Martin Engineering M3687-12/17 1Martin®DT2S Reversing Cleaner

Introduction

General The Martin®DT2S Reversing Cleaner is used in conjunction with a head

pulley primary cleaner such as a Martin®Primary Cleaner.

The Martin®DT2S Reversing Cleaner contacts the belt as it leaves the head

pulley or another accessible position on the return belt with proper support.

The blades of the Martin®DT2S Reversing Cleaner, when tensioned, lay in

the direction of belt travel giving a negative angle and presenting no snag or

danger to the belt or splices.

The Martin®DT2S Reversing Cleaner can be supplied or retrofitted with a

variety of cleaning blades.

If the material-handling process or product could be affected by

contamination from the use of these belt cleaners, the user is responsible for

taking the necessary steps to prevent contamination. Consult Martin

Engineering or a representative for alternate belt cleaners or belt cleaner

locations to use where contamination may be an issue.

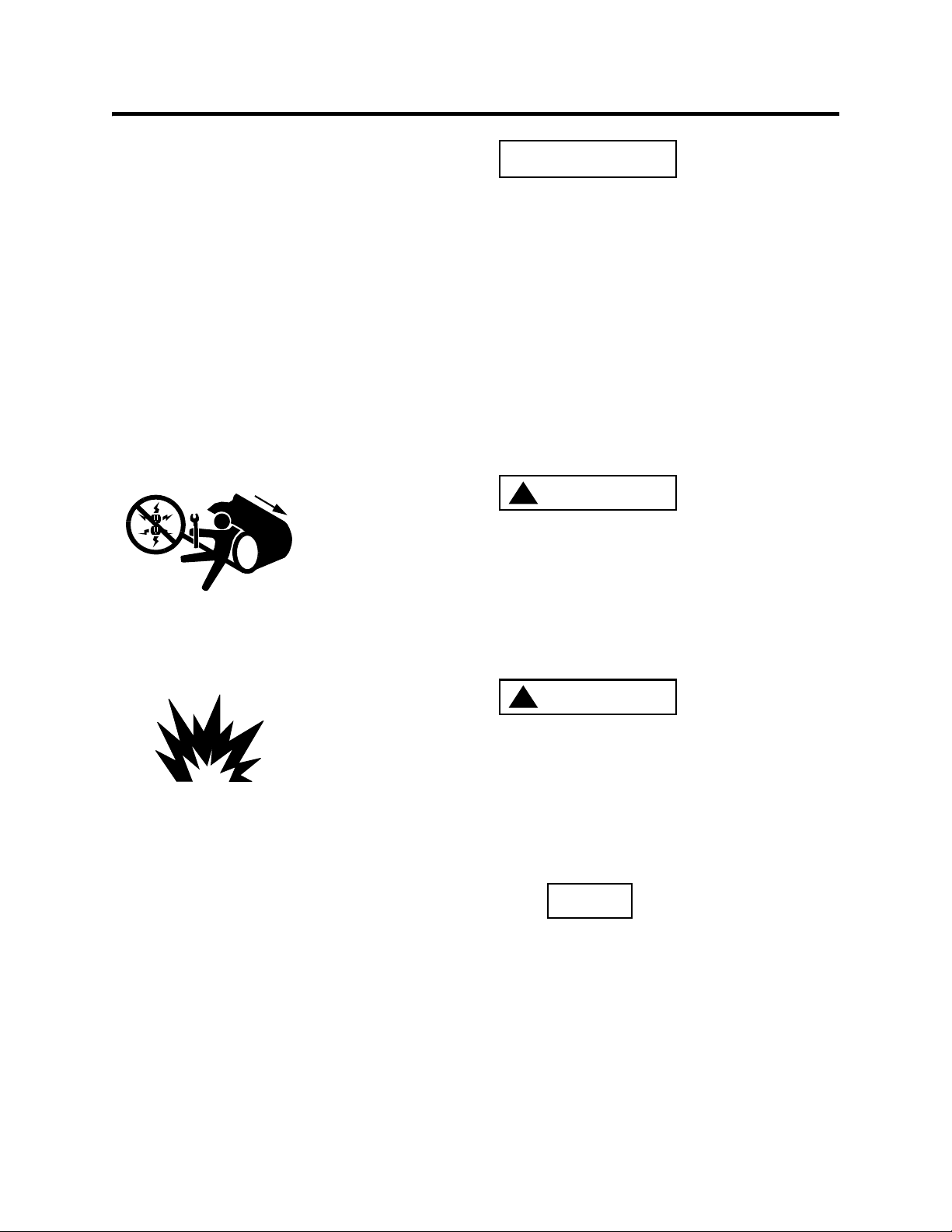

Installations

Without

Chutework

These procedures were written for equipment that is being installed on

enclosed pulley chutework. If the pulley is not enclosed, the equipment should

be installed using the best available field resources and methods to ensure that

the critical dimensions are followed for proper installation.

The Martin®Reversing Hanger Mount Weldment, P/N 33282, can be used for

installations without chutework.

Belt Cleaner

Inspection Access

If the belt cleaner is installed on enclosed pulley chutework, a Martin®

Inspection Door should be installed. Martin®Inspection Doors are available

from Martin Engineering or your representative.

References The following documents are referenced in this manual:

• American National Standards Institute (ANSI) z244.1-1982, American

National Standard for Personnel Protection - Lockout/Tagout of Energy

Sources - Minimum Safety Requirements, American National Standards

Institute, Inc., 1430 Broadway, New York, NY 10018.

• Federal Register, Volume 54, Number 169, Part IV, 29 CFR Part 1910,

Control of Hazardous Energy Source (Lockout/Tagout); Final Rule,

Department of Labor, Occupational Safety and Health Administration

(OSHA), 32nd Floor, Room 3244, 230 South Dearborn Street,

Chicago, IL 60604.

•Martin®Inspection Door Operator’s Manual, P/N M3891.

Materials

Required

Only standard hand tools are required to install and service this equipment.

Introduction