Manitou 120 AETJ COMPACT User manual

27 / 06 / 2002 First edition

06 / 12 / 2002 Update

17 / 02 / 2003 Update

03 / 06 / 2003 Update P. 3-5

02 / 09 / 2004 Update P. 2-5, 2-8, 2-10, 2-11, 2-16, 2-25, 2-27,

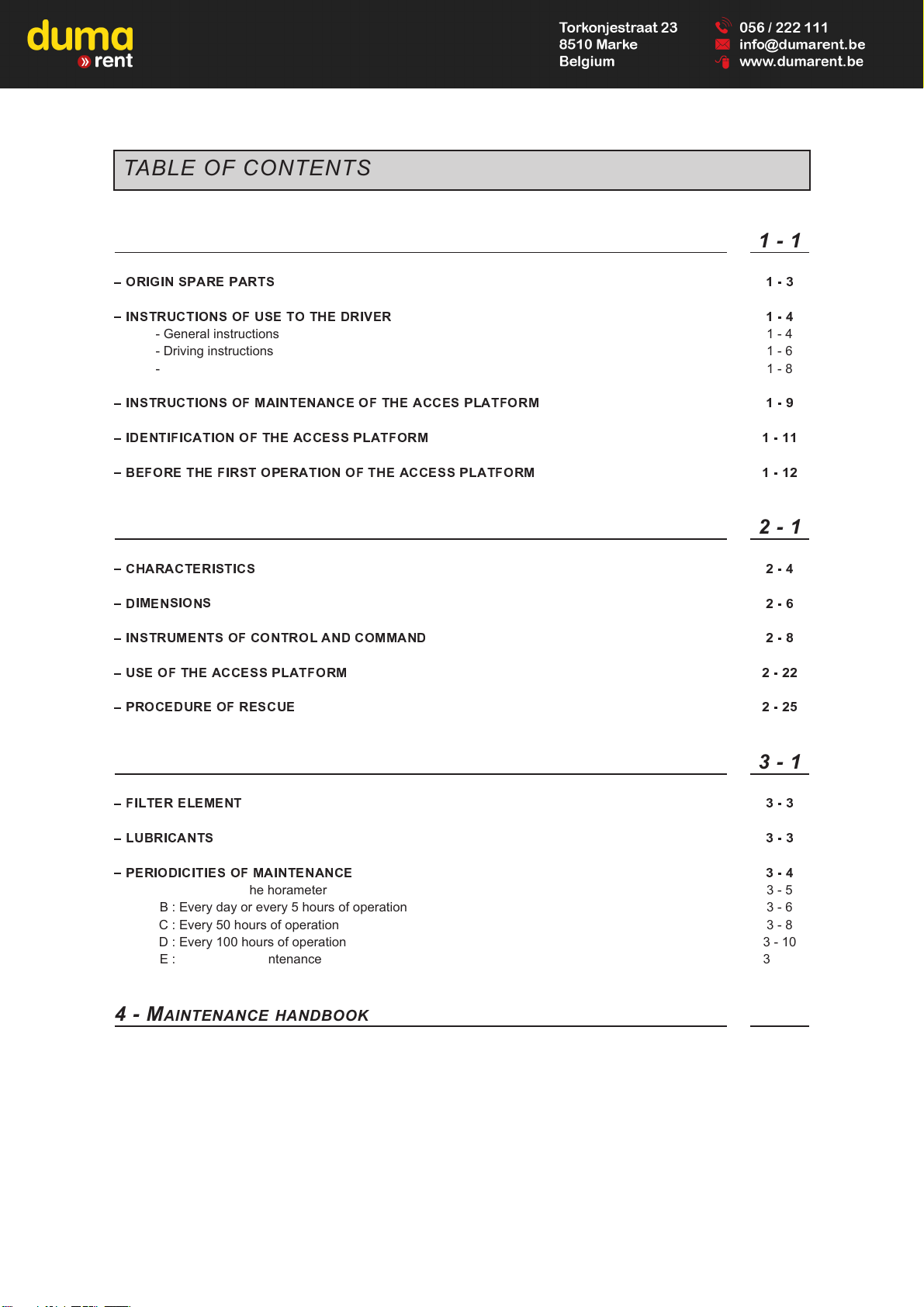

3 - MAINTENANCE (Maintenance

periodicity)

09 / 11 / 2004 Update MANITOU

01 / 09 / 2005 120AETJ > 120AETJ COMPACT

(From machine No 509104)

Update P. 2-10, 2-19, 2-20, 2-27

1 - INSTRUCTIONS

!

"

- General instructions

- Driving instructions

- Handling instructions

2 - DESCRIPTION

3 - MAINTENANCE

A : Reading of the horameter

B : Every day or every 5 hours of operation

C : Every 50 hours of operation

D : Every 100 hours of operation

E : Occasional maintenance

4 - MAINTENANCE HANDBOOK

TABLE OF CONTENTS

1 - 1

#

#

1 - 4

1 - 6

1 - 8

#

#

#

2 - 1

#

#

# $

#

#

3 - 1

#

#

#

3 - 5

3 - 6

3 - 8

3 - 10

3 - 14

4 - 1

BY ALLOWING THE USE OF NON-ORIGIN PARTS,

YOU RISK - Legally, to engage your responsability in case of accident.

- Technically, to generate some failings of fonctioning or to reduce the lifespan of the equipment.

The use of counterfait parts or components non-certified by the manufacturer can put an end to the contractual

guarantee conditions and causes the pull back of the conformity notification by the manufacturer.

BY USING THE ORIGIN PARTS IN THE OPERATIONS OF MAINTENANCE:

YOU PROTECTED

- The user who supplies somewhere else, makes this at his own risks.

YOURSELF

- The user who modifies or makes modified his access platform by a service supplier, should

consider that a new material is launching and he becomes responsible.

LEGALLY

- The user who copies or makes copied the origin parts, lays himself to legal risks.

- The conformity notification engages only the manufacturer for the parts selected or realized under

his control.

- The practical conditions of maintenance are fixed by the manufacturer. The fact that the user

does not respect those, does not engage the manufacturer.

YOU TAKE THE MANUFACTURER GIVES TO THE USER:

ADAVNTAGE OF - The know-how and his competence.

A KNOW-HOW - The guarantee of the quality of the works realized.

- Replacement components of origin.

- An aid to the preventive maintenance.

- An effective aid to the diagnosis.

- Some improvements thanks to the experience return.

- The training of the operator staff.

- Only the manufacturer knows in details the conception of the access platform and so has the best

technological capacities in order to make the maintenance of its.

1 - 3

THE MAINTENANCE OF OUR ACCESS PLATFORMS SHOULD BE IMPERATIVELY REALIZED WITH ORIGIN PARTS.

THE ORIGIN SPARE PARTS ARE ONLY DISTRIBUTED BY MANITOU

AND THE NETWORK OF THE CONCESSIONARIES.

The form of the network of the concessionaries can be supplied by phoning to the spare parts service:

TEL : +33 (0)2 40 09 10 21

ORIGIN SPARE PARTS

1 - 4

INSTRUCTIONS OF USE TO THE DRIVER

GENERAL INSTRUCTIONS

A - INSTRUCTIONS LEAFLET

- Read carefully and understand the instructions leaflet.

- The instructions leaflet should be always in the access platform, in the space foreseen to that end, and in the language

used by the driver.

- All the operations or maneuvrings, non-described in the instructions leaflet, are a priori proscribed.

- Respect the safety rules and the instructions described on the access platform.

- Replace absolutely all the plates or adhesives which are unreadable or ruined.

B - DRIVING PERMIT (CURRENT LAW FOR FRANCE)

(Or refer to the properly law of each country)

- Only the trained and qualified staff can use the access platform. This training is under the responsability of the

employer.

- During the use of the access platform, and for reason of safety, the presence of a user on the ground is obligatory.

- Get to know with the access platform on the ground where it must maneuvre.

- The driver is not enable to authorize the driving of the access platform by another person.

- Moreover, the use must be according to the rules of the profession.

- Do not use the machine in the event of a wind with a speed superior to 45 km/h. A lateral wind pressure more than 40

kg can not be exerted on the arms of the access platform.

- The safety helmet is obligatory.

- It is strongly advisable to have a safety harness during the use of the access platform.

- Equip with an individual fire extinguisher the access platform maneuvring in an area without extinguishing objects.

Some optional solutions exist, consult your agent or concessionary.

WHEN YOU SEE THIS SYMBOL, IT MEANS THAT:

ATTENTION ! BE CAREFUL ! YOUR SAFETY OR ONE OF THE

ACCESS PLATFORM IS ENGAGED.

1 - 5

C - MAINTENANCE

- The user who observes that his access platform is not in a good state of operation or does not correspond to the safety

rules, should inform immediately the official.

- It is forbidden to the driver to make himself all repairing or adjustement. He must keep his access platform in a perfect

state of cleanliness if he is charged of this task.

- The safety devices can not be shorted out or disconnected.

- Make the daily maintenance (See chapter: B - EVERY DAY OR EVERY 5 HOURS OF OPERATION).

- For your safety and one of the other, you do not modify by yourself the structure, the adjustement of the different

components of your access platform.

. Hydraulic pressure

. Calibration of the limiters

. Addition of equipment

In this eventuality, the responsability of the driver is not engaged.

- For permitting the maintenance in state of conformity, we advise you to test regularly your access platform by

your agent or concessionary, knowing that this periodicity is legally foreseen. (Refer to the current law).

- Do not replace the battery by a lighter battery (Stability compromised).

IN THE EVENT OF NECESSITY, CONSULT YOUR AGENT OR CONCESSIONARY.

1 - 6

DRIVING INSTRUCTIONS

A - LAYOUT TO THE DRIVING BOX

- Wear clothes adapted to the driving of the access platform, avoid the floating wears.

- Never drive with damp hands or shoes or soiled with flat corps.

- Avoid to have the foot and in general all party of the corps, outside the access platform.

- The safety helmet is obligatory.

- It is strongly advisable to have a safety harness during the use of the access platform.

B - BEFORE THE ACCESS PLATFORM STARTING

- If it is a new access platform, see chapter: BEFORE THE FIRST OPERATION OF THE ACCESS PLATFORM in the

party: 1 - INSTRUCTIONS AND RULE OF SAFETY.

- Test the good state of the tyres.

- Before starting the access platfrom, check the level of the hydraulic oil and the charge of the battery.

- However his experience, the user must get to know with the location and the use of all the control and command

instruments before using the access platform.

- The access platform should be in transportation position (the arms completely bended down) before climbing up in it.

- The access platform can only be used on a flat ground. An asphalted covering is generally necessary.

1 - 7

C - DRIVING OF THE ACCESS PLATFORM

SAFETY RULES

- Do not use the access platform if the battery is discharged as far as to slow the movements, in certain case, the

checking can stop the function.

- Do not use the access platform if it is not in a perfect state of operation or it does not have been checking.

- Wear clothes adapted to the driving of the access platform, avoid floating wears.

- In case of work in a busy area, forewarn all risk of accident.

- Look in the direction of the operation and always have a good visibility of the course.

- Stay, in all circumstances, boss of its speed.

- On humid, slippery, unequal ground, drive slowly.

- Go round the obstacles.

- The crossing of a pavement must be made only in transportation position.

Pay attention to the trenchs, scaffoldings and grounds recently diged or packed.

1 - 8

HANDLING INSTRUCTIONS

- The access platform can be maneuvred from the ground: forbid the approach of the access platform.

- The access platforms can not been used as cranes or lifts for the continuous transport of materials or people, and not

as jacks or supports.

- Watch over, by lifting the access platform, that nothing nor no body interfere with the evolution, and not to make

operatings errors.

- In case of work near aerial and electrical lines, make sure that the safety distance is adequate between the work area

of the access platform and the electrical line. Refer to the current law.

You must inform yourself to your local electrical agency.

You should be electrocuted or seriously hurt if you work or put the access platform too near the electrical cables. It is

deeply advised to make sure that the rules of safety on the site are according to the current local law concerning all

types of works near the electrical lines.

- Do not try to make operations which are superior to the capacities of the access platform.

- It is forbidden to work over people.

- Watch over that the material in the access platform (tubes, cables, containers, ..) can not go out or fall. Do not pile up

this material in focus to step over them.

- Do not use ladder or improvised constructions in the access platform to reach the superior heights.

- Do not use the desk base control to lift the access platform with people in the platform. This base control station is only

used in case of rescue procedure (the ill-healths of the people in the platform) and the maintenance.

IN THE EVENT OF NECESSITY, CONSULT YOUR AGENT OR CONCESSIONARY.

MAINTENANCE INSTRUCTIONS

A - GENERAL

- Read carefully the instructions leaflet.

- Clean up the access platform or the concerned area before all operation.

- Wear clothes adapted for the maintenance of the access platform, avoid the jewellery and the floating clothes. If

necessary, tie and protect your hair.

Watch over that the evacuation of the consumables and the spare parts must be made in all safety and ecological way.

- Make the necessary repairings, even minor, immediately.

- Repair all leakages, even minor, immediately.

- Do not try to loosen the connections, the hoses or an hydraulic component with the subpressure circuit.

The handling and the removal of the balancing valve equiping the jacks of your access platform, can be dangerous. A

balancing valve does not be removed when the concerned jack is at rest and the hydraulic circuit under residual pressure.

This operation is possible only with certified staff.

- Remove the variator before all operation of soldering.

- Do not remove metallic parts on the battery.

- The electrical box can be open only by the authorized staff.

- The periodic control specified by the certified control services is necessary.

- Weld, position the weight as close as possible to the place to weld.

1 - 9

MAINTENANCE INSTRUCTIONS OF THE ACCESS PLATFORM

B - MAINTENANCE

- Clean up the access platform of all tracks of oil or grease.

- Clean up the access platform or the area concerned before all operation.

- Do not wash with a mechanism of high pressure near the electrical components.

if necessary, protect against the penetration of water, of vapor or cleaning products, the components susceptible of

being damaged, particularly the electrical components and conexions.

- The maintenance in the conformity state of the access platform is obligatory.

- Make the daily maintenance (See chapter: B - EVERY DAY OR EVERY 5 HOURS OF OPERATION).

1 - 10

1 - 11

Our political being a concern of constant improvement of our products. Some

modifications can be introduced in our range of access platforms, without we

must inform our customers.

At the time of all orders for spare parts or for all informations of a technical

nature, always specify:

NOTE : For communicate easily all these numbers, it is advised to write them

in the space foreseen to this effect at the receipt of the access

platform.

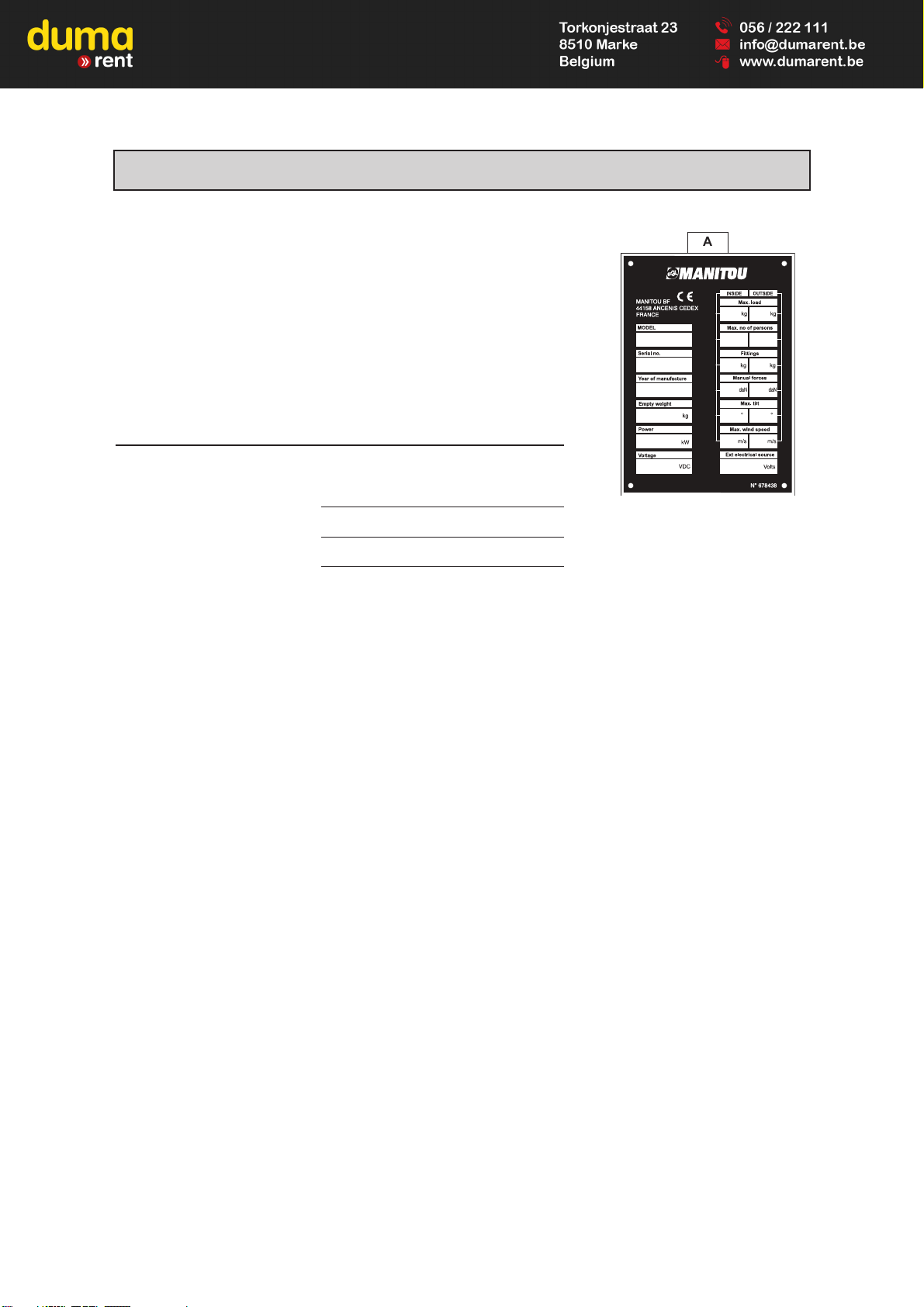

C

ONSTRUCTOR PLATE OF THE ACCESS PLATFORM

(

FIG

.

A

)

- Type

- Serial number

- Year of production

IDENTIFICATION OF THE ACCESS PLATFORM

%

INTRODUCTION

- Our access platform are realized with the concern to offer an important facility of maneuvre to the driver and a

maximum of maintenance facility.

- But before the first operation of the access platform, the user must read carefully and understand the different chapters

of this leaflet which will be realized to resolve all the problems of driving and maintenance. According to these

instructions, the user be able to derive the best of the capacitites of the access platform.

- The user must inform himself of the positions and functions of the different instruments of control and command, before

using the access platform.

Never use a new access platform before make the following checks.

GREASING

- Check the different points of greasing and the different levels (see chapter: PERIODICITY OF MAINTENANCE) and

complete if necessary.

The filled up of the lubricants is made in factory for mean climatic uses, of : -15°C to +35°C. For more important uses, it

must, before the first operation, drain and make again the filled up by using adapted lubricants in function of the

ambient temperatures. (inform you, if necessary, to your agent or concessionary).

HYDRAULIC CIRCUIT

- Check that there are no leakage or ooze of oil to the jointings, hoses, tubes and connections by a visual test. If

necessary, tighten or check the defective connections.

- Check the oil level in the tank.

TYRES

- Make sure of the perfect adjustment of the nuts of the wheels (see chapter: C - EVERY 50 HOURS OF OPERATION).

ELECTRICAL CIRCUIT

- Check the level and the specify gravity of the electrolyte in the battery.

- Look at the different components of the electrical circuit like the branchings and the fixings.

IN THE EVENT OF NECESSITY, CONSULT YOUR AGENT OR CONCESSIONARY

1 - 12

BEFORE THE FIRST OPERATION OF THE ACCESS PLATFORM

Table of contents

Other Manitou Boom Lift manuals

Manitou

Manitou 260 TJ User manual

Manitou

Manitou MAN'GO 12 User manual

Manitou

Manitou AETJL 120 Operating instructions

Manitou

Manitou 120 AETJ L Operating instructions

Manitou

Manitou MHT 10180 129 M ST4 S1 User manual

Manitou

Manitou 200 ATJ User manual

Manitou

Manitou 200 ATJ User manual

Manitou

Manitou 160 ATJ E3 User manual