ARY

IIANGF,:

ACCURACY:

SF.LF-CIIECK FACILITY:

CALIBRATION:

SCALES:

Cereal grains and

agriculturalseeds:

Flour and wheat:

Cigarettetobacco:

4

Paper: 4 to 13%for paper; 6 to 22%

for chemic

pulp and boards. Temperature 10to 3:

Moisture contents from belowair-dry to near

saturation.

The basic accuracy of the instrument is

TO.

5%

m.c. , but variations due to the nature

of the samples may reduce this to m. c.

The accuracy tends to fall at highmoisture

contents.

The instrument may be checkedagainst the

internal standard resistance of 1 MS)

at a

meter reading of 40.

The calibrations, which are made by comparison

withstandard analytical procedures, are based

on ground samples wherever possible.

'the standard apparatus includesany one ofthe

direct readingscales listed below,as ordered.

9 to 25%for wheat, rye and maize; 8 to 2'1%

for barloy and oats. Temperature -1 to 38oc

(30 to 100

0F). The scales are based on oven

drying for four hours at 120oc (248OF).

Tables are providedcoveringagricultural seeds.

9 to 25%for groundwheat; 10to 20%

for flour.

Temperature -1 to 38oc (30to 100OF); outside

the range 10 to 30 oc (50 to 86 01•)

there may be

a slight fall in accuracy. The scales are based

on oven drying for four hours at 120oc (248OF).

Tables givenfor other mill stocks and

products.

Sto 20%

for 'cigarette ragt (equivalent

to cut

wholeleat) and 9 to 21%

for cut lamina. Tent-

perature 10 to 30 oc (50 to S6OF). The seaI""

are based on oven drying for sixteen hours at

100Oc (212 OF).

93.31',

Tick beans:

Rice:

POWER SUPPLY:

DIMENSIONS:

WEIGHT:

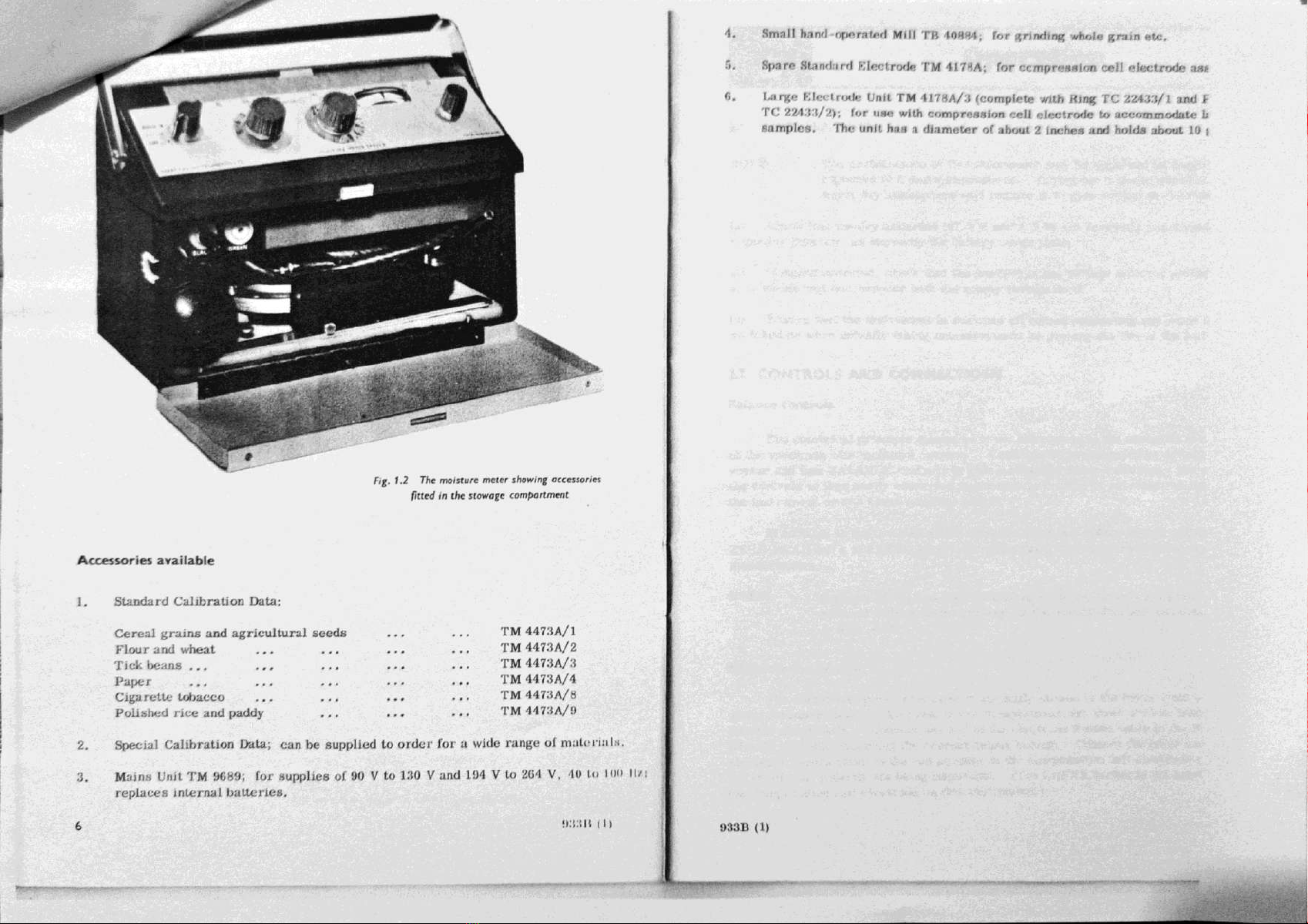

1.3 ACCESSORIES

Accessories supplied

to 90 OF). Supplementary information

provided covering manytypes of wood

p

paper andboards. The scales are basc

oven drying to constant weightat 102to

(215.5 to 221OF).

9 to 22.5%

for groundbeans. Tempera

10 to 30 O

c (50 to 86 OF). The scale iE

on oven drying for fifteen hours at 105c

(221 O

F).

10

to 22%

for polishedrice. Temperat

to 30 O

c (50to 86 OF). The scale is ba

ovendrying for fifteen hours at 105oc (

Internal batteries: one 67.5 V and two

Height

7 3/4 in

(1970 mm)

Width

11 3/8 in

(2880 mm)

Depth

5 1/4 in

(1350 mm

8 1b

(3.65 kg) withcompression cell ele

andbatteries.

1.

2.

3.

4.

5.

Compression Cell Electrode Assembly type TM4113A

(complete with Cla

Tc 22429, Electrode TM4178A, RingTB 22425/2, Plunger TB 22425/1a

3 ft ConnectingCableTM4130A).

Oneset of CalibrationData, TM4473Aseries, as ordered see under

Accessories available. Aset of calibration data comprises a slip-on

calculator scale anda booklet, card or sheet givingsupplementaryinforn

onsubstances covered by the calculator scale andin some cases, allied

One67.5 Vbattery; Exidetype DM5()1or Ever ReadytypeBIOI, VidorI

or equivalent.

Two 1.5 Vcells; Exide type T21 or Ever Readytype LPU2, Vidor LPV2

equivalent.

One4 BAhexagonalwrench, type 22951-006; for carrying out the Ste

dizationtest detailed in Sect. 4.2.

OneInstruction ManualNo. EB 933B.

933B(1)