MEMBRANE & FILTER CARTRIDGE REPLACEMENT*

Sediment Cartridge – Change when visibly dirty (4-8 months), or when system pressure drops by

more than 5 PSI

Carbon Cartridge – Change at the same time the sediment filter is changed (4-8 months)

DI Cartridge – The color of the DI resin will begin to turn orange from the bottom up. Replace the

cartridge once it has reached approximately 1” from the top of the cartridge(s). To more accurately

determine when to replace the DI cartridge, use your TDS monitor or meter. You will notice a dramatic

rise in the TDS level once the resin is exhausted.

Thin Film Composite (TFC) Membrane – Should be changed when rejection rate drops below 95%.

For example, if your tap water TDS is 100ppm, water exiting the TFC membrane should be 5ppm or

less. TFC membranes will typically last about 1-2 years. The use of a flush valve kit is recommended to

help extend the life of the TFC membrane.

*All listed service times are approximate. Actual service life may be significantly longer

or shorter depending on the water source quality and how often the unit is used.

Problem Possible Causes Solutions

Zero product water - missing flow restrictor - install flow restrictor

- dried-up or damaged TFC membrane - install new TFC membrane

Slow water production - clogged pre-filters - install new pre-filters

- low water pressure (< 45 PSI) - install booster pump or use higher

output TFC membrane

- low water temperature - install booster pump or use higher

output TFC membrane

- hard water or high TDS - install booster pump or use higher

output TFC membrane

- damaged TFC membrane - install new TFC membrane

Too much product water,

too little waste water, or DI

exhausts quickly

- product and waste water lines reversed - reverse product and waste water lines

on TFC membrane

- TFC membrane not fully seated - remove then re-insert TFC membrane

- damaged / ruptured TFC membrane - install new TFC membrane

- if chloramines are present, the carbon

filter may be exhausted

- replace carbon filter with

Chloramine-X filters and DI cartridge

TROUBLESHOOTING

Your new Marine Depot KleanWater RO or RO/DI filter should work trouble-free out of the box. If you

have difficulties or questions, please contact Marine Depot at 1-800-566-3474.

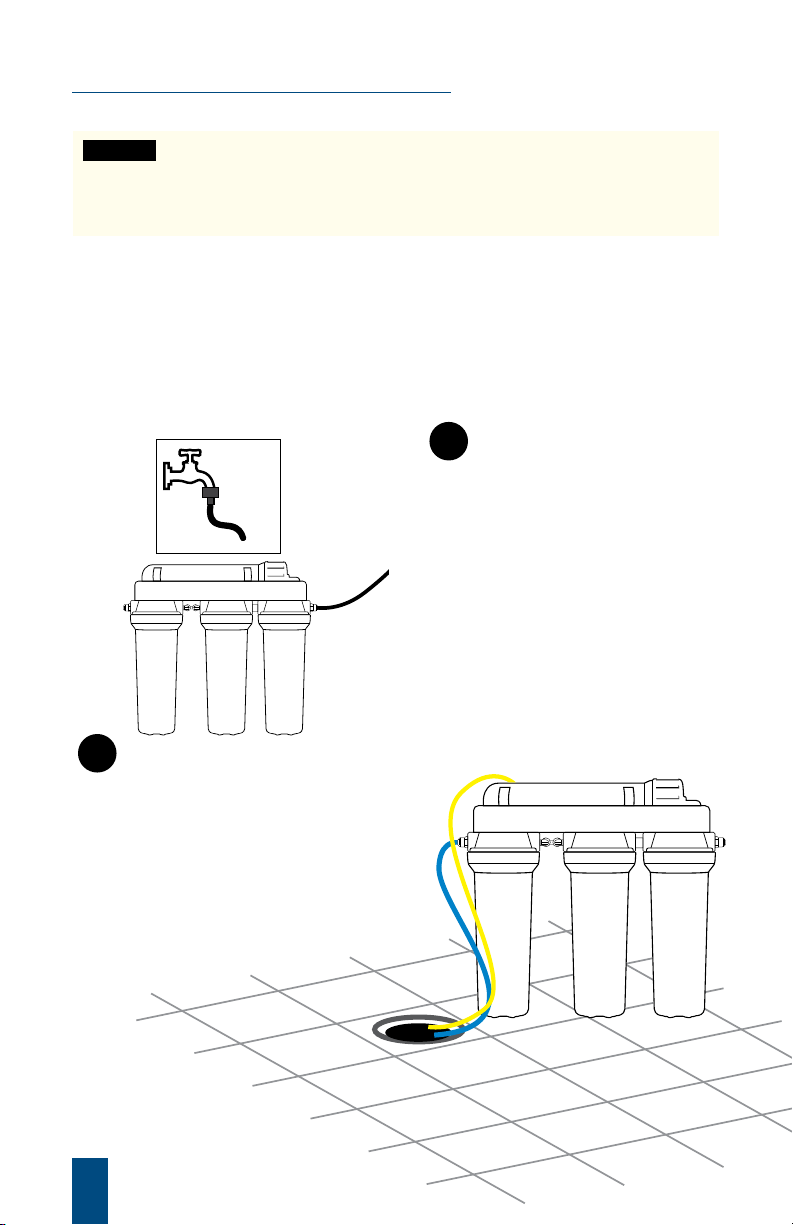

Note:The water supply should be turned off and the water pressure should be bled off

prior to working on the filter system itself. If you experience low/no product water and

your system has a flush valve, please ensure the flush valve is in the closed position

before collecting product water.

8Questions? Call 1-800-566-3474