TABLE OF CONTENTS

ii

IMPORTANT NOTICE .......................................................................................................................

Your Energy Efcient Convection Oven ..............................................................................................

How the Oven Operates ....................................................................................................................

Operating Controls and Indicators .....................................................................................................

Operating Instructions ........................................................................................................................

Cleaning/Preventive Maintenance .....................................................................................................

Trouble-Shooting Guide ....................................................................................................................

Illustrated Parts List ............................................................................................................................

Assembly Instructions ........................................................................................................................

Appendix ..........................................................................................................................................

i

ii

ii

1

1

2

2-3

4-6

7-19

20-23

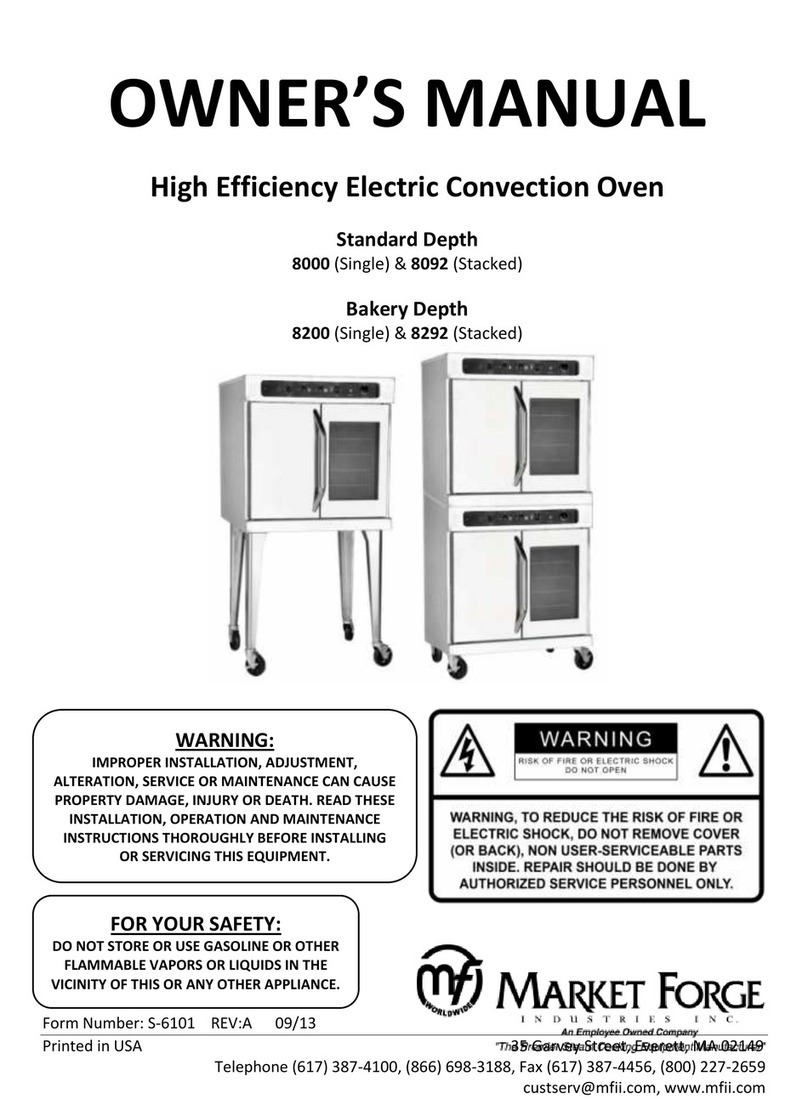

YOUR ENERGY EFFICIENT CONVECTION OVEN

HOW THE OVEN OPERATES

MSA-SB-2600 convection ovens are electrically powered, high

capacity ovens featuring high energy efciency. These ovens

are designed to radically cut power consumption, delivering the

cooking power of a 16 KW oven from only 11 KW’s of energy

input. Improvement of energy use is made possible by a care-

fully designed insulating system which keeps heat inside the

oven longer.

A convector fan distributes heat uniformly throughout the oven

interior, for fast even roasting and baking.

Like all Market Forge products, MSA-SB-2600 ovens are built

to the highest standards of workmanship, employing only the

nest materials and components. Of course, Power Saver

II ovens are fully approved by UL, and other ofcial testing

authorities.

MSA-SB-2600 ovens operate by use of two simple controls, a

power switch for turning on the fan motor and control circuit,

and a thermostat for setting the oven temperature. The oven is

otherwise automatic. A thermostat maintains oven temperature

by cycling heating elements on and off, with temperature uc-

tuating no more than 20°F from the setting. Uniform distribution

of heat within the oven is assured by continuous operation of a

convector fan.

A 60-minute and Constant Heat timer serves as an aid in us-

ing the oven, when the timer expires the heating elements shut

off. To prevent unnecessary loss of heat when the doors are

opened, an interlock switch stops fan operation whenever the

right-side door is opened. Should the operator wish to cool

the oven, opening just the left- side door will quickly ventilate

the oven interior.