www.mc-techgroup.com SP30-H../EX2 | 1.02.00 3

Content

1General information ................................................................................................................... 4

2Declaration of conformity.......................................................................................................... 4

3Electrical standards ................................................................................................................... 5

4Safety instructions..................................................................................................................... 5

5Information and safety instructions for using the tube in hazardous areas .......................... 6

6Warranty...................................................................................................................................... 6

7Used terms and signal indications............................................................................................ 7

8Application.................................................................................................................................. 8

9Description ................................................................................................................................. 8

9.1 Heated sample tube SP30-H../EX2 and SP30-H1.1-V/EX2 .................................................. 8

9.2 Temperature controller ......................................................................................................... 9

10 Technical Data.......................................................................................................................... 10

11 Preparation for Installation...................................................................................................... 11

12 Mounting................................................................................................................................... 11

13 Electrical connections ............................................................................................................. 12

13.1 Electrical connection of the heated sample tube................................................................. 13

14 Starting...................................................................................................................................... 14

15 Maintenance ............................................................................................................................. 15

16 Cleaning.................................................................................................................................... 15

List of illustrations

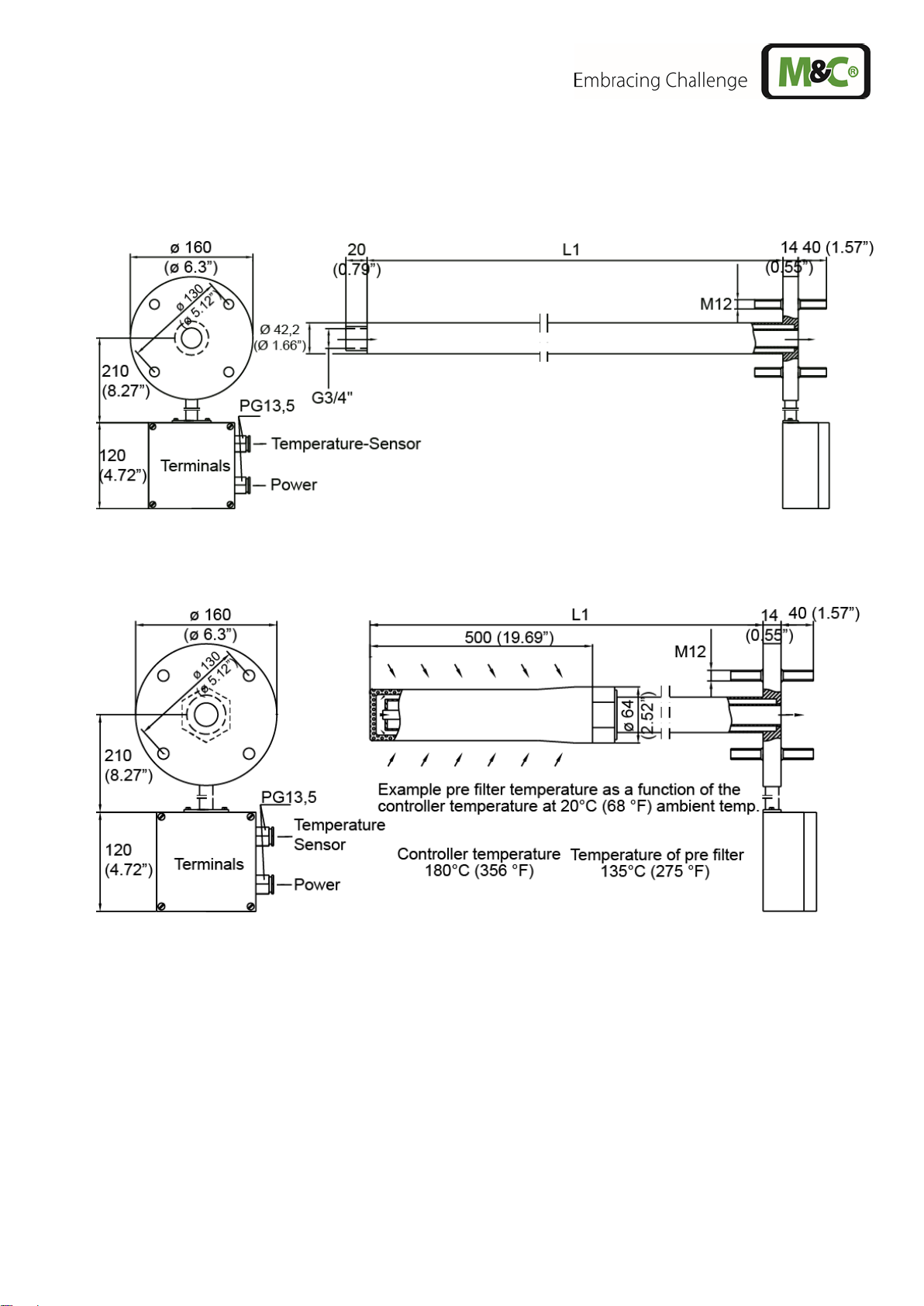

Figure 1 Dimensions SP30-H../EX2....................................................................................... 9

Figure 2 SP30-H1.1-V/EX2.................................................................................................... 9

Figure 3 Mounting of the heated sample tube SP30-H../EX2............................................... 12