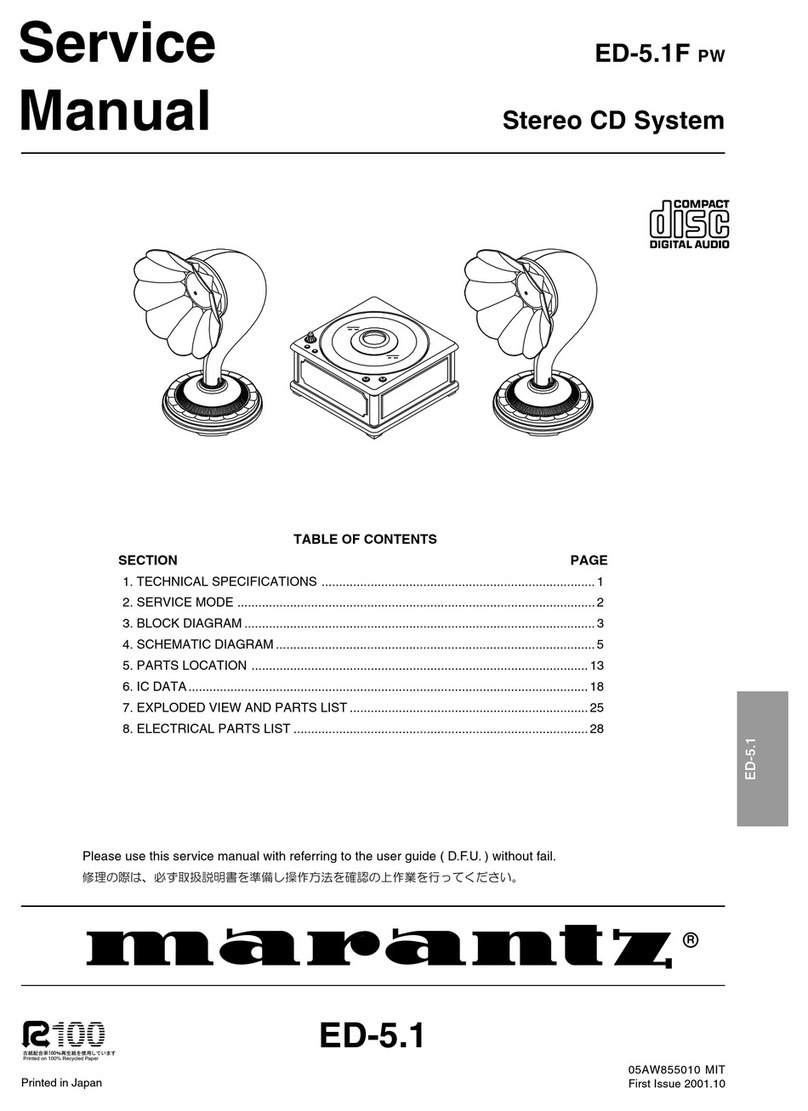

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components, MARANTZ company has created the ultimate in stereo sound.

Only original MARANTZ parts can insure that your MARANTZ product will continue to perform to the specifications for which

it is famous.

Parts for your MARANTZ equipment are generally available to our National Marantz Subsidiary or Agent.

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and

verified before it is return to the user/customer.

Ref. UL Standard No. 1492.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

010620MIT

USA

MARANTZ AMERICA, INC

1100 MAPLEWOOD DRIVE

ITASCA, IL. 60143

USA

PHONE : 630 - 741 - 0300

FAX : 630 - 741 - 0301

BRAZIL

PHILIPS DA AMAZONIA IND. ELET. ITDA

CENTRO DE INFORMACOES AO

CEP 04698-970

SAO PAULO, SP, BRAZIL

PHONE : 0800 - 123123

(Discagem Direta Gratuita)

FAX : +55 11 534. 8988

JAPAN

Technical

MARANTZ JAPAN, INC.

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 741 9190

EUROPE / TRADING

MARANTZ EUROPE B.V.

P.O.BOX 80002, BUILDING SFF2

5600 JB EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2732241

FAX : +31 - 40 - 2735578

TECHNICAL AUDIO GROUP PTY, LTD

558 DARLING STREET,

BALMAIN, NSW 2041,

AUSTRALIA

PHONE : 61 - 2 - 9810 - 5300

FAX : 61 - 2 - 9810 - 5355

CANADA

LENBROOK INDUSTRIES LIMITED

633 GRANITE COURT,

PICKERING, ONTARIO L1W 3K1

CANADA

PHONE : 905 - 831 - 6333

FAX : 905 - 831 - 6936

AUSTRALIA

QualiFi Pty Ltd,

24 LIONEL ROAD,

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - (0)3 - 9543 - 1522

FAX : +61 - (0)3 - 9543 - 3677

NEW ZEALAND

WILDASH AUDIO SYSTEMS NZ

14 MALVERN ROAD MT ALBERT

AUCKLAND NEW ZEALAND

PHONE : +64 - 9 - 8451958

FAX : +64 - 9 - 8463554

THAILAND

MRZ STANDARD CO.,LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

SUITE 8.1, LEVEL 8, MENARA GENESIS,

NO. 33, JALAN SULTAN ISMAIL,

50250 KUALA LUMPUR, MALAYSIA

PHONE : +60 3 - 2457677

FAX : +60 3 - 2458180

AMERICAS

SUPERSCOPE TECHNOLOGIES, INC.

MARANTZ PROFESSIONAL PRODUCTS

2640 WHITE OAK CIRCLE, SUITE A

AURORA, ILLINOIS 60504 USA

PHONE : 630 - 820 - 4800

FAX : 630 - 820 - 8103

AUSTRALIA

KOREA

MK ENTERPRISES LTD.

ROOM 604/605, ELECTRO-OFFICETEL, 16-58,

3GA, HANGANG-RO, YONGSAN-KU, SEOUL

KOREA

PHONE : +822 - 3232 - 155

FAX : +822 - 3232 - 154

SINGAPORE

WO KEE HONG DISTRIBUTION PTE LTD

130 JOO SENG ROAD

#03-02 OLIVINE BUILDING

SINGAPORE 368357

PHONE : +65 858 5535 / +65 381 8621

FAX : +65 858 6078