Owner/Operator

Manual

OwnerlOperator

Manual

Safety

Warnings

a

Thismachine is designed

to

produce

very

high

pressure atthe outlet

nozzle.Highpressure

from

spray

or

leaks

canpenetrate

skin

and

cause serious injury or

death.

Never

direct

the

spray

towards

any

part

of

the

body.

Never

try to stop

or

deflect leaks with your hand

Avoid contact with engine muffler.

Never

operate machine while under

the

influence

of

alcohol.

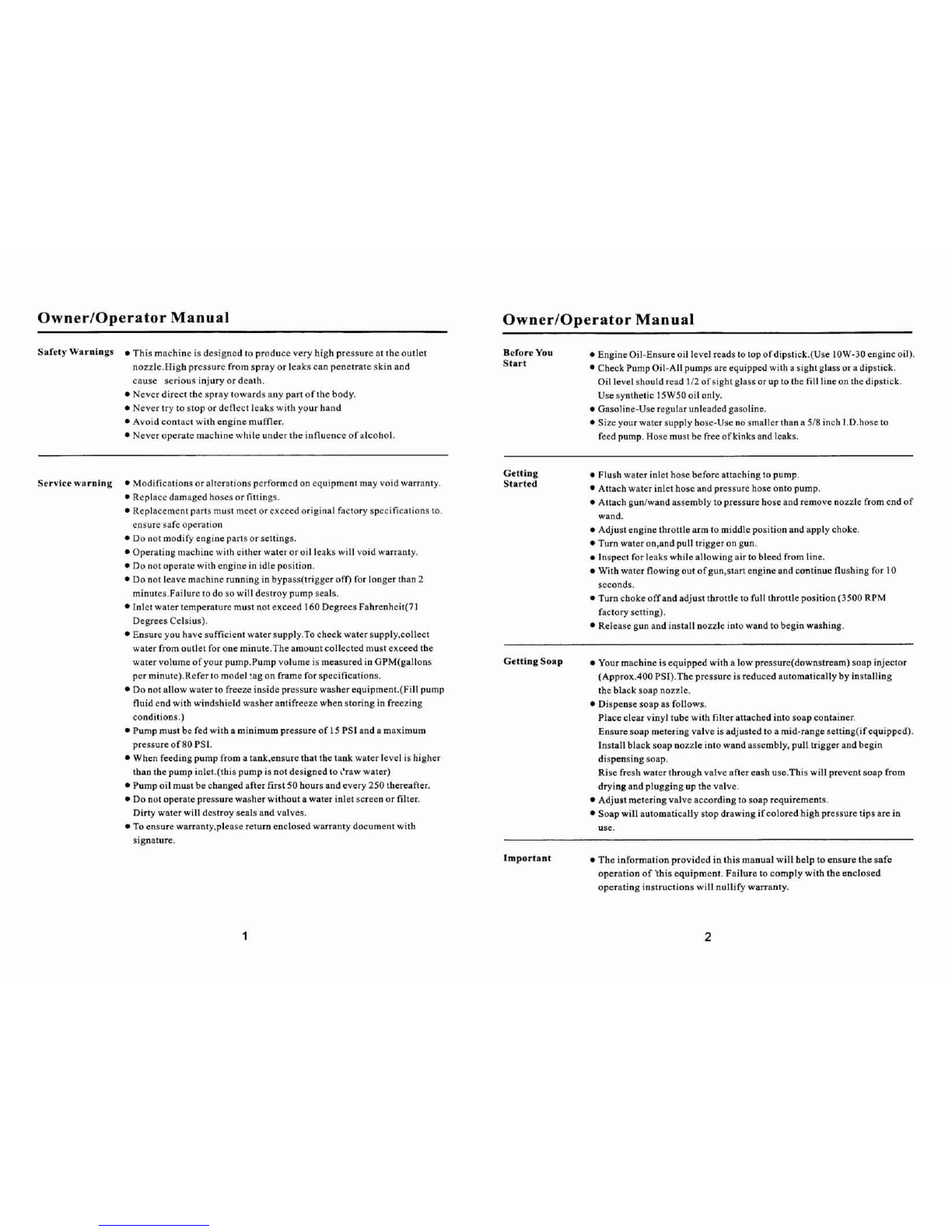

Service

warning

Modifications oralterations performed

on

equipment

may

void warranty.

Replace damaged hoses

or

fittings.

Replacement

parts

must

meet

or

exceed

original

factory specificationsto.

ensure

safe

operation

*

Do not modify engineparts orsettings.

Operating machine

with

either

water

oroil leqks will void warranty.

Do

not

operate

with

engine

in

idleposition.

Do

not

leavemachine running in bypassttrigger off) for longer than

2

minutes.Failure to

do

so

will destroy

pump

seals.

Inlet watertemperature must not exceed

160

Degrees Fahrenheit(71

Degrees Celsius).

Ensure

you

have sufficientwater supply.To

check

water suppIy,collect

water

from

outletfor oneminute.The amountcollected must

exceed

the

water volumeof

your

pump.Pump

volume

is

measured in GPM(ga1lons

per

minute).Refer

to

model fag

on

frame

forspecifications.

Do

not

allow

water to freezeinside pressure washer equipment.(Fill pump

fluid

end

with

windshield

washer

antifreezewhen storing in freezing

conditions.)

Pump must

be

fed

with

a

minimum pressure

of

15

PSI

and

a

maximum

pressure of

80

PSI.

When feeding

pump

from

a

tank,ensure

that

the

tank water level ishigher

than the

pump

inlet.(this pump isnot designedto

?raw

water)

Pump

oilmustbe changed after

first

50

hours

and

wery

250

thereafter.

Do

not

operatepressure washerwithout

a

water

inlet

screen orfilter.

Dirty

water will destroy

seals

and valves.

To

ensure

warranty,please

return

enclosedwarranty document

with

signature.

Before

You

e

Engine Oil-Ensure oil level

reads

to topofdipstick.(Use IOW-30 engineoil).

Start

Check Pump Oil-All pumps are equipped

with

a

sightglass or a dipstick.

Oil levelshould

read

112

of

sight

glass

orupto the

fill

line

on

the

dipstick.

Use

synthetic

15W50

oil only.

m

Gasoline-Use regular unleaded gasoline.

Sizeyour

water

supply

hose-Use

no smaller

than

a

518

inch

1.D.hose

to

feedpump. Hose mustbe free

of

kinks

andleaks.

Gettlng

*

Flush water inlet hose before attaching to

pump.

Started

Attach water inlet hose

and

pressure

hoseontopump.

Attach gun/wand assembly topressure host

and

removenozzle from end

of

wand.

Adjust engine throttle arm

to

middle

position and

apply

choke.

Turn

water

on,and

pull trigger on

gun.

m

Inspect

for

leaks whileallowingair

to

bleed from line.

a

With water

flowing

out

of

gun,stari

engineand cmtinueflushing

for

10

seconds.

Turnchoke

off

and

adjust

throttle to full throttle position

(3500

RPM

factory

setting).

Release

gun

and install nozzle intowand

to

begin washing.

Getting

Soalp

Your

machine

is

equippedwith

a

lowpressure/downstrcam) soapinjector

(Approx.400

PSI).The

pressure

is

reduced

automatically

by

installing

the

black

soapnozzle,

Dispense

soap

as

follows.

Place

clear vinyl tubewithfilterattached into

soap

container.

Ensure

soapmeteringvalveis

adjusted

to

amid-range setting(if equipped).

Insrall

black

soapnozzle intowand

assembly,

pull trigger

and

begin

dispensing

soap.

Rise

fresh

watertbroughvalve

after

eash use.This willprevent

soap

from

drying

and

plugging

up

thevalve.

Adjustmetering valve

according

to soaprequirements.

Soap

willautomatically stopdrawing ifcolored

high

pressure

tips

are

in

use.

Important.

The

informationprovided inthis manual will

help

to

ensure

the

safe

operation

of

thisequipment. Failure

to

comply

with

the

enclosed

operating instructions will nullify

warranty.