Table of Contents

Table of Contents .........................................................................................................................................2

Important Safety Instructions...................................................................................................................... 3

Box Contents .....................................................................................................................................6

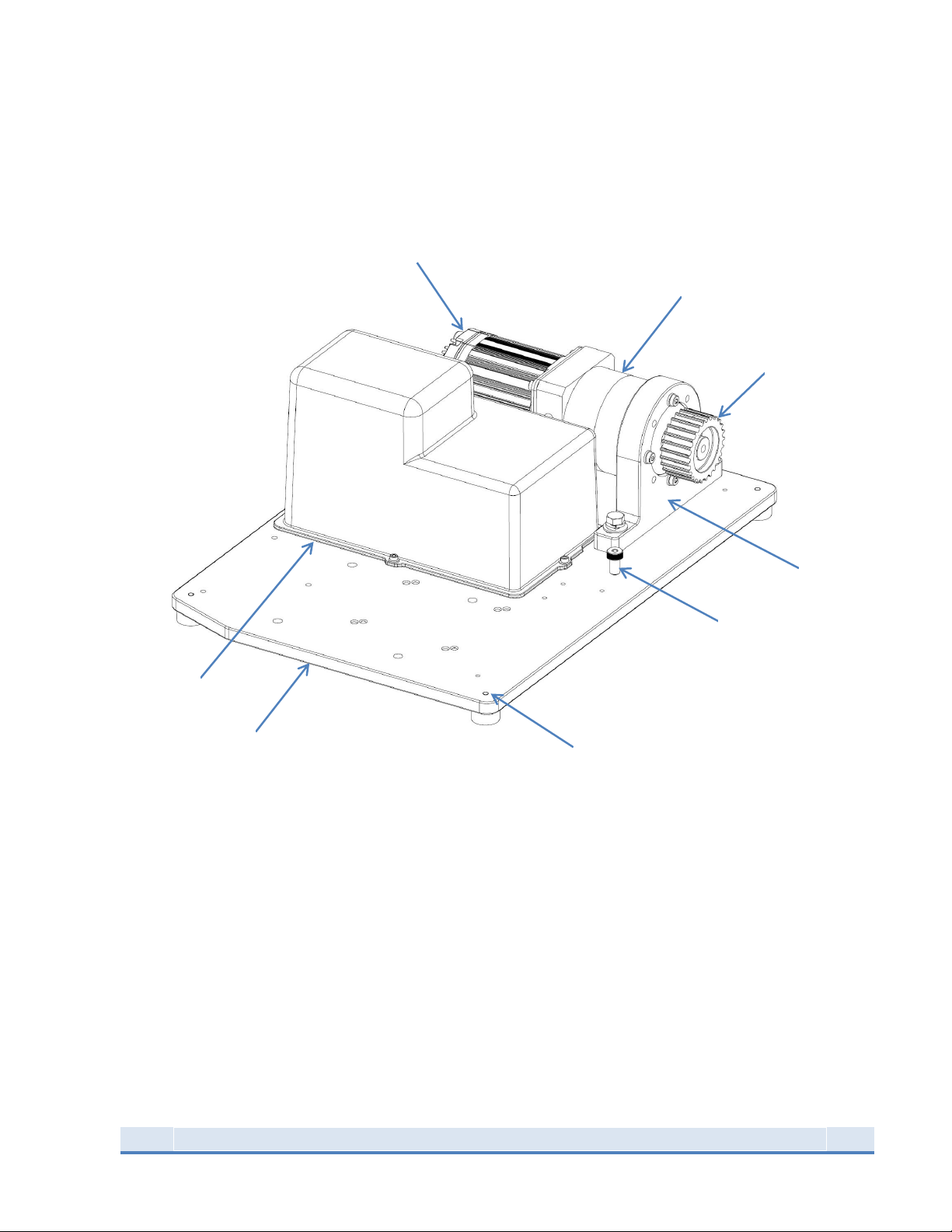

Set-Up Procedures........................................................................................................................................7

1. Removal of equipment from the packing carton.........................................................................8

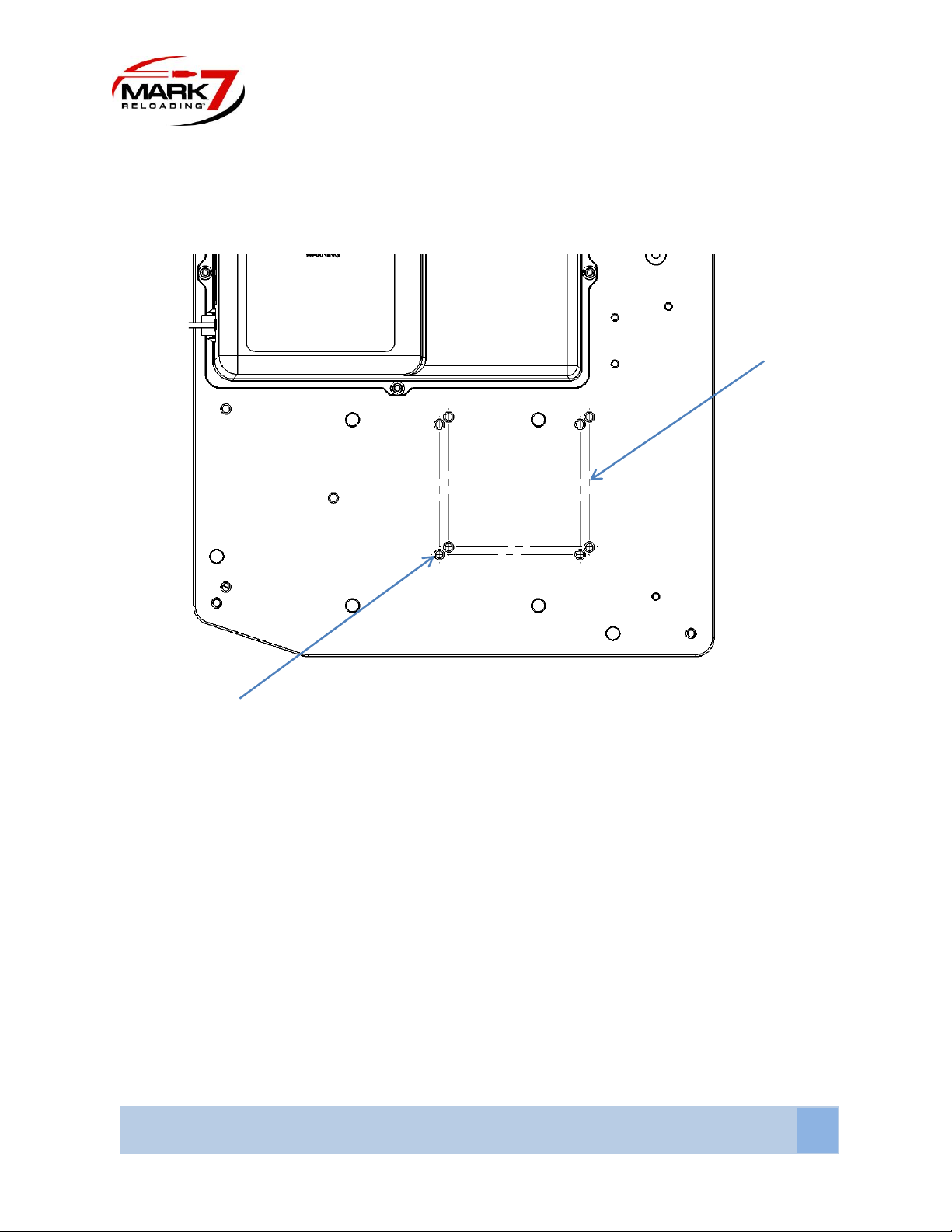

2. Determine mounting holes for either Super 1050 or RL 1050 ....................................................9

3. Mounting large sprocket............................................................................................................10

4. Belt installation..........................................................................................................................11

5. Belt tensioning...........................................................................................................................12

6. Belt Guard installation ...............................................................................................................13

7. Removing the ratchet system on the 1050................................................................................14

8. Tablet holder install ...................................................................................................................15

9. Tablet cable outlet installation ..................................................................................................17

10. Console Rear I/O inputs........................................................................................................... 18

11. Console Side I/O inputs............................................................................................................19

12. EMI FILTER for Bulletfeeders ...................................................................................................21

13. EMI FILTER for Casefeeders ....................................................................................................22

14. Recommended Cable management ........................................................................................24

15. Manully Driving the press .......................................................................................................27

Sensors........................................................................................................................................................28

(Optional).............................................................................................................28

DecapSense™(Optional) ...........................................................................................................................29

(Optional).............................................................................................................. 32

(Optional).........................................................................................................37

*original sensor attached to Dillon Powder Check (Optional)......................... 51

1050 Safety Shield with Electronic Disconnect (Optional)………………………………………………………………. 53

Operating Instructions: 1050 PRO ..............................................................................................................56

Sofware Firmware Updates ........................................................................................................................63

Autodrive Maintenance Intervals ...............................................................................................................69

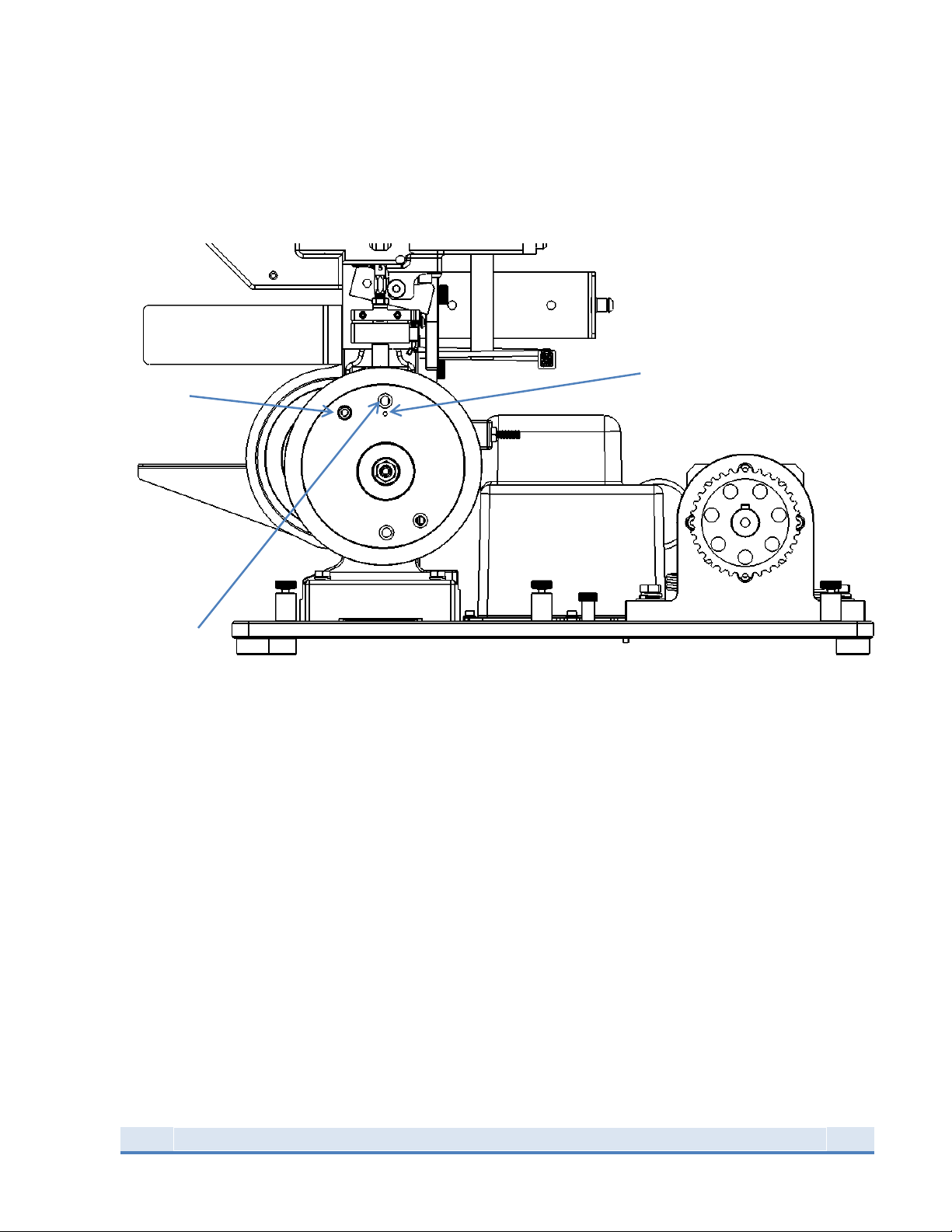

Dillon 1050 SUPER Lubrication Points.........................................................................................................69