SPECIFICATIONS

Inspection

Requirements

Mounting

For Additional Information See PR-282 Data Sheet

INSTALLATION

Model PR-282

Technical Information

TI.282-04

DIFFERENTIAL PRESSURE SENSOR

Inspect the package for damage. If damaged, notify the appropriate

carrier immediately. If undamaged, open the package and inspect

the device for obvious damage. Return damaged products.

Warning:

•Do not use on oxygen service, in an explosive/hazardous

environment, or with flammable/combustible media.

•Disconnect power supply before installation to prevent

electrical shock and equipment damage.

•Make all connections in accordance with the job wiring

diagram and in accordance with national and local

electrical codes. Use copper conductors only.

Caution:

•Use electrostatic discharge precautions (e.g., use of wrist

straps) during installation and wiring to prevent equipment

damage.

•Avoid locations where severe shock or vibration, excessive

moisture or corrosive fumes are present.

•Do not exceed ratings of the device.

Refer to Figure 5 for mounting dimensions.

1. Remove the transducer cover using a Phillips head

screwdriver.

2. Select the mounting location.

3. Mount transducer on a vertical surface with four #8 self-tapping

screws (not provided).

4. Pull wires through bottom of enclosure and make necessary

connections.

5. Replace cover and make pneumatic connections.

•Tools (not provided)

- Digital Volt-ohm Meter (DVM)

- Appropriate screwdriver for mounting screws

- Appropriate drill and drill bit for mounting screws

•Appropriate accessories

•Four #8 self-tapping mounting screws (not provided)

•Training: Installer must be a qualified, experienced technician

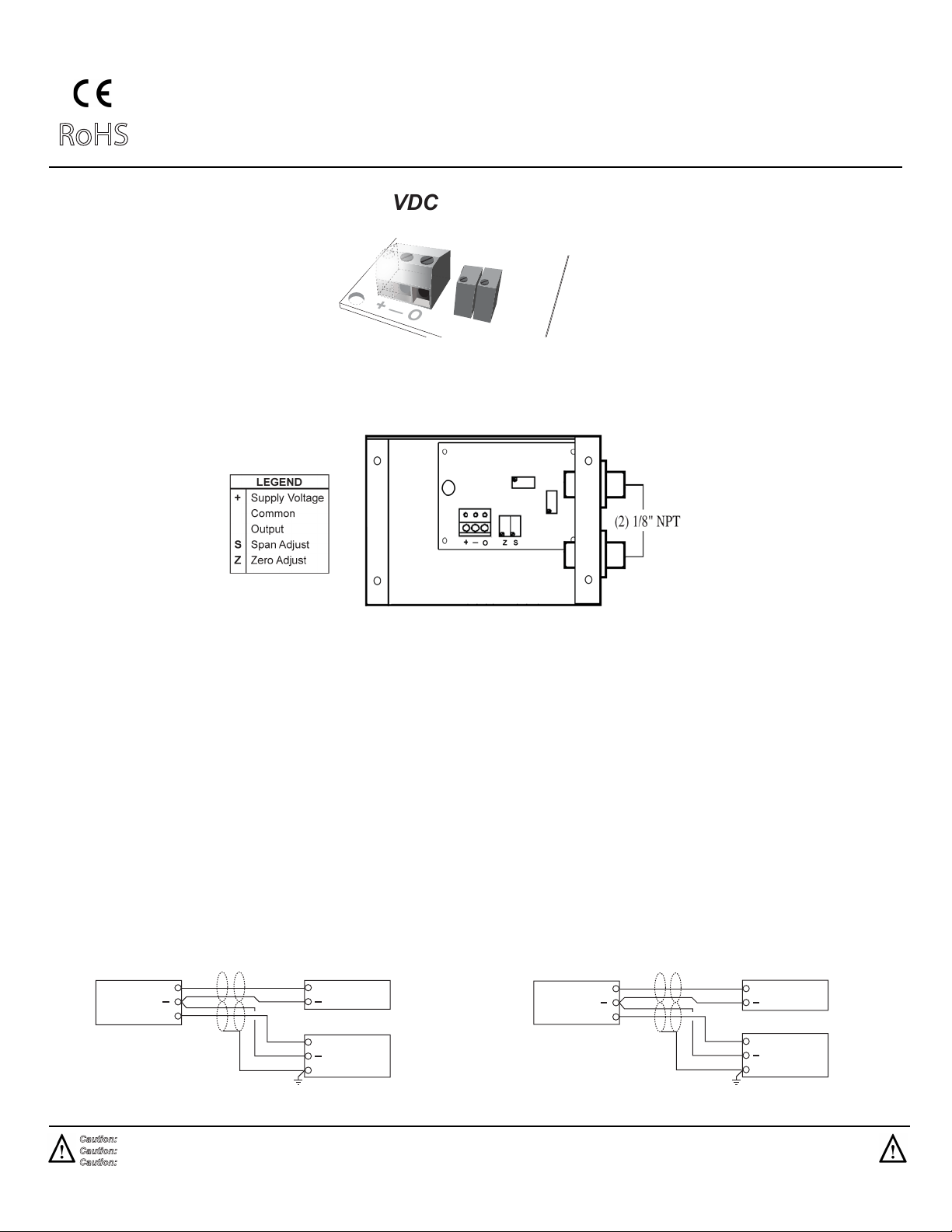

Wiring Use maximum 12 AWG wire for wiring terminals. Refer to

Figures 1, 2, 3, & 4for wiring information.

(Wiring Instructions continued on pages 2 and 3.)

RoHS

Accuracy*: ±1% FS

Overpressure: 300% of rated range

Burst Pressure: 500% of rated range

Maximum Static Pressure: 200% of DP range

Supply Voltage: 12-40 VDC

12-35 VAC (VDC output units only)

Supply Current: VDC Units - 10 mA max.

mA Units - 20 mA max.

Load Impedance: 3K ohms max. at 40 VDC (mA output units)

1K ohms min. (VDC output units)

Enclosure: 16 Ga Steel - NEMA 1

Finish: Baked on Enamel - PMS2GR88B

EMC Conformance: EN 55022, 55024, 61000-3-3,

61000-4-2, 3, 4, 5, 6 & 11

Compensated Temp Range: 0°F - 180°F (-18°C-82°C)

T.C. Error: ±0.025%/°F (.03%/°C)

Media Compatibility: Liquid/gases compatible to 316L SS

Port Connection: 1/8” NPT

Environmental: 10-90%RH Non-Condensing

Termination: Unpluggable screw terminal block

Wire Size: 12 Ga max.

Weight: 1.7 lbs. (.75 kg)

*Includes linearity, repeatability, hysteresis, stability and temp compensation

U.S. PATENT NO. 6484587

ORDERING INFORMATION: PR-282-

OUTPUT

OUTPUT

TYPE

SUPPLY

VOLTAGE

PRESSURE

RANGE

1) 0-1 VDC

2) 0-5 VDC

3) 0-10 VDC

4) 4-20 mA

(2-wire)*

1) 0-20 psid

2) 0-30 psid

3) 0-50 psid

4) 0-100 psid

5) 0-200 psid

6) 0-300 psid

7) Custom

A) 24 VDC

B) 24 VAC

1) Direct

OUTPUT

AVERAGING

OUTPUT

CLIPPING

2) Without B) Without

* Available with 24VDC supply voltage only