3INSTALLATION

Oven Location & Electrical Connection

AIR SUPPLY AND VENTILATION

The area, around and above the appliance must be kept

clear to avoid and obstruction of air ow needed for ven-

tilation. Adequate clearance must be maintained at all

times in front and side of the appliance for servicing and

proper operation.

CLEARANCE

When installing ovens against combustible surfaces (rear

or side walls) 0” clearance is required. When installing ov-

ens against non-combustible surfaces (rear or side walls)

0” clearance is required.

LOCATION

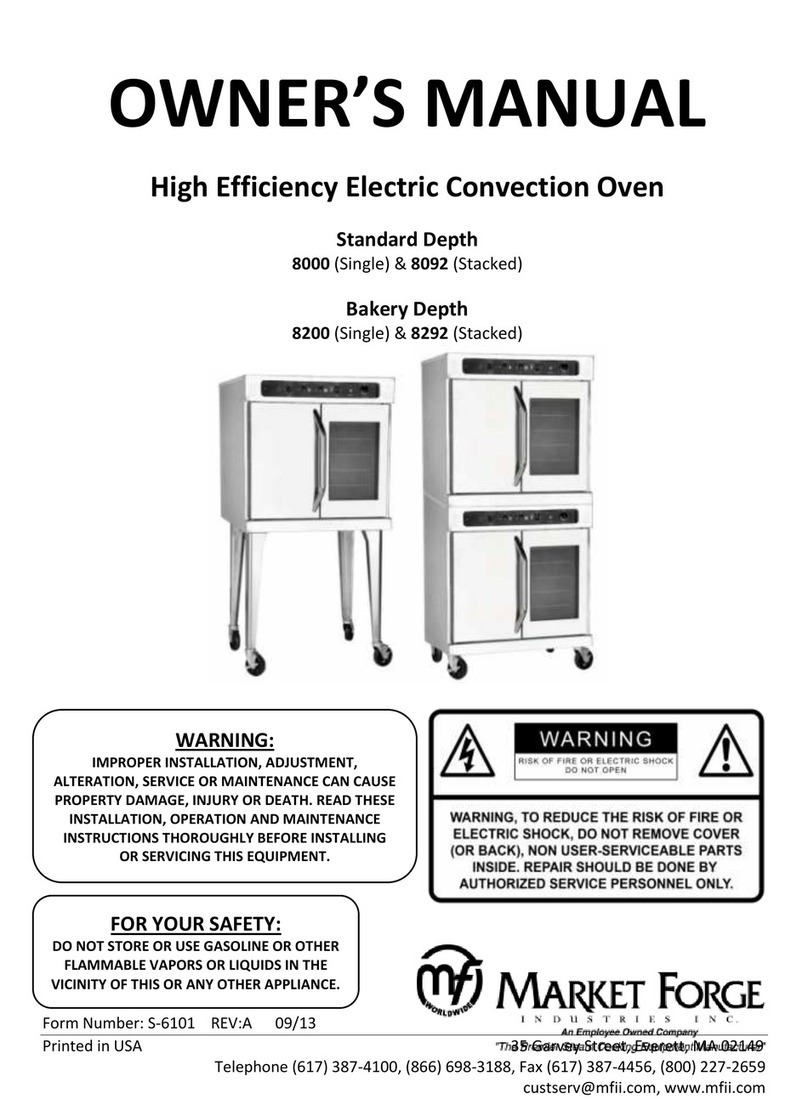

DO NOT MOUNT oven on a curb base. Use legs/cast-

ers provided. Adequate air space at the bottom and rear

of the unit must be provided for proper venting of blower

motor. DO NOT USE door to lift or move oven!!! All ov-

ens must be installed on leg assembly or casters shipped

with the unit. The leg/stand assembly parts or casters are

shipped separately.

LEVELING

A carpenter’s spirit level should be placed on the oven’s

center baking rack and the unit leveled both front-to-back

and side-to-side. If it is not level, cakes, casseroles, and

any other liquid or semi-liquid batter will not bake evenly,

burner combustion may be erratic, and the unit will not

function efciently.

If the oor is relatively smooth and level, the unit may be

further leveled with adjustment in the foot of the leg. Units

with casters must be leveled with shims. A unit will prob-

ably not return to the same position after being moved,

requiring re-leveling after each and every move.

ELECTRICAL CONNECTION

WARNING

Disconnect power supply before cleaning or

servicing.

Convection ovens have a single point power connection

at the terminal block. Check for single phase or three

phase connection and connect accordingly. The electrical

service in the building must be equipped with a properly

grounded receptacle, in accordance with local codes, or

in the absence of local codes, with the national electri-

cal code, ANSI/NFPA 70-latest edition, in Canada, con-

form with Canadian electrical codes CSA- C22.1. 208V

or 240V single and three phase wires should be properly

connected as shown in the wiring diagram. 480V connec-

tion is ONLY with three phase and a step down trans-

former.

Do not cut or remove the grounding wire. Wiring diagram

is located on the backside of the appliance.

RATING PLATE

WARNING

UNIT MUST BE CONNECTED ONLY TO THE

POWER INPUT IDENTIFIED ON THE RATING

PLATE!

IMPROPER CONNECTION TO POWER SUP-

PLY OTHER THAN WHAT IS DESIGNATED ON

DATE PLATE WILL VOID WARRANTY.

The rating plate is located in front of the oven below the

oven section. Information on this plate includes the model

number, serial number, power input, ampere draw and

clearances from combustible and non-combustible sur-

faces. Metal tag with serial number is located on the top

right corner of the unit.