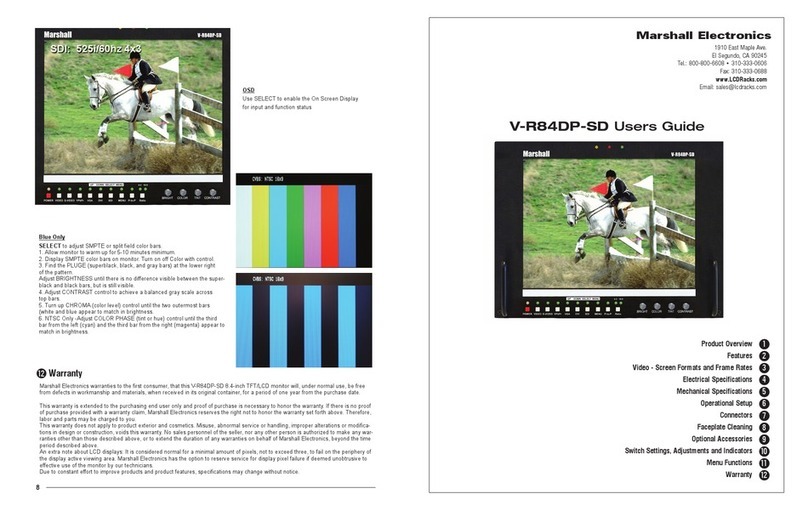

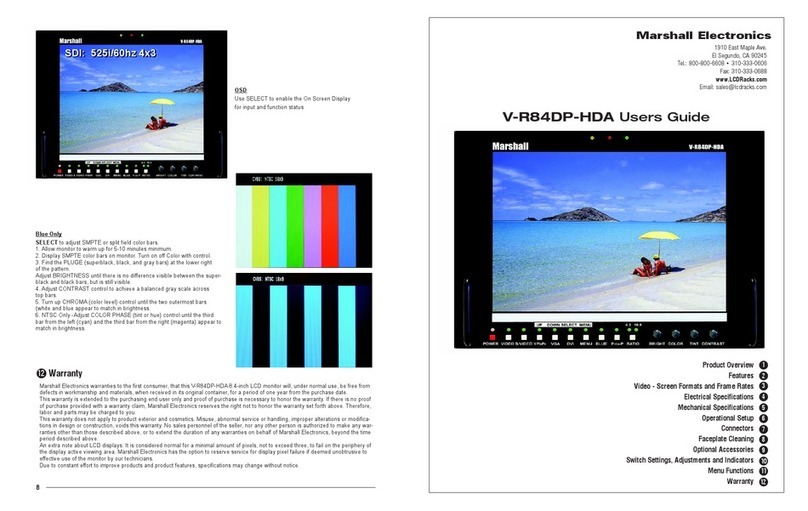

V-R84DP-HDSDI Users Guide

4

5Electrical Specifications

Display (Viewing Area) 8.4 Inch diagonal (170.4mm w x 127.8mm h)

Screen Aspect 4:3/16:9 switchable

Resolution (RGB Dots) 800H×RGB×600V (1.44 million pixels)

Viewing Angles 160° with protective screen and treatment (130°H x 120°V native)

Contrast Ratio 500:1

Dot Pitch .213mm square pixel

Pixel Response 10ms rise/25ms fall

Backlight Type CCFL (Cold Cathode Fluorescent Lamp)

Brightness 500 cd/m²

LCD Screen Treatments Anti Reflection, Anti Glare, Hardcoat

Protective Screen 0.118” (3mm) thick Optical Grade Polycarbonate with Anti-Glare and Anti-Abrasion

coatings. (600 Cheesecloth mil-M-13508C)

Video Format Standard and high definition

System NTSC/PAL auto recognition

Inputs 2 SDI (BNC) Self Terminating (SMPTE-259M) (ITU-BT-R601)

Active Outputs 1 SDI of on screen video (BNC) Available when power is applied

Color temperature D65 (6500° Kelvin)

Color Gamut SMPTE-C/EBU

Luma Linearity Typical +/- 3% with 5 ire increments (0 to 10 ire)

Power Required 10.4 to 16.8 VDC

Power Consumption Approx. 15 watt nominal

Operating Temperature 32°F to 120°F (0°c to 50°c)

Storage Temperature -4°F to 120°F (-20°c to 50°c)

Compliance ₠, FCC-Class A, ANSI-63.4 (Certificates on file)

RoHS WEEE/Environmental Do not dispose. Return to Manufacturer or Authorized Recycle Facility

6Mechanical Specifications

Dimensions 9”w x 6.875” h x 2.5” d (228.6mm x 174.6mm x 38.1mm)

Approx. Weight 3.3 lbs (1.5 Kg)

Power Supply Weight 1.0 Lb (.45 Kg)

7Faceplate Cleaning

Faceplate Cleaning

When cleaning the faceplate it is very important to use non-abrasive and ammonia free cleaning agents and a clean micro fiber

cloth. Do not use paper towels. Paper towel fibers are coarse and may scratch the surface of the Polycarbonate faceplate. Paper

towels may also leave streaks on the surface. Antistatic and fingerprint resistant cleaning agents are recommended.

Wash protective cover with a solution of mild soap or detergent and lukewarm water. Use a clean soft cloth, applying only light pres-

sure. Rinse with clean water and dry by blotting with a damp cloth or chamois. Grease, oil or tar may be removed with a good grade

of hexane, aliphatic naphtha, or kerosene. These solvents may be obtained at a paint or hardware store and should be used in ac-

cordance with manufacturer’s recommendations.

DO NOT USE: window cleaning sprays, kitchen scouring compounds or solvents such as acetone, gasoline, benzene,

alcohol, carbon tetrachloride, or lacquer thinner. These can scratch the sheet’s surface and/or weaken the sheet causing

small surface cracks called “crazing.”

Faceplate Dusting

Dust with a soft, damp cloth or chamois. Dry or gritty cloths may cause surface scratches and create a static electric charge on the

surface. Neutralizing static electricity effects by using recommended cleaning and polishing practice.

Faceplate Polishing

Protect and maintain surface gloss by occasional polishing with a good plastic cleaner and polish. Apply a thin, even coat with a soft

clean cloth and polish lightly with cotton flannel. Then wipe with a damp cloth to help eliminate electrostatic charges that can attract

dust particles

Marking on the Faceplate

Use SHARPEE or equivalent marker. Clean as per instructions with an ammonia free cleaning agent.

All signal types and frame rates are automatically detected

• 525 –60i / 625 - 50i (Interlaced NTSC/PAL)

• 720 x 1280 – 23.98P, 24P, 25P, 50P, 59.94P, 60P (Progressive)

• 1035 x 1920 - 59.94i, 60i (Interlaced)

• 1080 x 1920 – 50i, 59.94i, 60i / 23.98Psf, 24Psf, 25Psf, 29.97Psf, 30Psf

Psf=Progressive or Segmented Frame formats

Digital Screen Formats and Frame Rates: