point C.

■Make the air connections of the product.

Fig. 11: INSTALLATION OF THE HOOD

17

Fig. 12: ASSEMBLY OF PLATE FUELS

1.Inner Flue

2.Flue Connection Plate Fixing Screws

3.Flue Connection Plate

The outer and inner sheet metal ues are as-

sembled one within the other.

The cooker hood is set in the midst, and then

the ue connecting plate (3) is directly afxed to

the wall, under the cover or points E and F are

marked after performing a measurement. (Page

16 Fig.10)

Drill points E and F with Ø6mm drill bit, and in-

sert Ø6mm and plastic dowels. Insert the ue

connection plate with 3.9x22 screws (Page 16

Fig.10)

By pulling the inner ue (1) with screw (2) up-

wards and

left, screw it to the ue connection plate (3) on

the right and left (Fig.12).

9. ASSEMBLY OF SHEET METAL FLUES

18

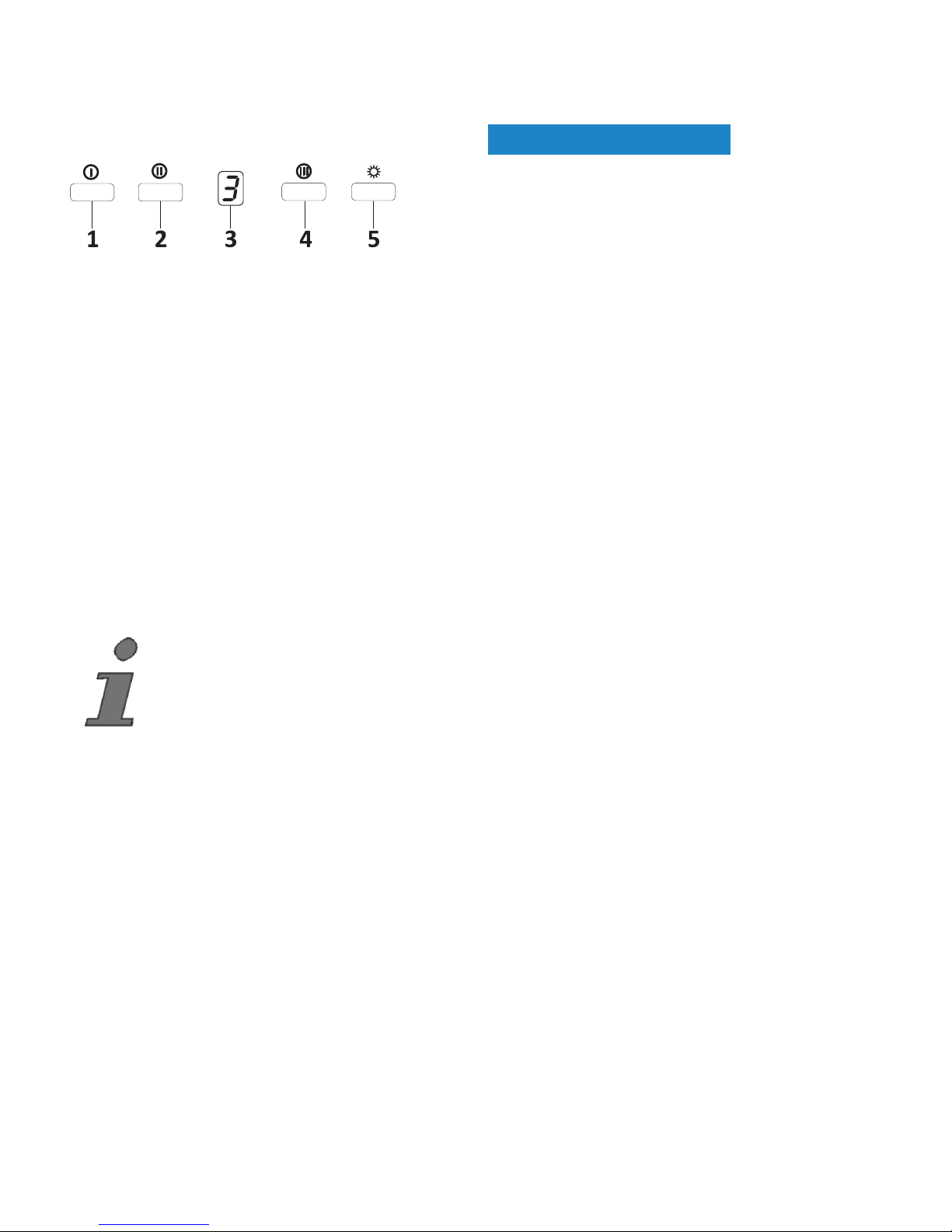

10 USE OF PRODUCT

10.1 3 Spd Touch Button

Fig. 13: Touch Button

1. Press this button to turn on the product.

When this button is pressed, product will also

operate at speed level 1 (Fig.13).

2. When this button is pressed, product will op-

erate at speed level 2 (Fig.13).

3. Dgt Display: You can see the operation rate

of product on this screen (Fig.13).

4. When this button is pressed, product will op-

erate at speed level 3 (Fig.13).

5. Press this button to turn on or off the lamp

(Fig.13).

To activate timer function, press and hold any of

buttons 1, 2 and 3 for 3 seconds. Then, 15 min-

ute timer function will be activated and the prod-

uct will turn off automatically after 15 minutes.

All active functions operated prior to activation

of timer function will be deactivated after 15

minutes. All active functions operated after acti-

vation of timer function will be reactivated after

15 minutes.

NOTE

Programmable functions can be set when the

motor and lamp are turned off and timer isn't

set.

Back light brightness settings

When you press - button for approx. 5 seconds,

percentage of blue colour is displayed. (for ex:

B 00) Red colour percentage will appear on the

screen if - button is pressed one more time. (for

ex. R 100)

Green colour percentage may be displayed on

the screen by pressing . button one more time.

(for ex: G 10) By pressing on the colour and

buttons percentage of which is shown on the

screen (can be set faster by pressing longer),

percentage can be set between 0 and 100.

New colour is saved (a beep sound is heard)

by pressing and holding - button for 5 seconds,

and setting mode is turned off. To exit the set-

ting mode without saving, Mot/off or lamp but-

tons can be pressed.

Back light option

Back light is set to be constantly on when

shipped from the factory. If desired, back light

can be set to off when motor and lamp are

turned off and timer is not set (i.e. when the

cooker hood is not in use) by pressing and

holding + button for about 5 seconds (a beep

sound is heard). In order to set the back light

back to constantly on again, + button is pressed

for about 5 seconds.

19

Boost Ventilation Mode:

The model you have purchased has a boost

Boost Mode: When the product is switched

to maximum speed while it is operated, a ’b’

symbol shall be displayed on the screen.

Boost symbol indicates that (boost ventilation)

mode is active on the model. Product shall

operate for 7 minutes in this mode and ‘b’

this period. After 7 minutes, product shall

automatically switch down one speed level

and shall resume operation in the lower speed

level.

Note: It is not possible to use timer feature in

the boost mode.

11. REPLACING THE LAMPS

DANGER

Disconnect the electrical supply of the cooker

-

cause they could burn your hands when they

are hot.

11.1 Replacement of Halogen Lamp

Fig. 13: Replacement of Halogen

the faulty bulb and replace with a new one with

the same rating.Fig. 13

11.2 Replacement of Spark Plug

Lamp

Fig. 14: Replacement of Spark Plug Lamp

the faulty bulb and replace with a new one with

the same rating.Fig. 14

20

12. AUTHORIZED SERVICE

If Lighting is Not Functioning:

■Make sure that the plug is plugged in, and that the fuses are intact.

■Check the bulbs. Make sure you unplugged the device before performing this check. Tighten the

bulbs if they are loose; you can replace the bulbs if they still don't work.

Possible Faults and What-to-Do Before

Calling the Technical Service:

A) If the appliance does not work in any way:

■

■Check the fuse, to which the appliance is connected, as well as the main fuse of your house.

or it operates with too much noise:

■

■

■

months.

■

Table of contents

Other Malloca Ventilation Hood manuals

Malloca

Malloca SLIM K1522 User manual

Malloca

Malloca MIN F-205 User manual

Malloca

Malloca HIH-864 User manual

Malloca

Malloca Space MH 900SP User manual

Malloca

Malloca MH 750BI User manual

Malloca

Malloca DRIVE F-152 User manual

Malloca

Malloca MC 9082 ISLAND User manual

Malloca

Malloca K-3410DR User manual

Malloca

Malloca MOV-656 ECO User manual

Malloca

Malloca K1153 User manual