Manitou 260 TJ User manual

647382 EN (13/02/2015)

260 TJ

280 TJ

MANITOU BF

BP 10249

44158 ANCENIS CEDEX - FRANCE

TEL: + 33 (0)2 40 09 10 11

YOUR DEALER

INSTRUCTIONS MANUAL

(ORIGINAL INSTRUCTIONS MANUAL)

THIS INSTRUCTIONS MANUAL MUST BE KEPT PERMANENTLY IN THE LIFT TRUCK

AND THE OPERATORS MUST HAVE READ AND FULLY UNDERSTOOD IT.

Foreword

This instruction for use is to explain the how

to operate the lifting platform and the maintenance that

must be performed periodically to ensure that the platform

remains in a completely safe and operational condition.

The platform has been designed and

produced to enable you to perform your overhead work

completely safely.

Before it was delivered, MANITOU and

the dealer have carefully inspected the platform so that it

comes to you in perfect working order.

647382 EN (01/02/2015)

1 - INSTRUCTIONS AND SAFETY ADVICE

2 - DESCRIPTION

3 - MAINTENANCE

4 - ELECTRICITY

THE TEXT AND THE ILLUSTRATIONS IN THIS DOCUMENT MAY NOT BE REPRODUCED,

EITHER IN WHOLE OR IN PART.

27/02/2012

14/06/2012

13/02/2015

1st PUBLICATION DATE

Update ( 1-20; 1-21; 2-4; 2-6; 2-8; 2-12; 2-13; 2-14; 2-17; 3-6; 3-9; 4)

Update EN280

647382 EN (01/02/2015)

FRONT REAR

260 TJ / 280 TJ

647382 EN (01/02/2015)

1-1

1 OPERATING

AND SAFETY

INSTRUCTIONS

1 OPERATING

AND SAFETY

INSTRUCTIONS

647382 EN (01/02/2015)

1-2

647382 EN (01/02/2015)

1-3

TABLE OF CONTENTS

INSTRUCTIONS TO THE COMPANY MANAGER 1-4

PREAMBLE 1-4

LESITE 1-4

THE OPERATOR 1-4

THE PLATFORM 1-4

THE INSTRUCTIONS 1-5

THE MAINTENANCE 1-5

INSTRUCTIONS FOR THE OPERATOR 1-6

PREAMBLE 1-6

GENERAL INSTRUCTIONS 1-6

DRIVING INSTRUCTIONS 1-8

INSTRUCTIONS FOR WELDING AND BLOW TORCH WORK ON THE EXTERNAL STRUCTURE 1-15

PLATFORM MAINTENANCE INSTRUCTIONS 1-16

GENERAL INSTRUCTIONS 1-16

MAINTENANCE 1-16

LUBRICANT AND FUEL LEVELS 1-16

LEVEL OF ELECTROLYTE IN THE BATTERY 1-16

HYDRAULIC 1-17

ELECTRICITY 1-17

WELDING ON THE ACCESS PLATFORM 1-17

WASHING THE PLATFORM 1-17

IFTHE PLATFORM IS NOT TO BE USED FOR ALONG TIME 1-18

INTRODUCTION 1-18

PREPARING THE PLATFORM 1-18

PROTECTING THE I.C. ENGINE 1-18

CHARGING THE BATTERIES 1-19

PROTECTING THE PLATFORM 1-19

BRINGING THE PLATFORM BACK INTO SERVICE 1-19

SCRAPPING THE PLATFORM 1-20

SAFETY DECALS 1-22

647382 EN (01/02/2015)

1-4

INSTRUCTIONS TO THE COMPANY MANAGER

PREAMBLE

WHENEVER YOU SEE THIS SYMBOL IT MEANS :

WARNING ! BE CAREFUL ! YOUR SAFETY OR

THE SAFETY OF THE PLATFORM IS AT RISK.

THE SITE

- Good personal control of the lifting platform’s operating area reduces the risk of accidents:

•The floor must not be unnecessarily broken or cluttered,

•No excessive slopes,

•Controlled pedestrian traffic, etc.

THE OPERATOR

-Only qualified, authorized personnel can use the platform. This authorization is given in writing by the appropriate person in the

establishment with respect to the use of platform and must be carried permanently by the operator.

On the basis of experience, there are a number of possible situations in which operating the platform is contra-

indicated. Such foreseeable abnormal uses, the main ones being listed below, are strictly forbidden.

- The foreseeable abnormal behaviour resulting from ordinary neglect, but does not result from any wish to put the

machinery to any improper use.

The reflex reactions of a person in the event of a malfunction, incident, fault, etc. during operation of the platform.

- Behaviour resulting from application of the “principle of least action”when performing a task.

- For certain machines, the foreseeable behaviour of such persons as : apprentices, teenagers, handicapped persons,

trainees tempted to drive a platform, operator tempted to operate a truck to win a bet, in competition or for their own

personal experience.

- The person in charge of the equipment must take these criteria into account when assessing whether or not a person

will make a suitable driver.

OBTAIN INFORMATION ON :

- How to behave when there is a fire.

- The location of the nearest first aid kit and fire extinguisher.

- The emergency telephone numbers for calling (the doctors, ambulance, hospital and fire brigade).

THE PLATFORM

A - THE PLATFORM’SSUITABILITY FOR US

-MANITOU has ensured that this platform is suitable for use under the standard operating conditions defined in this operator’s

manual, with an overload test coefficient of 1,25 and an operational test coefficient of 1,1, as stipulated in standardised norm EN

280 for MPLPs (Mobile Personnel Lifting Platforms).

Before commissioning, the company manager must make sure that the platform is appropriate for the work to be done, and

perform certain tests (in accordance with current legislation).

B - ADAPTATING THE PLATFORM TO THE USUAL ENVIRONMENTAL CONDITIONS

-In addition to series equipment mounted on your platform, many options are available, such as : flashing light, working headlight,

etc.

Contact your dealer.

-Take into account climatic and atmospheric conditions of the site of utilisation.

•Protection against frost (see chapter 3 - MAINTENANCE, LUBRICANTS page).

•Adaptation of lubricants (ask your dealer for information).

•I.C. engine filtration (see chapter 3 - MAINTENANCE, FILTER ELEMENTS page).

647382 EN (01/02/2015)

1-5

- The machines designed by MANITOU are designed to be used in the following temperature range:

• Minimum temperature: -20°C

• Maximum temperature: +45°C

- Special features are available, as an option, for particularly cold environments.

For operation under average climatic conditions, i.e. : between -15 °C and + 35 °C, correct levels of lubricants in all

the circuits are checked in production. For operation under more severe climatic conditions, before starting up, it

is necessary to drain all the circuits, then ensure correct levels of lubricants using lubricants properly suited to the

relevant ambient temperatures. It is the same for the cooling liquid.

-Aplatform operating in an area without fire extinguishing equipment must be equipped with an individual extinguisher.

There are solutions, consult your dealer.

Your platform is designed for outdoor use (see chapter: 2 - DESCRIPTION, CHARACTERISTICS pages) under

normal atmospheric conditions and indoor use in suitably aerated and ventilated premises. It is prohibited to use

the platform in areas where there is a risk of fire or which are potentially explosive (e.g. Refineries, fuel or

gas depots, stores of inflammable products…). For use in these areas, specific equipment is available (ask your

dealer for information).

C - MODIFYING THE PLATFORM

-For your safety and that of others, you must not change the structure and settings of the various components used in your

platform (hydraulic pressure, calibrating limiters, I.C. engine speed, addition of extra equipment, addition of counterweight,

unapproved attachments, alarm systems, etc.) yourself. In this event, the manufacturer cannot be held responsible.

-Your lifting platform is delivered with standard wheels or all-terrain wheels. It is FORBIDDEN to switch from one type of wheels

to another: RISK OF THE LIFTING PLATFORM BECOMING UNSTABLE.

THE INSTRUCTIONS

-The operator’s manual must always be in good condition and kept in the place provided on the platform and in the language

used by the operator.

-You must necessarily replace the instructions manual, as well as any plates or stickers, if they are no longer legible or are missing

or damaged.

THE MAINTENANCE

-Maintenance or repairs other than those detailed in the chapter 3 - MAINTENANCE must be carried out by qualified personnel

(consult your dealer) and under the necessary safety conditions to maintain the health of the operator and any third party.

Yourpatformmust beinspectedperiodically toensurethat itremainsin compliance.The frequencyofthis inspection

is defined by current legislation in the country in which the platform is use

-Example for France : The manager of the compagny using the platform must set up a maintenance book for each machine and

keep up-to-date (Ministerial Order of 2nd March 2004).

647382 EN (01/02/2015)

1-6

INSTRUCTIONS FOR THE OPERATOR

PREAMBLE

WHENEVER YOU SEE THIS SYMBOL IT MEANS :

WARNING ! BE CAREFUL ! YOUR SAFETY OR

THE SAFETY OF THE PLATFORM IS AT RISK.

The risk of accident while using, servicing or repairing your platform can be restricted if you follow the safety

instructions and safety measures detailed in these instruction.

-Only the operations and manœuvres described in these operator’s manual must be performed. The manufacturer cannot predict

all possible risky situations. Consequently, the safety instructions given in the operator’s manual and on the platform itself are

not exhaustive.

-At any time, as an operator, you must envisage, within reason, the possible risk to yourself, to others or to the platform itself

when you use it.

Failure to respect the safety and operating instructions, or the instructions for repairing or servicing your platform

may lead to serious, even fatal accident.

GENERAL INSTRUCTIONS

A - operator’s manual

- Carefully read and understand the operator’s manual.

- The operator’s manual must always be kept in the place provided for it on the platform and be written in the language used by

the operator.

- Any operations or manoeuvres not described in the operator’s manual must necessarily be forbidden right from the start.

- Follow the safety advice and the instructions on the platform.

- Ypu must necessarily replace the operator’s manual, as well as any plates or stickers, if they are no longer legible or are

damaged.

- A second operator must necessaily be present on the ground as a safety measure when using the platform.

- Familiarise yourself with the platform on the terrain it has to travel over.

- The machine must also be used in accordance with good engineering practice.

- Do not use the platform if the wind speed is over 45 km/h. The platform’s arms must not be subjected to a lateral force of more

than 40 kg (platforms for indoor use must not be used outside the building).

B - AUTHORIZATION FOR USE IN FRANCE

(ORSEE CURRENT LEGISLATION IN OTHER COUNTRIES)

-Only qualified, authorized personnel may use the platform. This authorization is given in writing by the appropriate person in the

company, in charge of using the platform, and must be permanently carried by the operator.

-The operator is not competent to authorise the driving of the platform by another person.

647382 EN (01/02/2015)

1-7

C - MAINTENANCE

-The operator must immediately advise his superior if his platform is not in good working order or does not comply with the safety

notice.

-The operator is prohibited from carrying out any repairs or adjustments himself, unless he has been trained for this purpose. He

must keep the platform properly cleaned if this is among his responsibilities.

-The operator must carry out daily maintenance (see chapter : 3 - MAINTENANCE, A - DAILY pages).

-The operator must ensure tyres are adapted to the nature of the ground (see area of the contact surface of the tyres in the

chapter : 2 - DESCRIPTION : CHARACTERISTICS pages). There are optional solutions, consult your dealer.

Do not use the platform if the tyres are damaged or excessively worn, because this could put your own safety or

that of others at risk, or cause damage to the platformk itself.

In the case of electric platforms, the operator must ensure that:

- The batteries are not replaced with lighter ones (compromising stability).

- Safety goggles are always worn when charging the batteries.

- The batteries are not charged in an explosive environment.

- There is no smoking and no naked flame directed towards the batteries when they are being handled during

removal, re-installation and checking the levels.

D - MODIFYING THE PLATFORM

-For your safety and that of others, you must not change the structure and settings of the various components used in your

platform yourself:

• hydraulic pressure,

• calibrating limiters,

• I.C. engine speed,

• addition of extra equipment,

• addition of counterweight,,

• unapproved attachments,

• alarm systems, etc...

-In this event, the manufacturer cannot be held responsible.

Your lifting platform is delivered with standard wheels or all-terrain wheels. It is FORBIDDEN to switch from one

type of wheels to another: RISK OF THE LIFTING PLATFORM BECOMING UNSTABLE.

E - IC PLATFORM AXLES

- STANDARD AXLE :

The chassis is rigid, so the platform can have a ground reach on only three wheels.

- OSCILLATING AXLE (IF THIS OPTION IS AVAILABLE) :

An oscillating axle enables the platform, when in transport position, to have a ground reach on four wheels. When

moving in working position over uneven terrain, the oscillating axle is locked (the chassis is rigid) so the platform

can have a ground reach on only three wheels.

647382 EN (01/02/2015)

1-8

DRIVING INSTRUCTIONS

A - BEFORE STARTING THE PLATFORM

- Ensure that the intermediate rail is fully in the locked position before operating the platform from the basket.

- If the platform is new, see the paragraph : before starting the platform for the first time in Chapter : 1 - safety advice and

instructions.

- Carry out daily maintenance (see chapter 3 - MAINTENANCE, A - DAILY pages).

- Before starting the platform, check the levels :

• IC PLATFORMS : • ELECTRIC PLATFORMS :

• IC engine oil • Hydraulic reservoir oil

• Hydraulic reservoir oil • Battery charge level

• Fuel

• Coolant

-The lifting platform must be in transport position (with the arms completely folded back or the scissors in the low position) before

you enter it.

-Make sure the horn works.

-Check before you use the lifting platform that the access door is properly locked.

B - DRIVER’SOPERATING INSTRUCTIONS

-Whatever his experience, the operator is advised to familiarize himself with the position and operation of all the controls and

instruments before operating the platform.

Wear suitable clothing for driving the platform, do not wear baggy clothes.

- Make sure you have the appropriate protective equipment for the job to be done.

- Prolonged exposure to high noise levels may cause hearing problems. It is recommended to wear ear muffs to protect against

excessive noise.

- Always pay attention when using the platform. Do not listen to the radio or music using headphones or earphones

- For increased comfort, adopt the correct position in the driver’s cab.

- The operator must always be in his normal position in the driver’s seat : extending arms or legs (or, in general, any part of the

body), outside the basket is forbidden.

- Safety helmets must be worn.

- MANITOU recommends a safety harness in the operator’s size be provided when the platform is in use (for the harness

attachement in the basket , see chapter 2 - DESCRIPTION, CHECKING AND CONTROL INSTRUMENTS pages).

- The control units must never in any event be used for any other than their intended purposes (e.g. climbing onto or down from

the platform, coat-rack, etc.).

- In the case of scissors-type platforms, it is forbidden to use the platform without the guardrails in place.

- Suspending a load under the basket or on any part of the lifting apparatus is strictly forbidden.

- The operator must not climb into or get down from the basket unless it is at ground level (with the lifting system folded).

-If the nacelle is equipped with a step, the basket must be situated directly below it before mounting or dismounting.

-The platform must not be fitted with any accessory increasing the machine’s wind profile.

-Do not use a ladder or any improvised constructions in the basket to reach greater heights.

-Do not climb on the sides of the basket to reach greater heights.

-Never use the lifting platform with wet or greasy hands and shoes.

C - ENVIRONMENT

-Comply with site safety regulations.

- The platform can be manoeuvred from the ground: ensure that you forbid access.

- If you have to use the platform in a dark area or at night, make sure it is equipped with working lights.

- The platforms may not be used as cranes or elevators for the permanent transport of people or materials, nor as jacks or

supports.

- When operating, ensure that there is no one or anything impeding the platform’s progress ans operation.

- When raising the platform, ensure that no one or anything inpedes the platform’s operation and do not perform any inappropriate

manœuvres.

647382 EN (01/02/2015)

1-9

-Do not allow anybody to come near the working area of the platform or pass beneath an elevated load. To do this, mark your

operating area with warning signs.

-Travelling on a longitudinal slope :

• Ensure that you adapt the platform’s travelling speed by controlling the speed with the travelling manipulator.

-Take into account the platform’s dimensions and its load before trying to negotiate a narrow or low passageway.

-Never move onto a loading platform without having first checked :

•That it is suitably positioned and made fast.

• That the unit to which it is connected (wagon, lorry, etc.) will not shift.

• That this platform is prescribed for the size and the total weight of the platform.

• That the slope is not greater than the platform’s maximum authorised slope.

-Never move onto a foot bridge, floor or freight lift, without being certain that they are prescribed for the weight and size of the

platform to be loaded and without having checked that they are in sound working order.

-Be careful in the area of loading bays, trenches, scaffolding, soft land and manholes.

-Ensure that the ground under the wheels and/or stabilisers is firm and stable before raising the basket.

-Do not attempt any operations outside the plarform’s capabilities.

-Ensure that the materials on the platform (pipes, cables, containers, etc ...) cannot slip off and fall. Do not heap up these

materials to the pint where you have to step over them.

If the basket must remain stationary over a structure for a long period, there is a risk that the basket will rest on this

structurebecauseoftheoilcoolinginthecylindersoraminorleakinthecylinderlockingsystem.Toeliminatethisrisk:

- Regularly check the distance between the basket and the structure and re-adjust if necessary.

- If possible use the platform at an oil temperature as close as possible to ambient temperature.

-In the case of work near aerial lines, ensure that the safety distance is sufficient between the working area of the platform and

the aerial line.

You must consult your local electrical agency. You could be electrocuted or seriously injured if you operate or park

the platform too close to power cables.

If the platform comes into contact with electric wires, press the Emergency Stop button. If you can, jump from the

basket without simultaneously being in contact with the basket and the ground.

If not, call for help, wam people not to touch the basket and to switch off the power supply to the wires or have it

switched off.

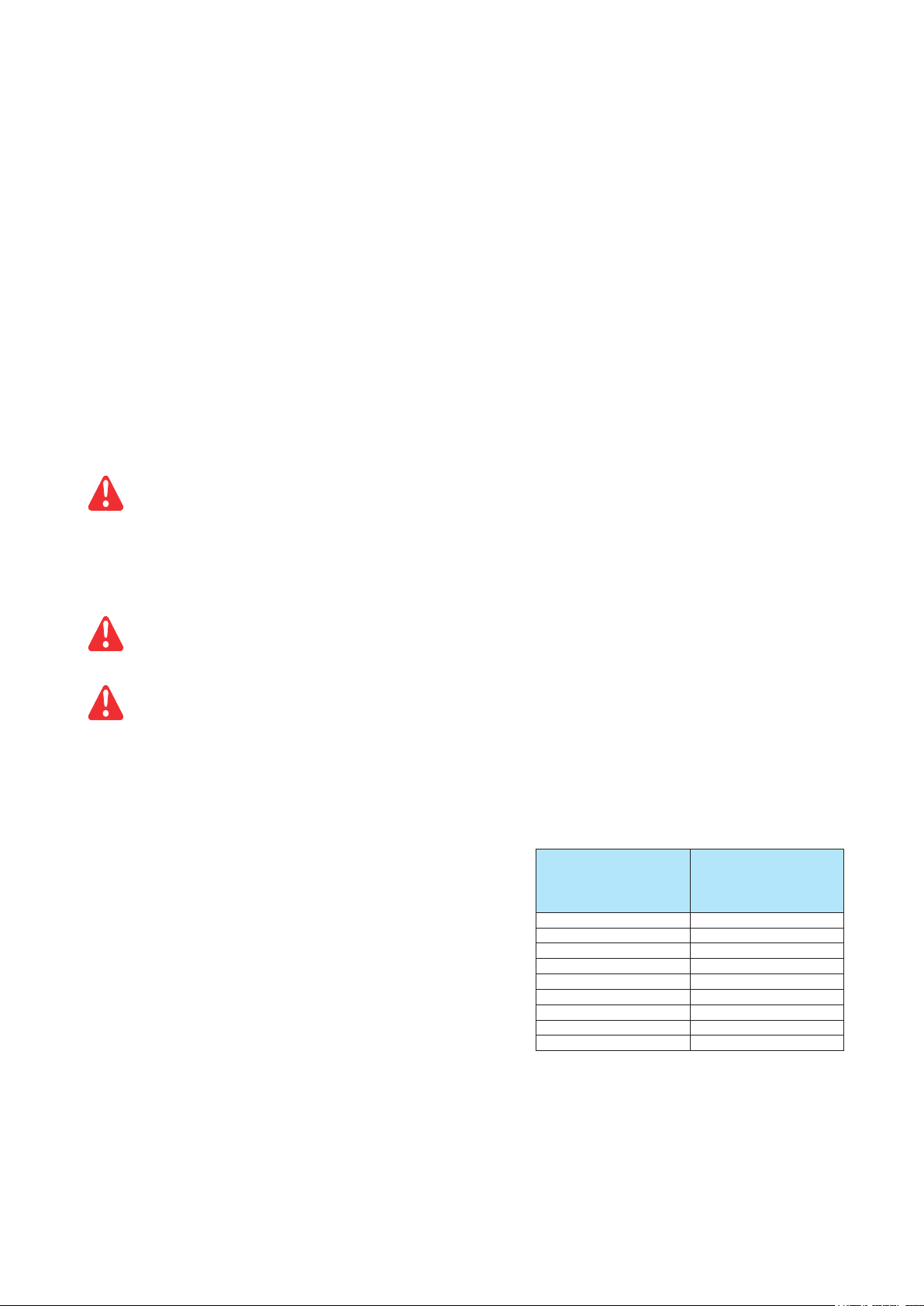

-It is forbidden to use the lifting platform close to electrical power lines; observe the safety distances.

NOMINAL VOLTAGE

IN VOLTS

DISTANCE ABOVE THE

GROUND

OR THE FLOOR

IN METRES

50 < U < 1000 2,30 M

1000 < U < 30000 2,50 M

30000 < U < 45000 2,60 M

45000 < U < 63000 2,80 M

63000 < U < 90000 3,00 M

90000 < U < 150000 3,40 M

150000 < U < 225000 4,00 M

225000 < U < 400000 5,30 M

400000 < U < 750000 7,90 M

647382 EN (01/02/2015)

1-10

If the wind is in excess of 45Km/h, do not perform any movements liable to endanger the lifting platform’s stability.

- To recognise this speed by eye, please refer to the empirical wind evaluation scale below:

BEAUFORT scale (wind speed at a height of 10m over flat terrain)

Degree Type of wind Speed

(knots)

Speed

(km/h)

Speed

(m/s) Ground effects Sea conditions

0 Calm

0 - 1 0 - 1 < 0,3

Smoke rises vertically. The sea is like a mirror.

1Very light

breeze

1 - 3 1 - 5 0,3 - 1,5

The smoke drift indicates the wind

direction.

Some wavelets, like fish scales, but no

foam.

2 Light breeze

4 - 6 6 - 11 1,6 - 3,3

Wind felt on exposed skin, leaves

rustle.

Small but noticeable wavelets.

3Gentle

breeze

7 - 10 12 - 19 3,4 - 5,4

Leaves and small twigs constantly

moving.

Very small waves, crests beginning to

break.

4Moderate

breeze

11 - 16 20 - 28 5,5 - 7,9

The wind raises dust and scraps of

paper, it moves small branches.

Small waves stretching, many sheeps.

5 Fresh breeze

17 - 21 29 - 38 8 - 10,7

Small trees in leaf start to sway. Wavelets form on stretches of water,

moderate waves of some length.

6Strong

breeze

22 - 27 39 - 49 10,8 - 13,8

Large branches are moved, overhead

wires whistle, umbrella use becomes

difficult.

Waves form with white foam crests

and airborne spray.

7 High wind

28 - 33 50 - 61 13,9 - 17,1

Whole trees are moving, effort

required to walk against the wind.

The sea heaps up; some foam from

breaking waves is blown into streaks

in the wind direction.

8 Gale

34 - 40 62 - 74 17,2 - 20,7

The wind breaks off twigs, walking

against the wind is very difficult.

Moderate height longer waves with

breaking crests forming spindrift.

9 Strong gale

41 - 47 75 - 88 20,8 - 24,4

The wind damages roofs (chimneys,

tiles, etc.).

Large waves, dense spindrift

wrenched from the waves, airborne

spray reducing visibility.

10 Storm

48 - 55 89 - 102 24,5 - 28,4

Rarely seen on land, trees uprooted,

dwellings incur significant damage.

Very large waves, foam forming large

amounts of airborne spray, reducing

visibility.

11 Violent storm

56 - 63 103 - 117 28,5 - 32,6

Very rare, extensive damage. Waves of exceptional height capable

of sinking medium-sized ships,

reduced visibility.

12 Hurricane

64 + 118 + 32,7 +

Disastrous damage. Sea completely white, air full of spray

and foam, severely reduced visibility.

647382 EN (01/02/2015)

1-11

D - VISIBILITY

-Maintain permanently good visibility throughout the route. To increase your visibility, you can move forwards with the pendular

arm slightly raised (pay attention to the risk of falls in the basket from knocking into a low doorway, overhead electric wires,

travelling cranes, highway bridges, tracks or any obstacle in the area in front of the platform). In reverse, look directly behind you.

In any case, avoid reversing over long distances.

-If visibility of your road is inadequate, ask someone to help, standing outside the area in which the platform will be moving, and

make sure you always have a good view of this person.

647382 EN (01/02/2015)

1-12

E - STARTING THE PLATFORM

PLATFORMS WITH IC ENGINES

SAFETY NOTICE

-Do not pull or push the lifting platform to start it. This type of manoeuvre would cause severe damage to the transmission. In

cases of necessity, towing requires that the lifting platform be placed in freewheeling mode (See chapter 3 - MAINTENANCE).

-If using an emergency battery for start-up, use a battery with the same characteristics and respect battery polarity when

connecting it. Connect at first the positive terminals before the negative terminals.

Failure to respect polarity between batteries can cause serious damage to the electrical circuit. The electrolyte in

the battery may produce an explosive gas. Avoid flames and generation of sparks close to the batteries.

Never disconnect a battery while it is charging.

INSTRUCTIONS

-Check the closing and locking of the hood(s).

-Turn the ignition key to notch I to switch on the electrical power, which automatically starts the pre-heating system (all the bars

must be displayed), the message “OK” is displayed.

-Check that everything is operating correctly by ensuring that no fault pages are displayed on the screen and no warning about

the fuel level

(a pump icon is present on the screen)

(see chapter 2 - DESCRIPTION, CHECKING AND CONTROL INSTRUMENTS pages).

-To start, turn the ignition switch to position I.

-Press the starter button.

-Do not engage the starter motor for more than 15 seconds and carry out the preheating for 10 seconds between unsuccessful

attempts.

-Check all control instruments when the I.C. engine is warm and at regular intervals during use, so as to quickly detect any faults

and to be able to correct them without any delay.

-If any faults are displayed on the screen, stop the engine and immediately take the necessary measures.

ELECTRIC PLATFORMS

SAFETY NOTICÉ

-Do not use the platform if the battery is discharged to the point that movements are slowed down. In certain cases, the platform

may stop (see chapter 3 - MAINTENANCE : EVERY DAY OR EVERY 10 HOURS FOR OPERATION pages, for the minimum

permissible charge level).

INSTRUCTIONS

-Set the battery cut-out to the ON position.

-Check the closing and locking of the hood(s).

-Turn the ignition key to the basket position.

-Check that everything is operating correctly by ensuring that no error messages are displayed on the screen and that the machine

maintenance light is not flashing (see chapter 2 - DESCRIPTION, CHECKING AND CONTROL INSTRUMENTS pages).

NB: For machines not fitted with a display or a maintenance warning light, faults can be identified from the light directly on the

variable speed drive unit (to access: open the cowl on the control size, remove the casing from the variable speed drive and see

whether the light is flashing).

-If any error messages are constantly displayed or the machine maintenance light is flashing, return the key to the neutral

position.

-Set the battery cut-off to the OFFposition.

-Immediately take the necessary measures.

647382 EN (01/02/2015)

1-13

F - DRIVING THE PLATFORM

SAFETY NOTICE

Operators should be aware of the risks connected with using the platform, notably:

- Risk of losing control.

- Risk of losing lateral and frontal stability of the platform.

The operator must remain in control of the platform.

- Do not carry out operations which exceed the capacities of your platform.

- Familiarise yourself with the platform on the terrain where it will be used.

- Ensure that the brakes work efficiently when stopping a travelling movement, taking into account the braking distances.

- Drive smoothly at an appropriate speed for the operating conditions (land configuration, load in the basket).

- take extreme care if manoeuvring the platform with the basket in the high position. Ensure you have adequate visibility.

- Take bends slowly.

- In all circumstances make sure you are in control of your speed.

- Travel slowly on damp, slippery or uneven terrain or on truck ramps.

- Always remember that the hydraulic form of steering is very sensitive to movements.

- Never leave the I.C. engine on when the platform is unattended.

- Look where you are going and always make sure you have good visibility along the route.

- Drive round obstacles.

- Never drive on the edge of a ditch or steep slope.

- Whatever your travelling speed, you must reduce the speed as much as possible before stopping.

- The lifting platform must work in an obstacle-free area, where there is no danger descending to the ground.

- The operator using the lifting platform must be assisted by an appropriately instructed person on the ground.

- Comply with the limits shown on the lifting platform’s load graph.

INSTRUCTIONS

-When moving the platform a long distance, always travel with the arms folded or the scissors in the low position.

-Engage the appropriate gear (see chapter 2 - DESCRIPTION, CHECKINGAND CONTROL INSTRUMENTS pages).

647382 EN (01/02/2015)

1-14

G - STOPPING THE PLATFORM

SAFETY NOTICE

-Never leave the ignition key in the platform during the operator’s absence.

-Make sure that the platform is not stopped in any position that will interfere with the traffic flow and at less than one meter from

the track of a railway.

-In the event of prolonged parking on a site, protect the platform from bad weather, particularly from frost (check the level of

antifreeze), close and lock all the platform accesses (cowls…).

-Park the lifting platform on a flat surface or on a slight slope of less than 10%.

INSTRUCTIONS

PLATFORMS WITH IC ENGINES

-Before stopping the platform after a long working period, leave the I.C. engine idling for a few moments, to allow the coolant liquid

and oil to lower the temperature of the I.C. engine and transmission.

Do not forget this precaution, in the event of frequent stops or warm stalling of the I.C. engine, or else the

temperature of certain parts will rise significantly due to the stopping of the cooling system, with the risk of badly

damaging such parts.

-Stop the I.C. engine with the ignition switch.

-Remove the ignition key.

-Check that all the accesses on the platform are closed and locked (cowls…).

ELECTRIC PLATFORMS

- Remove the ground/platform control selection key.

- Check that all the accesses on the platform are closed and locked (cowls…).

- Set the battery cut-out to the OFF position (ELECTRIC PLATFORM).

647382 EN (01/02/2015)

1-15

INSTRUCTIONS FOR WELDING AND BLOW TORCH WORK ON THE EXTERNAL STRUCTURE

Ensure that there are no hydraulic or electrolyte leaks on the platform.

When welding, work in the opposite direction from the control console to avoid sparks damaging it .

-Any welding and cutting (blow torch) work from the basket on a building’s metallic structures requires the following precautions

to be taken:

A - WITH ELECTRIC WELDING EQUIPMENT

-It is essential that the machine has a discharge braid connecting the platform’s chassis to the ground.

-It is also essential that the external structure to be welded is connected to the earth. If the above conditions are observed,

the platform can, in this case, be in contact with the structure or the elements to be welded without damaging the electronic

components.

-The power supply to the welding equipment must be via an earthed socked and any extension required just also be earthed.

-In all cases, ensure that there are no electrical arcs in the basket or on the platform (contact between the brazing rod or the torch

and the welding equipment’s earth). To ensure this, at any time the welding equipment’s earth must not be positioned on the

platform’s basket but instead only as close as possible to the element to be welded.

-Switch off the welding equipment before disconnecting the earth clamp from the element or elements to be welded.

B - WITH ABLOW TORCH

-Attach the blow torch’s bottles to the basket’s handrails.

-instructions for welding and blow torch work on the external structure

-Do not set the blow torch down on the lip of the basket while it is still operating or point it towards the control console or its power

cables.

647382 EN (01/02/2015)

1-16

PLATFORM MAINTENANCE INSTRUCTIONS

GENERAL INSTRUCTIONS

-Ensure the area is sufficiently ventilated before starting the platform.

- Wear clothes suitable for the maintenance of the platform, avoid wearing jewellery and loose clothes. Tie and protect your hair,

if necessary.

- Stop the I.C. engine before conducting any work on the platform, remove the ignition key and disconnect the “Minus” battery

terminal.

- Set the battery cut-out to the OFF position (ELECTRIC PLATFORM).

- Read the operator’s manual carefully.

- Carry out all repairs immediately, even if the repairs concerned are minor.

- Repair all leaks immediately, even if the leak concerned is minor.

- Make sure that the disposal of process materials and of spare parts is carried out in total safety and in a ecological way.

- Be careful of the risk of burning and splashing (exhaust, radiator, I.C. engine, etc.).

MAINTENANCE

-Perform the periodic service (see : 3 - MAINTENANCE) to keep your platform in good working conditions. Failure to perform the

periodic service may cancel the contractual guarantee.

MAINTENANCE LOG

-The maintenance work performed following the recommendations in Part 3 - MAINTENANCE and the other inspection, servicing,

repair and modification work performed on the lifting platform must be recorded in a maintenance log. A note must be made, for

each operation, of the date of the work, the names of the persons or companies that have performed them, the nature of the

’operation and, where applicable, the maintenance intervals. When components in the lifting platform have to be replaced, the

components’ references must be noted.

LUBRICANT AND FUEL LEVELS

-Use the recommended lubricants (never use contaminated lubricants).

- Do not fill the fuel tank when the I.C. engine is running.

- Only fill up the fuel tank in areas specified for this purpose.

- Do not fill the fuel tank to the maximum level.

- Do not smoke or approach the platform with a flame, when the fuel tank is open or is being filled.

LEVEL OF ELECTROLYTE IN THE BATTERY

-Check the level of the battery or batteries.

When doing this, ensure you take all the safety precautions (See : 3 - MAINTENANCE).

647382 EN (01/02/2015)

This manual suits for next models

1

Table of contents

Other Manitou Boom Lift manuals

Manitou

Manitou 200 ATJ User manual

Manitou

Manitou 200 ATJ User manual

Manitou

Manitou 120 AETJ L Operating instructions

Manitou

Manitou 160 ATJ E3 User manual

Manitou

Manitou MHT 10180 129 M ST4 S1 User manual

Manitou

Manitou MAN'GO 12 User manual

Manitou

Manitou 120 AETJ COMPACT User manual

Manitou

Manitou AETJL 120 Operating instructions