2Subject to change without notice | 83059300gUK | ait-deutschland GmbH

Table of contents

1 About this operating manual ...................... 3

1.1 Validity....................................................... 3

1.2 Reference documents............................... 3

1.3 Symbols and markings.............................. 3

1.4 Contact...................................................... 4

2 Safety ............................................................... 4

2.1 Intended use ............................................. 4

............................ 4

2.3 Personal protective equipment ................. 4

2.4 Residual risks............................................ 4

2.5 Avoid damage to property......................... 5

3 Operation and care....................................... 5

3.1 Energy and environmentally conscious

operation ................................................... 5

3.2 Maintenance.............................................. 5

4 Scope of supply............................................. 6

4.1 Accessories............................................... 6

4.2 Components of the device ........................ 6

5 Transport, installation and assembly ....... 7

5.1 Unpacking and transport........................... 7

5.2 Making transport easier ............................ 7

5.3 Carrying the device and transporting

with handcart............................................. 7

5.4 Installation................................................. 8

5.5 Installation / hydraulic connection to the

heating circuit and the domestic hot water ... 8

5.6 Safety module ........................................... 9

5.7 Expansion vessel ...................................... 9

5.8 Hydraulic connection for the

domestic hot water tank ............................ 9

6 Electrical installation..................................... 9

7 Installing the control device.......................11

...................... 12

8.1 Heating water quality .............................. 12

domestic hot water charging circuit......... 12

the domestic hot water tank .................... 13

9 Insulate hydraulic connections ................ 14

................................ 14

11 Commissioning ............................................ 14

12 Faults.............................................................. 14

12.1 Unlock the safety temperature limiter ..... 14

13 Dismantling and Disposal......................... 15

13.1 Dismantling ............................................. 15

13.2 Disposal and Recycling........................... 15

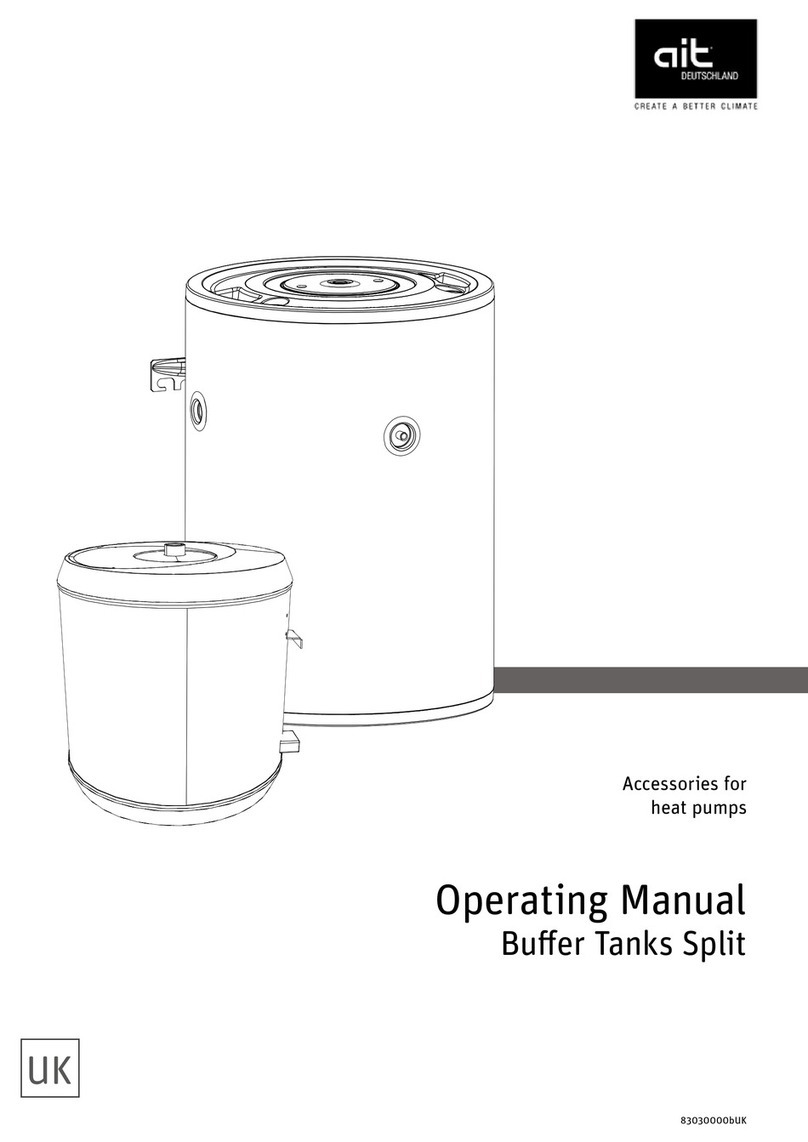

Technical data / Scope of supply............ 16

HSV ................................................................ 16

HSDV .............................................................. 18

Free pressing ............................................... 20

HSV 9M1/3 ....................................................... 20

HSDV 9M1/3..................................................... 20

HSV 12M3, HSV 12.1M3 .................................. 20

HSDV 12M3, HSDV 12.1M3 ............................. 20

Dimensioned drawings .............................. 21

HS(D)V 9M1/3 .................................................. 21

HS(D)V 12M3 ................................................... 22

HS(D)V 12.1M3 ................................................. 23

Installation plans.......................................... 24

HS(D)V 9M1/3 .................................................. 24

HS(D)V 12M3, HS(D)V 12.1M3......................... 25

Terminal diagrams ...................................... 26

HSV ................................................................ 26

HSDV .............................................................. 27

Terminal diagram, mains connection

heat pump 1~230V

+ electric heating element 3~400V ......... 28

Terminal diagram, mains connection

heat pump 1~230V

+ electric heating element 1~230V ......... 29

Terminal diagram, mains connection

heat pump 3~400V

+ electric heating element 3~400V ......... 30

Circuit diagrams........................................... 31

HSV ................................................................ 31

HSDV .............................................................. 33