JULY 19, 2017 8 STM-E, STM-EL, STM-EX & STM-ELX STERILIZERS

MISCELLANEOUS COMPONENTS

CAST-IN HEATING ELEMENTS

Located under the sterilizing cylinder is a bank of (3) U-

shaped heating elements. These elements are welded in

place in a protective aluminum shield. The elements can-

not be removed, and in the unlikely event that one or all

fail, the complete cylinder must be replaced.

THE LOW WATER CUT-OFF (MANUAL RESET)

Fastened to a special mounting brace behind the front

panel, the Low Water Cut-Off acts to shut off the complete

unit, should the water run dry. The Low Water Cut Off is

factory set, to shut the unit off when the cylinder tempera-

ture rises between 380oand 440° Fahrenheit.

When the Sterilmatic is turned on without water or the

water has been evaporated away, the temperature of

the aluminum sterilizing cylinder will rise and by heat in-

duction effect the Low Water Cut-Off. Its inner electrical

contacts will be forced open from heat expansion, thus

cutting off the ow of electric current to the heating ele-

ments. With the replacement of water into the cylinder

the cylinder temperature will drop and the contacts of the

Low Water Cut-Off can be again closed. The unit will only

restart after the manual button has been re-set.

THE ELECTRIC CONTACTORS

The Electric Contactors are located on the top of the unit,

underneath the top ue cover. These important compo-

nents receive an electrical impulse when the Timer is

turned on. When the unit reaches a pre-set pressure of

13-13.5 PSI the #1 switch will cut out causing the front

contactor to become de-energized. This, in turn, will dis-

connect the left and right bank of heaters and the timer

motor will start.

THE TIMER

The Sterilmatic is put into operation with the manual set-

ting of the timer. With the setting of the timer, an electrical

current is directed to the pressure control. The current en-

ergizes the pressure control, which activates the contac-

tor coils to cause a current ow to the heating elements.

When the cylinder pressure reaches 13 to 13.5 PSI, the

timer motor and pilot light are energized. At the end of

the cycle the timer will cut off the ow of electricity to all

the components except the exhaust, the exhaust solenoid

and the timer motor. They will revert back to their original

deactivated state. The timer motor and pilot light will con-

tinue to be energized after the timed sterilizer cycle has

been completed and for two additional minutes. Only after

this will the timer and white pilot light be de-energized. If

the timer fails to operate the Sterilmatic, replace it. The

timer is replaceable only as a complete unit as factory

repairs to it would not be practical in the economical inter-

ests of the customer.

THE STEAM PRESSURE GAUGE

The Steam Pressure Gauge registers the pressure of

steam, which is within the sterilmatic sterilizing chamber.

To replace this unit, it is necessary to disconnect the cop-

per tubing and to remove the two nuts holding the gauge

framework in place.

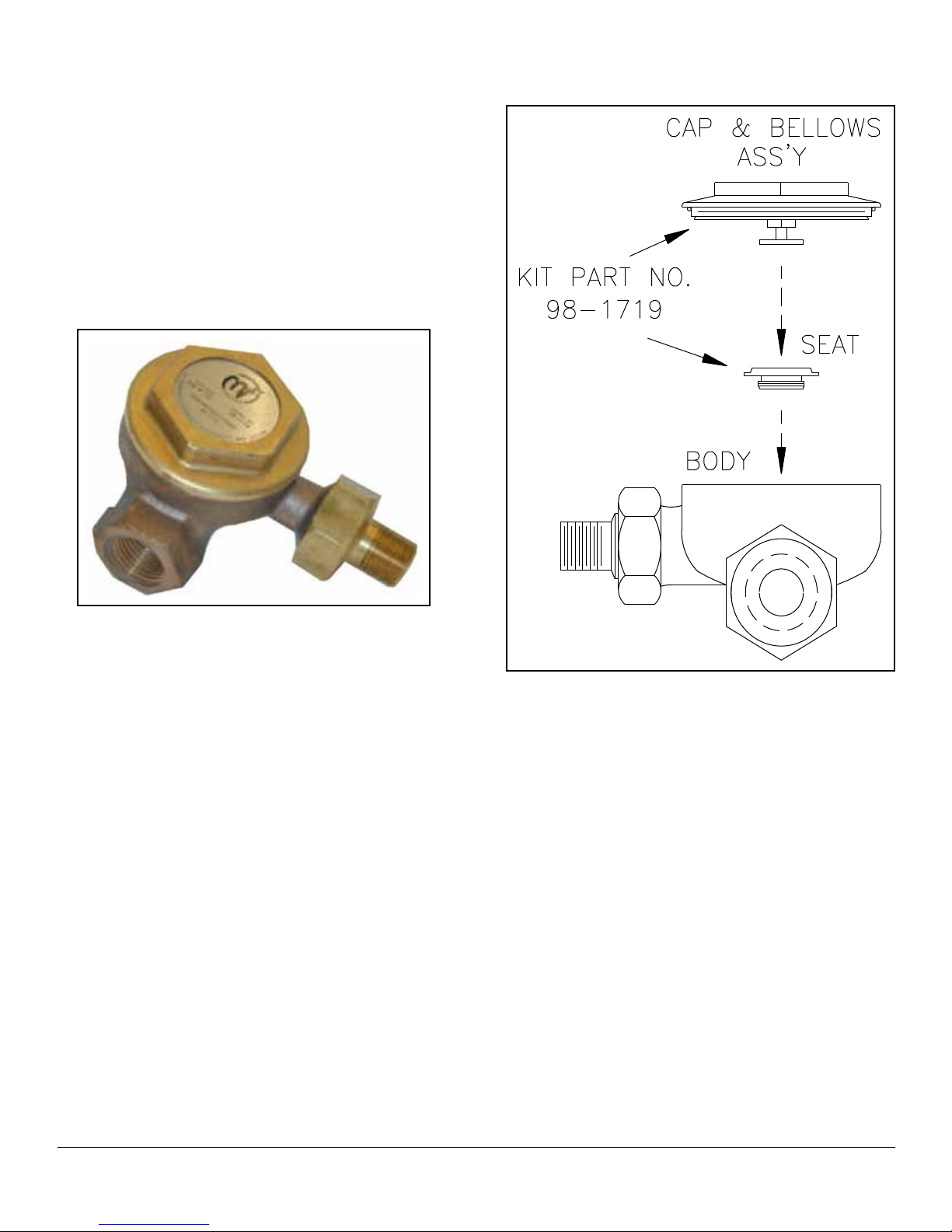

THE SAFETY VALVE

The Safety Valve is factory set to automatically open and

exhaust excess steam from within the sterilizing cylinder,

thereby assuring that operating pressures remain within

safe limits. The lever action of the safety valve must be

free to operate unrestricted at all times. If the Safety Valve

should leak continually with a pressure build-up or should

it cause an interruption on a sterilizing cycle premature-

ly (below 124° Centigrade on the temperature gauge),

it must be replaced. However, the temperature gauge

should rst be checked for accuracy.

THE FLUE

The Flue serves as a protective shield for the steam trap

safety valve, exhaust valve, and electrical components as

well as a mounting base for the control panel. The pres-

sure gauge, dial thermometer, exhaust valve switch and

timer, protrude through the control panel. The Flue cover

may be removed to allow more room for servicing the

control components. The control panel face may then be

removed by unscrewing the sheet metal screws, which

mount it to the Flue.

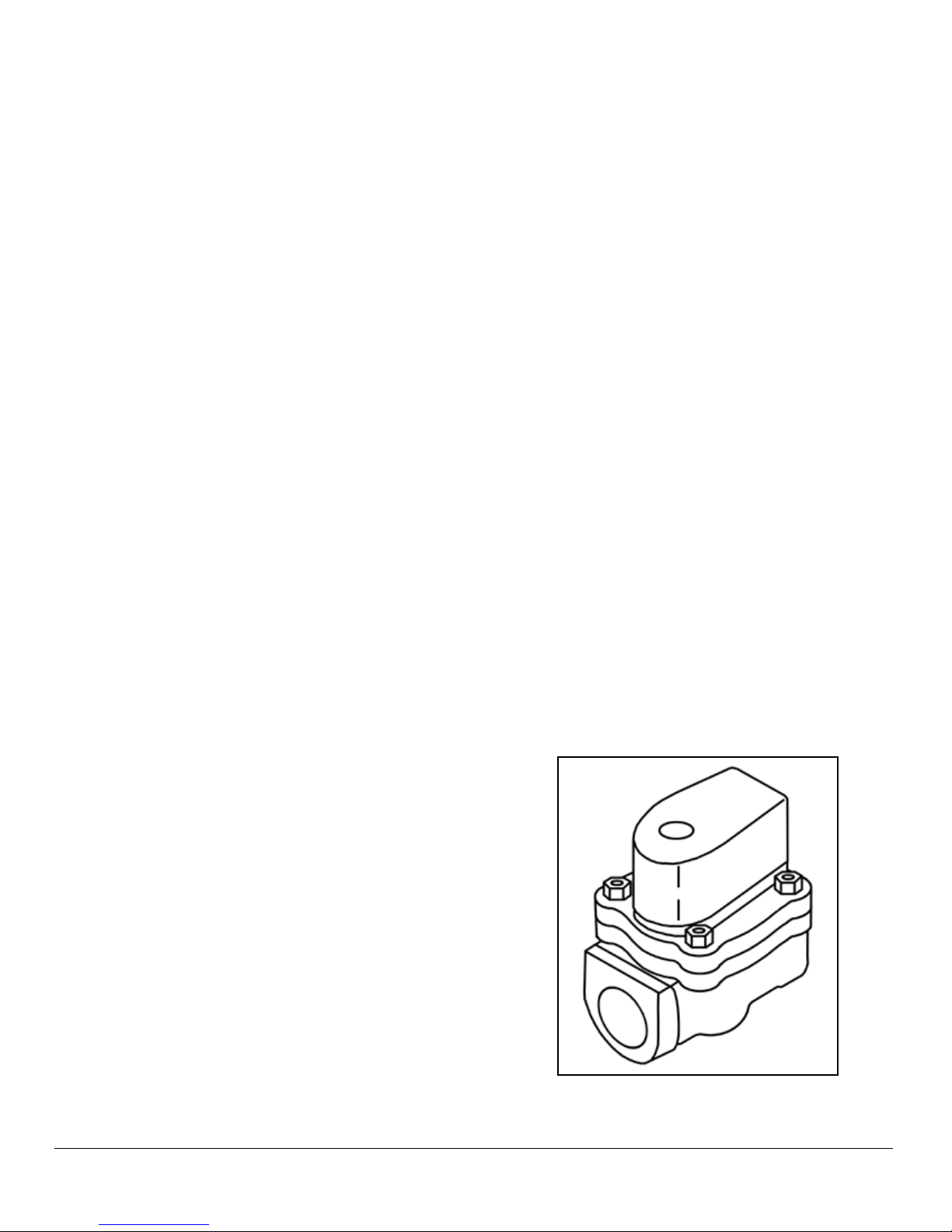

THE EXHAUST SOLENOID VALVE

The exhaust solenoid is normally closed and only opens

at the end of the cycle when it is energized.

Figure 7