Contents

ABOUT THIS MANUAL................................................................3

What you can do with this manual ...........................................3

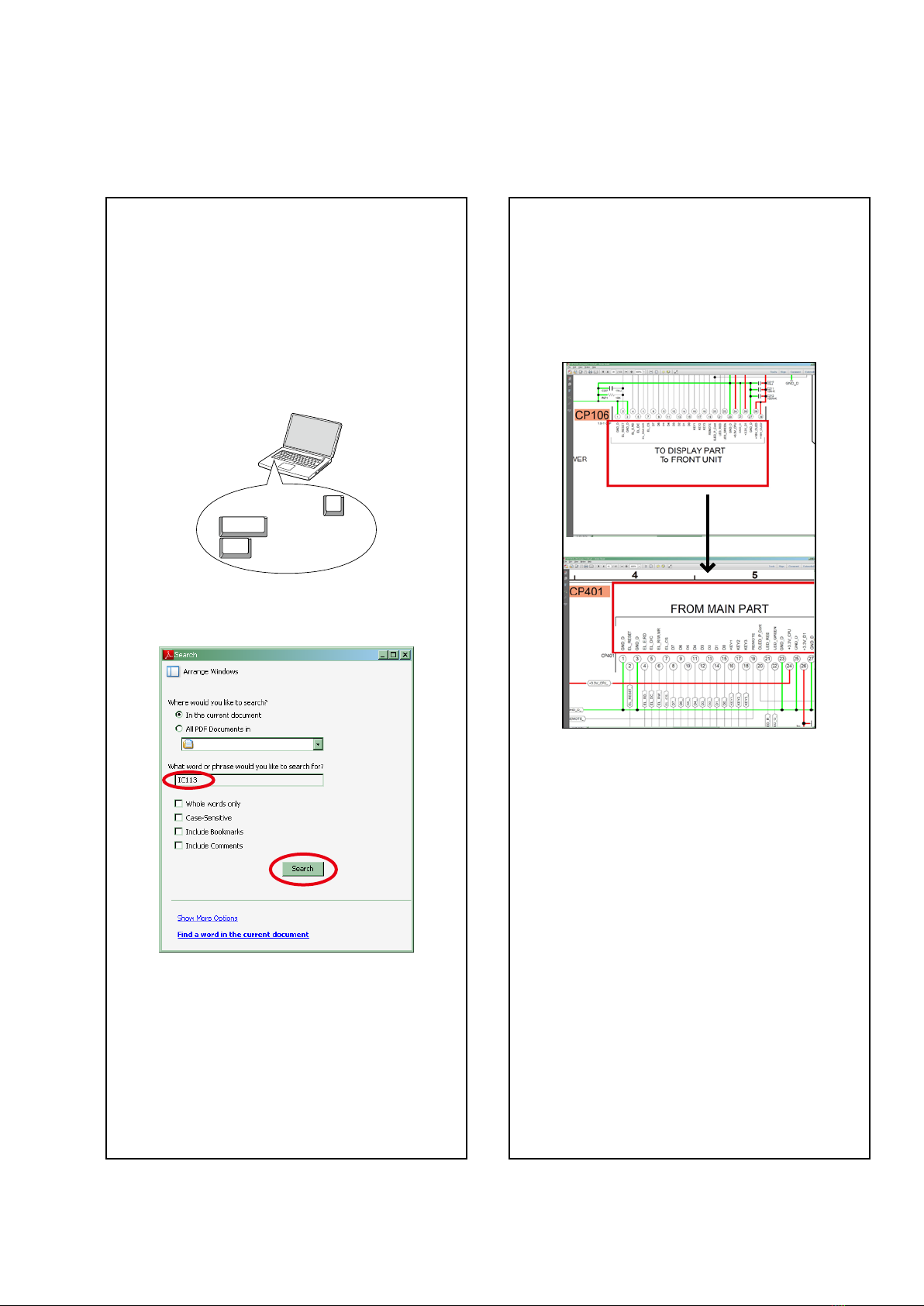

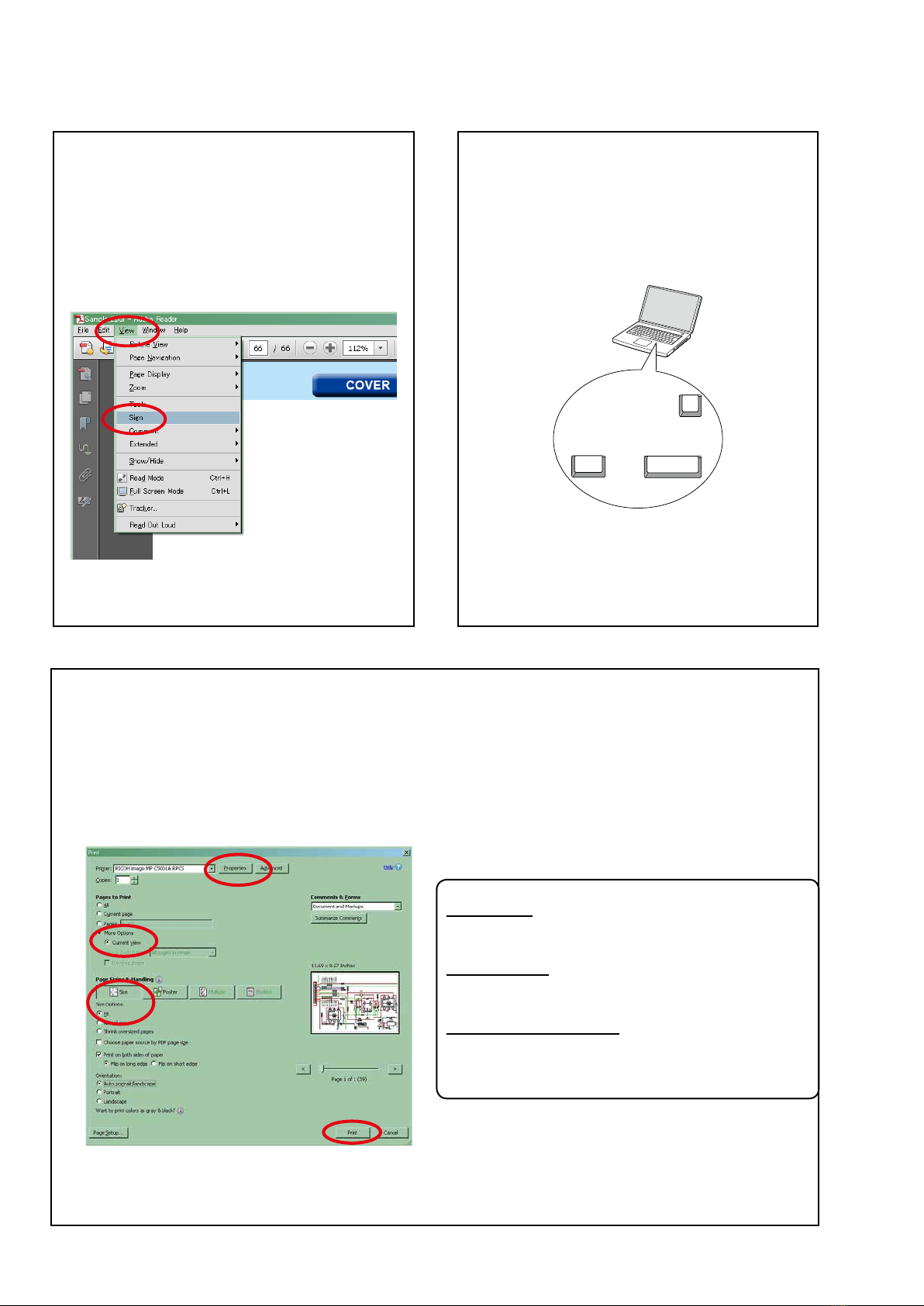

Using Adobe Reader (Windows version)...................................4

SAFETY PRECAUTIONS...............................................................6

NOTE FOR SCHEMATIC DIAGRAM..............................................7

NOTE FOR PARTS LIST................................................................7

TECHNICAL SPECIFICATIONS ....................................................9

DIMENSION ..............................................................................10

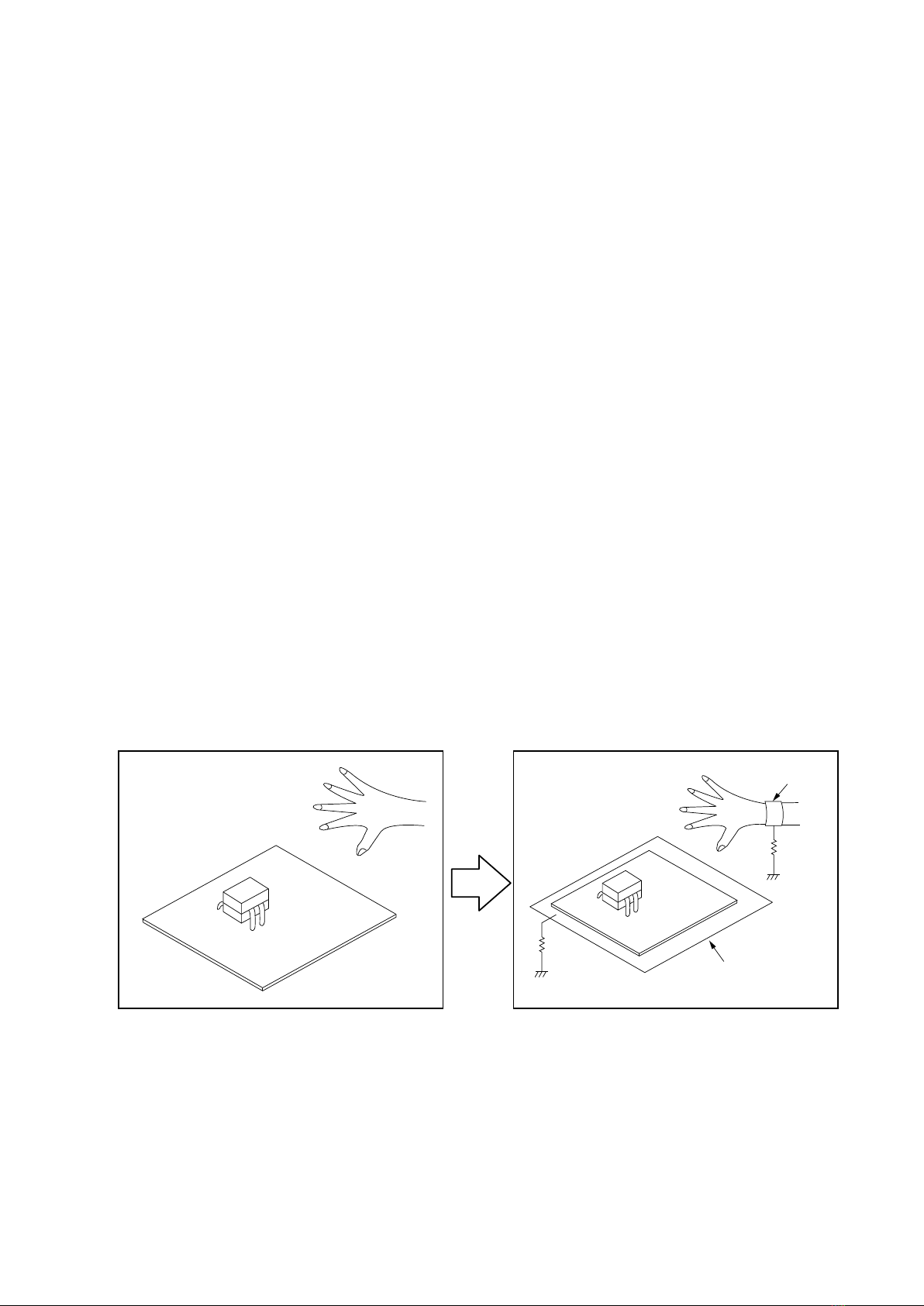

CAUTION IN SERVICING ...........................................................11

Initializing This Unit.................................................................11

JIG FOR SERVICING ..................................................................11

DISASSEMBLY ..........................................................................12

1. FRONT PANEL ASSY............................................................14

2. RADIATOR ASSY .................................................................14

3. HDMI PCB...........................................................................15

4. VIDEO PCB..........................................................................16

5. PREOUT PCB.......................................................................16

6. MAIN PCB...........................................................................17

7. SMPS PCB...........................................................................17

8. TRANS ................................................................................17

SPECIAL MODE.........................................................................18

Special mode setting button ..................................................18

1. Version Display Mode ........................................................19

2. PANEL / REMOTE LOCK Selection Mode ............................22

3. Selecting the Mode for Service-related Operations...........23

DIAGNOSTIC PATH DIAGRAM ............................................26

4. Protection Pass Mode ........................................................48

5. CY920 Reboot Mode ..........................................................48

6. CY920 Initialization Mode ..................................................49

JIG FOR SERVICING ..................................................................50

PROCEDURE AFTER REPLACING THE MICROPROCESSOR, ETC.52

FIRMWARE UPDATE PROCEDURE............................................53

1. Updating via USB ...............................................................53

2. Updating via DPMS ............................................................62

ADJUSTMENT...........................................................................69

SURROUND MODES AND PARAMETERS..................................70

TROUBLE SHOOTING................................................................73

1. POWER ...............................................................................73

2. Analog video......................................................................74

3. HDMI/DVI ...........................................................................78

4. AUDIO ................................................................................80

5. Network / Bluetooth / USB.................................................83

6. SMPS ..................................................................................88

CLOCK FLOW & WAVE FORM IN DIGITAL BLOCK.....................90

LEVEL DIAGRAM.......................................................................91

BLOCK DIAGRAM .....................................................................97

POWER DIAGRAM ..................................................................100

WIRING DIAGRAM..................................................................101

PRINTED WIRING BOARDS.....................................................102

SCHEMATIC DIAGRAMS (01/29).............................................110

SCH01_HDMI SW1 ................................................................110

SCH02_HDMI SW2 ................................................................ 111

SCH03_NET_PHY...................................................................112

SCH04_CPU_LEVEL_CHG......................................................113

SCH05_DIGITAL_CNT............................................................114

SCH06_CPU...........................................................................115

SCH07_FRONT HDMI.............................................................116

SCH08_DSP ...........................................................................117

SCH09_ADV8003...................................................................118

SCH10_ADV8003 DDR...........................................................119

SCH11_D SUPPLY..................................................................120

SCH12_HDMI TX....................................................................121

SCH13_DIR_A PLD ................................................................122

SCH14_MAIN DAC.................................................................123

SCH15_ADV7850...................................................................124

SCH16_INPUT........................................................................125

SCH17_VIDEO .......................................................................126

SCH18_VIDEO_FRONT_CNT..................................................127

SCH19_VIDEO_RC5 ...............................................................128

SCH20_AMP1 ........................................................................129

SCH21_AMP2 ........................................................................130

SCH22_MAIN_SPK.................................................................131

SCH23_MAIN_TUNER_REG ...................................................132

SCH24_MAIN_RS CNT_AUDIO IN..........................................133

SCH25_FRONT.......................................................................134

SCH26_FRONT_RS232...........................................................135

SCH27_SMPS.........................................................................136

SCH28_HDAM.......................................................................137

SCH29_PREOUT.....................................................................138

EXPLODED VIEW ....................................................................139

PACKING VIEW .......................................................................140

SEMICONDUCTORS ................................................................141

1. IC's....................................................................................141

2. FL DISPLAY.......................................................................156

2