SPECIFICATIONS

For Additional Information See TE-703/704 Data Sheet

8189 Century Boulevard • Minneapolis, MN 55317-8002 • USA

800-843-5116 • 952-556-4900 • Fax 952-556-4997

Model TE-703/704

Technical Information

TI.703/704-03

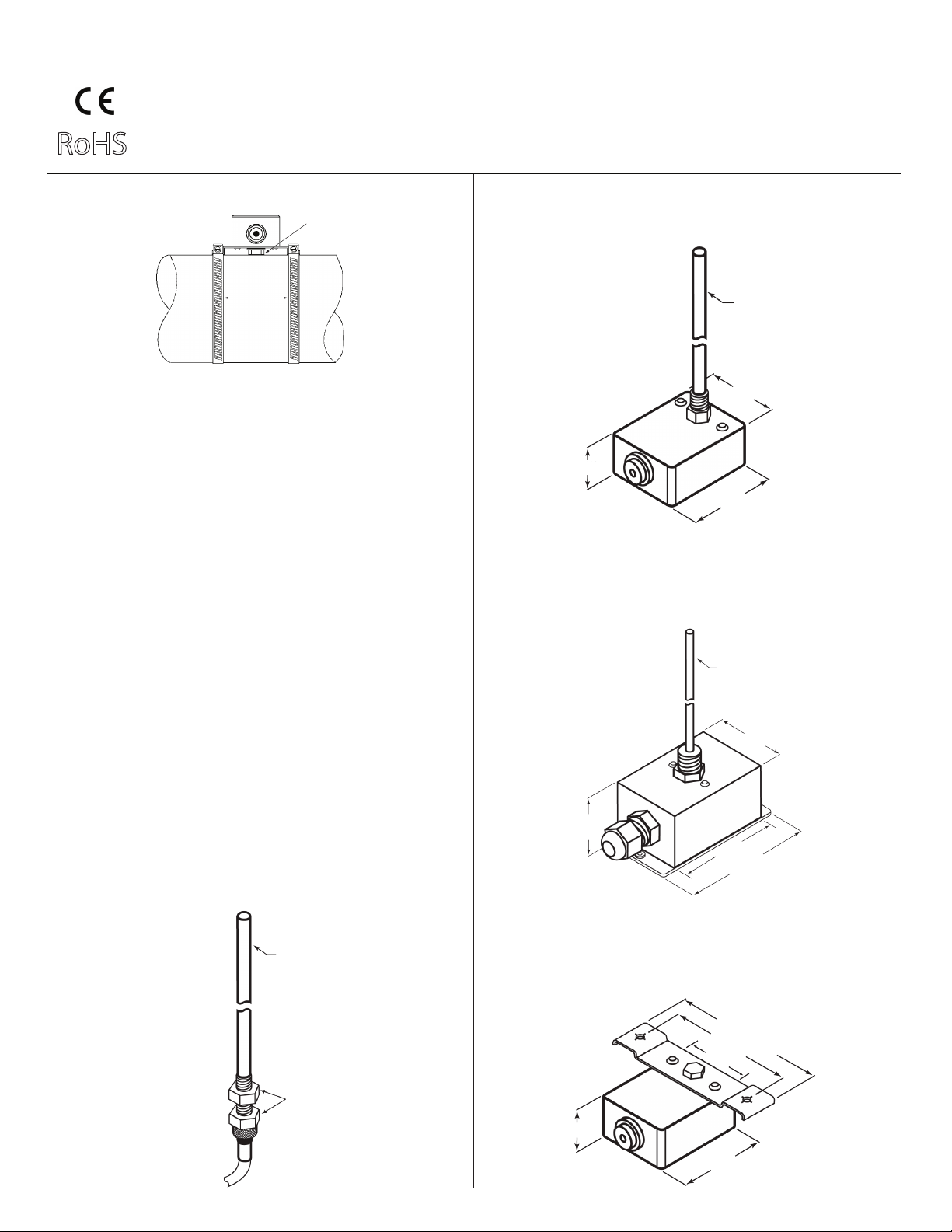

PIPE TEMPERATURE SENSORS

RoHS

Platinum RTD Sensors:

±0.1% @ 32°F (0°C), Alpha: 385 per DIN 43760

Nickel RTD Sensors (#2):

±0.5°C @ 0°C (32°F), 5,000 PPM/K T.C.R.

Nickel RTD Sensors (#4):

±0.5°F @ 70°F (21.1°C), 6,000 PPM/K T.C.R.

Balco RTD Sensors:

±0.5°F @ 70°F (21.1°C), 4,300 PPM/K T.C.R.

Thermistor Sensors:

±0.2°C interchangeability @ 77°F (25°C)

Operating Temperature:

-40°F to 210°F (-40°C to 100°C)

Ambient Temperature:

-40°F to 160°F (-40°C to 70°C)

Probe Material:

1/4" (6.3mm) O.D., 0.020" (0.5mm) wall, 304 Stainless Steel

Flange Material:

Galvanized Steel

Bulkhead Fitting:

Brass with poly compression sleeve

Plastic Enclosure:

Polycarbonate 30% glass filled, rated UL 94V-5-0

Steel NEMA-1 (IP-30):

18 Ga. Galvanized Steel

Steel NEMA-4 (IP-65):

18 Ga. Cold Rolled Steel, Powder coated

Warranty:

Five Years (Lifetime on Moisture Migration)

EMC Conformance:

EN 55022, 55024, 61000-3-3, 61000-4-2, 61000-4-3,

61000-4-4, 61000-4-5, 61000-4-6 & 61000-4-11

U.S. PATENT NO. 6457857, 6555748, 6599012, 7036224

ORDERING INFORMATION: TE-703-

INSTALLATION TEMP SENSOR PROBE

LENGTH

AImmersion style

with adapter

BPolycarb Plastic

Enclosure (IP-54)

CGalvanized Steel

Enclosure

(NEMA-1 / IP-30)

DPainted Steel

Enclosure

(NEMA-4 / IP-65)

A 4" (100 mm)

B6" (150 mm)

C8" (200 mm)

1 100-Ohm Platinum RTD

2 1,000-Ohm Nickel RTD

(5,000 PPM)

3 1,000-Ohm Platinum RTD

4 1,000-Ohm Nickel RTD

(6,000 PPM)

5 1,000-Ohm Balco RTD

7 10,000-Ohm NTC Thermistor

(Type III)

8 10,000-Ohm NTC Thermistor

(Carel)

10 3,000-Ohm NTC Thermistor

12 10,000-Ohm NTC Thermistor

(Type II)

13 5,000-Ohm NTC Thermistor

14 1,035-Ohm Silicon PTC

15 100,000-Ohm NTC Thermistor

16 10,000-Ohm NTC Thermistor

.........(Eliwell)

17 20,000-Ohm NTC Thermistor

18 2,252-Ohm NTC Thermistor

21 1,800-Ohm NTC Thermistor

ORDERING INFORMATION: TE-704-

ASurface Mount

Strap-On

BPolycarb Plastic

Enclosure (IP-54)

CGalvanized Steel

Enclosure

(NEMA-1 / IP-30)

DPainted Steel

Enclosure

(NEMA-4 / IP-65)

Examples:

TE-703-A-10-A-3: Immersion style with 1/2" adapter, 3,000 ohm thermistor & 4" probe.

TE-703-D-10-C-2: NEMA-4 enclosure, 3,000 ohm thermistor, 8" probe & 1/4" NPT brass fitting. Example: TE-704-C-1: NEMA-1 enclosure with 100 ohm Platinum RTD surface mount sensor.

ADAPTER

11/8" NPT

21/4"NPT

31/2" NPT

INSTALLATION TEMP SENSOR

1 100-Ohm Platinum RTD

2 1,000-Ohm Nickel RTD

(5,000 PPM)

3 1,000-Ohm Platinum RTD

4 1,000-Ohm Nickel RTD

(6,000 PPM)

5 1,000-Ohm Balco RTD

7 10,000-Ohm NTC Thermistor

(Type III)

8 10,000-Ohm NTC Thermistor

(Carel)

10 3,000-Ohm NTC Thermistor

12 10,000-Ohm NTC Thermistor

(Type II)

13 5,000-Ohm NTC Thermistor

14 1,035-Ohm Silicon PTC

15 100,000-Ohm NTC Thermistor

16 10,000-Ohm NTC Thermistor

.........(Eliwell)

17 20,000-Ohm NTC Thermistor

18 2,252-Ohm NTC Thermistor

21 1,800-Ohm NTC Thermistor