Zakład Wytwórczy Aparatów Elektrycznych Sp. z o.o.

9

mechanism, the surface of the earthing point has to be precisely cleaned. At the end of the earthing rail, a Ø13

mm hole has to be made for the fastening screw. After leveling the surface and lubricating it with the below

mentioned vaseline, the rail has to be attached to the earthing point, paying attention to precise tightening of

the screw.

3.3. Connection of control and power circuits.

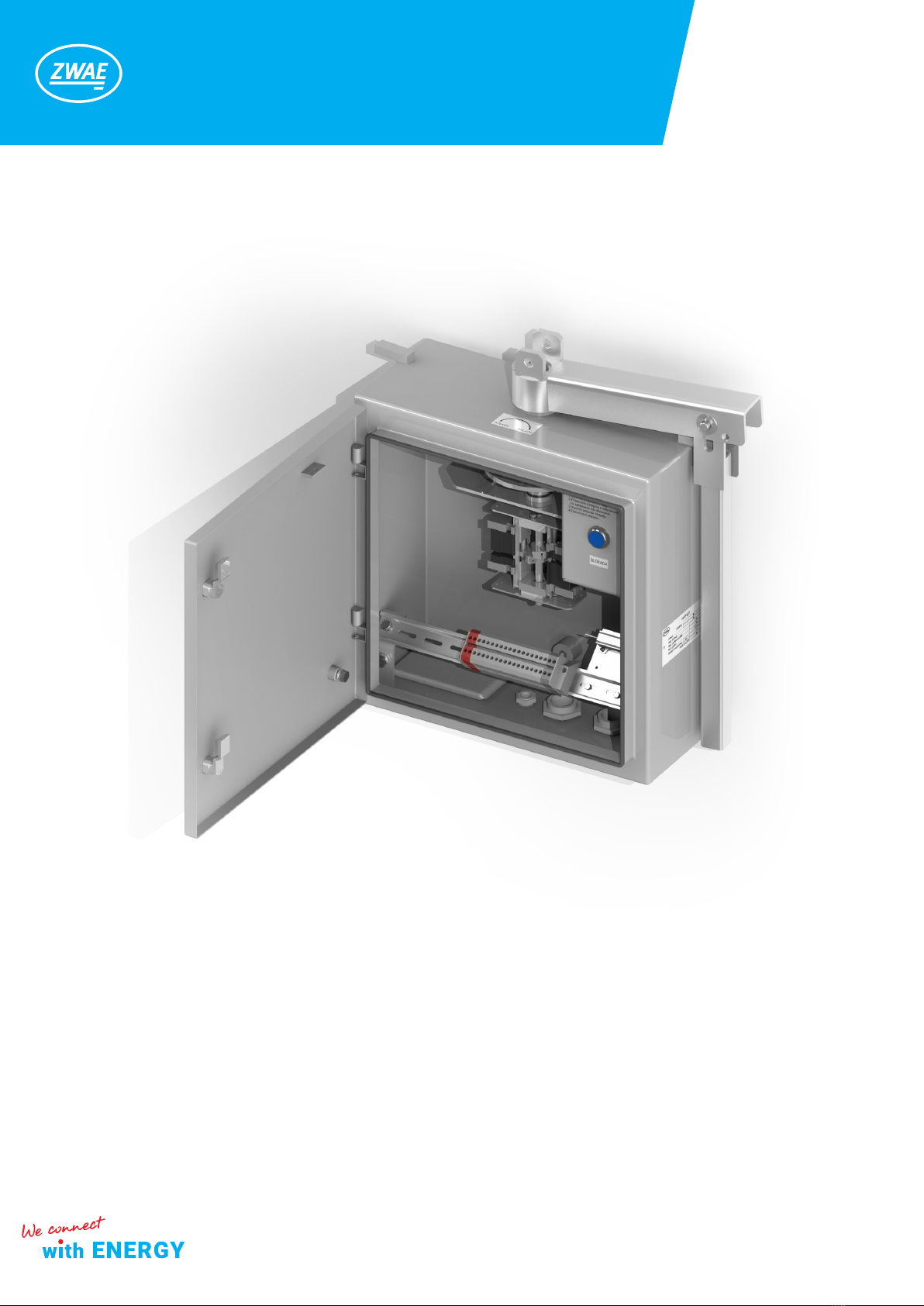

The cables should be inserted into the housing of the operating mechanism through the gland at the bottom

of operating mechanism. The connection of the control cable's wires with the terminal strip of the operating

mechanism should be made in accordance with the switchgear's proper plan. The maximum cross-section of

wires connected to the terminal strip can be 4.0 mm2.

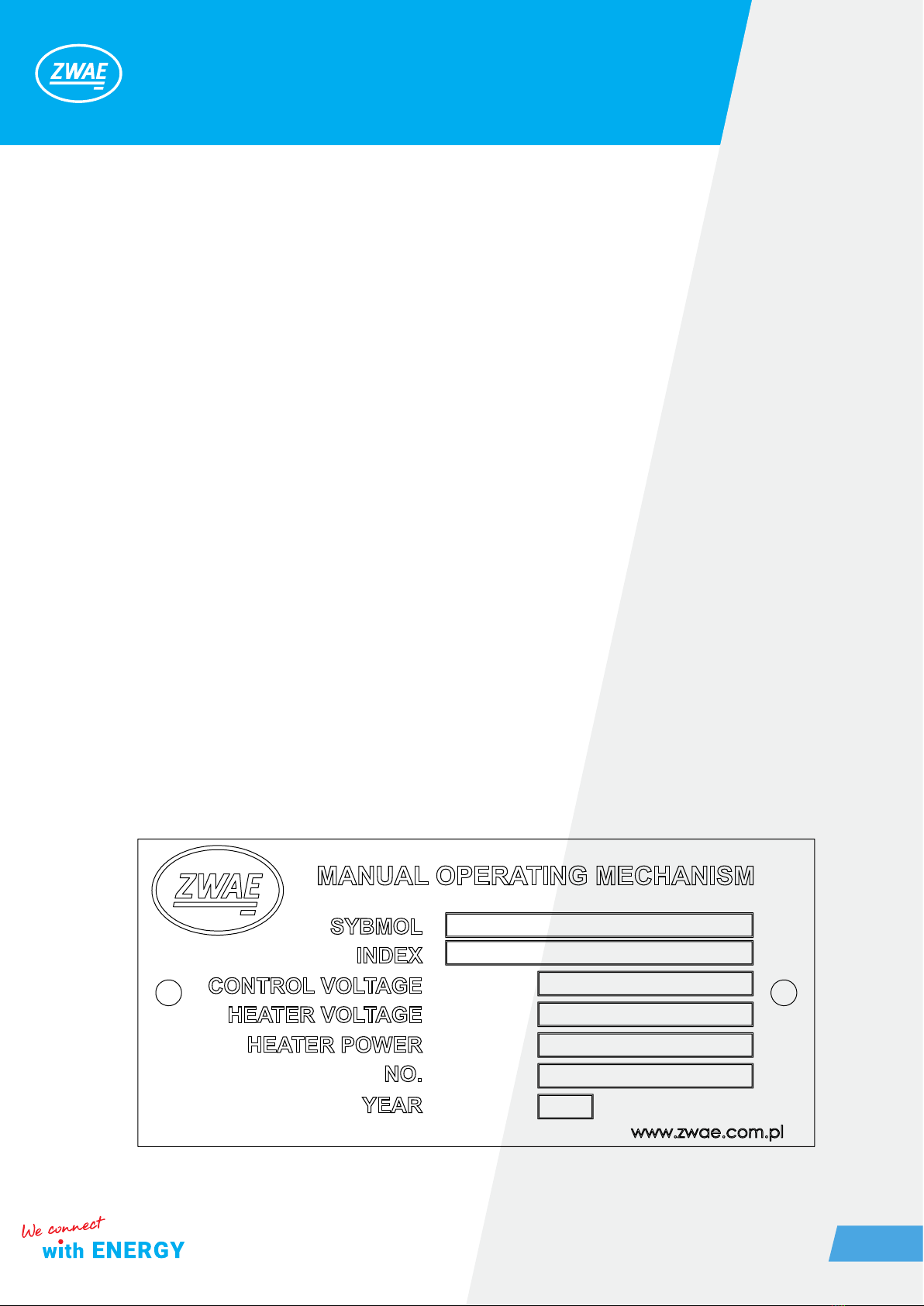

The electrical scheme is set individually, its paper version is supplied with the operating mechanism and its

number is indicated on the nameplate.

3.4. Test before rst run

Before putting the operating mechanism into service, the quality of its assembly and the correct interaction

with the apparatus must be checked. For that purpose, 5-10 shifts should be made using manual operating

lever, carefully observing the interaction of the parts. In a case of any irregularities in the operation of the oper-

ating mechanism or the apparatus cooperating with it, a re-adjustment of the respective assemblies should be

carried out and the tests should be repeated.

4. OPERATING MANUAL

4.1. Maneuvering

In order to operate the operating mechanism manually the following steps should be done:

1. Applying voltage to the coil of electromagnetic lock by holding down the button * [4] (locking the electromag-

net in a voltage free condition prevents the operating mechanism from switching).

*If there is no locking electromagnet, one should pull and turn the tie rod of electromagnetic lock[9] from the "Locked"

position to the "Unlocked" position.

2. Raise the manual operating lever to place it parallelly [1].

3. Rotate the shaft causing the apparatus to switch

5. INSPECTIONS AND MAINTENANCE

5.1. Visual inspection

It is recommended to carry out visual inspections once a year and after each failure or short circuit in the

switchgear. These should be checked in particular: