Man E 2942 LE 302 Operating instructions

Table of contents

Other Man Engine manuals

Man

Man D2862 LE221 Operating instructions

Man

Man E0834 LE302 User manual

Man

Man D 2840 LE 403 User manual

Man

Man D 2868 Instructions for use

Man

Man D 2842 LE 620 Operating instructions

Man

Man V8-1200 User manual

Man

Man D 2840 LE 301 Operating instructions

Man

Man D2868 LE433 User manual

Man

Man E0834 E302 User manual

Man

Man D 28 Series Installation instructions

Man

Man D 2866 LUE 605 Operating instructions

Man

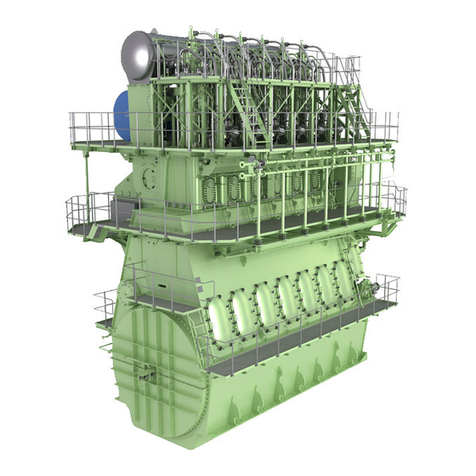

Man B&W L35MC6-TII User manual

Man

Man D 2866 E User manual

Man

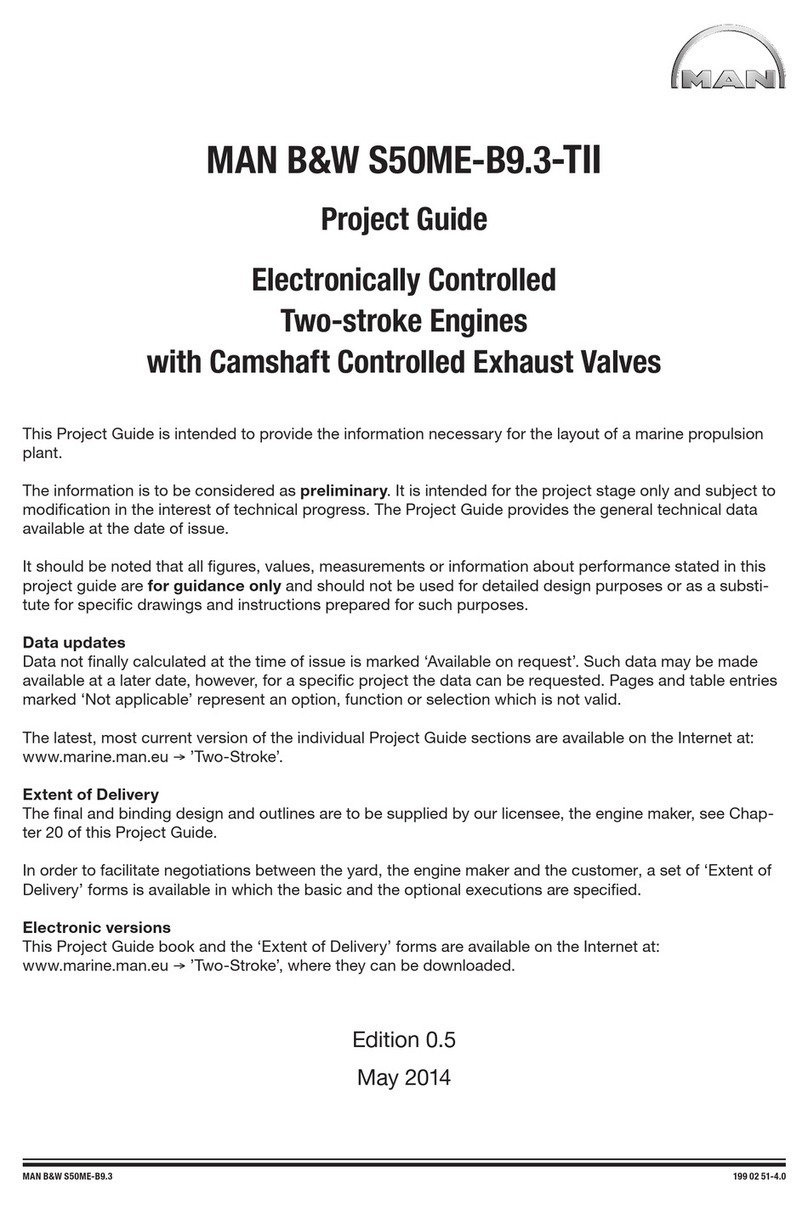

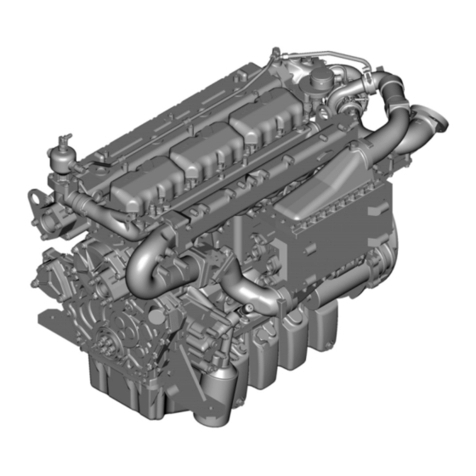

Man B&W S50ME-B9.3-TII User manual

Man

Man E0834 LE312 User manual

Man

Man D 2876 LE 101 Operating instructions

Man

Man D 2848 LE 401 User manual

Man

Man E 0824 E 301 User manual

Man

Man V8-1000 User manual

Man

Man D 2866 LE 201 User manual

Popular Engine manuals by other brands

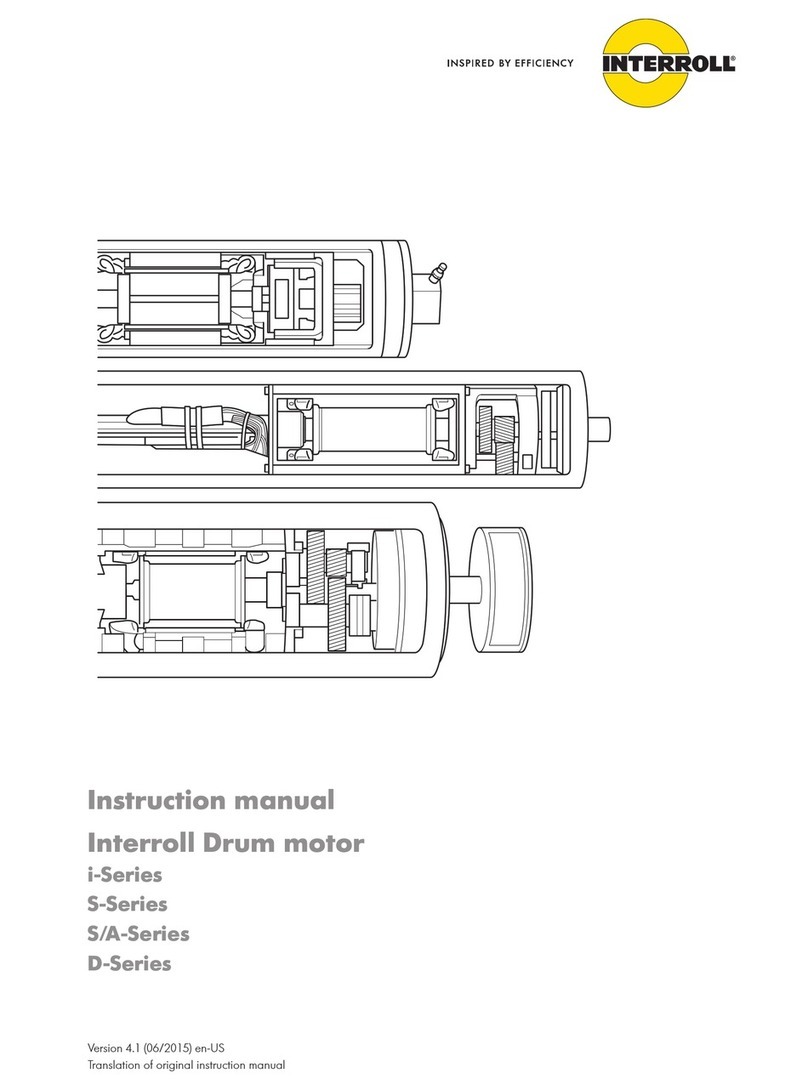

Interroll

Interroll i Series instruction manual

Briggs & Stratton

Briggs & Stratton Sno/Gard 170400 Series Operator owner's manual

Power Fist

Power Fist 8703126 user manual

Briggs & Stratton

Briggs & Stratton 12C700 Series Operating & maintenance instructions

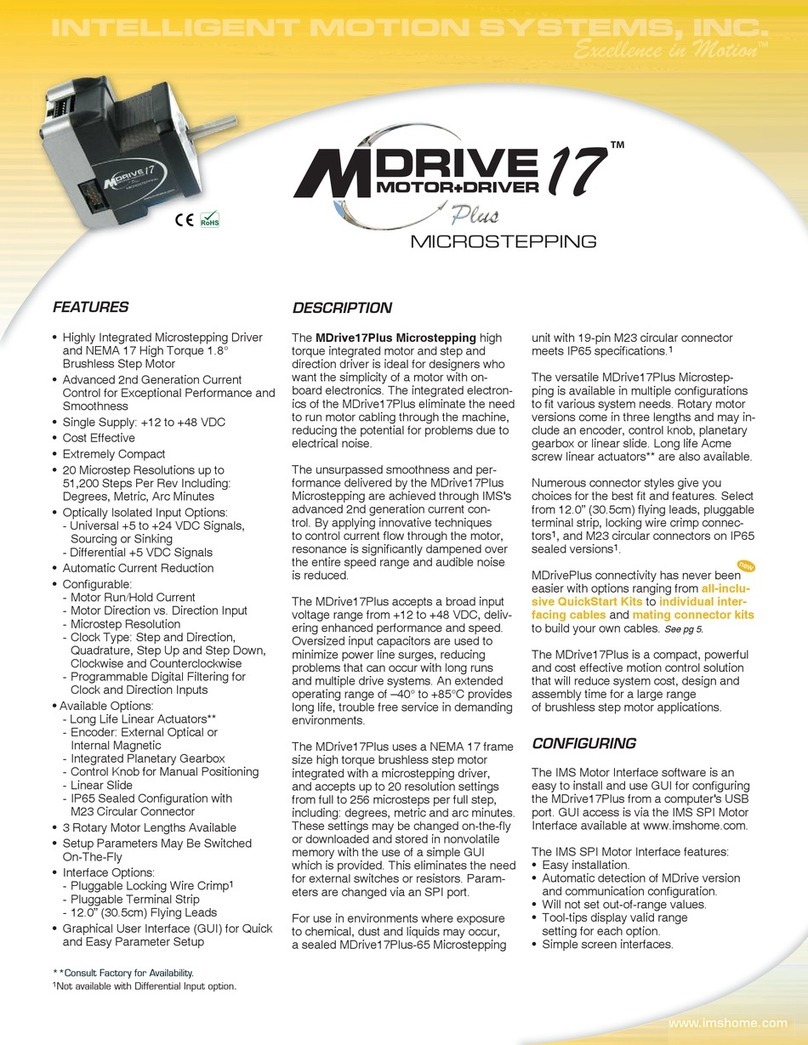

IMS

IMS MDM17Plus Specification sheet

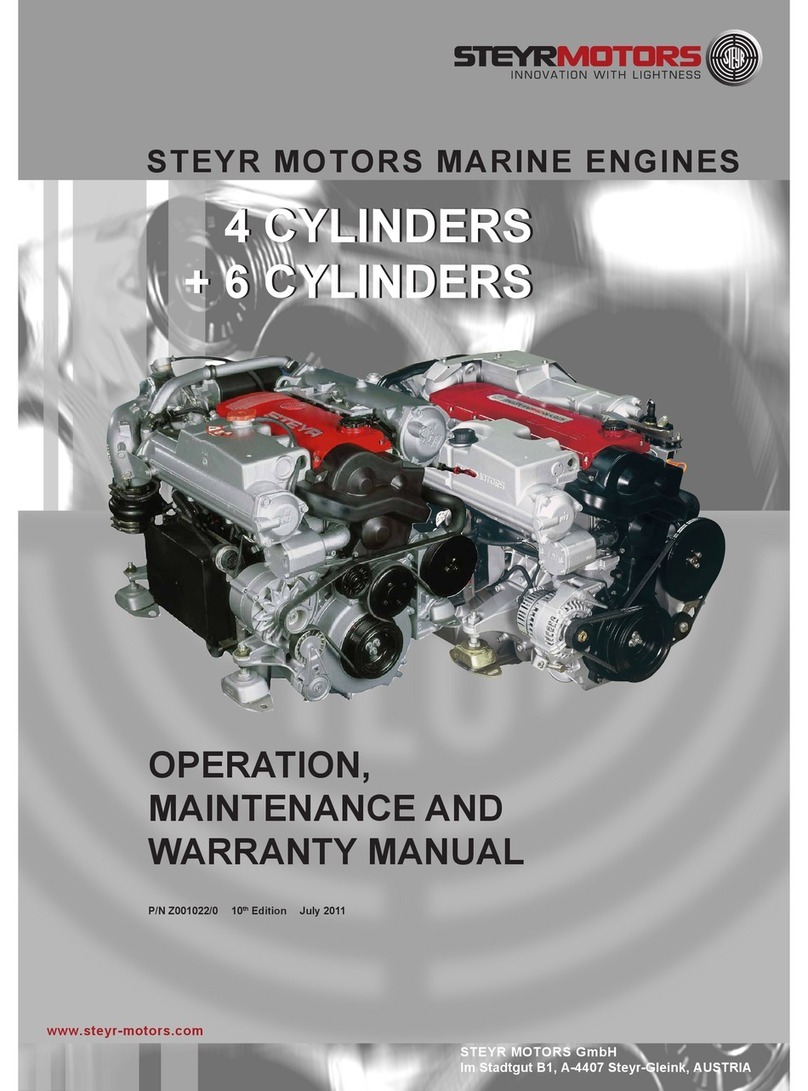

STEYR

STEYR MO156K25 Operation, maintenance and warranty manual

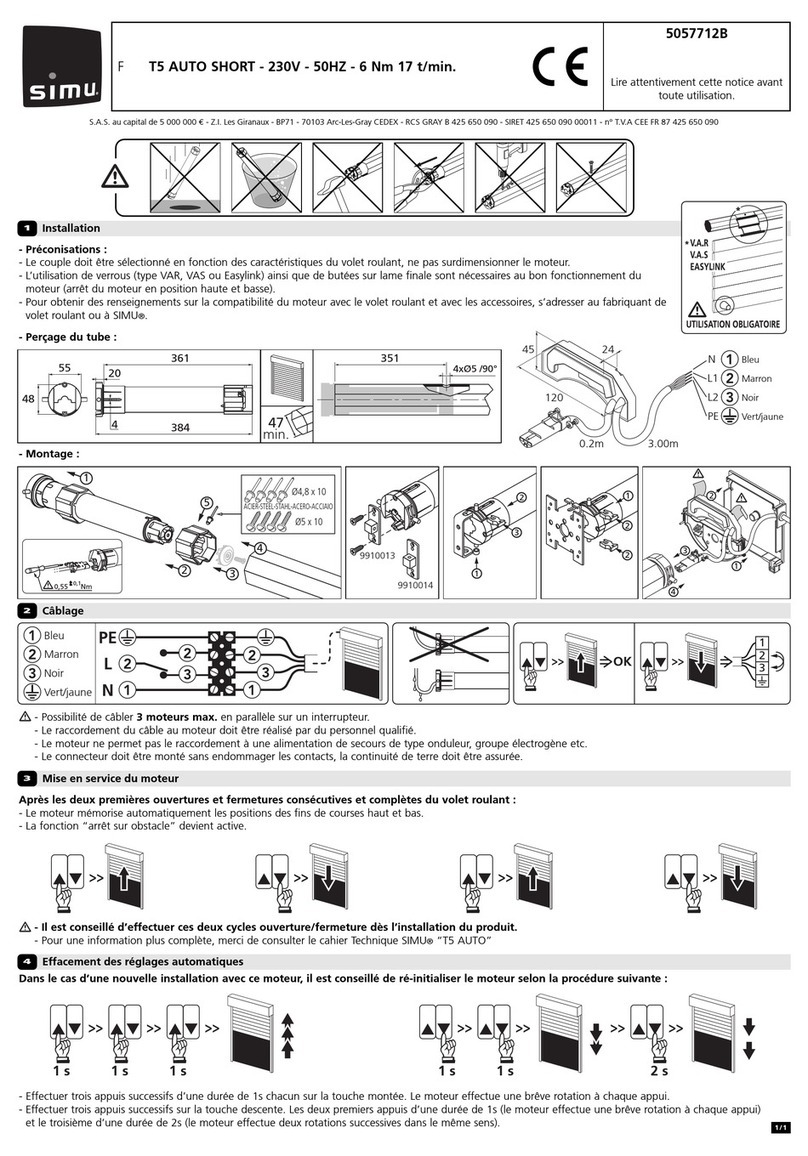

Simu

Simu T5 AUTO instructions

PEUGEOT

PEUGEOT XS1P37QMA-2 Workshop manual

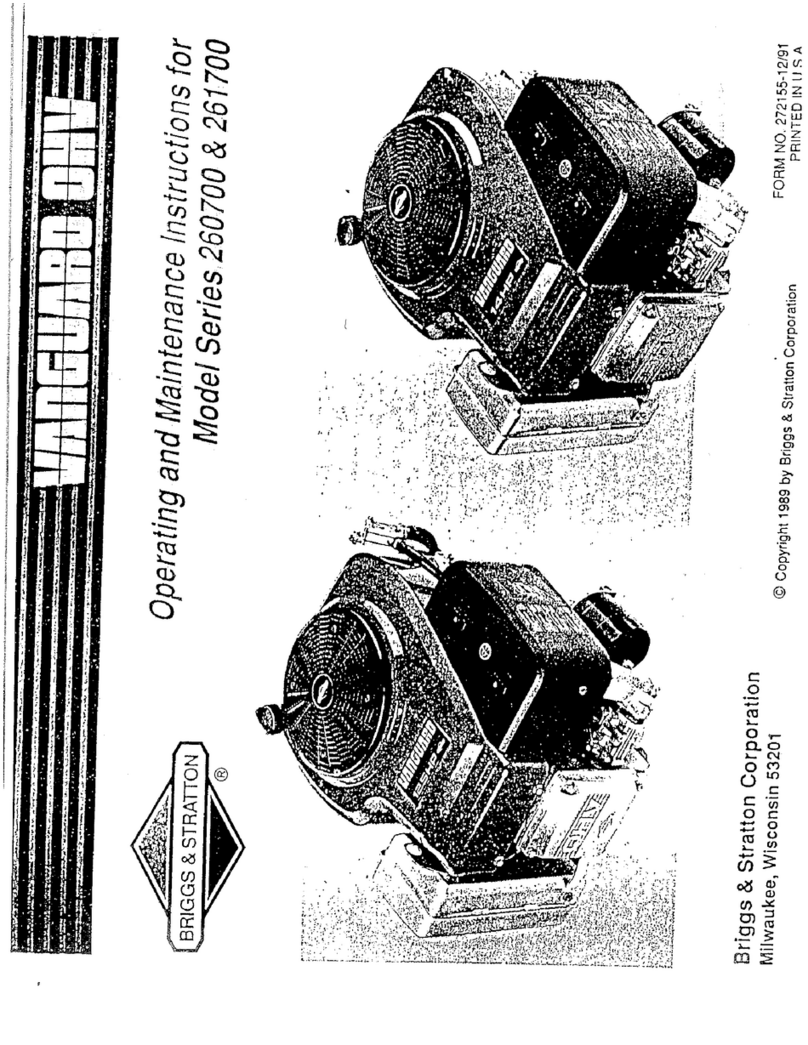

Briggs & Stratton

Briggs & Stratton 260700 Operating and maintenance instructions

Leroy-Somer

Leroy-Somer LSRPM Series Installation and Maintenance

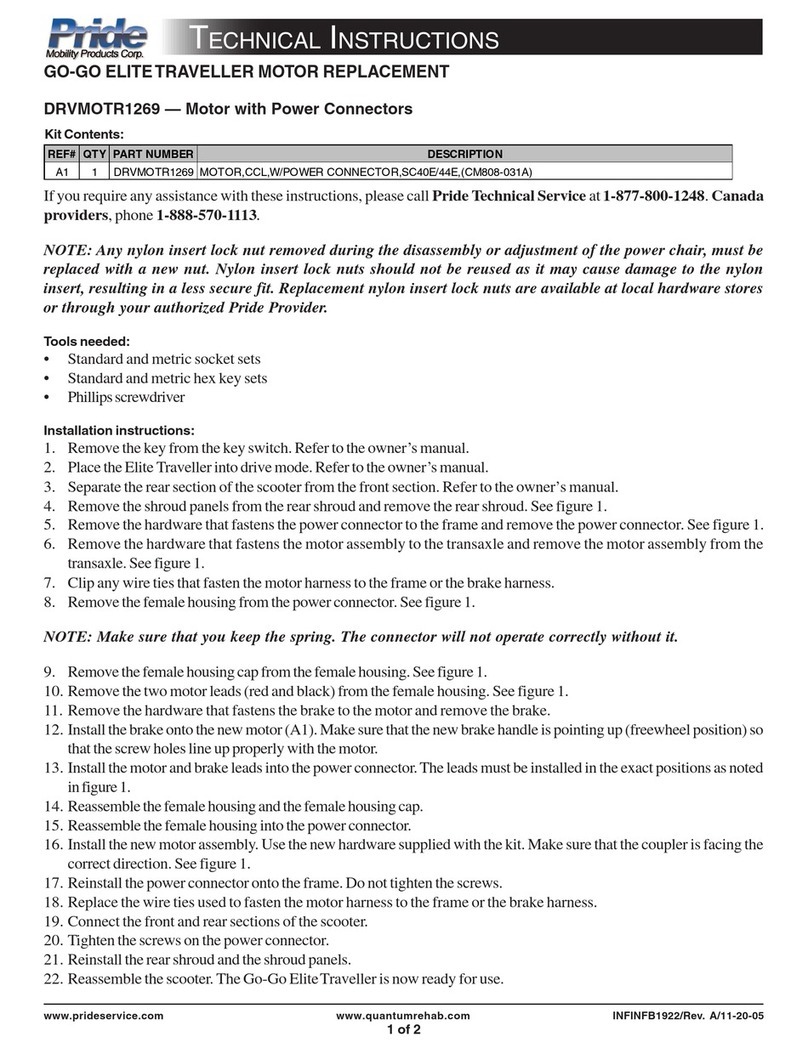

Pride Mobility

Pride Mobility DRVMOTR1269 Technical instructions

MTD

MTD 420cc Operator's manual