1.

Introduction

1 - 3

R

OTATION

G

EAR

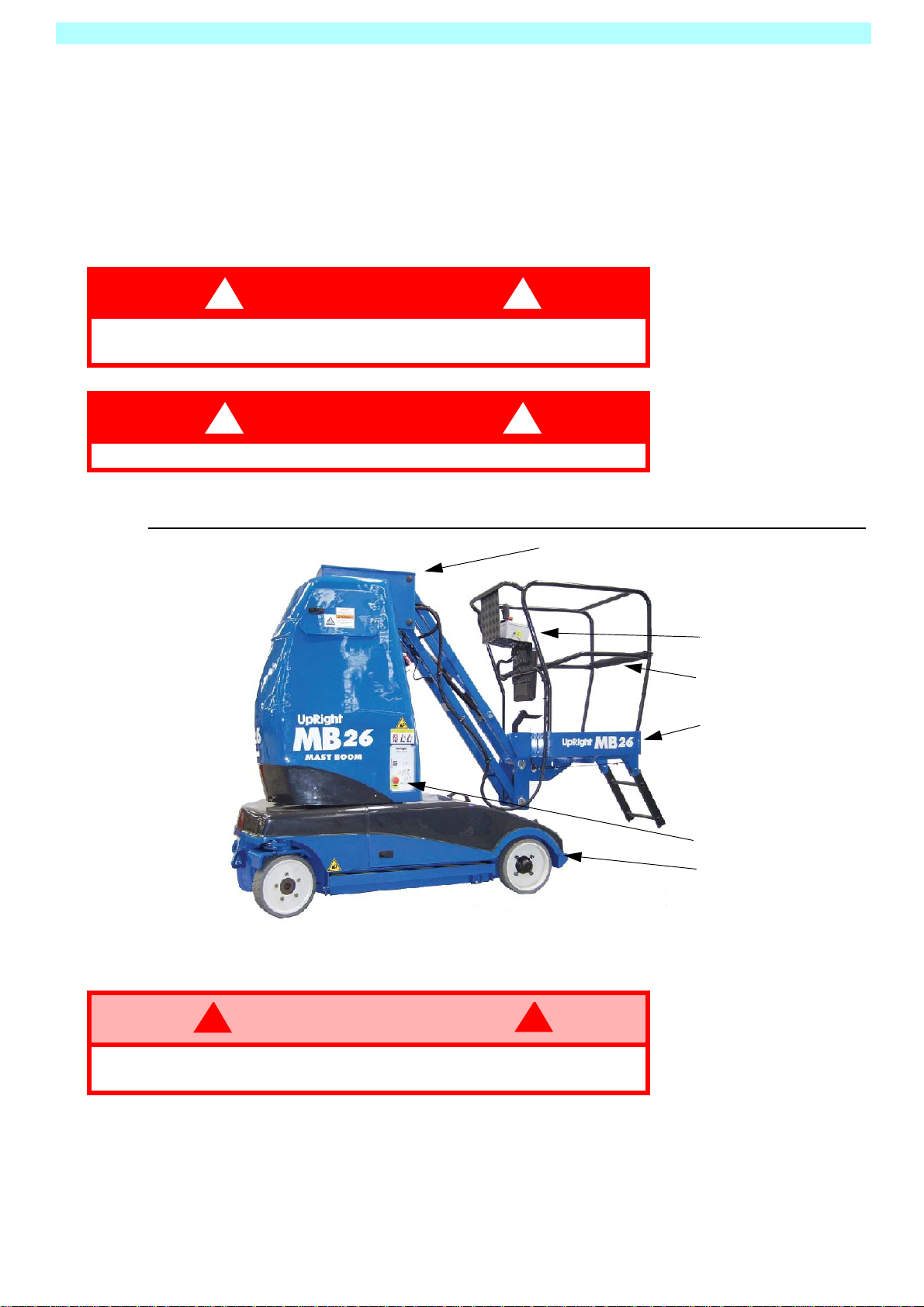

The complete mast, jib and cage assembly can be rotated to provide a maximum

outreach of 2.6m in the case of the MB20 and 2.96m in the case of the MB26 machine.

This dimension is measured from the centreline of rotation and is carried out by means

of an integral hydraulic motor driving a Worm Drive Unit, around a Slew Gear.

D

RIVE

& S

TEER

S

YSTEM

An electronic controller, mounted in the chassis, is pre-programmed to adjust the upper

speed limit of each individual function. The controller limits the rotational speed of the

electronic motor and oil pump, thereby limiting the maximum oil flow rate.

The following functions are controlled and driven by the electro-hydraulic system:

•Traction Drives (Fwd & Rev) mast stowed/mast raised.

•Steering and Jib elevation.

•Mast elevation, descent and rotation.

•The Jib descent function is gravity operated and is determined by built in flow

regulators.

P

OWER

S

YSTEM

The Power System (Prime Mover) incorporates four 6V batteries driving a 4KW electro-

hydraulic pump. The pump drives all hydraulic cylinders and the traction drive motors. A

single multi-valve control block diverts the oil pressure to the individual actuators. The

oil flow rate is limited by the pre-programmed speed setting on the motor but is

determined by the position of the joystick in the Upper Control Box.

1.3

W

ORKSHOP

P

ROCEDURES

All information contained in this manual is based on the latest product information

available at the time of printing. We reserve the right to make changes at any time

without notice.

No part of this publication may be reproduced, stored in retrieval system, or transmitted,

in any form by any means, electronic, mechanical, photocopying, recording, or

otherwise, without the prior written permission of the publisher. This includes text,

figures, and tables.

CAUTION

!!

Detailed descriptions of standard workshop procedures, safety

principles and service operations are not included. Note that this

manual does contain warnings and cautions against some specific

service methods that could cause personal injury, or could damage

a machine or make it unsafe.

Please understand that these warnings cannot cover all

conceivable ways in which service, whether or not recommended

by UpRight, might be done, or of the possible hazardous

consequences of each conceivable way, nor could UpRight

investigate all such ways.

Anyone using service procedures or tools, whether or not

recommended by UpRight must satisfy themselves thoroughly that

neither personal safety nor machine safety will be jeopardized.

When in doubt, contact your local distributor or UpRight.