MILANO FLUSH TO WALL SUITE Code J1426

I0091MT

2/3

INSTALLATION INSTRUCTIONS

8. The water supply to the inlet valve must be connected in accordance with AS/NZ3500.1. Fit the

blanking plug provided to seal the inlet hole in the base of the cistern and connect the flexihose to the

water inlet.

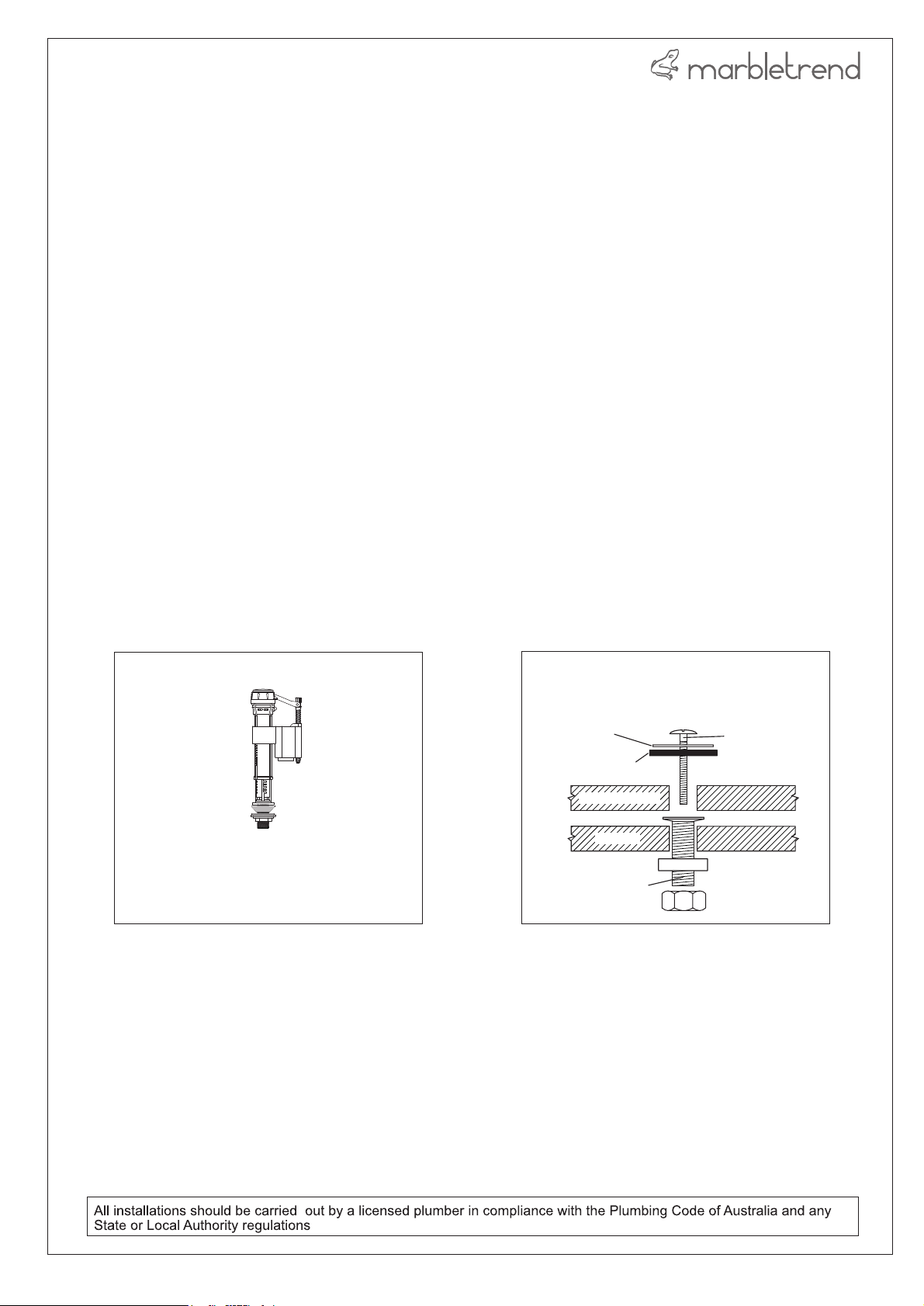

Note: for bottom water entry option a bottom water entry valve is required(not supplied). Refer to DIAGRAM 3.

9. Place the WC into position ensuring that it seals firmly to the pan connector

10. Insert the floor bracket fixing screws through the fixing holes in the base of the pan and tighten. Attach the

decorative caps.

11. For mortar bedding use a 4:1 sand and standard cement mix (do not use Rapid Hardening cement). If the

floor is tiled, cut out the tiles beneath the pan to create a good bonding surface.

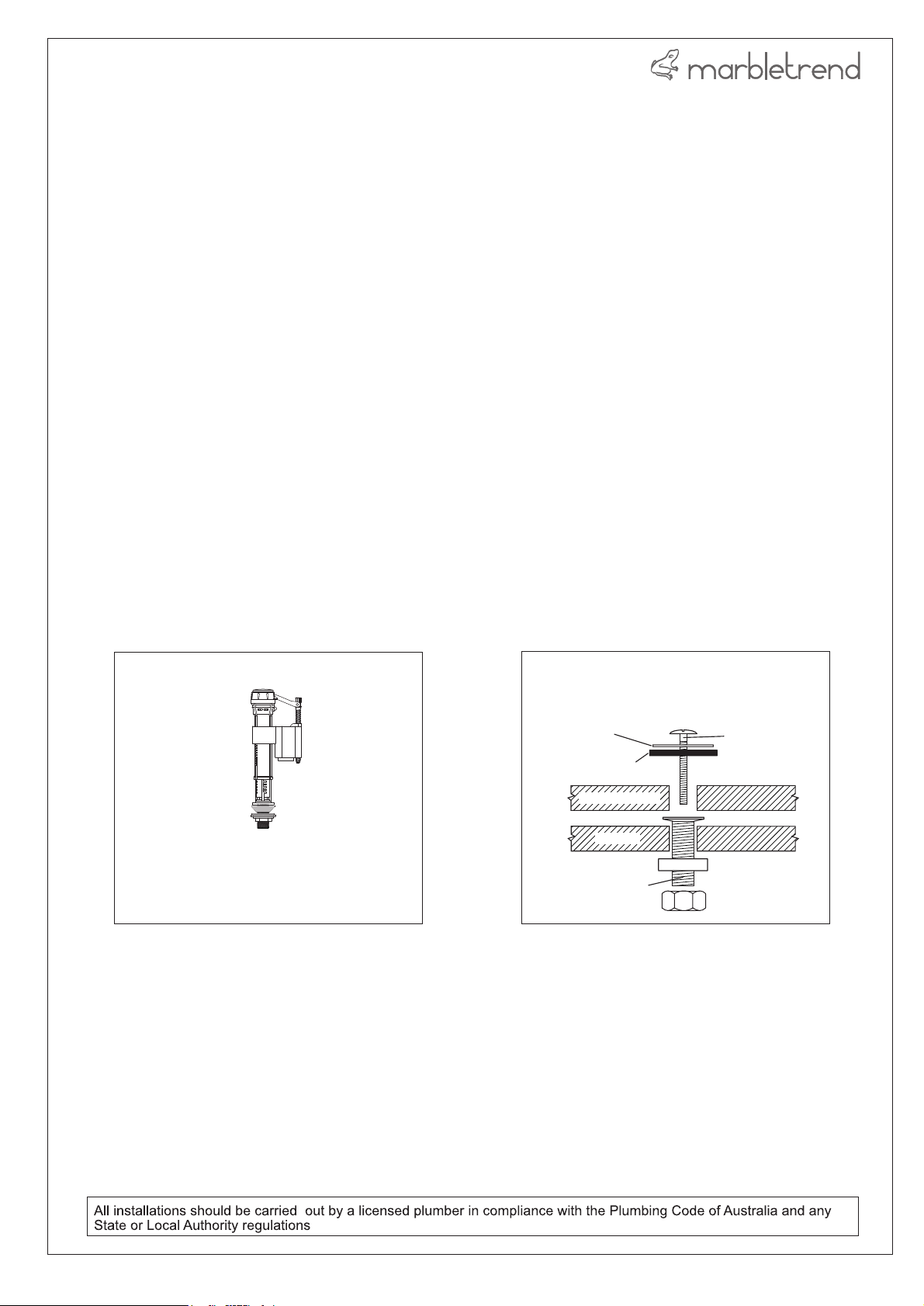

12. Place the rubber foam sealing-ring in position and place the cistern in position on the WC pan. Check that

the rubber seal is seated correctly.

13. Secure the cistern to the pan by screwing the cistern fixing bolts and washers to the threaded insert in the

top of the cistern platform (the body of the outlet valve may be temporarily removed from the base to make

this easier). Screw down firmly to compress the foam seal ring. Refer to DIAGRAM 4

14. For back water entry - attach the inlet valve water supply hose to the water supply.

15. Always flush the water supply pipes before connecting the cistern inlet valve to the cistern tap.

16. Fill the cistern and check the water level, if necessary adjust the inlet valve float.

17. Attach the cistern lid and buttons and test flush several times while checking for leaks.

18. Waterproof sealant finishing may be used around the base of the WC.

19. Fit seat

HEX NUT

PLASTIC WASHER

BOLT

SS WASHER

THREADED INSERT

CISTERN FIXING BOLTS

ASSEMBLY

DIAGRAM 4

WC PAN

CISTERN BASE

RUBBER WASHER

OPTIONAL INLET VALVE (XI210) REQUIRED

FOR BOTTOM WATER ENTRY INSTALLATIONS

FLUSH WATER VOLUME TO BE ADJUSTED TO

THE LEVEL MARK ON THE CISTERN

DIAGRAM 4