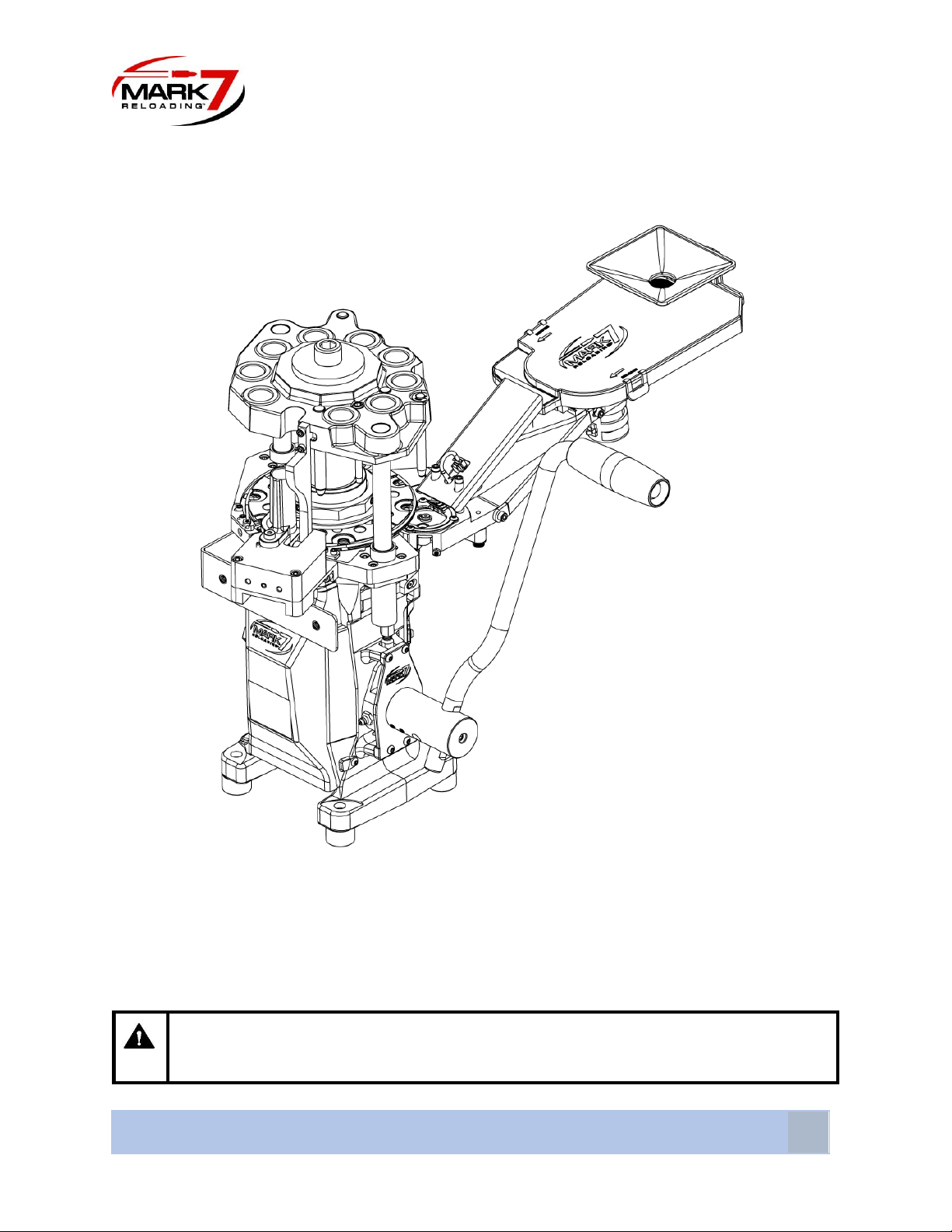

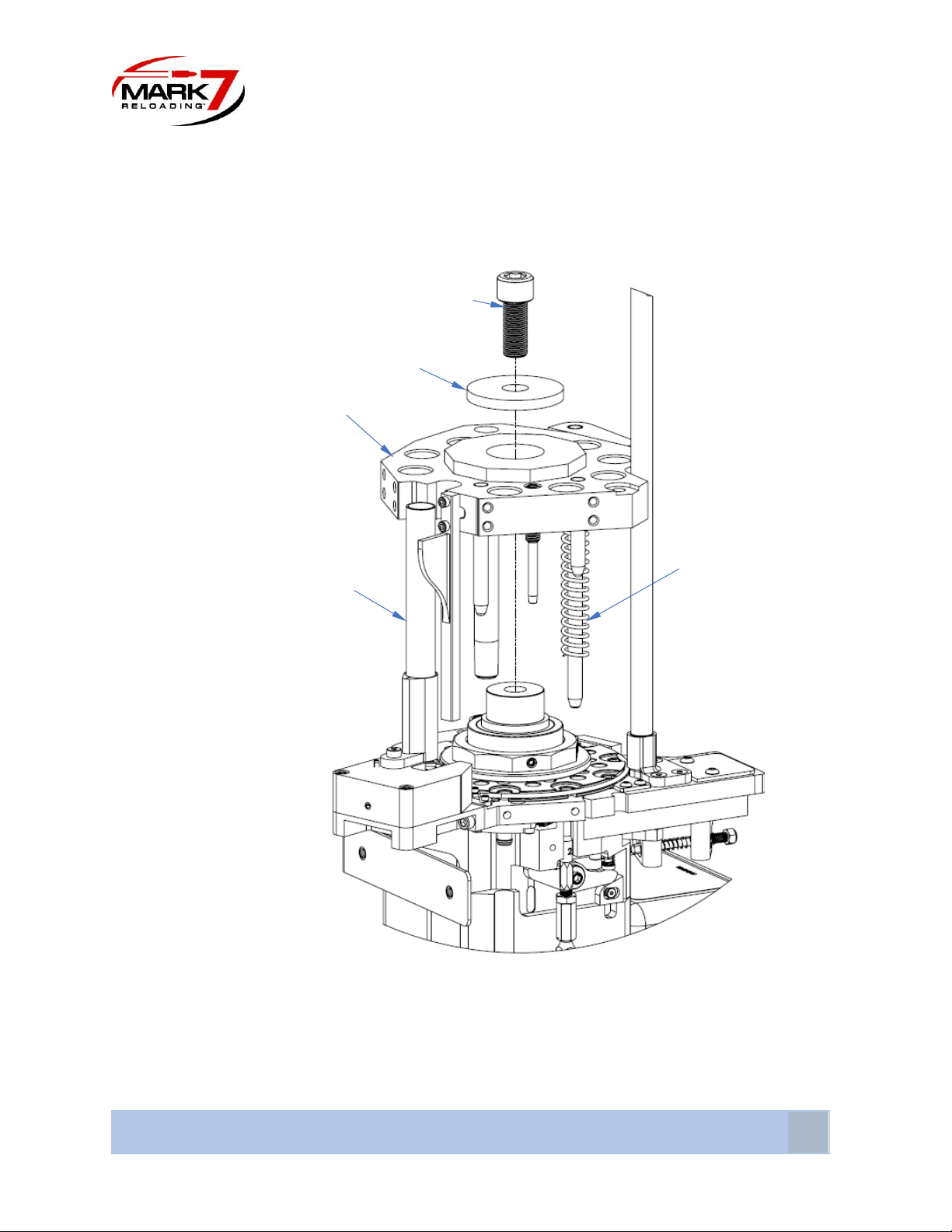

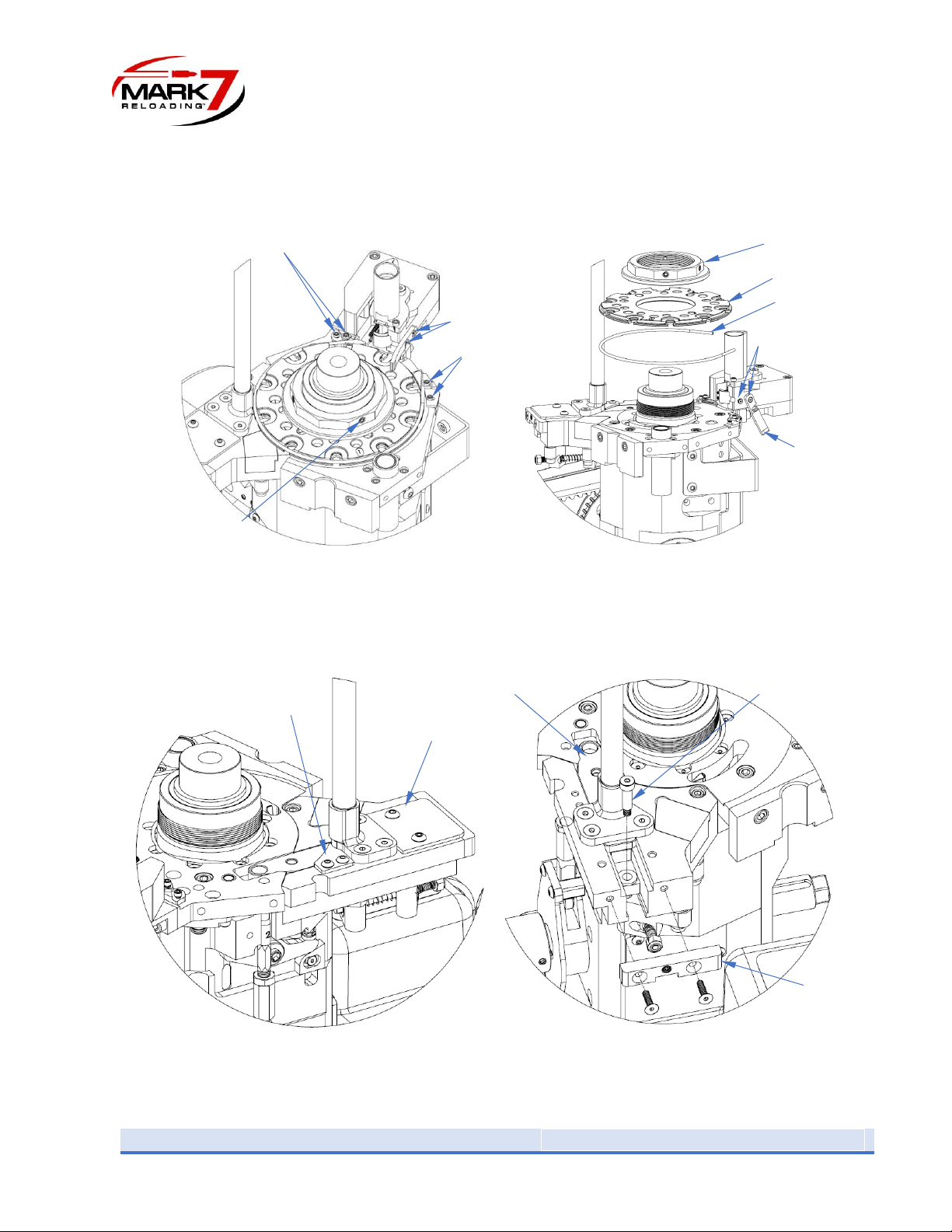

Mark 7’s Automated Primer Xpress is a totally new, patent pending technology which provides

nearly 100% successful primer orientation for your loading machine. This completely unique

design features an oscillating primer reservoir which effortlessly orients primers and allows

continuous primer feeding. No more stopping your machine to reload primers using clumsy

tubes! Simply add more primers into the built-in funnel without interruption to your loading

operation. The large hopper can hold 300+ primers and includes a tough polycarbonate safety

cover, which also keeps dust and debris out of the system. In the unlikely event that an up-side-

down primer does make it into the feed ramp, our failsafe sensor will detect it and sound an

alarm for manual presses and stop the operation on automated machines. In addition, change

over between small and large size primers is easy to do and all parts are included. Dual optical

sensors automatically start/stop the feed system to provide primers as needed. Primers are fed

into your machine using a simplified single slot feed disc mechanism for positive, reliable primer

positioning.

Warning!

•Primers are explosive and improper handling can lead to primer detonation and injury

to the user. Follow all safety guidelines when operating this devise.

•Always have the steel safety shield installed before operating this devise.

•Always wear safety glass when working with primers.

•Never force any primers. If a jam occurs, carefully remove excess primers, and gently

clear the jam.

•Primer dust can accumulate on the surfaces where primers travel. Periodically clean all

surfaces of the Primer Xpress with a clean, damp cloth.

•Never smoke when reloading or around primers and/or powder.

•Only store primers in their original packaging. If primers are left in the tray after loading,

remove them and return them to the original packaging.

•Always keep the cover on the primer hopper when operating the devise.

•Primer pockets should be clean and military cases must have the primer crimp removed

before seating primers.