Mantis ULV BioMant-ONE User manual

!

Operating*instructions*for:*

BioMant-ONE,,

Weed,control,machine,

MANUFACTURER:

Mantis ULV

Vierlander Straße 11a

21502 Geesthacht

Phone: +49 (0) 4152 8459-0

February 2020

www.mantis-ulv.com

Mantis ULV Sprühgeräte GmbH

Page 2 of 29

Table of Contents

Foreword ................................................................................................................................................ 4

Symbols and terms .............................................................................................................................. 4

Intellectual property rights ................................................................................................................... 4

1. Introduction .................................................................................................................................... 5

1.1. EC- Declaration of Conformity ............................................................................................ 5

1.2. Adaptations ............................................................................................................................ 5

1.3. Operation by third parties .................................................................................................... 5

2. Description of the weed control machine BioMant One .......................................................... 6

2.1. Design of the weed control machine BioMant One ......................................................... 6

2.2. Functional principle of the weed control machine BioMant One ................................... 7

2.3. Operating areas .................................................................................................................... 7

2.4. Technical Specifications ...................................................................................................... 8

2.4.1. Technical data ................................................................................................................. 8

2.4.2 Type plate ........................................................................................................................ 8

2.4.4 Explanations for the type plate ..................................................................................... 8

3 Operating regulations .................................................................................................................. 9

4 Safety instructions ...................................................................................................................... 10

4.1 Safety instructions .............................................................................................................. 10

4.2 Pictograms ........................................................................................................................... 12

4.3 Safety devices ..................................................................................................................... 12

4.4 Control panel ....................................................................................................................... 13

4.5 Emergency switch .............................................................................................................. 13

4.5.1 Testing of Emergency switch .......................................................................................... 14

4.6 Main power switch .............................................................................................................. 14

4.7 LPG shut-off valve .............................................................................................................. 14

5 Assembly instructions ................................................................................................................ 15

5.1 Installation on a vehicle ..................................................................................................... 15

5.2 Assembly ............................................................................................................................. 15

5.3 Electrical Equipment .......................................................................................................... 15

5.4 Fuel supply .......................................................................................................................... 15

5.5 Measures prior to commissioning .................................................................................... 16

6 Commissioning, test run and working operation .................................................................... 17

6.1 Commissioning ................................................................................................................... 17

Mantis ULV Sprühgeräte GmbH

Page 3 of 29

6.2 Test run / working operation ............................................................................................. 18

6.3 After the test run / working operation ............................................................................... 18

7 Working with the BioMant One weed control machine ......................................................... 19

7.1 Starting of machine operation ........................................................................................... 19

7.2 Actions during operation .................................................................................................... 19

7.3 Actions after operation ....................................................................................................... 19

7.4 Replacing of the water filter .............................................................................................. 19

7.5 Charging of batteries .......................................................................................................... 20

7.6 Refilling of fuel tank ............................................................................................................ 20

7.7 Anti-lime scale agent .......................................................................................................... 20

7.8 Adjustment of the dosage for anti-lime scale agent ...................................................... 22

8 Maintenance works and troubleshooting ................................................................................ 23

8.1 Daily maintenance .............................................................................................................. 23

8.2 Regular maintenance ......................................................................................................... 23

8.3 Troubleshooting .................................................................................................................. 23

9 Disassembly, transport, storage and disposal ....................................................................... 25

9.1 Disassembly ........................................................................................................................ 25

9.2 Transport ............................................................................................................................. 25

9.3 Storage ................................................................................................................................. 25

9.4 Disposal ............................................................................................................................... 26

10 Annexes .................................................................................................................................. 27

10.1 EC- Declaration of Conformity .......................................................................................... 27

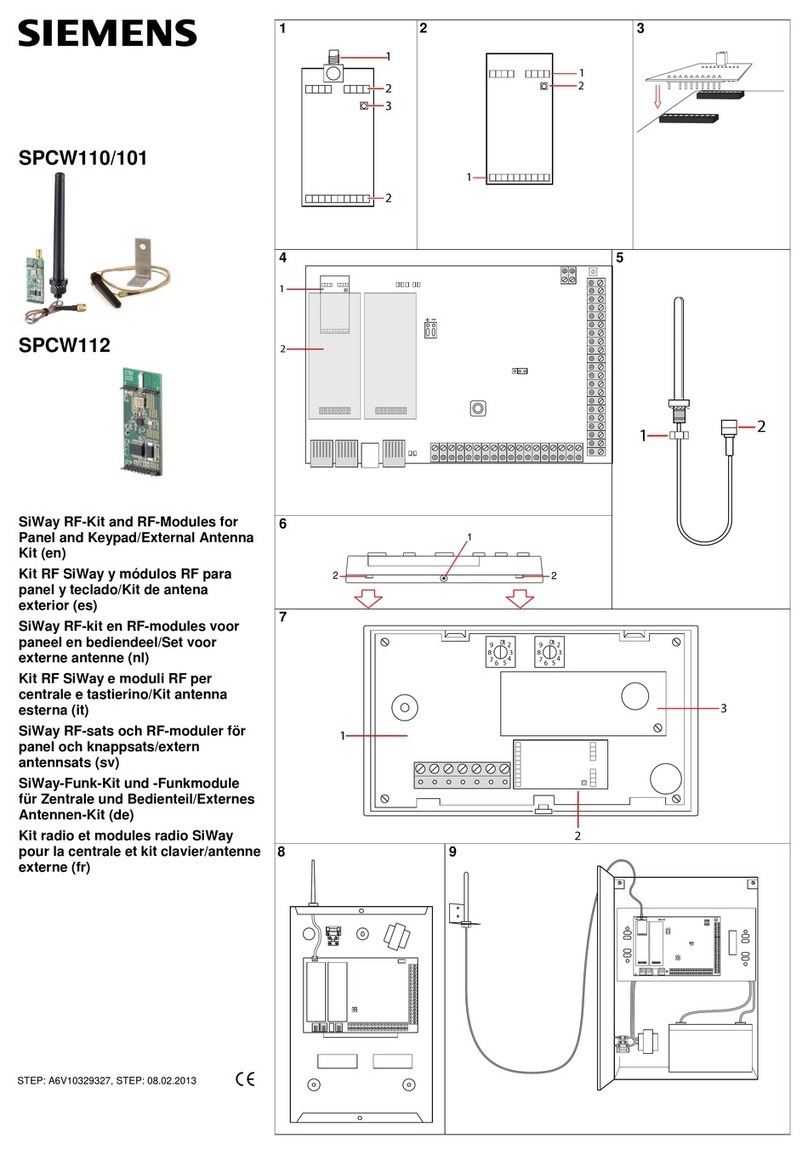

10.2 Schematic diagram ............................................................................................................. 28

10.3 Spare parts list .................................................................................................................... 29

Mantis ULV Sprühgeräte GmbH

Page 4 of 29

Foreword

These Operating Instructions are part of the BioMant One weed control machine . These Operating

Instructions describe the operation and functions of the machine and include the corresponding

assembly, maintenance and safety instructions. You are obliged to observe and to comply with these

instructions (especially the safety instructions).

To be able to safely work with the weed control machine BioMant One it is required to thoroughly

read and understand these Operating Instructions.

Symbols and terms

These Operating Instructions include warnings and instructions for the safe handling of the weed

control machine BioMant One. These Instructions were completed with one of the pictograms below.

Thoroughly familiarise yourself with the instructions stated below.

Note with additional information. This draws the user's attention to possible

points to be observed or safety regulations.

This note indicates risks that are connected to working with the weed control

machine BioMant One.

The images in these Operating Instructions can be different from the actual images on the machine.

These Operating Instructions have been created with the highest care. If any problems occur, please

contact your dealer or directly contact the manufacturer.

The manufacturer does not accept any responsibility for downtimes, production outages, or losses

due to a defective weed control machine BioMant One.

Intellectual property rights

Without prior written authorisation of the manufacturer it shall not be allowed to reproduce and/or

publish any contents of these Operating Instructions through printing, photocopying, microfilm, or

other means.

For further information about use and maintenance of the machine which is not included in these

Operating Instructions, please contact the manufacturer.

Despite all continuous efforts of the Mantis ULV Sprühgeräte GmbH to further improve this product

on all levels (especially in the area of safety), unforeseeable circumstances cannot be prevented. If,

for this reason, unsafe situations should occur, then immediately contact the manufacturer.

All rights explicitly reserved. Unless approved by copyright, reproductions, edits and translations

require the manufacturer’s prior consent.

Mantis ULV Sprühgeräte GmbH

Page 5 of 29

1. Introduction

These Operating Instructions include all information needed for the correct and safe working with

the weed control machine BioMant One.

Before the commissioning of the weed control machine BioMant One, it is absolutely required that

you have read and understand these Operating Instructions. Therefore, you must have familiarised

yourself with the functioning and the safety instructions before the commissioning of the weed

control machine BioMant One.

For your own safety and to prevent damages on the machine, always observe the safety instructions

included in these Operating Instructions!

1.1. EC- Declaration of Conformity

Because the weed control machine BioMant One complies with the provisions of the EC Declaration

of Conformity, The manufacturer has prepared an appropriate EC Declaration of Conformity. Please

find the EC Declaration of Conformity attached in Annex 10.1.

1.2. Adaptations

If the weed control machine BioMant One must be adapted in future, the responsible person must

check whether these adaptation have an effect on the information content of these Operating

Instructions. If the content of these Operating Instructions is not up to date anymore due to the

adaptations, the responsible person has to revise these Operating instructions accordingly.

1.3. Operation by third parties

If the weed control machine BioMant One is sold partly or completely, dismantled and/or moved,

then the one who reuses the weed control machine BioMant One or components of it, shall be fully

responsible for the safety of the newly erected system.

In this case, the manufacturer shall not be liable for the reuse of the whole system or parts of it,

because several process conditions influence the safety of the process. With this, they also affect the

safety of the system.

Mantis ULV Sprühgeräte GmbH

Page 6 of 29

2. Description of the weed control machine BioMant One

The weed control machine BioMant One is an alternative weed control system that does not require

chemical substances. This chapter describes the functions and the operation of the weed control

machine BioMant One.

2.1. Design of the weed control machine BioMant One

The weed control machine BioMant One is hot-water low-pressure unit with optional additional high-

pressure function built in a stainless-steel housing and includes the following components:

> Hood, doors, sleeves for forklift truck

> Burner module (diesel or LPG) for the generation of hot water

> Fuel tank(s) (diesel or LPG)

> High pressure pump

> Water tank and water filter

> Temperature control

> Calcification protection system

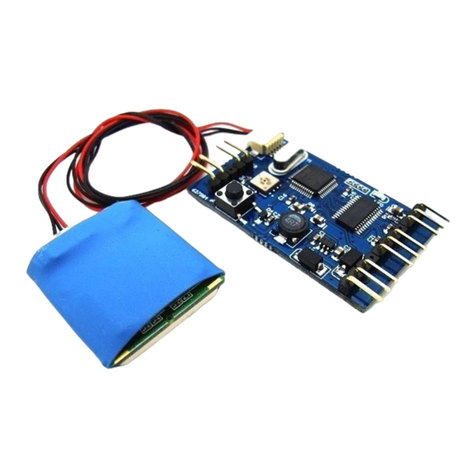

> Control panel and electrical system

> Optional: battery pack

> Optional: Hose reel, spray lances, Spray beam, or other accessories.

Fig.1:

Main overview

Water tank 500 or 1.000 litres

(optional: Filter system for surface water)

Touch screen-Control panel

(optional: remote control)

Calcification protection system

Electrical pump

with storage battery or 230 V

power supply

Maintenance-free battery

pack (optional)

Hose reel (optional)

Integrated water filter

LPG or diesel burner for the

generation of hot water

Frame structure of

stainless steel

Temperature control for constant

output water temperature

Sleeves for forklift truck forks

Mantis ULV Sprühgeräte GmbH

Page 7 of 29

2.2. Functional principle of the weed control machine BioMant One

The BioMant One weed control machine is a spray system for weed control with of hot water. The

system is equipped with a burner and provides a flow rate of 15 l/min. The machine can be operated

by one person.

2.3. Operating areas

The weed control machine BioMant One is only allowed to be operated via the control panel or, if

installed, via the remote control. In an emergency, the machine can be switched off by the

Emergency switch installed on the control panel.

It is not allowed touse the Emergency switch to switch the machine off.

Fig.2:

Control panel with Emergency Off switch

An unobstructed work area needs to be provided for the operation of the BioMant One weed

control machine. Remove all risks of impact and tripping.

Keep order and cleanliness in the work area to exclude risks of impact and

tripping.

Mantis ULV Sprühgeräte GmbH

Page 8 of 29

2.4. Technical Specifications

This section contains the technical data of the machine.

2.4.1. Technical data

Machine

:

Weed control machine BioMant One

Manufacturer

:

Mantis ULV Sprühgeräte GmbH

Year of manufacturing

:

Refer to type plate

Serial-No.

:

Refer to type plate

Hot water heater

:

Diesel- or LPG burner

Power supply

:

By battery pack or external electrical power supply

Fuel tank or external

electrical power

supply

:

Diesel: 95 litres / LPG: 108 litres

Nominal voltage

:

230 V or with battery pack: 72 V

Net weight

:

With diesel burner= 460 kg

With LPG burner = 510 kg

With storage battery pack = 810 kg

Dimensions

:

1350 x 1000 x 1400 mm (with 500 litres tank)

2.4.2 Type plate

Fig.3:

Type plate

2.4.4 Explanations for the type plate

Manufacturer

:

Mantis ULV Sprühgeräte GmbH

Machine

:

Weed control machine BioMant One

Year of make

:

Year of make of the machine

Serial-No.

:

Individual machine-No.

Because the weed control machine BioMant One complies with the requirements of the applicable

European directives, the CE mark is on the type plate.

Mantis ULV Sprühgeräte GmbH

Page 9 of 29

3 Operating regulations

The weed control machine BioMant One is only allowed to be used for the intended purpose.

Unauthorised persons are not allowed to change the settings of the weed control machine BioMant

One. If you want to change the settings, please contact your specialist dealer or directly contact the

manufacturer.

Before the commissioning of the weed control machine BioMant One, make yourself thoroughly

familiar with these Operating Instructions. Observe all instructions and safety instructions in these

Operating Instructions.

If it is not used as intended, this cannot only endanger the operator or persons nearby, but also

cause damages on the machine. The usage of the machine other than specified without the explicit

authorisation of the manufacturer is not allowed.

Mantis ULV Sprühgeräte GmbH

Page 10 of 29

4 Safety instructions

The weed control machine BioMant One is equipped with different safety devices. Despite these

safety devices there remains residual risks in various positions. The following chapter contains some

safety instructions referring to these residual risks. For safe working with the weed control machine

BioMant One, all persons who have to work on or with the weed control machine BioMant One must

make themselves familiar with these instructions.

4.1 Safety instructions

For all works on the BioMant One, the machine must be disconnected from the

power supply, depressurised and secured against accidental restarting.

All persons, who work with or on the weed control machine BioMant One,

must have made themselves sufficiently familiar with these Operating

Instructions and especially with these safety instructions. It is strictly

required to observe these safety instructions.

Only competent and authorised persons are allowed to work with the weed

control machine BioMant One

The weed control machine BioMant One sprays water at a temperature of 99.5

°C. Never point the spray lance at persons or animals. Spraying at persons

or animals can cause serious burns.

In high-pressure mode, water at high pressure spouts out of the spray lance.

Never point this high-pressure jet at persons or animals. If water at high

pressure is pointed at persons or animals, this can cause serious injuries.

Before starting, check if the doors of the weed control machine BioMant One

are closed. The machine is only allowed to be used with all coverings

closed.

Before starting the machine, check it for possible damages. If the machine is

damaged, you must not start the machine but first it has to be repaired

by the manufacturer or a BioMant dealer.

Despite of the splash-proof design of the machine pay attention to the live

components nearby the machine. They can cause electrocution or

damage the machine.

Be careful, when you open the coverings. If the covering is open, sharp moving

parts can still move.

Mantis ULV Sprühgeräte GmbH

Page 11 of 29

The fuel (diesel or LPG) is explosive and highly flammable. Therefore open fire

and smoking is strictly forbidden near the weed control machine BioMant

One.

Troubleshooting on the BioMant One is only allowed with the fuel supply

closed.

Only operate the BioMant One in a well ventilated room. The exhaust gas that

comes out of the heating boiler can be hazardous to health.

The weed control machine BioMant One must not be operated in an

environment with explosives.

Only the manufacturer or a BioMant One dealer is allowed to change the

machine parameters.

Regularly check all safety functions, e.g. blocking devices and pressure switches

for their operability.

There is an exhaust gas outlet on the top side of the machine. This must remain

free and provide the unimpeded exit of exhaust fumes.

Spray gun, spray lance and possible accessories become hot during the machine

operation. Therefore, wear protective gloves and protective clothing. Hot

components can cause burnings.

Make sure that there is a sufficiently large work area without obstructions to

exclude the risk of tripping.

Make sure that there is order and cleanliness around the weed control machine

BioMant One to exclude the risk of slipping.

The BioMant One weed control machine is designed for heating up and spraying

of clean (drinking) water. Do not use untreated (surface) water which is

taken from ponds, channels, ditches, rivers and shafts water without the

special filter.

Do not use any other fluids than treated (drinking) water. Do not add any other

fluid/substances to the water (except for anti-lime scale agent).

While the battery is being charged it is not allowed to switch on the BioMant or

refill the fuel tank.

For all questions on function or components, please contact your dealer or the

manufacturer.

Mantis ULV Sprühgeräte GmbH

Page 12 of 29

To ensure optimum safety and reliability use only original spare parts.

Before starting any works on the heating boiler, let it cool down first. The

heating boiler is filled with hot water that can cause burnings.

4.2 Pictograms

The pictograms warn of hazards that cannot be avoided. Never remove the pictograms! Damaged or

missing pictograms must be replaced immediately.

Pictogram

Meaning

Position of placement

Risk of burning

On the burner outlet

Read the Operating

Instructions

On the control panel

Smoking and open

flames are strictly

forbidden

Do not point the spray

lance at persons

On the tank filler cap

On the control panel

4.3 Safety devices

There is a hood on the front side of the weed control machine BioMant

One, which is supplemented by four doors on the side. They can be opened

to get access to the inside of the machine. Before starting the machine, the

doors and the hood must be reclosed. It is not allowed to open the hood

and the doors during operation.

Fig.4:

Doors and hood of the machine

Take care when opening the hood and the doors because the components in the

machine can be hot.

Mantis ULV Sprühgeräte GmbH

Page 13 of 29

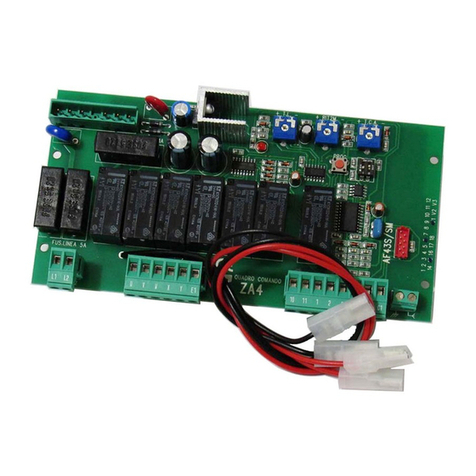

4.4 Control panel

Emergency switch [1]

All functions are switched off

Weed control [2]

Green coloured symbol = Weed control ON

High-pressure cleaning [3]

Green coloured symbol = High-pressure

function ON

4.5 Emergency switch

In an emergency, the machine must be able to be switched off immediately. For this purpose, the

weed control machine BioMant One is equipped with an Emergency switch. The Emergency switch is

below the control panel.

Fig.5:

Emergency switch

1

2

3

Mantis ULV Sprühgeräte GmbH

Page 14 of 29

4.5.1 Testing of Emergency switch

The Emergency switch has to be tested every 50 operating hours. For this purpose, proceed as

follows:

> Press the Emergency Off switch and check if the machine switches off immediately and

safely.

> The Emergency “Off” status must remain, e.g. the machine must not be able to be switched

on again.

> Unlock the Emergency off switch (pull out) and check if it can be put into operation again.

Only push the Emergency switch in an emergency. It is not allowed to switch the

machine off using the Emergency switch as a standard feature (except for

testing the Emergency switch).

4.6 Main power switch

If your weed control machine BioMant One is equipped with a battery pack, it will have a main power

switch. Turning the main power switch switches the whole machine off. The main power switch is

lockable depending on the configuration. To be able to engage the main power switch, the key must

be in the switch.

c or

Fig.6:

Main power switch with or without key

4.7 LPG shut-off valve

If your BioMant One model includes a LPG-Burner, it will also be

equipped with an LPG shut-off valve, This valve must be turned on

completely to open the LPG supply.

Fig.7:

Shut-off valve for LPG hot water burner

Mantis ULV Sprühgeräte GmbH

Page 15 of 29

5 Assembly instructions

This chapter includes instructions for the assembly of the weed control machine BioMant One.

Before starting work, it is strictly required to thoroughly familiarise yourself with these instructions.

Work on BioMant One machines may only be carried out by authorised

persons

Before starting any works on the BioMant One, the machine must be

disconnected from the power supply and secured against accidental

restarting.

For lifting of the machine use an approved lifting device with sufficient capacity.

5.1 Installation on a vehicle

The machine can be installed on the loading platform of a vehicle, pickup car or trailer.

> Ensure that the machine is placed on a stable, flat base.

> Make sure that the machine stands firm on the trailer or the loading platform of the vehicle

and is secured against shifting, tilting or falling over.

> For carrying and transporting of the machine the trailer or the vehicle must have sufficient

bearing and loading capacity.

5.2 Assembly

For the replacement of components only use parts that comply with the manufacturer's

specification. These Operating Instructions include a list of spare parts attached as Annex 10.3.

5.3 Electrical Equipment

These Operating Instructions include an electrical circuit diagram attached as Annex Error! Reference

source not found.. Works on the electrical system may only be carried out by a trained specialist.

5.4 Fuel supply

Prior to all works on the BioMant One, it is required to disconnect the machine from the power

supply and to secure it against accidental restarting.

It is also forbidden to charge the batteries (if present) while working on the BioMant One.

Place the BioMant One in a well-ventilated room to evacuate exhaust fumes and prevent the

generation of potentially explosive gases.

Please find an overview on the fuel system attached to these Operating Instructions (see 10.4).

Mantis ULV Sprühgeräte GmbH

Page 16 of 29

5.5 Measures prior to commissioning

> Thoroughly read these Operating Instructions.

> Check if the machine is undamaged. If in doubt, do not start the machine and contact the

manufacturer or your BioMant dealer.

> Check the hoses of the water supply and the high-pressure hose te ensure they are in

proper condition. If you detect any damages, you are not allowed to start the machine, but

you must contact the manufacturer or your BioMant dealer.

> Check the oil level of the pump using the oil dipstick placed at the top of the pump. The oil

level always needs to be above the marking on the dipstick/inspection glass. If this is not

the case, refill oil.

> Coverings and safety devices must be installed and work properly.

> For machines with battery pack: Make sure that all batteries have been fully charged.

Mantis ULV Sprühgeräte GmbH

Page 17 of 29

6 Commissioning, test run and working operation

Commissioning takes place after the assembly of the weed control machine BioMant One has been

completed. For commissioning follow the instructions in this chapter.

Prior to the real working operation, first perform a test run of the machine.

6.1 Commissioning

You must not start the machine if you detected any defects during the

assembly and before the commissioning.

Warn all persons who are nearby the machine before starting the machine.

Only operate the BioMant One in a well ventilated room. The exhaust fumes

that from the boiler can be hazardous.

> Fill the fuel tank. You are required to use clean fuel (filter it, if necessary).

> Fill the anti-lime scale tank with BioMant Kalk-Stop to prevent the machine from clogging

up with lime-scale deposits.

> Adjust the dosing unit for anti-lime scale liquid depending on the hardness of the water you

will use, as described in chapter 10.3

> Fill the water tank or connect a water supply hose.

> Connect the high-pressure hose and mount a spray gun equipped with a lance and spray

head (or spray beam)

> Completely unroll the high-pressure water hose.

> Open the hood at the front of the machine.

> If equipped with an LPG boiler: Completely open the LPG valve (see Fig.7:).

> Switch the main power switch on (if your machine is equipped with a battery pack (see

Fig.7:).

> After switching on the control panel, select the "Weed control" function.

> The machine starts up automatically when you engage the spray gun.

> Let the water flow out of the spray lance, the burner will now activate itself.

> First, the display will shows red, indicating that the required working temperature has not

been reached yet.

> Keep the spray gun pressed to keep the boiler in operating

> After a short time, the display menu will be displayed in yellow, indicating the right

temperature is almost reached.

> Keep the spray gun pressed

> Finally, the display will show green, signalling the correct water temperature has been

reached and the machine is ready for use.

Mantis ULV Sprühgeräte GmbH

Page 18 of 29

If the temperature is too high, the display menu will be display in red.

6.2 Test run / working operation

During the test run, a person has be within reach of the Emergency switch.

The water jet is at high pressure and / or warm! Never point the jet at persons

or animals.

Always hold the spray gun with two hands. Because a slight setback occurs

when opening the spray gun, you must always be in a safe and stable

position.

Settings may only be changed with the spray gun closed.

> During operation check the machine for unusual noises and vibrations.

> Check all functions of the machine for proper functioning.

> Check all safety devices of the BioMant One for completeness.

> Test the Emergency switch of the machine.

6.3 After the test run / working operation

> Switch the system off via the main switch (see Fig.7: ).

> Switch the main switch on again to reset the machine.

> Preselect the weed control function and activate the spray gun. Do this for a few minutes to

allow the machine to cool down.

> The machine is cooled down (the water running from the machines is cooled off), be careful

the hose can still be warm.

Avoid repeated pressing and releasing of the spray gun within too short periods

of time because this causes a loss in water temperat high current

consumption and pollution of the machine.

Mantis ULV Sprühgeräte GmbH

Page 19 of 29

7 Working with the BioMant One weed control machine

The BioMant One weed control machine is only allowed to be operated by

persons who are qualified and authorised to do so.

7.1 Starting of machine operation

> When starting the BioMant One machine, check it for unusual noises and vibrations.

> Check all functions of the machine for proper functioning.

7.2 Actions during operation

> Check the machine for unusual noises and vibrations and if you notice anything unusual,

immediately switch the machine off. Determine the reason and eliminate it, if possible.

Otherwise, contact the manufacturer or your BioMant One dealer.

7.3 Actions after operation

> Switch the machine off using the main power switch (see Fig.7:) or (depending on the

configuration) disconnect the machine from the external power supply.

> Switch the main switch or the external power supply on again to reset the machine.

> Preselect the weed control function and engage the spray gun. Do this for a few minutes to

allow the machine to cool down.

> The machine is cooled down (the water running from the machines is cooled off), be careful

the hose can still be warm.

7.4 Replacing of the water filter

> Screw off the plexiglass housing (clockwise).

> Replace the filter cartridges by new filter cartridges be removing them from the plexiglass

housing and inserting the new filter cartridge.

> Screw on the plexiglass housing again (counterclockwise).

Fig.7:

Location of Waterfilter

Mantis ULV Sprühgeräte GmbH

Page 20 of 29

7.5 Charging of batteries

If the display of a BioMant One which is equipped with a battery pack shows the

message „Battery low“, then you must immediately abort your works und switch off

the weed control machine. Connect the charger to the machine and the also to a

power outlet.

It is not allowed to use the machine during charging of the batteries.

7.6 Refilling of fuel tank

> LPG burner: Unscrew the black tank filler cap on the side of the machine. It is at the top of

the machine or bottom right. Screw the tank lance of the LPG pump on the opening (as

instructed by your filling station).

> Diesel burner: Using the key that comes with the machine, open the tank cap at the top of

the machine and fill the machine up with diesel.

Fig.8:

Positions of LPG or diesel tank connection

LPG and Diesel are inflammable and explosive producst, you must therefore

refrain from smoking in promximy of the mahcine or be near an open fire.

7.7 Anti-lime scale agent

> Unscrew the hose of the anti-lime scale system.

> Replace the empty canister by a full canister of BioMant Kalk-Stop.

> Reconnect the hose.

> Adjust the dosing unit for anti-lime scale according to the hardness of your water, as

described in 10.3 below.

Charging connection

LPG tank connection

Tank connection for diesel

Table of contents

Popular Control Unit manuals by other brands

ZAFFER

ZAFFER ONE user manual

Allen-Bradley

Allen-Bradley 1771-OBDS installation instructions

Advanced Energy

Advanced Energy Thyro-S manual

National Instruments

National Instruments ATCA-3671 Getting started guide

Kemper

Kemper 137 02 Installation and operating instructions

Forbes Marshall

Forbes Marshall FMPRV41 Installation and maintenance manual