2

TABLE OF CONTENTS

Installation Instructions............................................................................................................................................... 3

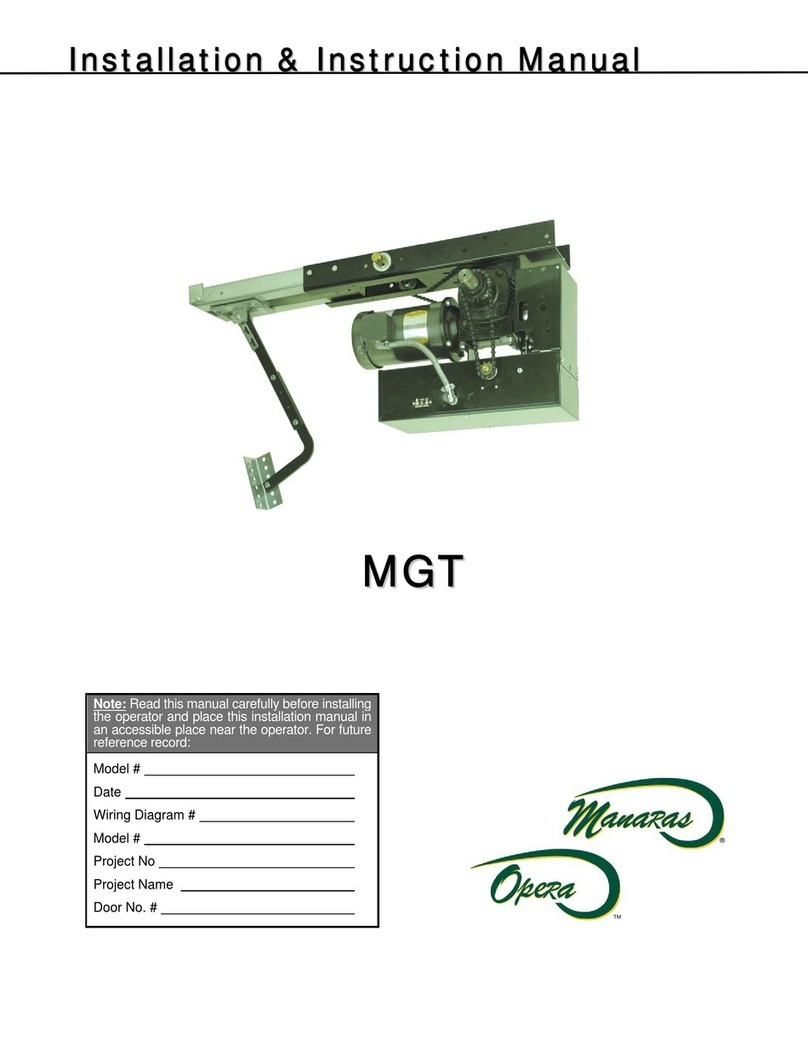

1 General Specifications and Dimensions.........................................................................................................................................................4

2 Door & Operator Hardware...............................................................................................................................................................................5

2.1 Delivery of Operator..................................................................................................................................................................................5

2.2 Hardware Supplied....................................................................................................................................................................................5

3 Operator Installation..........................................................................................................................................................................................6

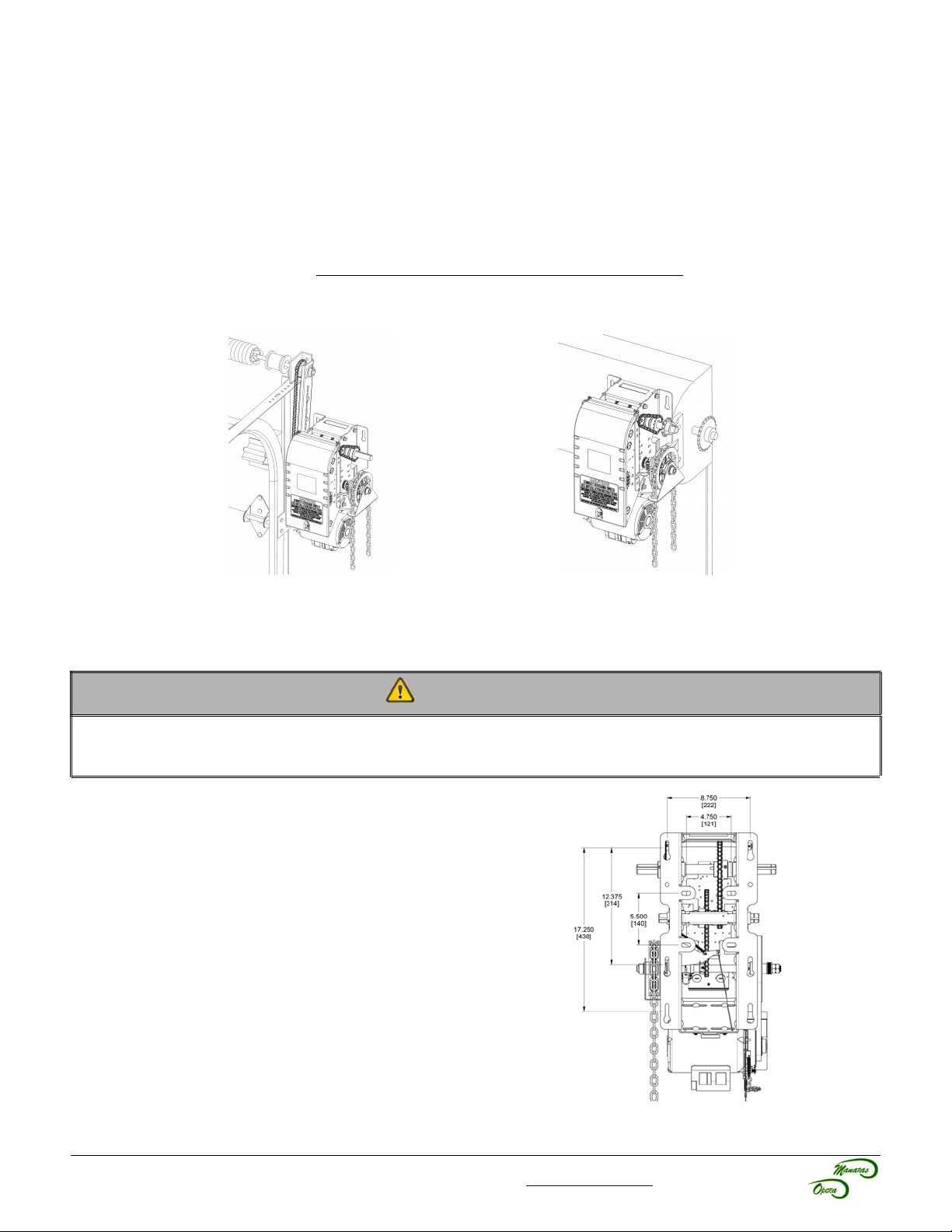

3.1 Operator Mounting Options.......................................................................................................................................................................6

3.2 Operator Mounting Holes..........................................................................................................................................................................6

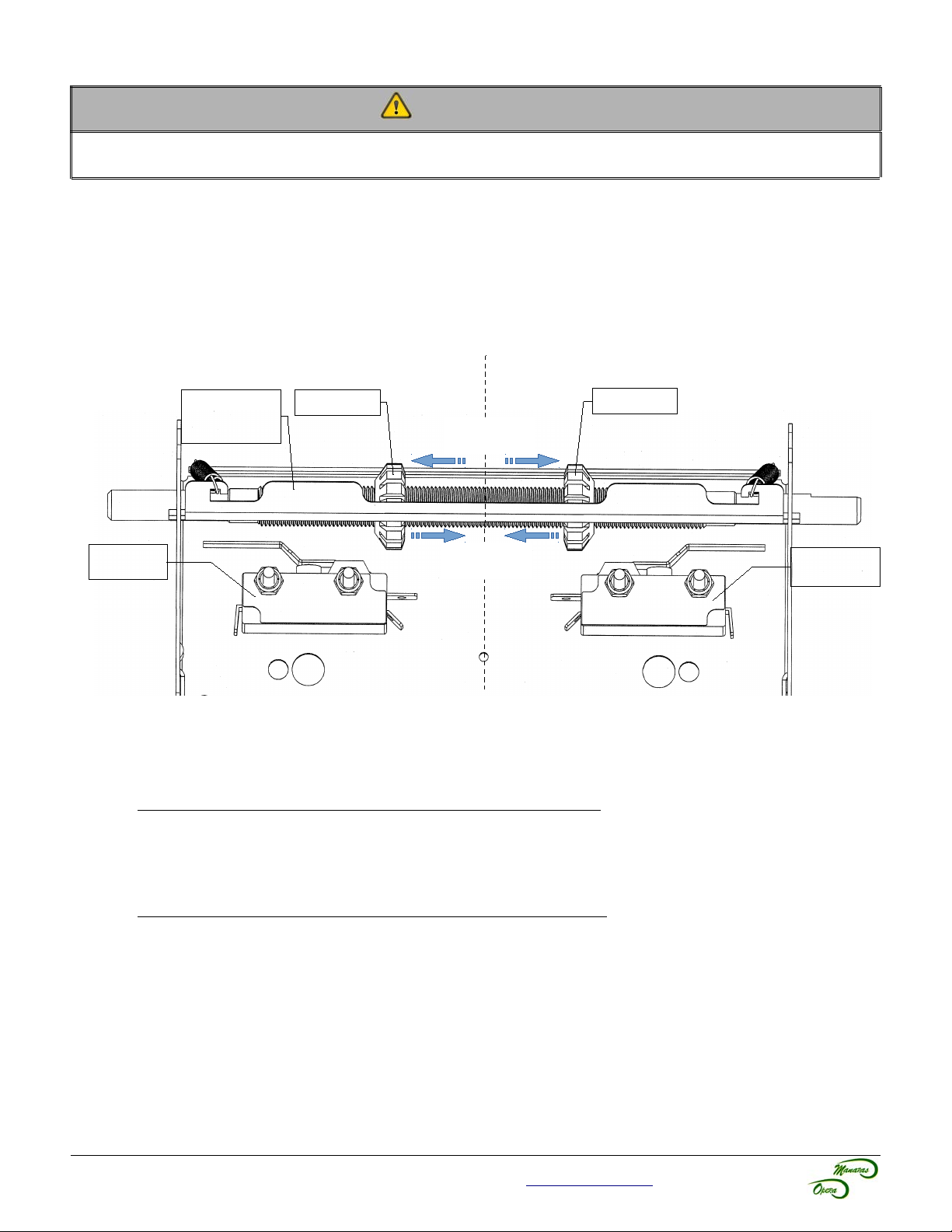

3.3 Sprockets, Spreader Bar and Drive Chain Installation.............................................................................................................................7

4 Operator Control Box........................................................................................................................................................................................8

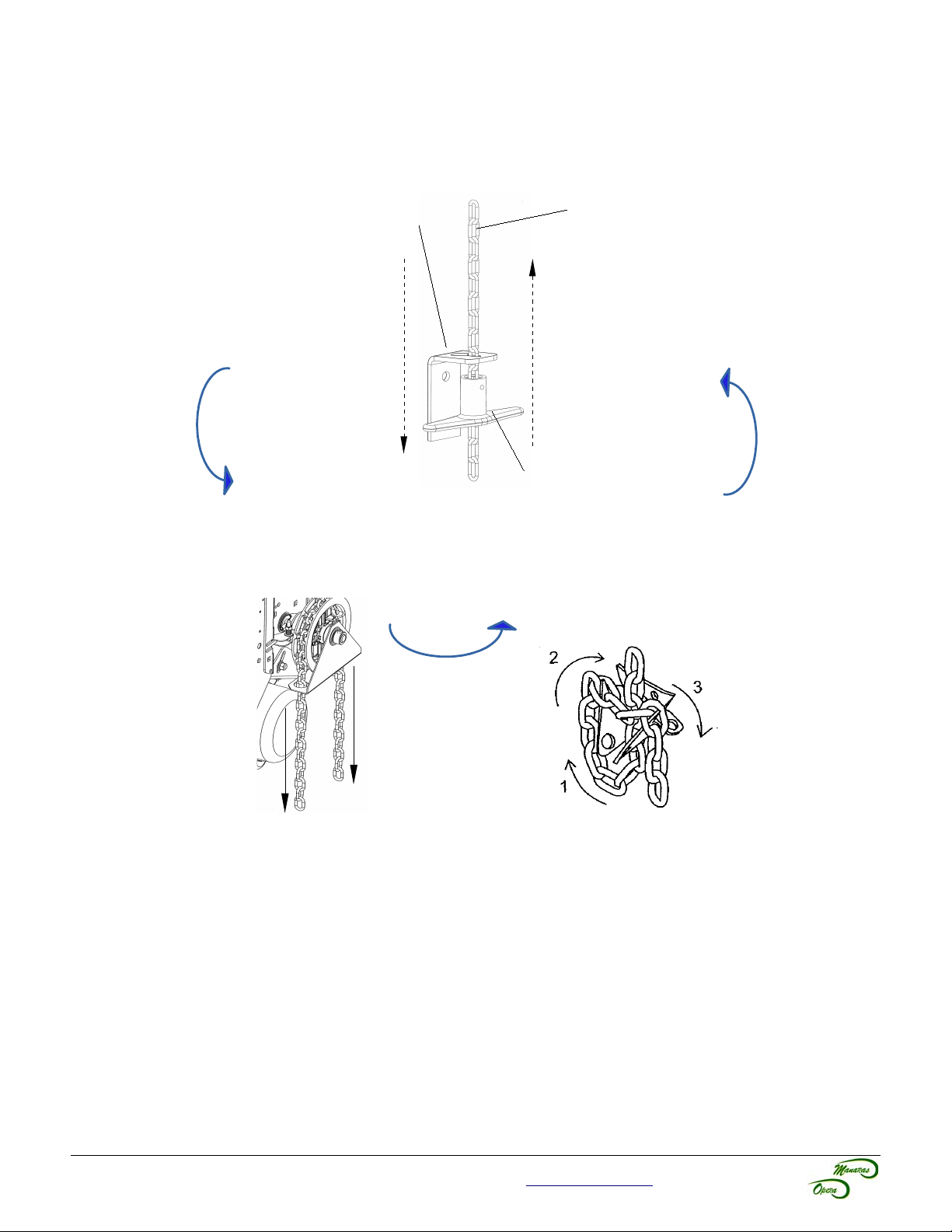

5 Manual Hand Chain and Disconnect Chain.....................................................................................................................................................9

5.1 Installation.................................................................................................................................................................................................9

5.2 Operating Mode......................................................................................................................................................................................10

6 Limit Switches & Limit Cams: Adjustment & unctionality.........................................................................................................................11

6.1 Limit Switch Adjustments: Open and Close Cam Settings.....................................................................................................................11

6.2 Limit Switch Functionality........................................................................................................................................................................11

6.3 Limit Switch Adjustment Using Manual Hand Chain if applicable)........................................................................................................12

6.4 Limit Switch Adjustment Without Manual Hand Chain if applicable).....................................................................................................12

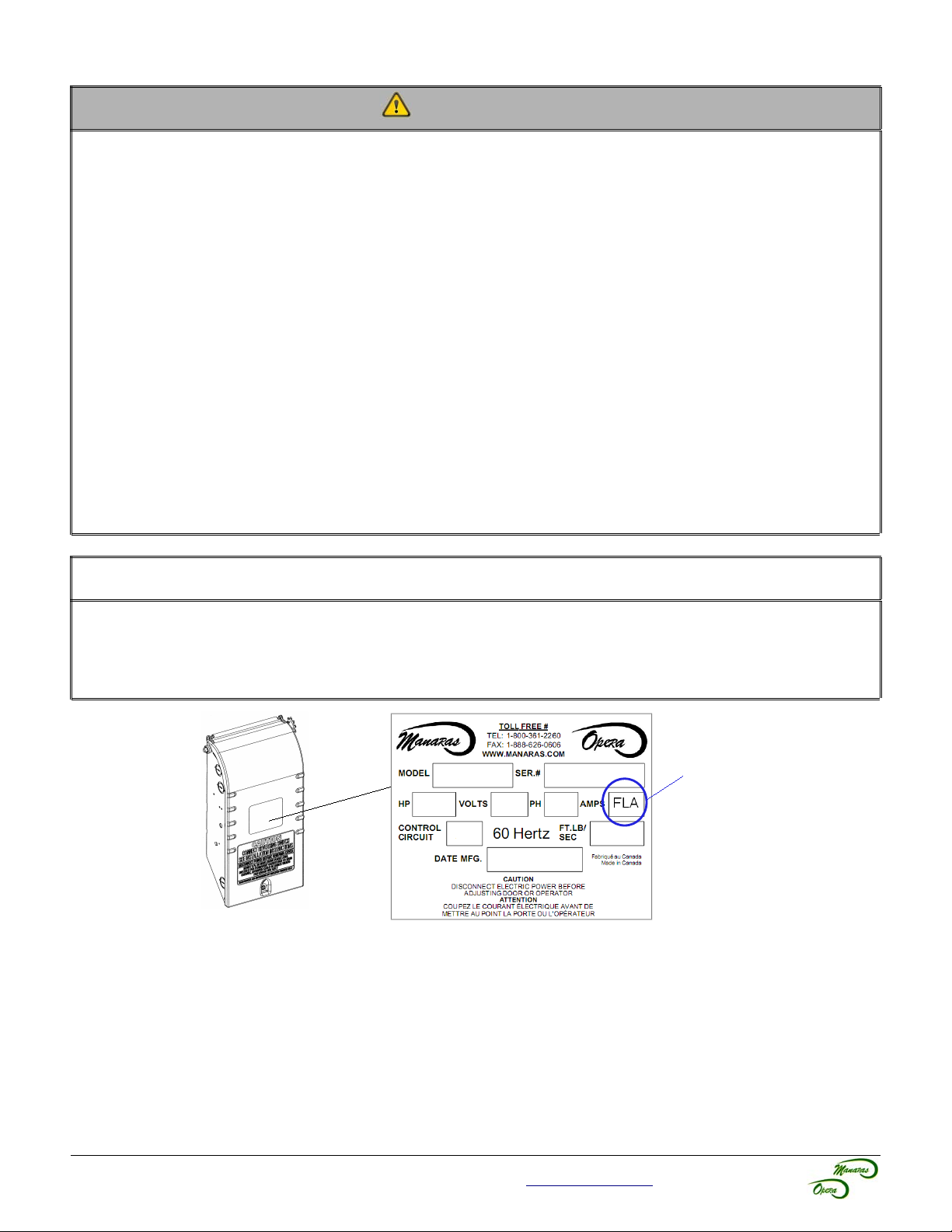

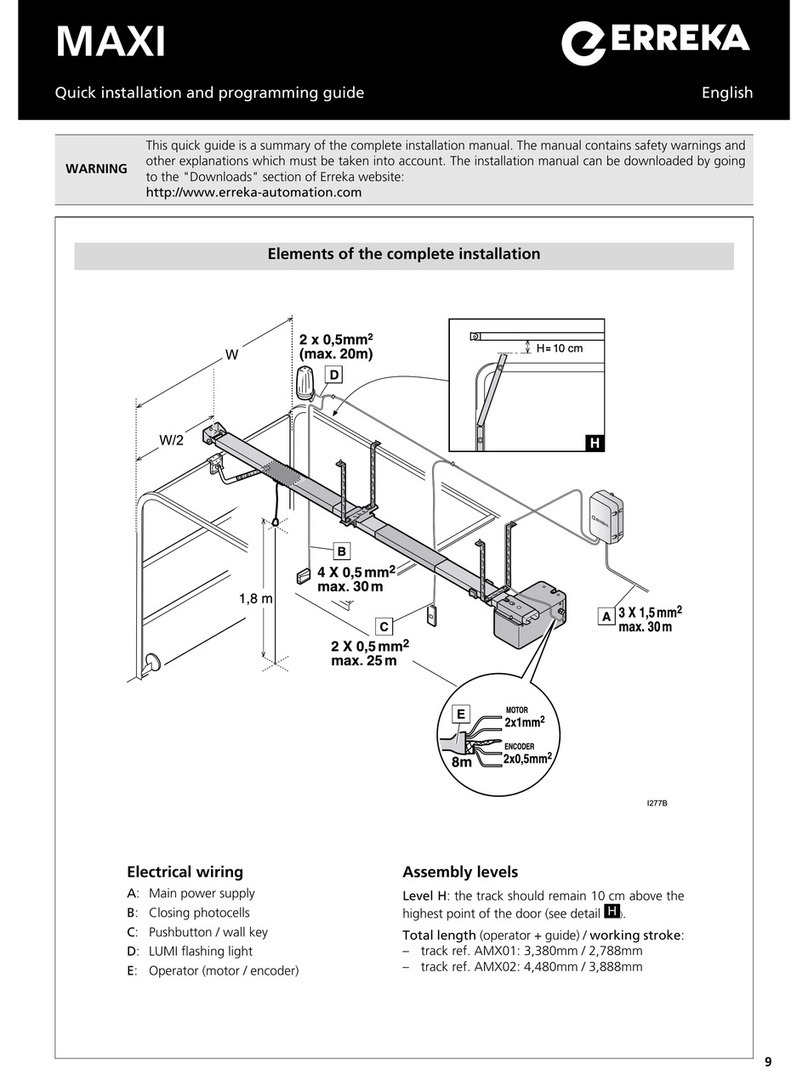

7 Electrical Wiring...............................................................................................................................................................................................13

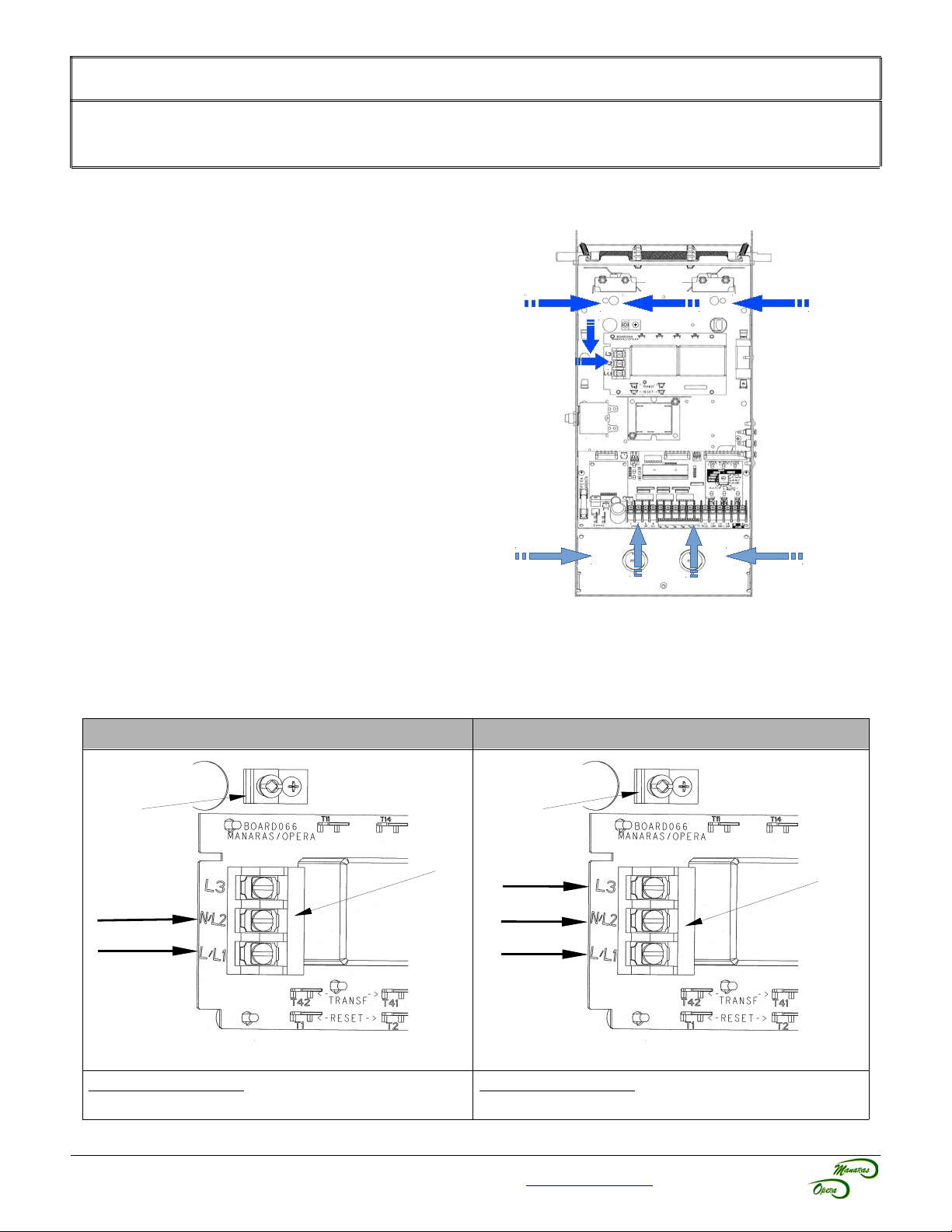

7.1 Low Voltage Controls) and High Voltage Power) Connections............................................................................................................14

7.2 Main Power Supply Connection..............................................................................................................................................................14

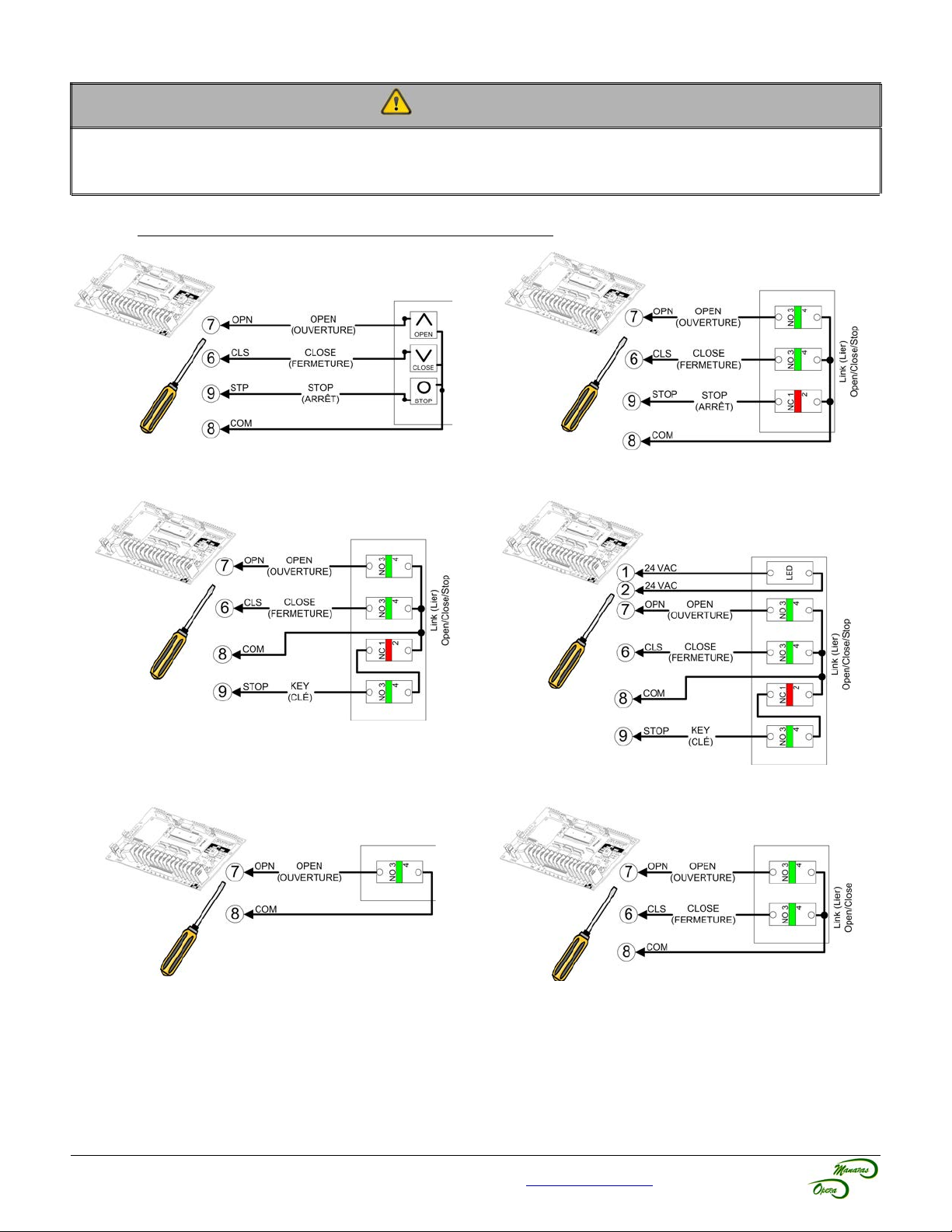

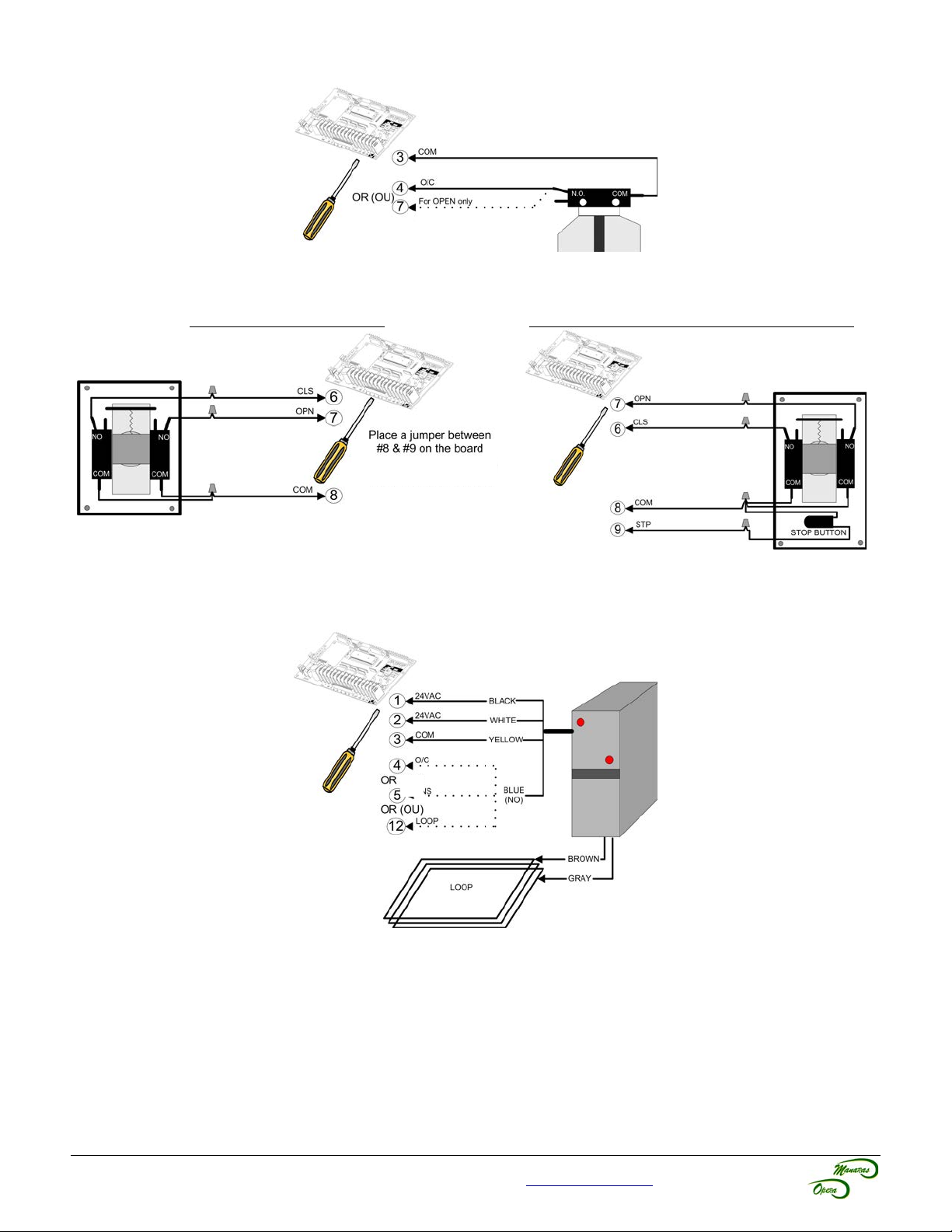

7.3 Push-Button Control Station Connection................................................................................................................................................15

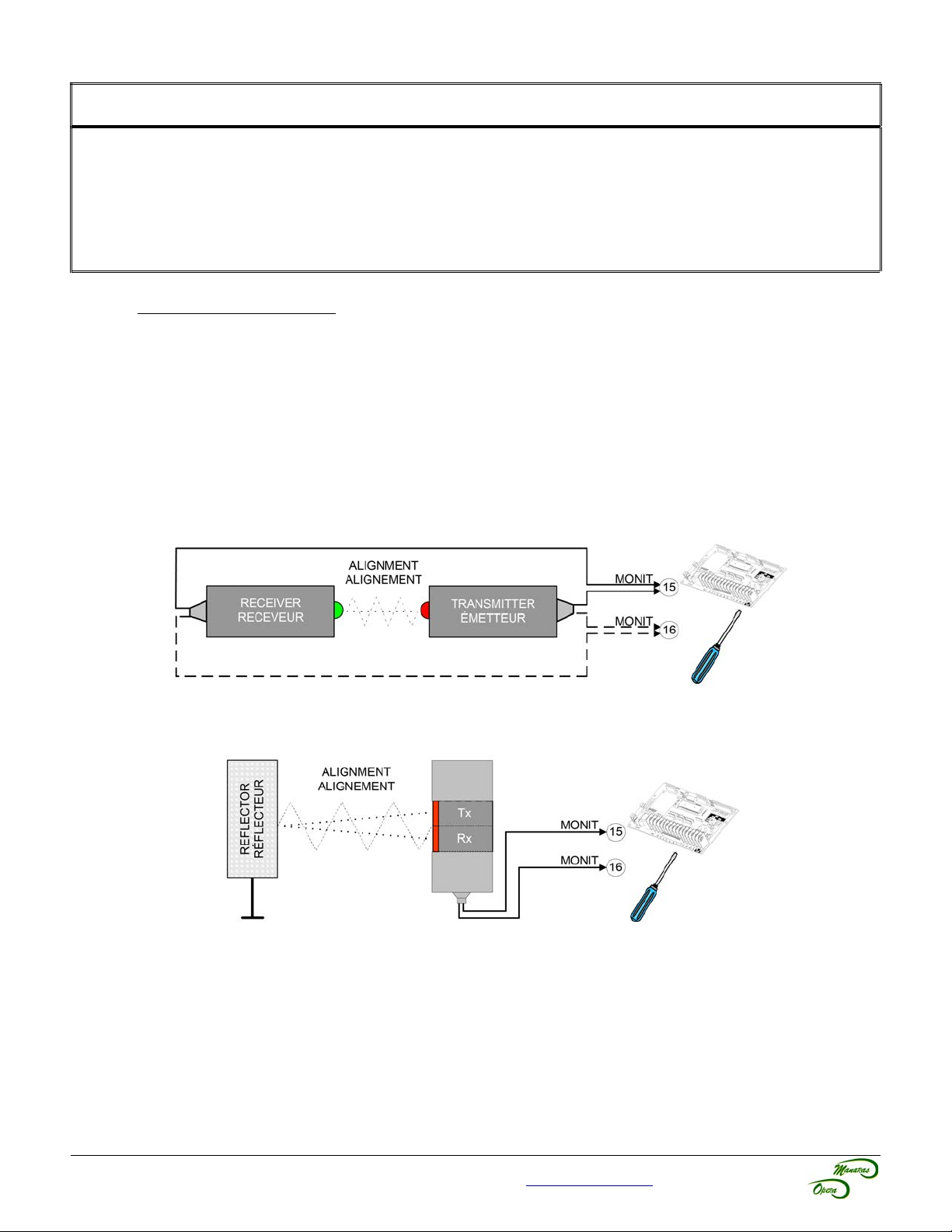

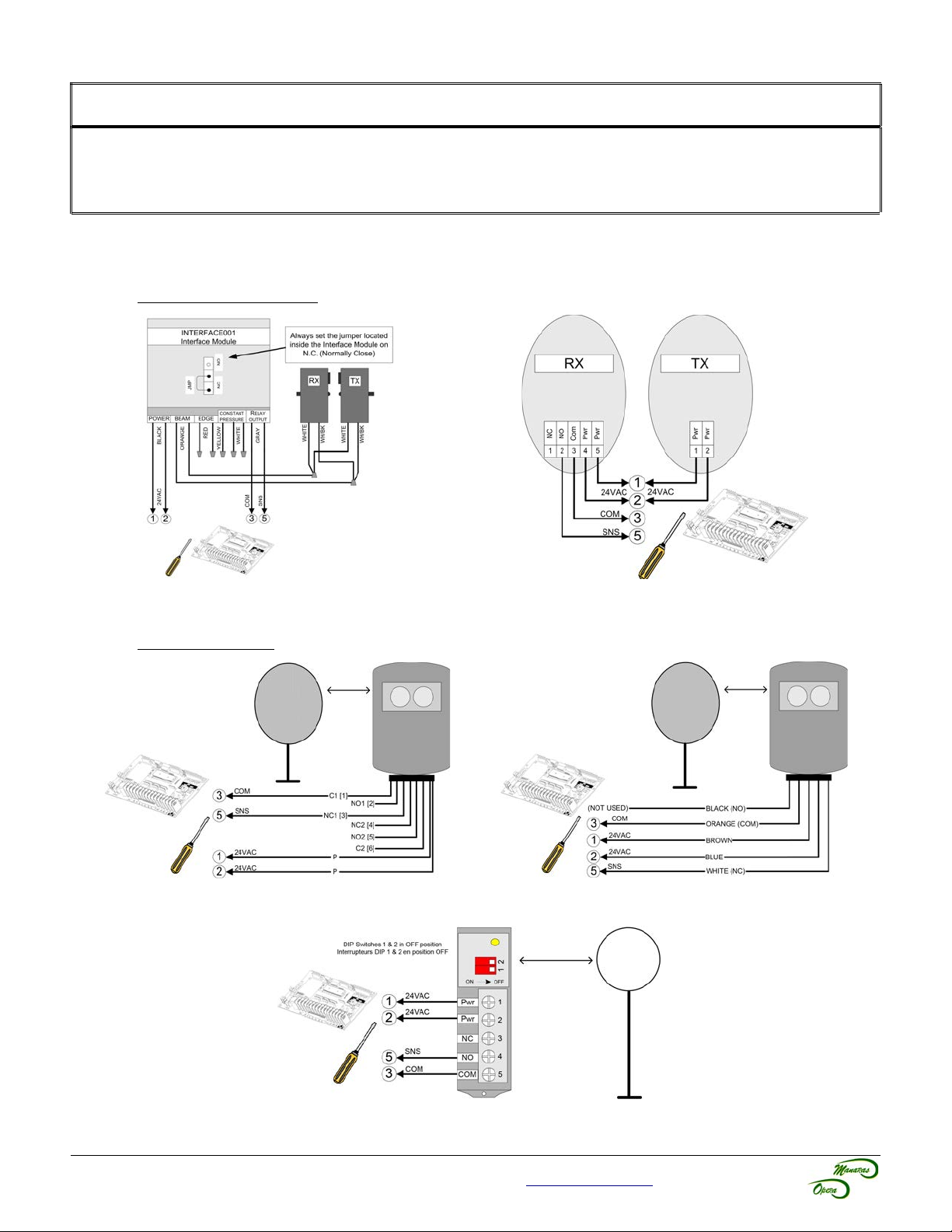

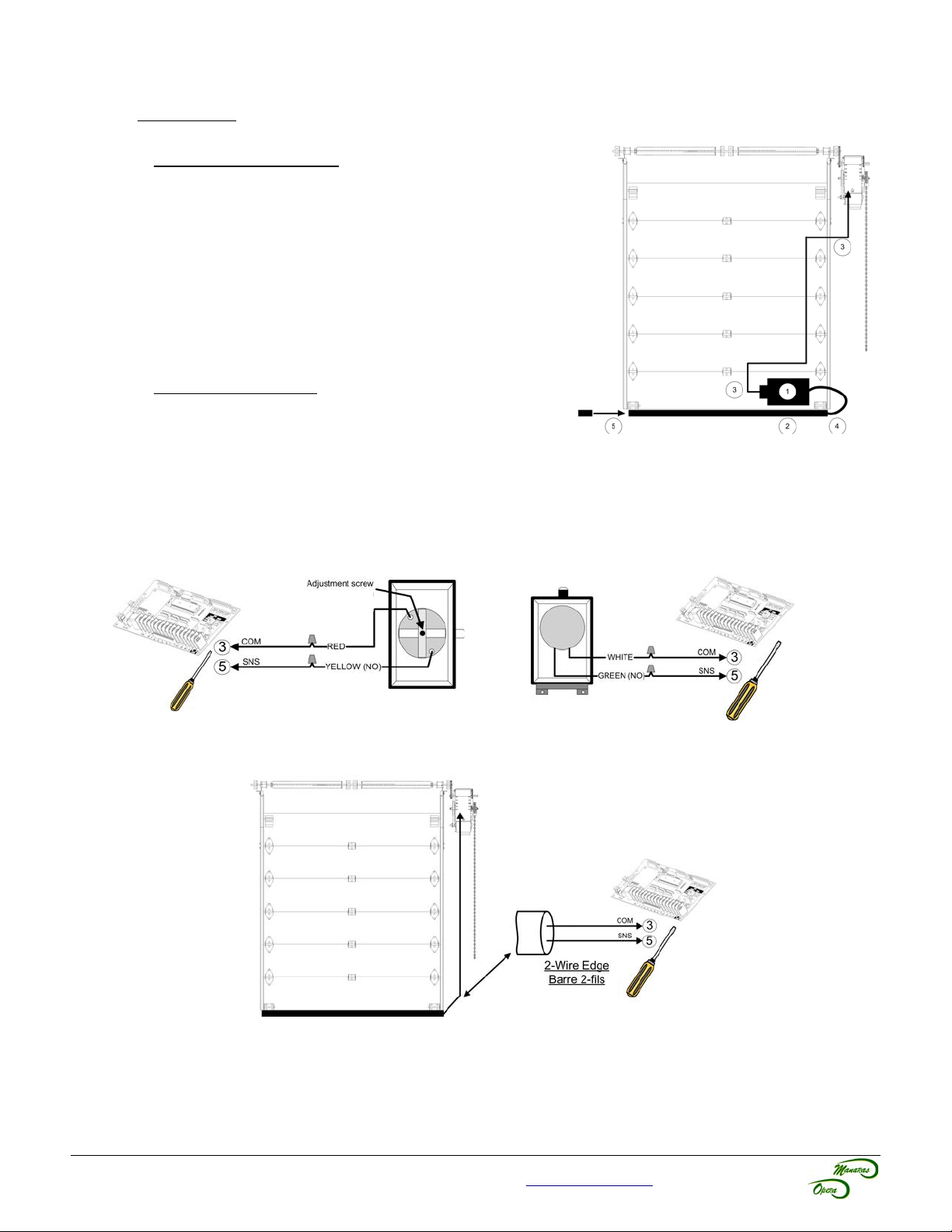

7.4 Monitored External Entrapment Protection Device Connection.............................................................................................................16

7.5 Optional Accessory Connections............................................................................................................................................................18

8 Electronic Control Board (ECB) – BOARD 070M..........................................................................................................................................21

8.1 General Layout........................................................................................................................................................................................21

8.2 On-Board LED Monitoring Status...........................................................................................................................................................22

8.3 Electronic Control Board ECB) Programming.......................................................................................................................................24

9 On-Board Radio Receiver...............................................................................................................................................................................28

9.1 Radio Receiver Components and Compatible Transmitting Devices.....................................................................................................28

9.2 On-Board Radio Receiver Programming Instructions............................................................................................................................28

9.3 Optional External Radio Receivers Ordered Separately)......................................................................................................................28

9.4 Radio Control Functions – 1 and 3-Button Transmitters.........................................................................................................................29

10 Operator Start-up.............................................................................................................................................................................................31

11 Clutch Adjustment...........................................................................................................................................................................................32

User Instructions........................................................................................................................................................ 33

1 Operation Instructions.....................................................................................................................................................................................33

2 Quick ix Instructions.....................................................................................................................................................................................34

Maintenance Instructions........................................................................................................................................... 35

1 Preventative Maintenance Schedule..............................................................................................................................................................35

1.1 Mechanical Inspection.............................................................................................................................................................................35

1.2 Electrical Inspection................................................................................................................................................................................36

1.3 Band Brake Maintenance........................................................................................................................................................................37

2 Troubleshooting Guide....................................................................................................................................................................................39

3 Electrical Drawings..........................................................................................................................................................................................41

3.1 1 Phase Operator with BOARD 070M....................................................................................................................................................41

3.2 3 Phase Operator with BOARD 070M....................................................................................................................................................42

3.3 External Wiring with BOARD 070M........................................................................................................................................................43

4 Mechanical Exploded Views and Replacement Components.....................................................................................................................44

4.1 MSJ General View...................................................................................................................................................................................44

4.2 MSJ Frame Assembly View....................................................................................................................................................................45

4.3 Opera Brake BRAKE 013).....................................................................................................................................................................46

4.4 Opera Control Box with BOARD 070......................................................................................................................................................47

4.5 Replacement Motors, Transformers, Solenoids and Resets..................................................................................................................48

Notes............................................................................................................................................................................ 49

Warranty...................................................................................................................................................................... 51

For technical support, please call 1-800-361-2260 or visit www.manaras.com for more information