SECTION 1 - Specifications

© Copyright 2008DN IS-IPPC101.1 ® Registered trademark MAMAC SYSTEMS, Inc.

3 of 20

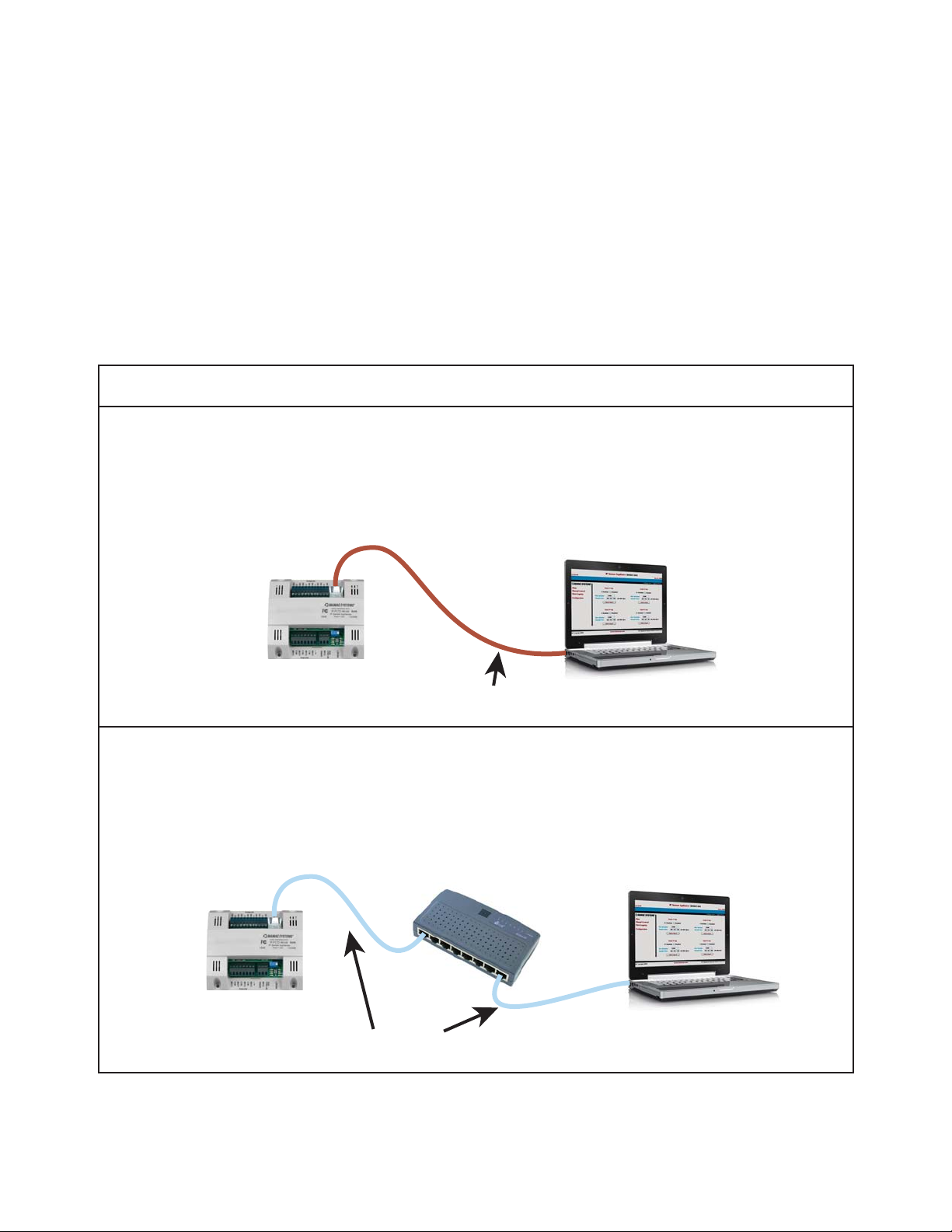

Anyone who can surf the web now can do sensor monitoring, control,

data logging, and email alerts without any training or custom software.

All you need is a web browser running on any laptop, PDA, or cell

phone anywhere in the world.

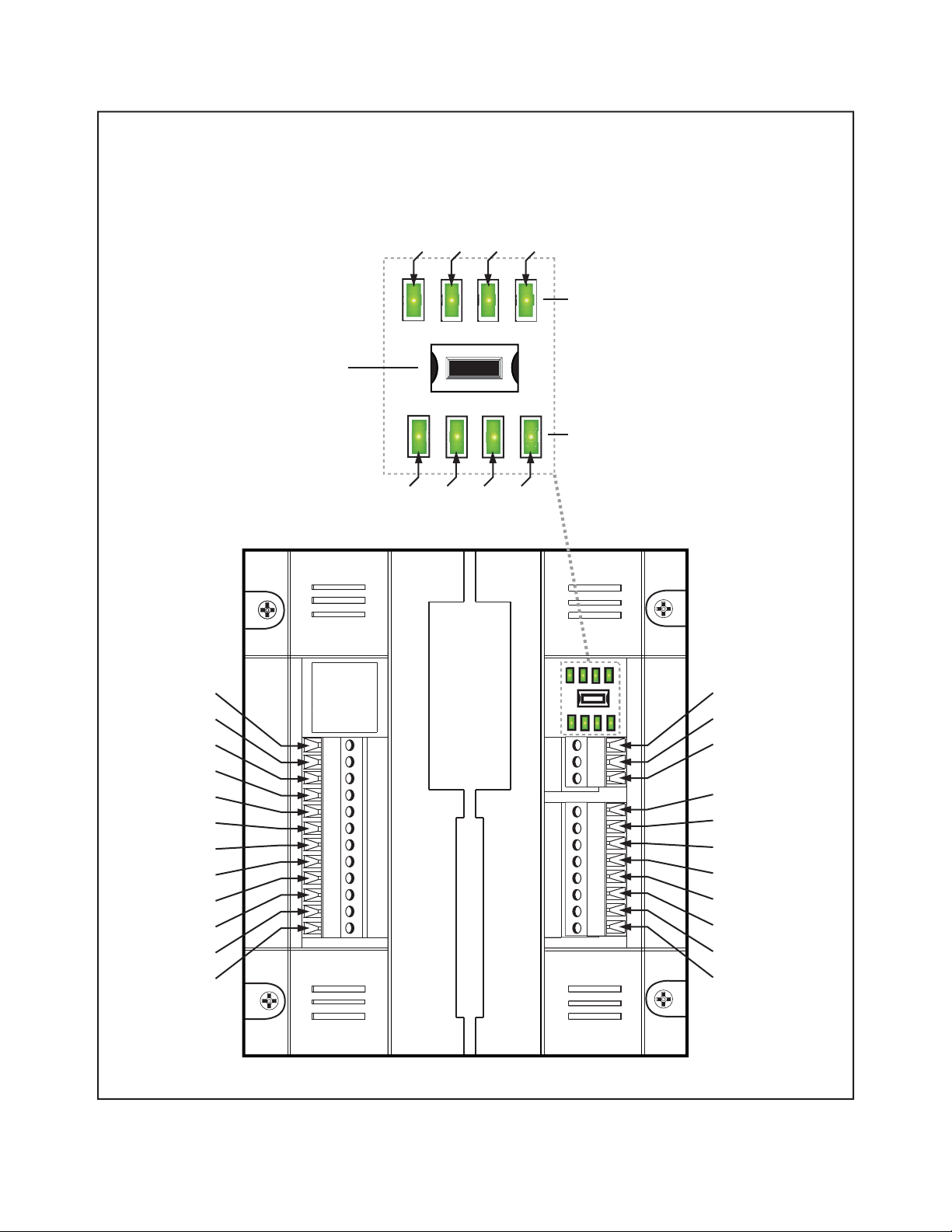

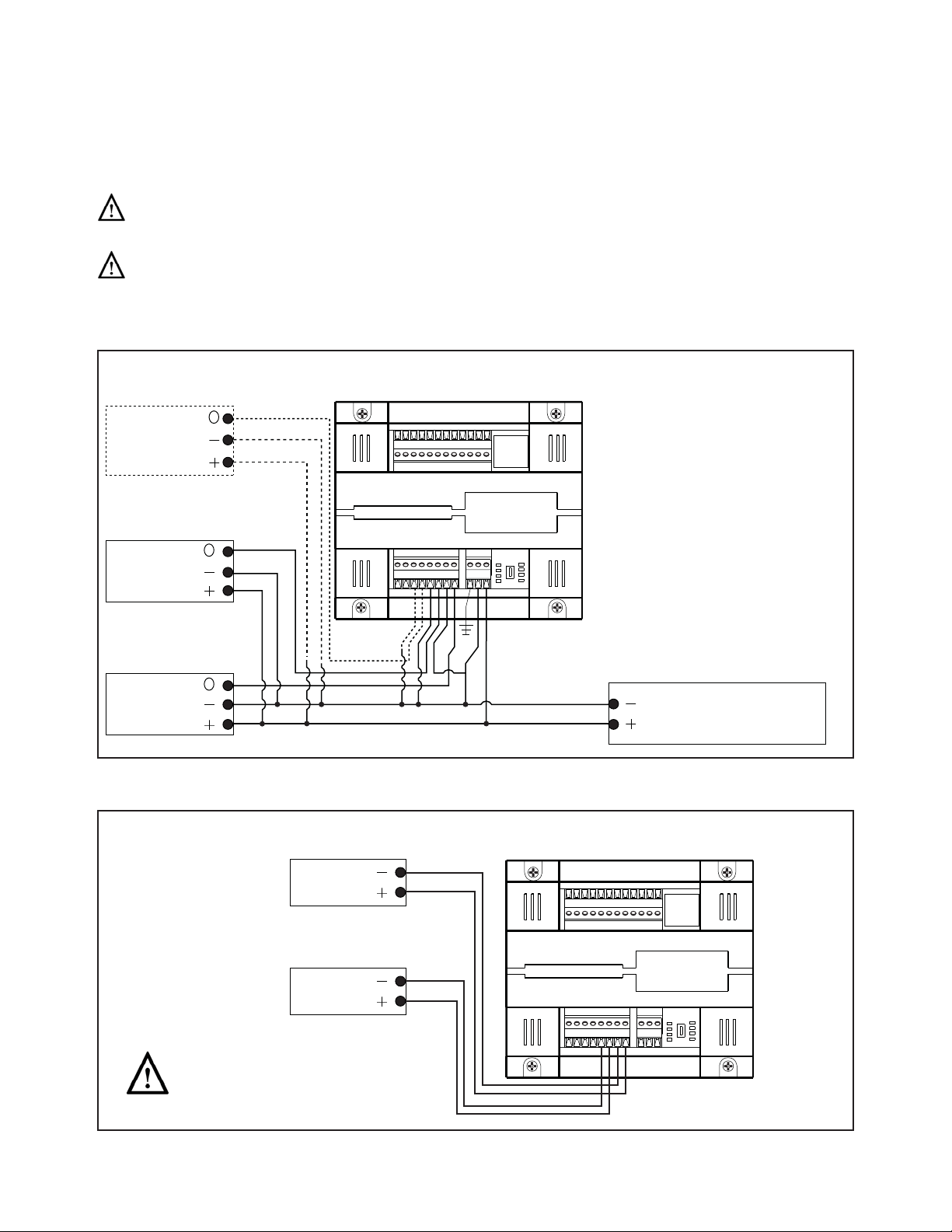

The Maverick IP Sensor Appliance incorporates a web server,

analog/digital inputs and relay outputs. Power the appliance with

any 24VAC transformer, plug it into a hub/router, launch any web

browser, punch in the default IP and connect. No custom software to

load, no discovery routines, no custom cables, or training.

The IP Sensor Appliance serves up static web pages with dynamic

data updates every second or two. Most users can set up and utilize

the appliance without any training or support in less than 5 minutes

due to the innovative and familiar web browser based configuration.

The Maverick is an ideal low cost solution for light commercial,

residential and remote monitoring applications. The appliance can

also be used to enhance existing HVAC control systems by adding

email alerts and data logging to critical points.

SPECIFICATIONS:

Termination: Removable terminal blocks 16

Ga max, RJ-45 Ethernet jack

Weight: 0.5 lbs. (.25 kg)

Supply Voltage: 24 VAC/VDC Data Logging: 2048 samples each input

Logging Interval: 1.0 second to 99.99 hours

Environmental: 10-90%RH non-condensing

Operating Temp: -40˚F-125˚F (-40˚C-52˚C)

Storage Temp: -40˚F-150˚F (-40˚C-66˚C)

Enclosure: UL 94V-5-O Polycarbonate plastic

Supply Current: 250 mA (6 VA)

Digital Input: 10.00 VDC maximum

Ethernet: 10-Base T

IP Assignment: Static or DHCP

Email: SMTP to two email addresses

Input Impedance: 125K ohms (VDC or

Digital) 250 ohms (4-20 mA)

Output Relay Rating: 250 VAC @ 5.0 Amps

UL Listed

1.1.0