Masalta MF16 User manual

OPERATION MANUAL

CONCRETE CUTTER MF16

WARNING

!

To reduce the risk of injury, all operators and maintenance personnel must read and understand these

instructions before operating, changing accessories, or performing maintenance on Masalta power

equipment. All possible situations cannot be covered in these instructions. Care must be exercised

by everyone using, Maintaining or working near this equipment.

1

CONTENTS

ⅠRULES FOR SAFE OPERATION

General Safety …………………………………….1-2

Diamond Blade Safety ……………………….……..2

Cutter Transportation Safety ………………….……2

Emergencies …………………………………………3

Maintenance Safety …………………………………3

ⅡOPERATION

Introduction ……………………………………….….3

Determining the Right Machine ……………………3

Operating Principle ………………………………….3

Delivery Checks ……………………………………..3

Installing Blade ………………………………………4

Type of Cutting ………………………………………4

Before Starting …………………………………….…4

To Start Cutting ………………………………………4

Cutting ………………………………………………...5

Belts & Pulleys ……………………………………….5

Dry Cutting ……………………………………………5

ⅢMAINTENANCE

Troubleshooting ……………………………………6-7

ⅣLUBRICATION AND SERVICE …………….…8

ⅤSPECIFICATION ………………………………..8

ⅥWARRANTY …………………………………..8

ⅦREPLACEMENT PARTS LIST ……………9-12

ⅠRULES FOR SAFE OPERATION

WARNING:

Failure to follow instructions in this manual may lead to

serious injury or even death! This equipment is to be

operated by trained and qualified personnel only! This

equipment is for industrial use only.

The following safety guidelines should always be used

when operating the MASALTA concrete Cutters:

GENERAL SAFETY

■DO NOT operate or service this equipment before

reading the entire manual.

■This equipment should not be operated by persons

under 18 years of age.

■NEVER operate this equipment without proper

protective clothing, shatterproof glasses, steel-toed

boots and other protective devices required by the job.

■NEVER operate this equipment when not feeling well

due to fatigue, illness or taking medicine.

■NEVER operate this equipment under the

influence or drugs or alcohol.

■NEVER use accessories or attachments,

which are not recommended by MASALT

A

for this equipment. Damage to the

equipment and/or injury to user may result.

■The manufacturer does not assume

responsibility for any accident due to

equipment modifications.

■Whenever necessary, replace nameplate,

operation and safety decals when they

become difficult to read.

■ALWAYS check the machine for loosened

threads or bolts before starting.

■NEVER touch the hot exhaust manifold,

muffler or cylinder. Allow these parts to cool

before servicing engine or saw.

■High Temperatures – Allow the engine to

cool before adding fuel or performing

service and maintenance functions.

Contact with hot components can cause

serous bums.

■The engine section of this cutter requires

an adequate free flow of cooling air.

NEVER operate the cutter in any enclosed

or narrow area where free flow of the air is

restricted. If the air flow is restricted it will

cause serious damage to the saw or engine

and may cause injury to people. Remembe

r

the cutter’s engine gives off DEADL

Y

carbon monoxide gas.

■ALWAYS refuel in a well-ventilated area,

away from sparks and open flames.

■ALWAYS use extreme caution when

working with flammable liquids. When

refueling, stop the engine and allow it to

cool. DO NOT smoke around or near the

machine. Fire or explosion could result

from fuel vapors, or if fuel is spilled on a hot

engine.

■NEVER operate the cutter in an explosive

atmosphere or near combustible materials.

An explosion or fire could result causing

severe bodily harm or even death.

■Topping-off to the fuel filler port is

dangerous, as it tends to spill fuel.

2

■NEVER use fuel as a cleaning agent.

■ALWAYS read, understand, and follow procedures in

operator’s Manual before attempting to operate

equipment.

■ALWAYS be sure to operator is familiar with proper

safety precautions and operating techniques before

using the cutter.

■Stop the engine when leaving the cutter unattended.

■Block the unit when leaving or when using on a slope.

■Maintain this equipment in a safe operating condition

at all times.

■ALWAYS stop the engine before serving, adding fuel

and oil.

■NEVER Run engine without air filter. Severe engine

damage may occur.

■NEVER Run engine without air filter. Severe engine

damage may occur.

■ALWAYS service air cleaner frequently to prevent

carburetor malfunction.

■ALWAYS store equipment properly when it is not

being used. Equipment should be stored in a clean,

dry location out of the reach of children.

■NEVER operate this cutter in areas that contain

combustible material or fumes. Fire and/or explosions

may result from errant sparks from the equipment.

WARNING:

■DO NOT operate this equipment unless all guards and

safety devices are attached and in place.

■Caution must be exercised while servicing this

equipment. Rotating and moving parts can cause

injury if contacted.

■Keep all inexperienced and unauthorized people away

from the equipment at all times.

■Unauthorized equipment modifications will void all

warranties.

DIAMOND BLADE SAFETY

■Use appropriate steel centered diamond blades

manufactured for use on concrete cutters.

■ALWAYS inspect diamond blades before each use.

The blade should exhibit no cracks, dings, or flaws in

the steel centered core and/or rim. Center (arbor) hole

must be undamaged and true.

■Examine blade flanges for damage, excessive wear

and cleanliness before mounting blade.

Blade should fit snugly on the shaft and

against the inside/outside blade flanges.

■Ensure that the blade is marked with an

operating speed greater than the blade

shaft speed of the cutter.

■Only cut the material that is specified by

the diamond blade. Read the

specifications of the diamond blade to

ensure the proper tool has been matched

to the material being cut.

■ALWAYS keep blade guards in place.

Exposure of the diamond blade must not

exceed 180 degrees.

■Ensure that the diamond blade does not

come into contact with ground or surface

during transportation. DO NOT drop the

diamond blade on ground or surface.

■The engine governor is designed to

permit maximum engine speed in a

no-load condition. Speeds that exceed

this limit may cause the diamond blade to

exceed the maximum safe allowable

speed.

■Ensure that the blade is mounted fo

r

proper operating direction.

CUTTER TRANSPORTATION SAFETY

■Use the lifting bail and appropriate lifting

equipment to ensure the safe movement

of the cutter.

■DO NOT use the handle bars and/or front

pointer as lifting points.

■NEVER tow the saw behind a vehicle.

■Ensure that both pointer bars are

positioned appropriately to minimize thei

r

exposure during transportation.

■Safeguard against extreme cutte

r

attitudes relative to level. Engines tipped

to extreme angles may cause oil to

gravitate into the cylinder head making

the engine difficult to start.

■NEVER transport the cutter with the

blade mounted.

3

EMERGENCIES

■ALWAYS know the location of the nearest fire

extinguisher and first aid kit. Know the location of the

nearest telephone. Also know the phone numbers of

the nearest ambulance, doctor and fire department.

This information will be invaluable in the case of an

emergency.

MAINTENANCE SAFETY

■NEVER lubricate components or attempt service on a

running machine.

■ALWAYS allow the machine a proper amount of time

to cool before servicing.

■Keep the machinery in running condition.

■Fix damage to the machine immediately and always

replace broken parts.

■Dispose of hazardous waste properly. Examples of

potentially hazardous waste are used motor oil, fuel

and fuel filters.

■DO NOT use food or plastic containers to dispose of

hazardous waste.

ⅡOPERATION

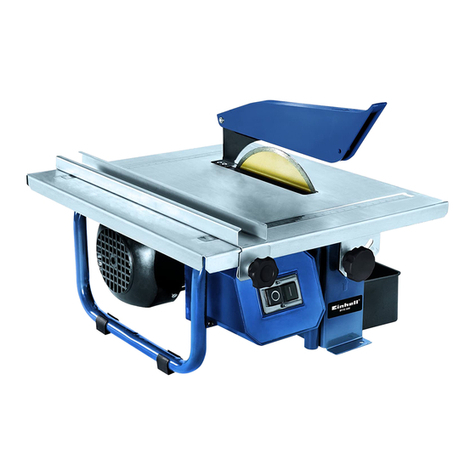

Introduction/Determining the Right Machine

Congratulations on your purchase of our Cutter! You’ve

made an excellent choice! Our floor cutter has been

specifically designed as the ideal machine for the

professional contractor who is engaged in concrete and

asphalt flat sawing.

The machines used for the primary purpose of “flat”

sawing. This type of sawing is described as “flat” because

the pavement is cut somewhere close to a horizontal

plane. It is the most common type of diamond blade

cutting.

Concrete cutters in the industry are available in a variety

of types, sizes and styles, they range from manual or self

propelled in horsepower from 7-72hp. It is possible to cut

both concrete (green or cured, with or without rebar) or

asphalt with a concrete cutter. Our MF16

utilized for jobs requiring precision cutting

including floors, pavements, walkways, ramps

and other flat sawing applications.

You will find a cutter to fit a wide variety of job

applications.

Upon receipt of your machine, CAREFULL

Y

CHECK FOR ANY FREIGHT DAMAGE. Any

damage should be immediately reported to the

carrier and a claim registered.

Operating Principle/Delivery Checks/

Installing Blade/Types of Cutting

OPERATING PRINCIPLE

The following instructions were compiled to

provide you information on how to obtain long

and trouble free use of the unit. Periodic

maintenance of this unit is essential. Read the

manual in its entirety and follow the instructions

carefully. Failure to do so may injure yourself o

r

a bystander.

DELIVERY CHECKS

Immediately upon taking delivery of your new

equipment and before putting it into service:

■Read the handbook completely—it could

save a great deal of unnecessary expense.

■Read the engine manual supplied.

■Check the general condition of the

equipment—has it been damaged during

delivery?

■Check engine oil level.

■Check fuel levels.

Recommend lubricants are detailed in the

CARE AND MAINTENANCE section.

4

INSTALLING BLADE

1. Be certain that the spark plug is disconnected or saw

is unplugged.

2. Remove the blade shaft nut, and take off outside blade

shaft flange.

3. Clean off any foreign particles on the clamping

surfaces of flanges and on the mounting surface of the

blade.

4. Place the blade on the blade shaft, lining up the offset

drive pin in the blade with the drive pin in the mounting

collar (if the pin system is available on the machine). If

your blade has a directional rotational arrow, position

arrow for down cut (diamond tail trailing for down cut).

5. Replace the outside blade shaft flange on the blade

shaft. Drive pin on the inside collar must project

through the drive hole in the blade and into the outside

collar (if the pin system is available on the machine).

6. Tighten the blade shaft nut securely against star

washer and outside flange, using wrench supplied.

7. Reconnect the spark plug or (with switch “off”) plug in

the electric supply cord.

TYPES OF CUTTING

Cut speed depends entirely on using the correct blade for

the material to be cut. Wet or dry, diamond blades of

various specifications are available for cutting concrete or

asphalt.

Before Starting/Cold Start/Hot Start/

To Start Cutting

BEFORE STARTING

1. Use correct blade for cutting conditions.

2. Ensure arbors and flanges are clean and undamaged.

3. Mount blade and tighten securely using wrench.

4. When wet cutting, check water jets for adequate flow.

5. Align pointer with cutter blade.

Caution – Set unit up in an open area. Avoid close

proximity to structures or other equipment. Failure to

do so may cause inadvertent injury to operator or

other persons in the area.

Cold start – Open the fuel valve under the gas tank all the

way. Position the engine stop switch, located on the

engine, to run. Open the throttle approximately

half way and apply the choke. Pull the starte

r

rope sharply. When the engine starts, open the

choke and adjust the throttle as necessary to

keep it running. Allow the engine to warm up fo

r

a few minutes before placing it under the load.

If the engine doesn’t start after (3) pulls, open

choke slightly to prevent flooding. Always

operate the engine at full throttle when unde

r

load.

Hot Start – Open the valve under the gas tank

all the way if it has been shut off. Open the

throttle approximately half way. Do not apply

the choke. Pull the starter rope sharply until the

engine starts. When the engine starts, adjust

the throttle. Always operate the engine at full

throttle when under load.

NOTE: These starting instructions are general

guidelines only. Since many engine options are

available, consult the Engine Manual included

with this unit for specific instructions.

Caution – Gasoline Engines – To improve

the engine service life, allow the engine to

idle without load for (2) to (5) minutes

before shutting it down. When the idling

period is up, use the stop switch located on

the engine and turn it to stop. Close the fuel

valve under the gas tank. Engine flooding

can occur if the valve is left open during

transport.

TO START CUTTING

1. Start engine and let engine warm up. All

cutting is done at full throttle.

2. Align blade and cutter with cut. If we

t

cutting, open water valve and turn wate

r

safety switch on.

3. Lower blade into cut slowly.

4. Cut as fast as blade will allow. If blade

climbs out of cut, reduce forward speed o

r

depth of cut.

5. Use only enough side pressure on cutte

r

handles to follow cutting line.

5

Cutting/Belts & Pulleys

CUTTING

Lower the blade into concrete to required depth by turning

the tilt crank counterclockwise. Ease the saw slowly

forward. Slow forward pressure if the saw begins to stall.

Note: For deeper cuts (4 inches/102mm or more), several

cuts should be made in incremental steps of 1-1/2 inch

(38mm) to 2 inches (51mm) until the desired depth is

reached.

Push the saw steadily forward using the front pointer as a

guide. Exert enough forward pressure so that the

engine/motor begins to labor, but does not slow down. If

the saw begins to stall, retard forward movement until full

RPM is restored to the blade. If saw stalls, raise the blade

out of the cut before restarting. Avoid excessive side

pressure or twisting of the blade in the cut.

BELTS & PULLEYS

NEVER MAKE ADJUSTMENTS TO V-BELTS AND

PULLEYS WHILE ENGINE IS RUNNING.

1. The best tension for a v-belt drive is the lowest tension

at which the belts will not slip under full load.

2. Take up tension until the belts are snug in the grooves.

Run the drive for about five (5) minutes to “seat” the

belts. The impose the peak load. If the belts slip,

tighten them until they no longer slip at peak load.

Most new belts will need additional tensioning after

seating.

3. Remember, too much tension shortens belt and

bearing life.

4. Check the belt tension frequently during the first day of

operation. Check the belt tension periodically

thereafter and make any necessary adjustments.

5. The two most common causes of sheave

misalignment are:

a) The engine drive shaft and the blade shaft are not

parallel.

b) The pulleys are not located properly on the shafts.

6. To check alignment, use a steel straight edge. See

Figure 1.

7. Line up the straight edge along the outside

face of both pulleys shown in the drawing.

All pulleys have (2) set screws in the

bottom of their grooves. Set screws require

thread locking lock title.

8. Misalignment will show up as a gap

between the pulley face and straight edge.

Make sure there is clearance between

arbor pulley and saw base on both sides.

DRY CUTTING

●Never operate any saw without safet

y

guards in place.

●Do not exceed maximum operating

speed established for blade diameter.

●Do not force blade into material: allow

blade to cut at its own speed.

●Do not make long continuous cuts.

Never dry cut for more than 30 seconds

at a time. Allow blade to cool.

●Do not cut or grind with side of blade o

r

cut a curve or radius. Do not cut dr

y

with blades recommended for we

t

cutting.

●Do not operate saw with blade diamete

r

larger than machine’s capacity.

ⅢMAINTAINENACE - TROUBLESHOOTIN

G

PROBLEM CAUSE REMEDY

UNEVEN SEGMENT WEAR ●(In wet cutting) Insufficient water ●Flush water system.

(usually on one side of blade). ●Check flow to both sides of blade.

●Equipment defects also can cause ●Replace bad bearings, worn arbor

the segments to wear unevenly. shaft or misalignment to spindle.

●Saw head is misaligned. ●Check alignment for squareness,

both vertically and horizontally, of

the saw blade.

SEGMENT CRACKS ●Blade is too hard for material ●Use a blade with a softer

being cut. bond/matrix.

SEGMENT LOSS ●Blade overheats because of lack of ●(Wet Cutting) Check water lines.

coolant (water or air). ●Make sure flow is adequate on

●Core is worn from undercutting. both sides of blade and there are

●Defective collars/flanges set blade no blockages

out of alignment. ●Use sufficient water to flush

●Blade is too hard for material out the cut.

being cut. ●(Dry Cutting) Run blade free of

●Blade is cutting out of round, cut periodically to air cool.

causing a pounding motion. ●Clean collars/flanges or replace

●Improper blade tension. if they are under recommended

diameter.

●Use proper blade specification

for material being cut.

●Replace worn bearings; realign

blade shaft or replace worn blade

mounting arbor.

●When ordering blades match

shaft speed of saw.

●Check spindle speed to ensure

blade is running at correct RPM.

●Avoid twisting or turning blade

in the cut.

CRACKS IN CORE ●Blade flutters in cut as a result of ●Tighten the blade shaft nut.

losing blade tension. ●Make sure blade is running at

●Blade specification is too hard for proper speed and that drive pin

the material being cut. is functioning properly.

●Use a softer bond/matrix to

eliminate stress.

LOSS OF TENSION ●Core overheating. ●Make certain blade RPM

●Core overheating as a result of is correct.

blade spinning on arbor. ●Check water flow, distribution

●Core overheating from rubbing the and lines.

material being cut. ●Tighten the blade shaft nut.

●Unequal pressure at blade clamping Make certain the drive pin

collars/flanges. is functioning.

●Blade is too hard for the material ●Properly align the saw to

being cut. square cut.

●Collars/flanges must be

identical in diameter and

the recommended size.

●Use a softer bond/matrix to

reduce stress.

6

ⅢMAINTAINENACE - TROUBLESHOOTING

PROBLEM CAUSE REMEDY

BLADE WOBBLES ●Blade is on a damaged or ●Check for bad bearings, bent shaft,

worn saw. or worn mounting arbor.

●Worn collar. ●Check collars/flanges to make sure

●Blade runs at an incorrect speed. they are clean , flat and of correct

●Collar/flange diameters are not diameter.

identical. ●Set engine at proper RPM.

●Blade is bent as a result of ●Use proper size blade

dropping or twisting. collars/flanges.

●DO NOT use bent blade.

Contact blade manufacturer.

BLADE WILL NOT CUT ●Blade is too hard for material ●Select proper blade for material

being cut. being cut.

●Blade has become dull. ●Sharpen by cutting on softer

●Blade does not cut material abrasive material to expose

it was specified for. diamonds. If continually

sharpening, the blade is too hard

for the material being cut.

●Break-in on the material to be cut.

If it does not dress itself, sharpen

as you would a dull blade.

UNDERCUTTING THE CORE ●Abrasive wearing of the core ●Use water to flush out fines

faster than the segments. generated during cutting

●Use wear-restardant cores.

ARBOR HOLE OUT-OF- ●Collars/flanges are not properly ●Make certain the blade is mounted

ROUND tightened, permitting blade to on the proper shaft diameter. Tighten

rotate or vibrate on the shaft. the shaft nut with a wrench to make

●Collars/flanges are worn or dirty. certain that the blade is secure.

Blade is not properly mounted. ●Clean collars/flanges, make sure

they are not worn.

Tighten arbor nut.

●Make sure the pin hole slides over

drive pin.

BLADE WORN OUT OF ●Shaft bearings are worn. ●Install new blade shaft bearings or

ROUND ●Surges occur because engine blade shaft, as required.

is not properly tuned. ●Tune engine according to

●Blade arbor hole is damaged manufacturer's manual.

from incorrectly mounting ●If core is worn or arbor hole damaged,

the blade. DO NOT USE. Contact blade

●Bond/matrix is too hard for manufacturer.

●material. ●Replace worn shaft or mounting

Blade si slipping, wearing one arbor bushing.

half of blade more than other. ●Make certain that drive pin is

functioning.

●Tighten spindle nut.

7

8

ⅣLUBRICATION AND SERVICE

●Check oil levels, wiring, hoses (air, fuel, water) and

lubricate machine daily.

●Repair or replace all worn or damaged

components immediately.

●Check drive belt tension, do not over-tension.

●Make sure machine has full set of matched belts.

●Check bladeshaft, make sure arbor and threads

are not worn, damaged, or bent.

●Bladeshaft bearings should be tight, no free play

side-to-side or up and down.

●Grease blade shaft bearings daily.

●Blade collars should be clean, free of nicks and

burrs. No diameter wear and not out of round.

●Drive pin not excessively worn or bent and free of

gouges.

●All guards in place and secure.

●All fasteners tight and secure.

●Air filter/oil filter (hydraulic or engine) clean.

●Flush clean water through the pump and spray the

assembly every night. This prolongs the pump and

blade life.

Lubricants:

Engine Oil SAE 10W/30

General Grease #1 Lithium

●Clean machine before starting lubrication

maintenance.

●Insure machine is on solid, level ground before

starting maintenance.

●During lubrication maintenance insure strict

cleanliness is observed at all times.

●To avoid the risk of accidents, use the correct tool

for the job and keep tools clean.

●The draining of engine oil is best carried out when

the oil is warm NOT hot.

●Any spilled oil must be cleaned up immediately.

●Use only clean containers for oil and only CLEAN,

FRESH oils and grease of correct grade.

●Contaminated Water/Fluids/Oils/Filters Must Be

Disposed of Safely.

ⅤSEPECIFICATION

Motor

MF16-1 Diesel, 186 7.5kw output

MF16-2 Petrol, 188F 9.8kw output

MF16-3 Petrol, Robin EH36D 8.6kw output

MF16-4 Petrol, Honda GX390K1 9.8kw output

Weight

MF16-1 149kgs

MF16-2 126kgs

MF16-3 124kgs

MF16-4 126kgs

Max. Cutting Depth - - - - - - - - 140mm (5.5 in)

Blade size - - - - - - - - - - - - - 300-400mm (12-16in)

Depth Adjustment Mechanism–Handle Rotation

Driving Mechanism - - - - - - - - - - Manual Push

Water Tank Capacity – - - - - - - - - - - - - - 37L

ⅥWARRANTY

MASLATA products are covered by warranty for a

period of six (6) months from the date of purchase

against defects in material or workmanship

provided that:

·The product concerned has been operated and

maintained in accordance with the operating

instructions.

·Has not been damaged by accident, misuse o

r

abuse

·Has not been tampered with or repaired by any

unauthorized person.

The owner is responsible for the cost o

f

transportation to and from the authorized repaire

r

and the unit is at the owners risk while in transit to

and from the repairer.

ITEM

NO. PART NO. DESCRIPTION QTY ITEM

NO. PART NO. DESCRIPTION QTY

1 05780012 BOLT M12X20-GB5780 2 33 00180902 BEARING & BRACKET 2

2 09300012 SPRING WASHER 12-GB93 2 34 01096008 KEY C8 X 38 - GB1096 1

3 18030104 DEEP WASHER 2 35 18090002 PRINCIPAL AXIS 1

4 00180303 RUBBER WHEEL ( REAR) 2 36 01190006 PIN C6 - GB119 1

5 18030103 INDICATOR 1 37 06170008 NUT M8 - GB6170 1

6 00180302 BEARING & BRACKET 2 38 18090301 BLADE FLANG (INNER) 1

7 09300012 SPRING WASHER 12-GB93 8 39 07300008 PIN 1

8 05780012 BOLT M12-GB5780 8 40 00180007 BLADE 1

9 18030101 WHEEL RACK MODULE 1 41 18090302 BLADE FLANG (OUT) 1

10 06187012 NUT 12-GB848 1 42 18090004 NUT 1

11 09300012 SPRING WASHER 12-GB93 1 43 01096000 KEY - GB1096 1

12 08480012 WASHER 12-GB93 1 44 18110001-1 EINGINE PULLEY FOR DIESEL 1

13 05784012 BOLT M12 X 120 - GB5784 1 18110001-2 ENGINE PULLEY FOR HONDA 1

14 18100000 BASE ASSY 1 18110001-3 ENGINE PULLEY FOR ROBIN 1

15 06170012 NUT M12 - GB6170 4 45 01154400-1 V-BELT SPA-GB11544 FOR DIESEL 1

16 09300012 SPRING WASHER 12-GB93 4 01154400-2 V-BELT SPA-GB11544 FOR PETROL 1

17 09700012 WASHER 12-GB97 4 46 00181100-1 DIESEL ENGINE 1

18 05783012 BOLT M12 - GB5783 4 00181100-2 HONDA ENGINE 1

19 00180301 RUBBER WHEEL ( FRONT) 2 00181100-3 ROBIN ENGINE 1

20 18030102 DEEP WASHER 2 47 18070000 BASE ASSY. OF ENGINE 1

21 09300008 SPRING WASHER 8 - GB93 2 48 05784010 BOLT M10 X 30 - GB5784 8

22 05780008 BOLT M8 X 20 - GB5780 2 49 09300010 SPRING WASHER 10 - GB93 8

23 18080000 BLADE GUARD 1 50 09700010 WASHER 10 - GB97 8

24 09600010 WASHER 10 - GB96 1 51 06178012 NUT M12 - GB6178 3

25 05781010 BOLT M10 - GB5781 1 52 08480012 WASHER 12 - GB848 1

26 06200010 NUT M10 - GB62 1 53 05780012 BOLT M12 X 45 - GB5780 1

27 09600010 WASHER 10 - GB96 1 54 18010001 POINTER 1

28 00180008 SCREW 1 55 05780012 BOLT M12 X 110 - GB5780 1

29 05780010 BOLT M10 X 25 - GB5780 1 56 18010002 NUT 1

30 18090001 WASHER 1 57 08480012 WASHER 12 - GB848 1

31 09300010 SPRING WASHER 10 - GB93 1 58 18010003 POINTER WHEEL 1

32 18090005 PULLEY 1 –– –––– –––––––––––– ––

MF16 PARTS LIST 1

10

ITEM NO. PART NO. DESCRIPTION QTY

59 00180006 PLASTIC PIPE 3

60 00180005 TEE PIPE 1

61 00180002 COCK 2

62 18050006 ELBOW BEND 1

63 00180501 NUT 1

64 00180502 NUT 1

65 18050011 ELBOW 1

66 18050000 WATER TANK 1

67 00180009 THROTTLE CABLE 1

68 00180010 THROTTLE CONTROL 1

69 00180011 HANDLE BAR GRIP 2

70 18060000 HANDLE LEVER 2

71 18040000 TANK COVER 1

72 00180003 INJECTION MOUTH 1

73 05781010 BOLT M10 - GB5781 4

74 09700010 BOLT M10 -GB97 4

75 00180004 KNOB 3

76 00180001 WRENCH 1

77 05781008 BOLT M8 X 30 - GB5781 1

78 09300008 SPRING WASHER 8 - GB93 1

79 09700008 WASHER 8 - GB97 1

80 18030006 BOARD PLUG 1

81 18030007 ORIENTATION BOARD 1

82 09700010 WASHER 10 - GB97 2

83 09300010 SPRING WASHER 8 - GB93 2

84 05781010 BOLT M10 - GB5781 2

85 08480008 WASHER 8 - GB848 1

86 09300008 SPRING WASHER 8 - GB93 1

87 05784008 BOLT M8 X 20 - GB5784 1

88 18030200 NANUAL RAISE/LOWER ASSY. 1

89 18030003 NUT 1

90 05784006 BOLT M6 X 10 - GB5784 1

91 18030005 SCREW 1

92 00180301 BEARING & BRACKET 1

93 06187010 NUT M10 - GB6787 1

94 18030400 BRACKET 1

95 18030405 HANDL LEVER 1

96 18030404 HANDLE GRIP 1

97 07300006 BOLT M6 - GB73 1

MF16 PARTS LIST 2

12

Add:RM 501, Fortune Plaza, No.278 of Suixi Rd., Hefei 230041,China

Tel: 86-551-5609770, 5609780 Fax: 86-551-5609010, 5621707

Http://www.masalta.com.cn

Version:01/05

Table of contents

Popular Cutter manuals by other brands

SIRI

SIRI SIRIPRO 57 Operating and maintenance manual

EINHELL

EINHELL BT-TC 600 operating instructions

KNOVA

KNOVA KN AP-130A instruction manual

CUES

CUES CURRAHEE Operation & maintenance manual

Huskie Tools

Huskie Tools REC-S624H Operation manual

JB GURY

JB GURY UNIVERSAL Comet CENTURY Parts and service manual

IDEAL

IDEAL 4205 operating instructions

EFA

EFA Z100 Operating Instructions, Maintenance instructions, Spare Part List

Cedima

Cedima CF-1020 B Translation of the original operating manual

Parkside

Parkside PSFS 250 A1 Operation and safety notes

LVD

LVD Orion 3015 Plus Series user manual

Big Daishowa

Big Daishowa C0525C Operation manual