Technical Installation Specifications

The following details are specified for proper installation and for the unit to meet the advertised design pressure

(DP) rating.

SIf using less than a nominal 2″x buck in masonry

openings; the rough opening must be no more than

1/2″(13) wider and 1/4″(6) taller than the outside

measurement of the frame. Installation methods are

limited to Jamb Screw method using 3/16″concrete

screws.

SMarvin recommends the use of sloped sills on all concrete

openings (either pre−cast or poured).

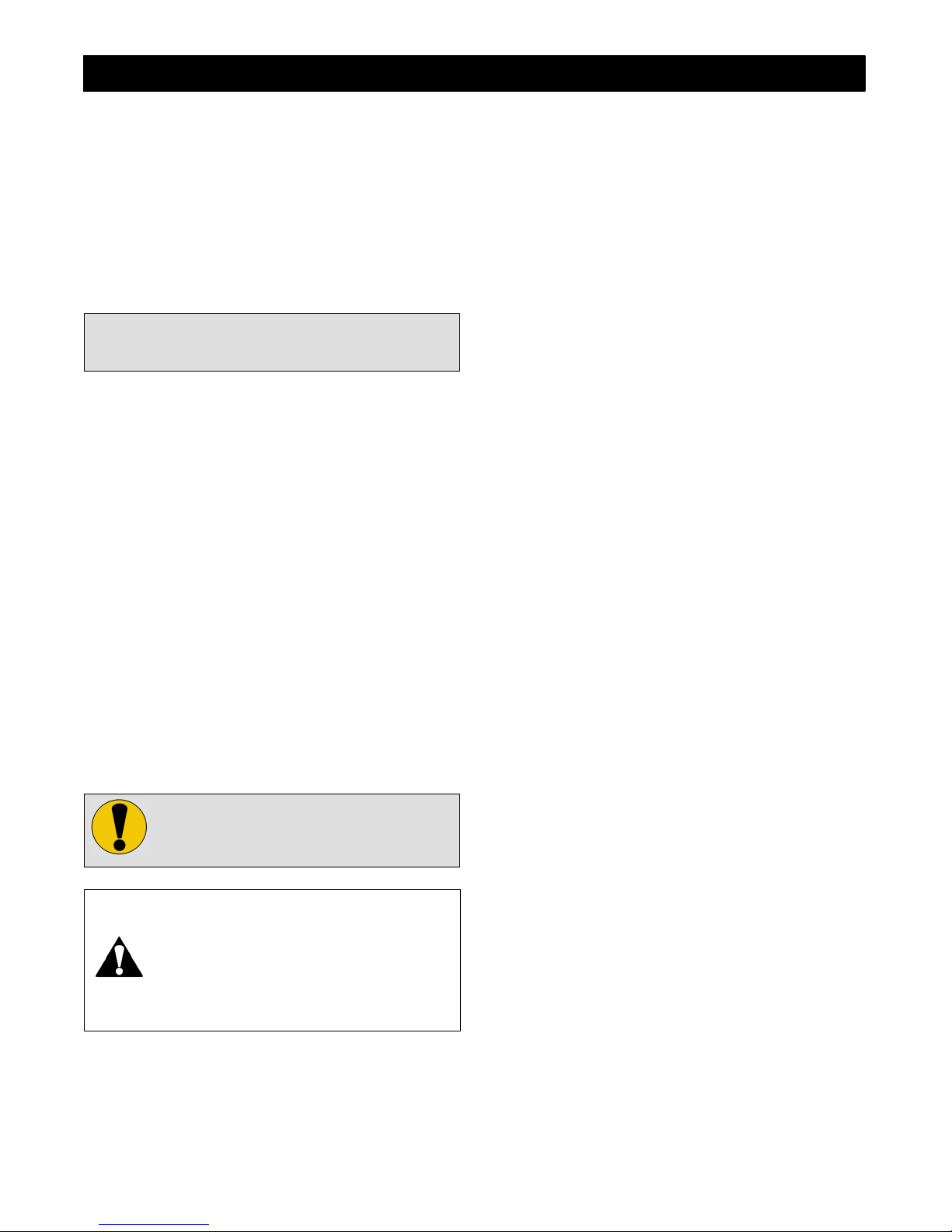

SRegarding recessed masonry openings: the window

frame must not come in direct contact with

masonry/concrete/concrete block. Construct framing

from treated lumber or plywood and fasten to the masonry

opening jambs, header, and sill. This framing must be

designed (and anchored to the opening) properly to

withstand certified and advertised DP ratings for your

particular unit.

SFor installations in typical wood frame construction (with

sheathing and building paper or air barrier material)

where a continuous air barrier system is used, refer to

ASTM E2112−01 or reference the “Continuous Air

Barrier Systems” section for details on preparing the

rough opening and sealing the installation.

SFor installations in concrete block, or masonry

construction, etc., follow local codes for sealing and water

management details.

SProperly flash and/or seal all windows at the exterior

perimeter.

SSealants used for installation must be Grade NS Class 25

per ASTM C920 and compatible with the building exterior,

window exterior surface, and flashing/water management

materials.

SFlashing materials must comply with ASTM E2112−01,

section 5.13 and be compatible with all materials used in

installation including panning systems, air barriers and

building papers, sheathing, and the window unit.

Flashing material must not contain asphalt and must

be compatible with flexible PVC (vinyl) when used in

conjunction with nailing fin.

SOptional foams used for installation must be low expansion

only. Foam and foam application must comply with ASTM

E2112−01, SEC 5.9.2.

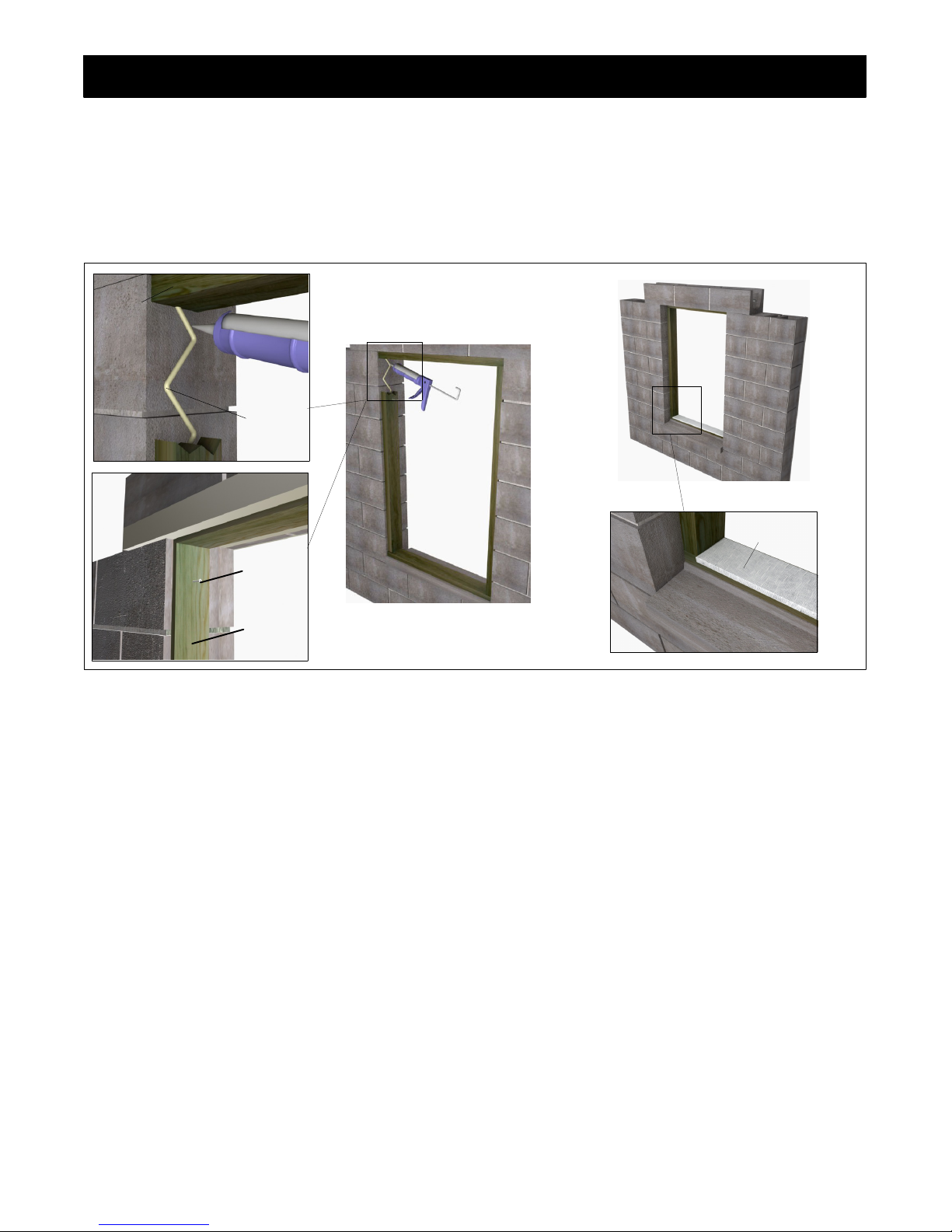

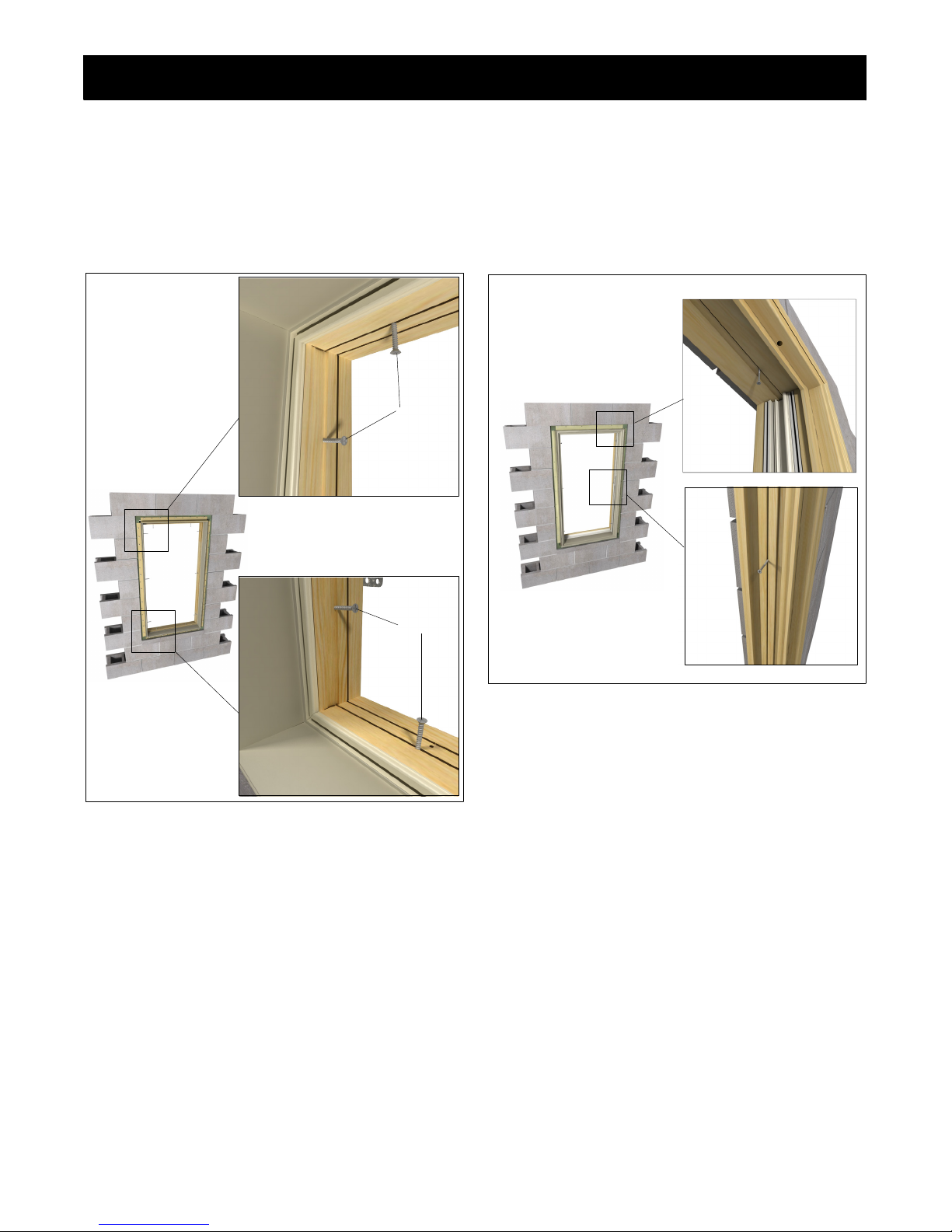

SShims are required between the window frame and framing

members at all locking points and at every point of

attachment (excluding nailing fin and brick mould casing)

as well as at all points detailed within these instructions.

SFor units with flat casing install with installation brackets,

structural masonry brackets, or jamb screws.

SDo not use chemically treated products for shim material.

SFasteners penetrating chemically treated lumber must be

a minimum of 0.90 oz/ft2zinc hot dipped galvanized or

stainless steel type 304 or 316.

SClad window frames must not come into direct contact with

chemically treated wood products.

SRough Opening Width: 1/4″−1″(6−25) wider than

window/door frame outside measurement.

SRough Opening Height: 1/4″−1/2″(6−13) higher than

window/door frame outside measurement.

SMasonry Opening Width: 1/4″−1/2″(6−13) wider than

window/door frame outside measurement.

SMasonry Opening Height: 1/8″−1/4″(3−6) higher than

window/door frame outside measurement.

Architectural Detail Manual Specifications:

SRough Opening:Width 1″(25); Height 1/2″(13).

SMasonry Opening:Width 1/2″(13); Height 1/4″(6).

Be aware that the use of rigid sill pans and

other barriers will decrease the rough

opening height clearance. Adjust opening

dimensions accordingly.

WARNING: Drilling, sawing, sanding or

machining wood products generates wood

dust, a substance known to the State of

California to cause cancer. Avoid inhaling

wood dust or use a dust mask or other

safeguards for personal protection.

California Health and Safety Code Section

25249.6.

2Window Installation

StormPlus and Structural Installations

19970019

2012−04−10