2

WARNING: PRODUCT USE LIMITATION

These products are not designed for, nor intended for use in patient-

connected applications, including, but not limited to, medical and dental

use and, accordingly, have not been submitted for FDA approval.

SAFETY PRECAUTIONS

CAUTIONS: Use of Pump Heads other than those specified will result

in unsatisfactory performance, damage to the drive unit

and voiding of applicable warranties.

The drive system can only be used with one Pump Head

at a time. Use of this drive unit with multiple Pump Heads

will result in unsatisfactory performance, damage to the

drive unit and voiding of applicable warranties.

When mounting the Pump Head to the drive unit, the

mounting screws should only be tightened fingertight.

Excessive tightening of the mounting screws will result

in binding and unsatisfactory performance.

WARNING: Be sure the Pump Drive is turned off before proceeding.

Loose clothing could be caught in the drive.

EU Declaration of Conformity

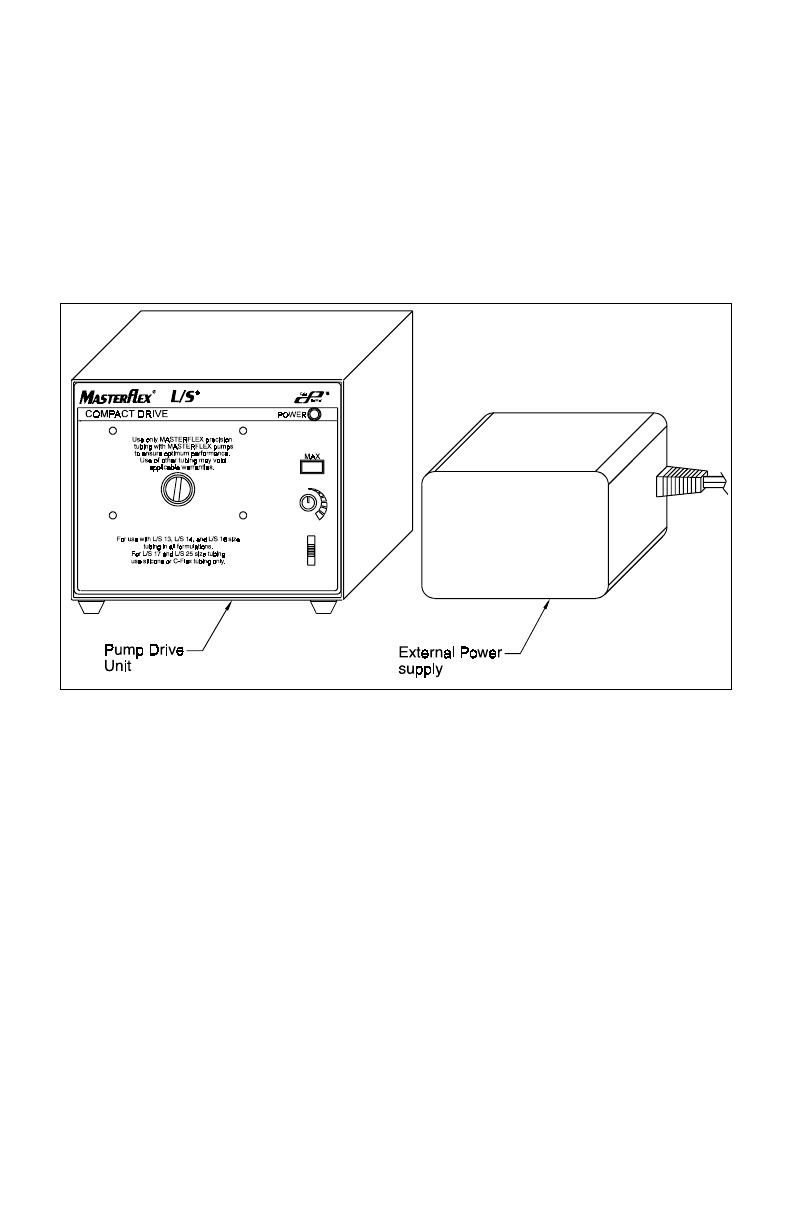

Name of Apparatus: MASTERFLEX®Compact L/S®PumpSystem

Model Numbers:77200-00,-10,-12

Description of Apparatus:VariableSpeed PeristalticPump Motor Drive.Usedwithpump

headandtubing to pump fluids.

77200-00 (115V AC), -10 (230V AC), -12 (12V DC)

BarnantCompanydeclares that theabovemodels are in conformity to the following

harmonized standardsanddirectives:

Applicable Applicable Manufacturer’s

Directives Specifications Report Number

89/336/EEC EN61326-1/A1:1998 TR9420

92/31/EEC

93/68/EEC

Manufacturer:

Barnant Company Division

Cole-Parmer InstrumentCompany

28W092Commercial Avenue

Barrington, IL60010-2392

USA

Tel.:847-381-7050

Manufacturer’s Signature:

JamesW.Doll Date

VicePresident, Engineering

23August,2000

C-FLEX — Reg TM Consolidated Polymer Technologies, Inc.

Trademarks bearing the ®symbol in this publication

are registered in the U.S. and in other countries.

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com