English 7

These operating instructions are intended for operating

staff.

☞Please familiarize yourself with the instructions and

recommendations contained in these operating

instructions before setting up, commissioning and

servicing the machine.

☞You will then have full control over the machine and

use it efficiently. The care and maintenance described

in these operating instructions are in the interests of

your own safety and preserve the machine’s value.

☞The manufacturer accepts no liability for personal

injury or damage to property due to the incorrect use

of this machine.

Please read the safety instructions carefully!

Safety instructions, General remarks English 7

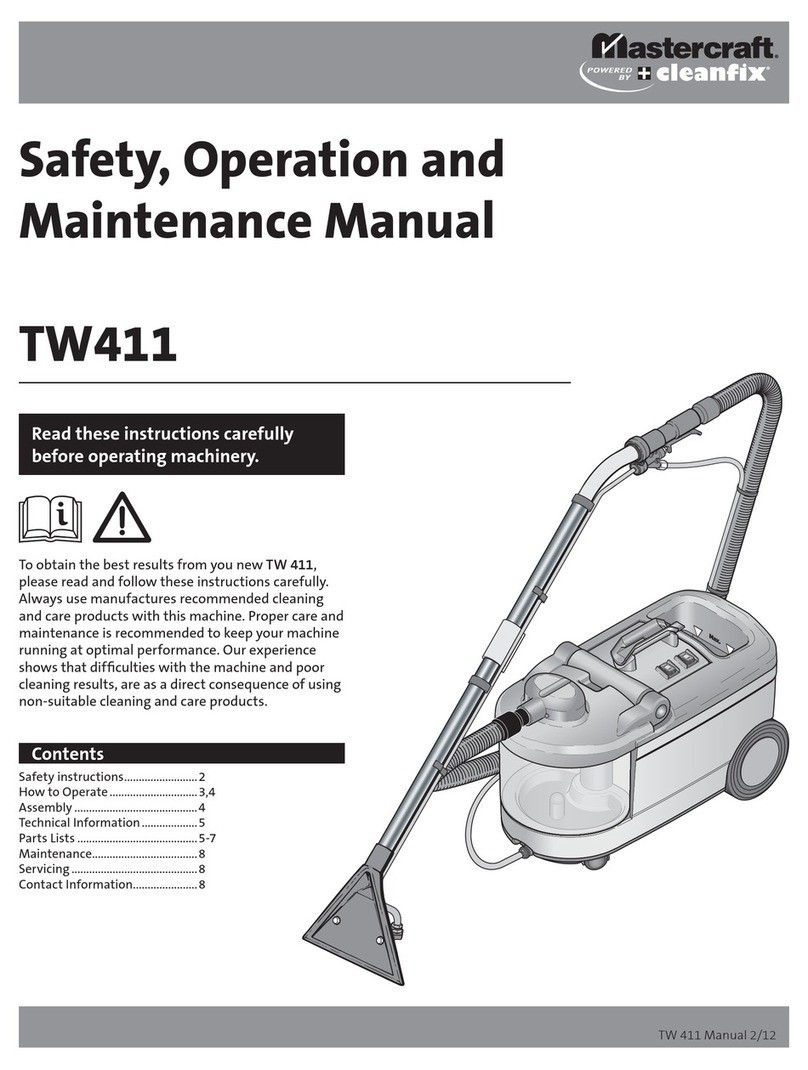

Description of pictures English 8

Technical Specification English 8

Commissioning / operation English 9

Thorough cleaning English 9

Shampooing English 9

Assembly instructions for Spraymaster English 9

Routine cleaning, Polishing English 10

Service, Service instuctions, Storage English 10

Protection de l'environnement English 10

Declaration of Conformity English 11

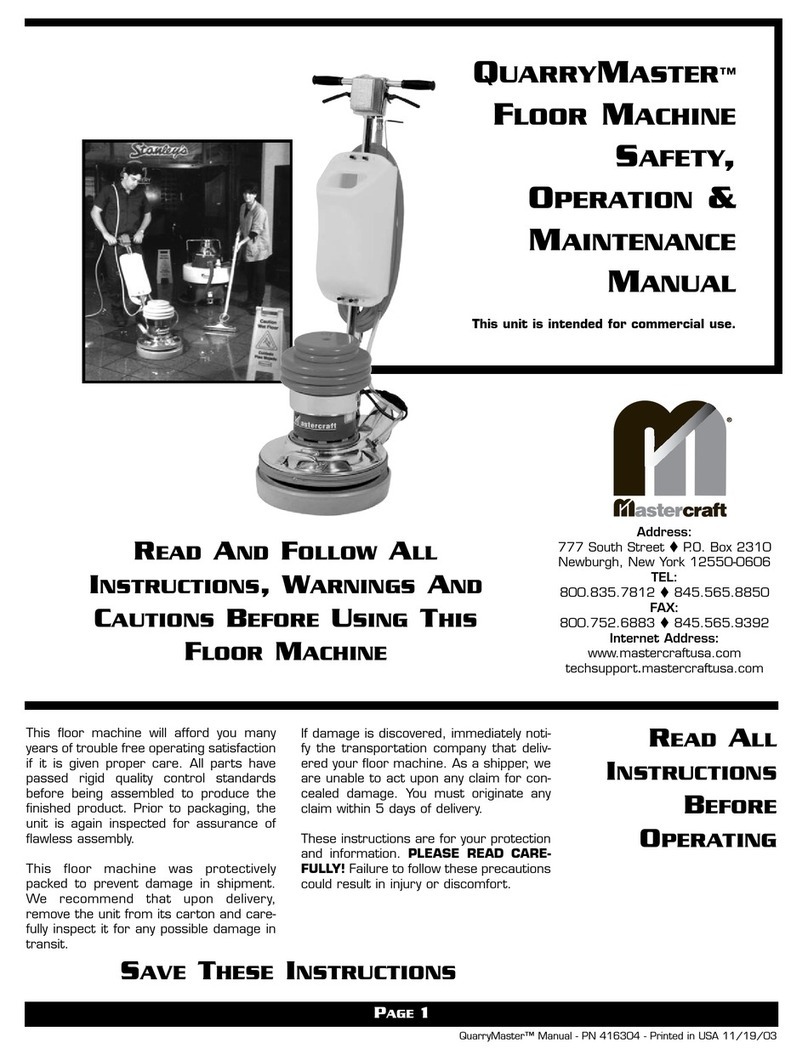

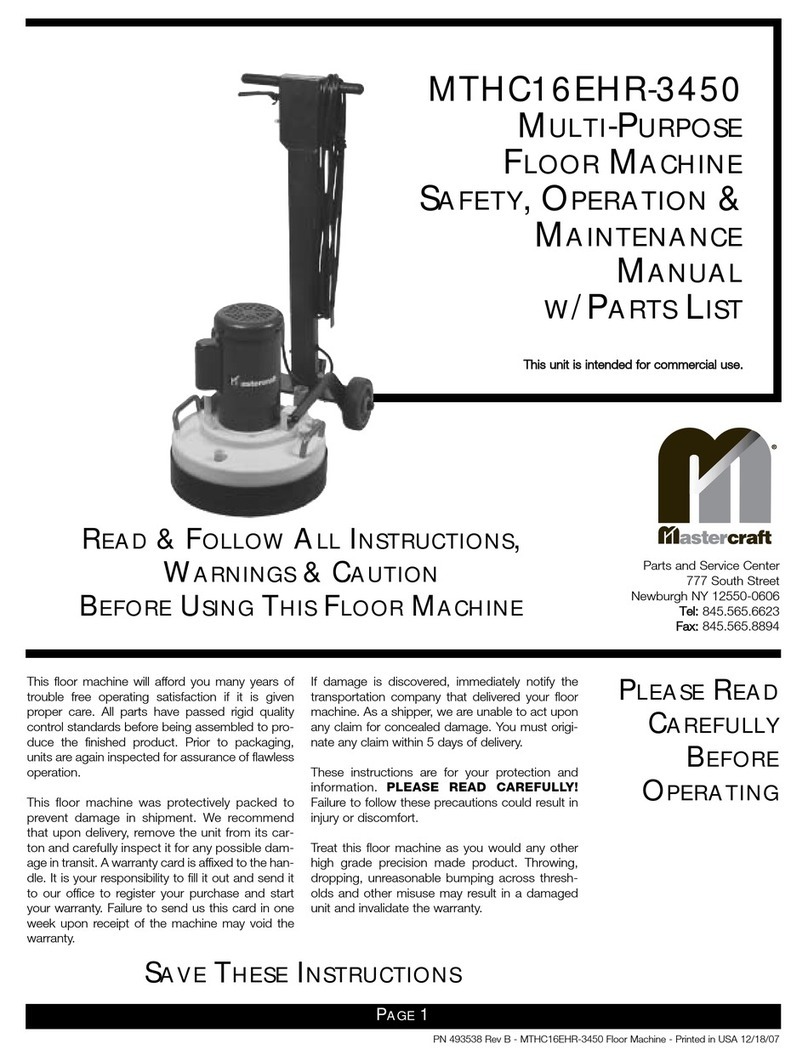

●The single-disc machine may only be used by

persons trained in its use and explicitly entrusted with

its operation.

●This equipment is not intended to be used by persons

(including children) with restricted physical, sensory or

mental abilities or who have no experience and/or

knowledge of its use, unless supervised by a person

who is responsible for their safety, or they have

received instructions from this person on how to use

the equipment.

● The single-disc machine is not suitable for cleaning

surfaces which release health-hazardous dusts and

liquids. Do not use the machine on steps.

● Never drive the machine over electric cables.

Danger of electric shocks!

●During operations with the suction unit, the floor must

be dry.

( R44-120, R 44-450, Duo-Speed )

The operation of the single-disc machine is subject to the

currently valid national regulations.

It is essential to observe not only the operating instructions

and the binding regulations on accident prevention valid in

the country of use, but also the generally acknowledged

rules for safe and correct working procedures. No methods

involving safety risks must be employed. The use of

automatic machines on public paths and roads is

prohibited.

The high speed single disc machine R44-450, must not be

used for wet cleaning (deep cleaning and shampooing).

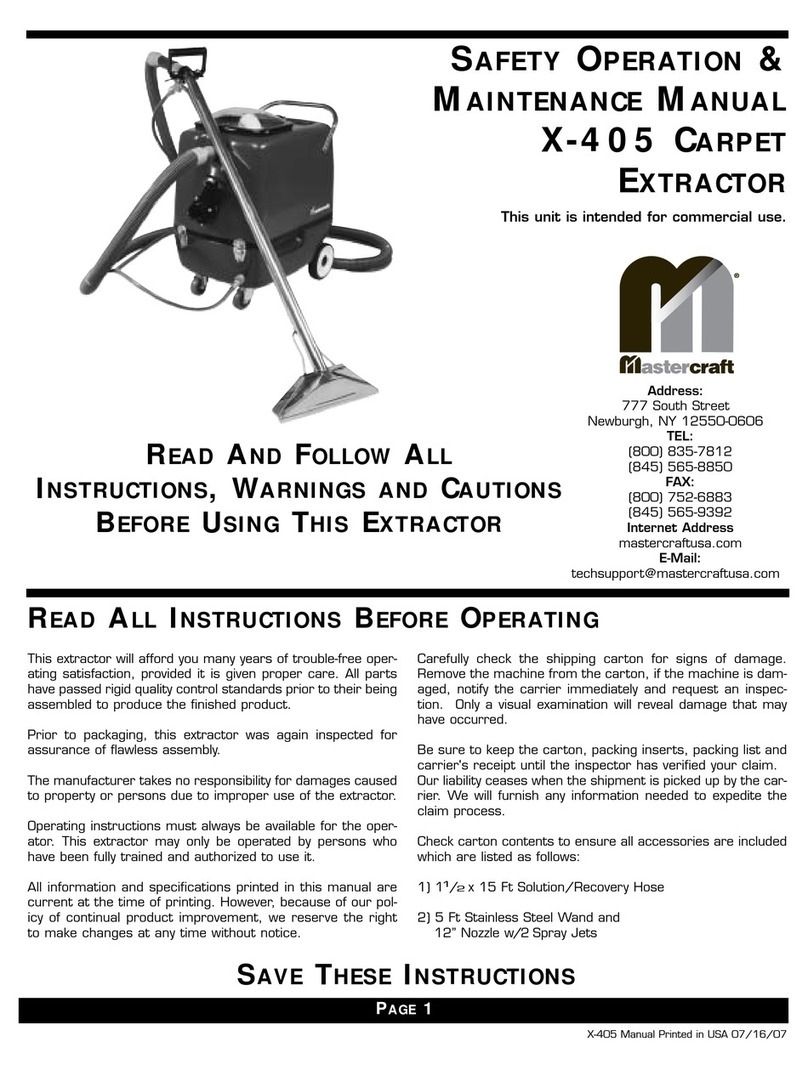

●This machines is made for professional use e.g.

Hotels, Schools, Hospitals, Factories, Shops, Offices,

and Renting or Leasing Business.

●All single-disc machines are intended exclusivelyfor

use in buil-ding interiors.

●Any use beyond this is considered incorrect. The

manufacturer accepts no liability for any resultant

damage; the user alone bears the risk.

●Correct use also includes adherence to the operating,

servicing and maintenance conditions recommended

by the manufacture.

●The relevant accident prevention regulations as well

as all the generally acknowledged safety and working

practices must be followed.

●Unauthorized modifications to the machine exclude

the manufacturer’s liability for resultant damage.

●Before machine use, floorcoverings must be tested

for suitability for this cleaning process.

●Pay attention to the area compression of point-elastic

floors, e.g. in gymnasiums.

●The manufacturer accepts no liability for damage to

equipment and to the floor being cleaned from using

the wrong brushes and clea-ning agents.

The operator’s attention is drawn explicitly to the fact that

the machines may only be used for their intended purpose.

If the machines are not used for their intended purposes,

the user must accept full respon-sibility. Any liability of the

manufacturer ist thus excluded.

●When the machine is stationary, the brush unit must

be immediately switched off to prevent damage to the

floorcovering.

●During transportation in lifts, the currently valid user

instructions and safety regulations – and particularly

those concerning maximum loading – must be

observed.

● The machine operation position is behind the

machine.

● The single-disc machine may only be serviced and

repaired by per-sons with technical and legal

authorization.

●When using cleaning and care agents, the

manufacturer’s danger warnings must be followed

and protective goggles and clothing must be worn.

●Only muse low-foaming, non-combustible cleaning

agents which do not contain generally

health-hazardous substances.

● Explicit reference is made to the risks of using highly

flammable, com-bustible, toxic, health-hazardous,

corrosive or irritant substances.

●Delivery, instruction on safety procedures, handling

and maintenance and initial operation are generally

carried out by our authorized specialist.

●If this is not the case, the operator is responsible for

instructing machine users.

Contents

Safety instructions

General remarks

Correct use

Product liability

Sources of risk

Machine operation position

Approved maintenance staff

Cleaning agents

Initial operation

Read these instructions

carefully before operating

the machine!